Overview

Fan bearings represent essential components within cooling systems, as they provide critical support for the rotating shafts of fans. This support is vital for ensuring efficient airflow and preventing overheating in electronic devices. The article underscores the importance of various types of fan bearings—such as ball, sleeve, and fluid dynamic supports—each possessing distinct characteristics that influence their performance, durability, and applicability across different scenarios. Consequently, the selection of the appropriate bearing type is crucial for achieving optimal temperature regulation in electronics, thereby enhancing the overall reliability and efficiency of these devices.

Introduction

In the intricate world of electronics cooling, fan bearings stand out as essential components, ensuring the smooth operation of systems that power modern life. These pivotal elements maintain airflow and prevent overheating, thereby safeguarding the longevity and efficiency of electronic devices.

With a variety of bearing types available—each tailored to specific applications—engineers face the critical task of selecting the right option to optimize performance. From the robust durability of ball bearings to the quieter operation of sleeve bearings, a comprehensive understanding of these components is vital for anyone involved in thermal management.

As technology advances, the necessity for effective maintenance practices that prolong the life of these crucial elements becomes increasingly clear, ensuring that cooling systems continue to perform at their best.

Define Fan Bearings: Essential Components in Cooling Systems

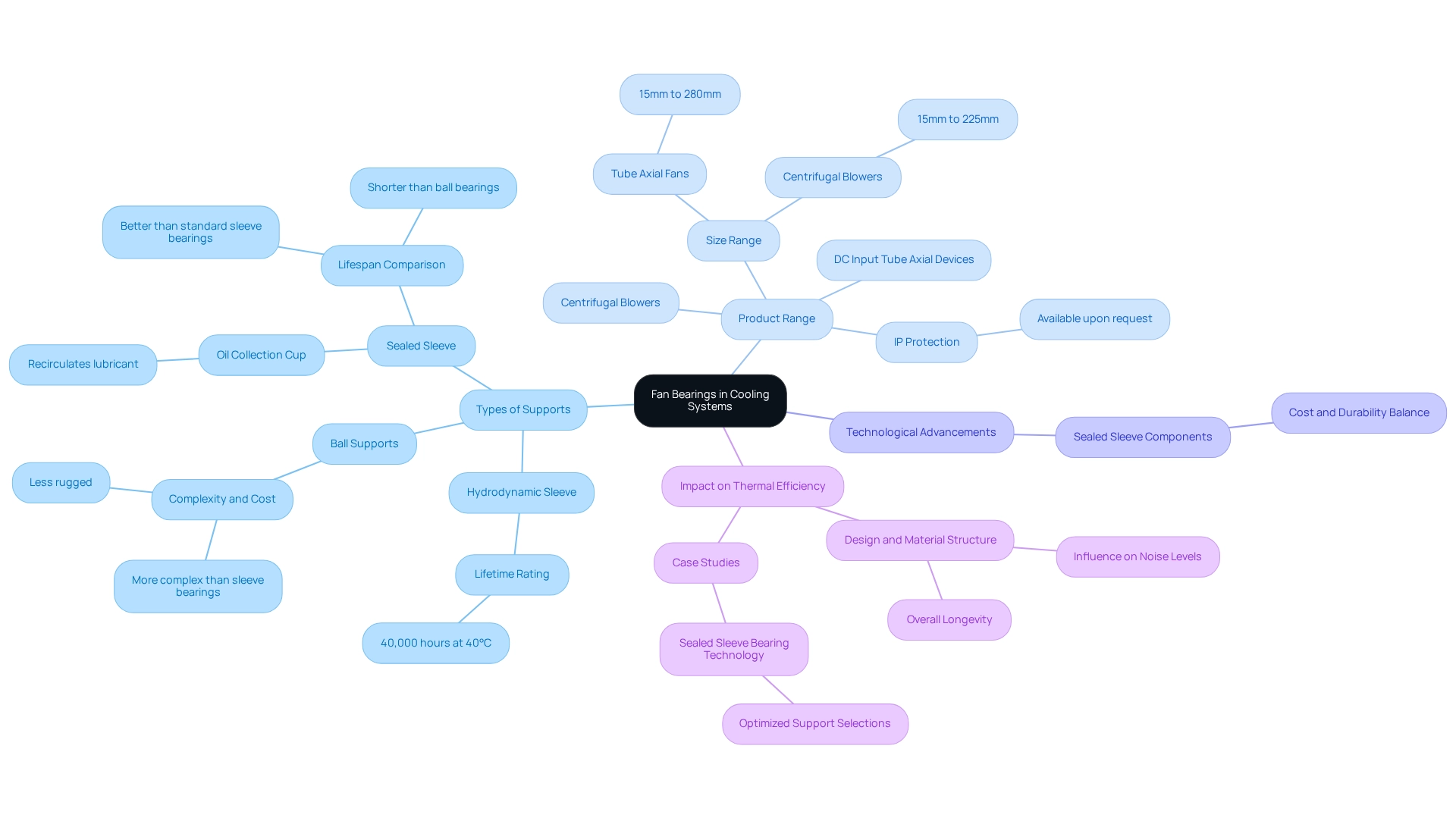

Fan bearing components are essential mechanical parts that support the rotating shaft of a fan, ensuring smooth operation while reducing friction. Their role in temperature regulation, particularly within electronic systems, is paramount; effective heat dissipation is essential for optimal functionality. Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers an extensive selection of DC input tube axial devices and centrifugal blowers. These products are optimized for performance and low noise, which are crucial for effective cooling solutions. The product line includes sizes ranging from 15mm to 280mm for tube axial fans and 15mm to 225mm for centrifugal blowers, with IP protection available in most models upon request.

Fan supports are categorized into several types, including hydrodynamic sleeve supports and ball supports, each tailored to specific operational requirements. For example, hydrodynamic sleeve supports boast a lifetime rating of 40,000 hours at 40°C. In contrast, ball components, while enhancing durability and performance, tend to be more complex and costly. Recent advancements in fan support technology have led to the development of sealed sleeve components, which feature an oil collection cup that recirculates lubricant, thereby prolonging the lifespan of sleeve fan systems. This innovation strikes a balance between cost and durability, positioning sealed sleeve components as a viable option for diverse applications.

The design and material structure of fan bearing components significantly impact thermal efficiency, noise levels, and overall longevity, underscoring their importance in electronic systems. Understanding the principles of various fan bearing types is vital for selecting the appropriate fan to meet specific thermal requirements. The influence of fan support design on temperature management is evident in case studies, such as those focusing on sealed sleeve support technology. These studies illustrate how optimized support selections can enhance the performance of temperature regulation systems, offering a lifespan that exceeds that of standard sleeve supports while remaining shorter than that of ball supports. As the electronics sector continues to evolve, fan supports are indispensable in achieving efficient temperature regulation solutions, supported by Gagner-Toomey’s comprehensive range of thermal management offerings.

Explain the Importance of Fan Bearings in Electronics Cooling

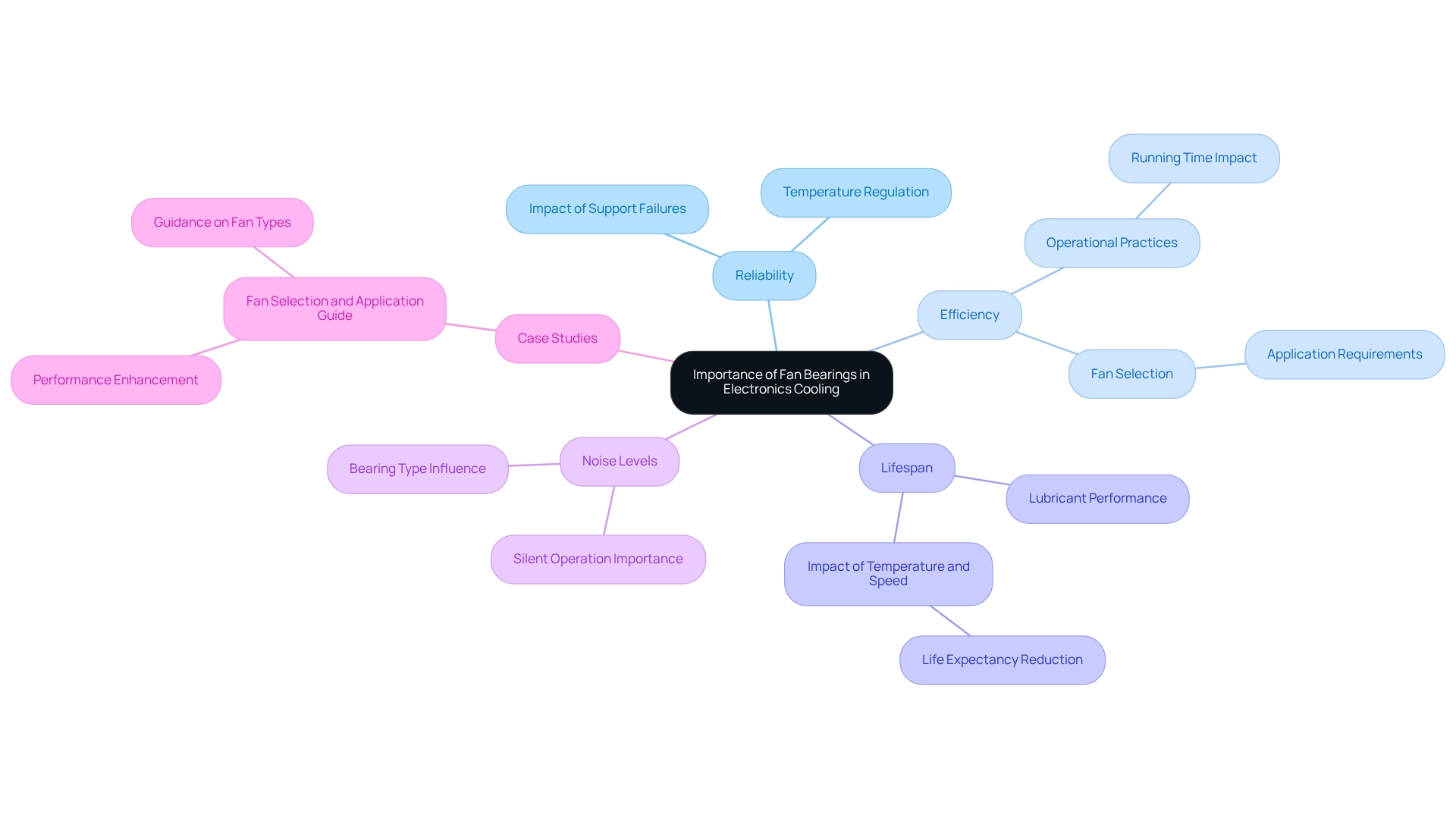

Fan bearing components are essential for ensuring the reliability and efficiency of cooling systems within electronic devices. They facilitate smooth rotation thanks to the fan bearing, which is essential for maintaining airflow and preventing overheating. Insufficient or malfunctioning supports lead to increased friction, resulting in higher energy consumption and potential system failures. For example, in computer systems, effective fan bearing supports are crucial for maintaining optimal temperatures, thereby extending component lifespan and enhancing overall performance. Additionally, the type of support selected can significantly influence noise levels, a critical consideration in consumer electronics where silent operation is often desired.

Statistics reveal that the lifespan of ball supports and lubricants is profoundly affected by temperature and speed, with life expectancy halved for every 15°C increase in temperature. This statistic underscores the importance of selecting appropriate supports to mitigate overheating risks and highlights the necessity for engineers to consider thermal conditions in their designs. Engineers emphasize that operating a fan for merely 8 hours daily can dramatically extend its lifespan, illustrating the significance of operational practices in prolonging component durability.

Case studies, such as the ‘Fan Selection and Application Guide,’ demonstrate that the appropriate choice of fan based on application requirements can enhance efficiency and reliability. These studies indicate that the correct selection of fan components is not merely a technical detail but a vital aspect of ensuring effective temperature regulation in electronic devices. The repercussions of support failures can be substantial, leading to increased failure rates in refrigeration systems and ultimately affecting the performance of the entire electronic device. Therefore, understanding the importance of fan bearing supports is essential for engineers who aim to improve temperature regulation in their designs.

Identify Types of Fan Bearings and Their Applications

Fan bearing components are integral to cooling systems, with various types available, each presenting unique characteristics and applications.

-

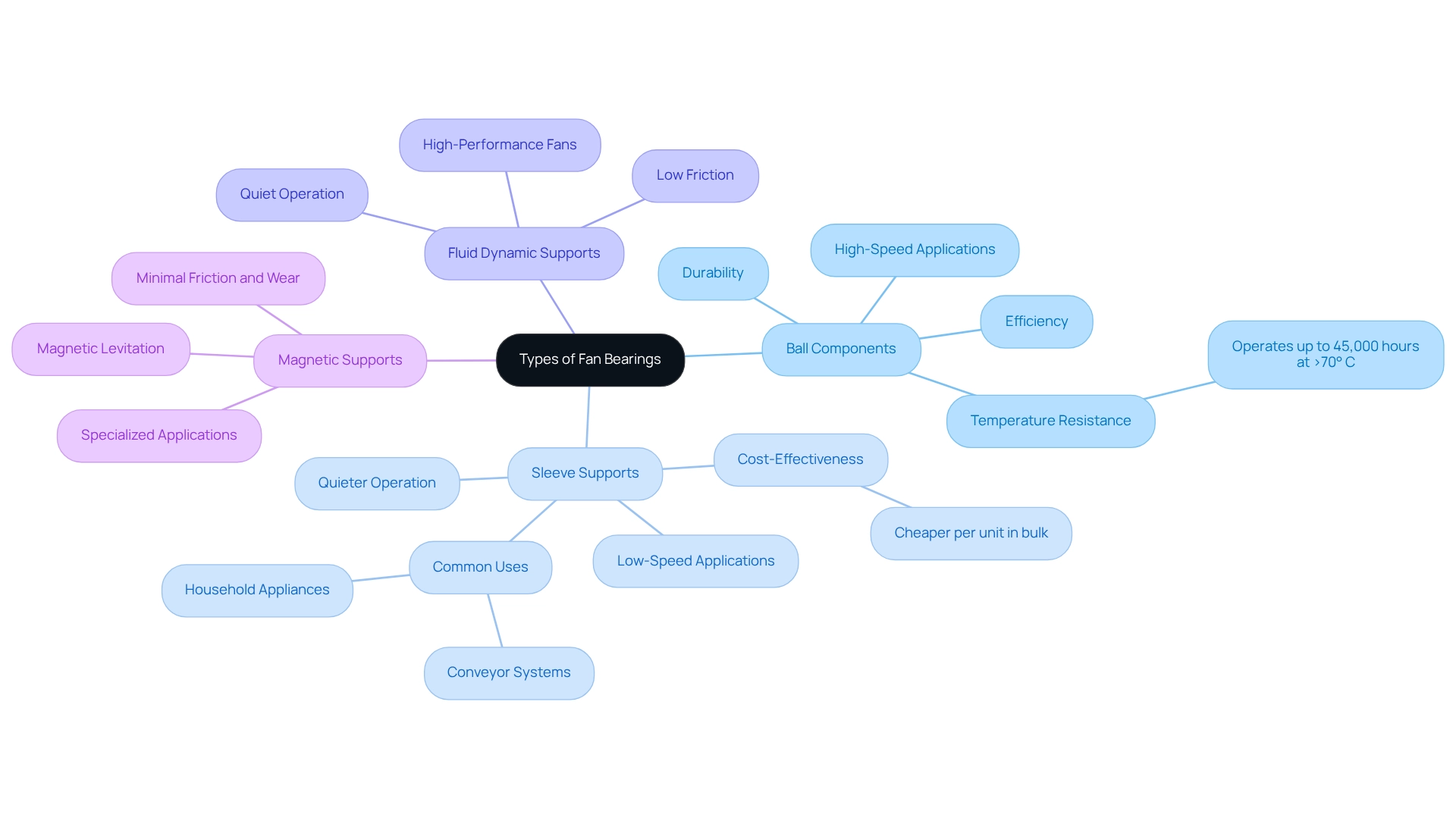

Ball Components: Renowned for their durability and efficiency, ball components employ small spheres to minimize friction. They excel in high-speed applications, making them the preferred choice for computer cooling devices. Notably, when subjected to temperatures exceeding 70° C, ball support devices can operate for up to 45,000 hours, underscoring their reliability in demanding conditions. In contrast, sleeve fans may fail at the same temperature, highlighting the superior efficiency of ball types in extreme environments.

-

Sleeve Supports: These supports utilize a sleeve to uphold the shaft, resulting in quieter operation compared to ball supports. They are ideally suited for low-speed applications and are commonly utilized in household appliances and conveyor systems, where smooth, low-maintenance performance is critical. Although sleeve components are less expensive per unit when purchased in bulk, they do not match the durability of ball components, which offer greater long-term value despite a higher initial cost. As indicated in the case study titled ‘Cost vs. Longevity in Component Selection,’ ball components represent a more prudent investment over time for applications demanding long-term reliability.

-

Fluid Dynamic Supports: By employing a thin film of liquid to support the shaft, fluid dynamic supports deliver low friction and noise levels. They are particularly suited for high-performance fans where longevity and quiet operation are essential, making them a favored option in advanced cooling solutions.

-

Magnetic Supports: These cutting-edge devices utilize magnetic levitation to eliminate physical contact, resulting in minimal friction and wear. They are typically employed in specialized applications that require high precision and reliability.

Understanding the performance features of these components is vital for engineers. For instance, ball rollers are favored in computer heat dissipation systems due to their enhanced durability and effectiveness, while sleeve rollers are often chosen for their cost-effectiveness in low-maintenance scenarios. As Gary Masessa noted, SANYO DENKI has been a trusted supplier of temperature management solutions across various industries, with fans serving as a critical component in many advanced devices. Furthermore, as the electronics cooling market evolves, selecting the appropriate type of support becomes increasingly important to meet specific cooling requirements. SANYO DENKI also provides support for customization and technical assistance through their experienced application and field engineers, offering valuable resources for engineers during the selection process.

Discuss Maintenance Practices for Prolonging Fan Bearing Life

To prolong the life of fan bearing components, implementing effective maintenance practices is essential.

-

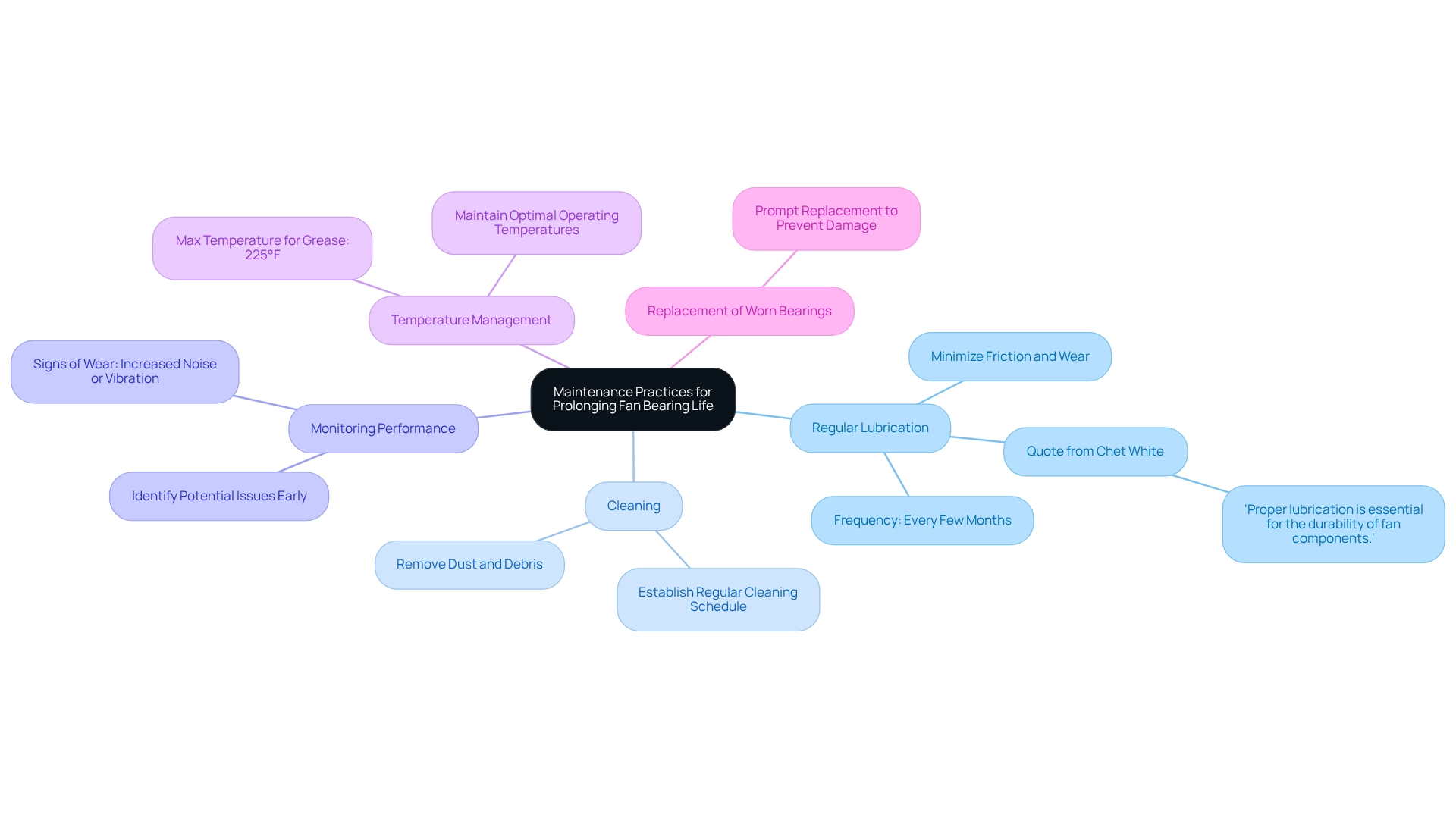

Regular Lubrication: Adequate lubrication is vital for minimizing friction and wear. Depending on the specific application, lubrication should typically be performed every few months to ensure optimal performance. As Chet White, Senior Application Engineer, emphasizes, ‘Proper lubrication is essential for the durability of fan components.’

-

Cleaning: Ensuring the fan and its components are free from dust and debris is essential to avoid contamination that can result in early failure. Establishing a regular cleaning schedule based on the operating environment is recommended.

-

Monitoring Performance: Regular performance checks can help identify potential issues early. Engineers should be vigilant for signs of wear, such as increased noise or vibration, and address these promptly to avoid further complications.

-

Temperature Management: Maintaining optimal operating temperatures is crucial for prolonging the lifespan of components. This may entail guaranteeing adequate airflow and temperature regulation around the fan, as the highest temperature for grease in the supports should not surpass 225 degrees Fahrenheit. Adhering to this guideline is essential for preventing overheating and ensuring reliable operation.

-

Replacement of Worn Bearings: Bearings that exhibit significant wear should be replaced promptly to prevent damage to the fan and associated components.

By following these best practices, engineers can greatly improve the reliability and efficiency of cooling systems, resulting in enhanced operation and prolonged service life. A comprehensive guide on industrial fan bearing emphasizes the critical role of proper bearing selection and maintenance in maximizing fan lifespan and performance, reinforcing the commitment of Gagner-Toomey Associates to excellence in customer service and product representation.

Conclusion

Fan bearings are integral to the efficient operation of cooling systems in electronic devices, directly influencing both performance and longevity. This critical role encompasses various bearing types, including:

- Ball bearings

- Sleeve bearings

- Fluid dynamic bearings

- Magnetic bearings

Each type is tailored to specific applications. Understanding these distinctions is vital for engineers tasked with optimizing thermal management solutions; the right choice can enhance cooling efficiency, reduce noise, and prolong the lifespan of the systems.

Moreover, maintaining these bearings through regular lubrication, cleaning, and performance monitoring is essential for preventing premature failures and ensuring reliable operation. The significance of temperature management cannot be overstated; overheating poses a substantial risk to bearing longevity. By implementing effective maintenance practices and selecting the appropriate bearing type, engineers can significantly improve the reliability and performance of cooling systems.

In summary, fan bearings are not merely components; they are the backbone of effective electronics cooling. As technology continues to advance, the need for informed selection and diligent maintenance of fan bearings will only grow. Emphasizing their importance ensures that electronic devices operate efficiently and reliably, ultimately safeguarding the longevity and performance that modern technology demands.

Frequently Asked Questions

What are fan bearing components and their purpose?

Fan bearing components are essential mechanical parts that support the rotating shaft of a fan, ensuring smooth operation while reducing friction. They play a crucial role in temperature regulation, particularly within electronic systems, as effective heat dissipation is vital for optimal functionality.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is recognized as the world’s largest producer of standard and custom air-movers. They offer an extensive selection of DC input tube axial devices and centrifugal blowers, optimized for performance and low noise, which are essential for effective cooling solutions.

What sizes are available for tube axial fans and centrifugal blowers?

The product line includes tube axial fans ranging from 15mm to 280mm and centrifugal blowers from 15mm to 225mm. Most models also have IP protection available upon request.

What types of fan supports are available and what are their features?

Fan supports are categorized into several types, including hydrodynamic sleeve supports and ball supports. Hydrodynamic sleeve supports have a lifetime rating of 40,000 hours at 40°C, while ball supports enhance durability and performance but are more complex and costly.

What recent advancements have been made in fan support technology?

Recent advancements include the development of sealed sleeve components, which feature an oil collection cup that recirculates lubricant, extending the lifespan of sleeve fan systems. This innovation balances cost and durability, making sealed sleeve components suitable for various applications.

How do design and material structure affect fan bearing components?

The design and material structure of fan bearing components significantly impact thermal efficiency, noise levels, and overall longevity, which are crucial factors in electronic systems.

Why is it important to understand the principles of various fan bearing types?

Understanding the principles of various fan bearing types is vital for selecting the appropriate fan to meet specific thermal requirements, ensuring effective temperature regulation.

What insights do case studies provide regarding fan support design?

Case studies focusing on sealed sleeve support technology illustrate how optimized support selections can enhance the performance of temperature regulation systems, offering a lifespan that exceeds that of standard sleeve supports while being shorter than that of ball supports.

What role do fan supports play in the electronics sector?

Fan supports are indispensable in achieving efficient temperature regulation solutions in the electronics sector, supported by Gagner-Toomey’s comprehensive range of thermal management offerings.