Overview

A maglev fan is an advanced device that leverages magnetic levitation technology, enabling operation without physical contact between its moving parts. This innovative design results in significantly reduced friction, noise, and wear. Notably, the article underscores that this technology not only enhances performance and energy efficiency but also extends the lifespan of the fan. Consequently, maglev fans are particularly well-suited for applications that demand quiet and reliable cooling solutions.

Introduction

Maglev fans signify a groundbreaking advancement in cooling technology, employing magnetic levitation to eliminate physical contact between moving parts. This innovative design not only enhances energy efficiency but also significantly reduces noise and wear, rendering these fans ideal for a variety of applications—from high-performance electronics to automotive climate control.

However, as industries increasingly pursue sustainable solutions, one must consider: can maglev fans genuinely replace traditional fans across all sectors, or do they possess limitations that could impede their widespread adoption?

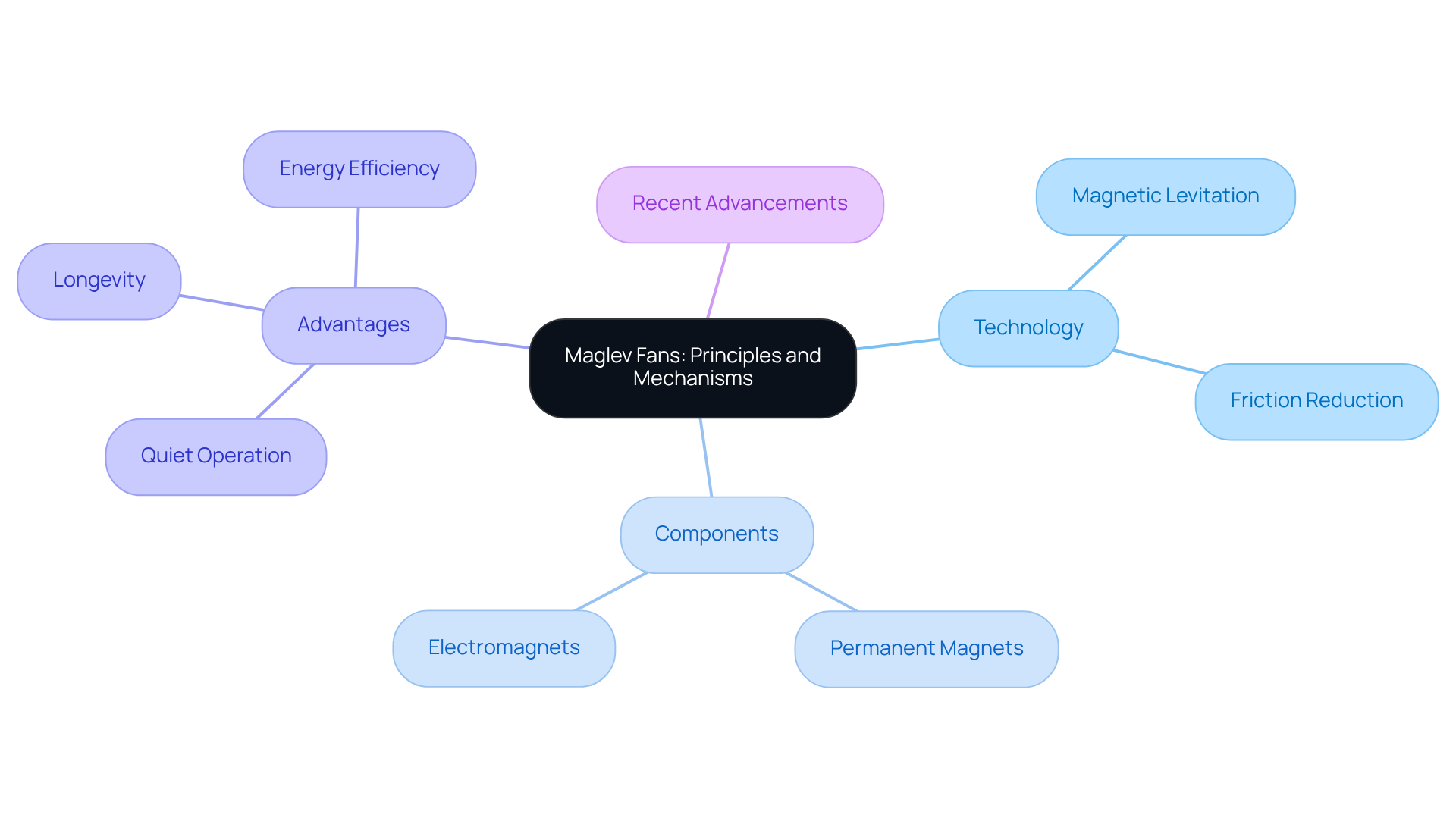

Define Maglev Fans: Principles and Mechanisms

Maglev fan devices, also known as magnetic levitation systems, utilize advanced magnetic levitation technology to operate without any physical contact between their moving components. This innovative mechanism allows the blades of the maglev fan to hover in the air, significantly reducing friction and wear.

Central to this technology are permanent magnets and electromagnets that create a magnetic field, enabling the free rotation of the blades of the maglev fan. In contrast to conventional air circulators, which depend on mechanical bearings that are prone to deterioration and noise generation, a maglev fan operates quietly and efficiently.

This design not only enhances performance but also prolongs the lifespan of the maglev fan, making the maglev fan an attractive option for applications that require silent operation and reliability.

Recent advancements in magnetic levitation technology, particularly with the maglev fan, have further improved energy efficiency, allowing these devices to maintain high speeds while consuming less power. Engineers have noted that the absence of physical contact in maglev fan devices results in smoother operation, a feature particularly beneficial in environments where sound reduction is critical.

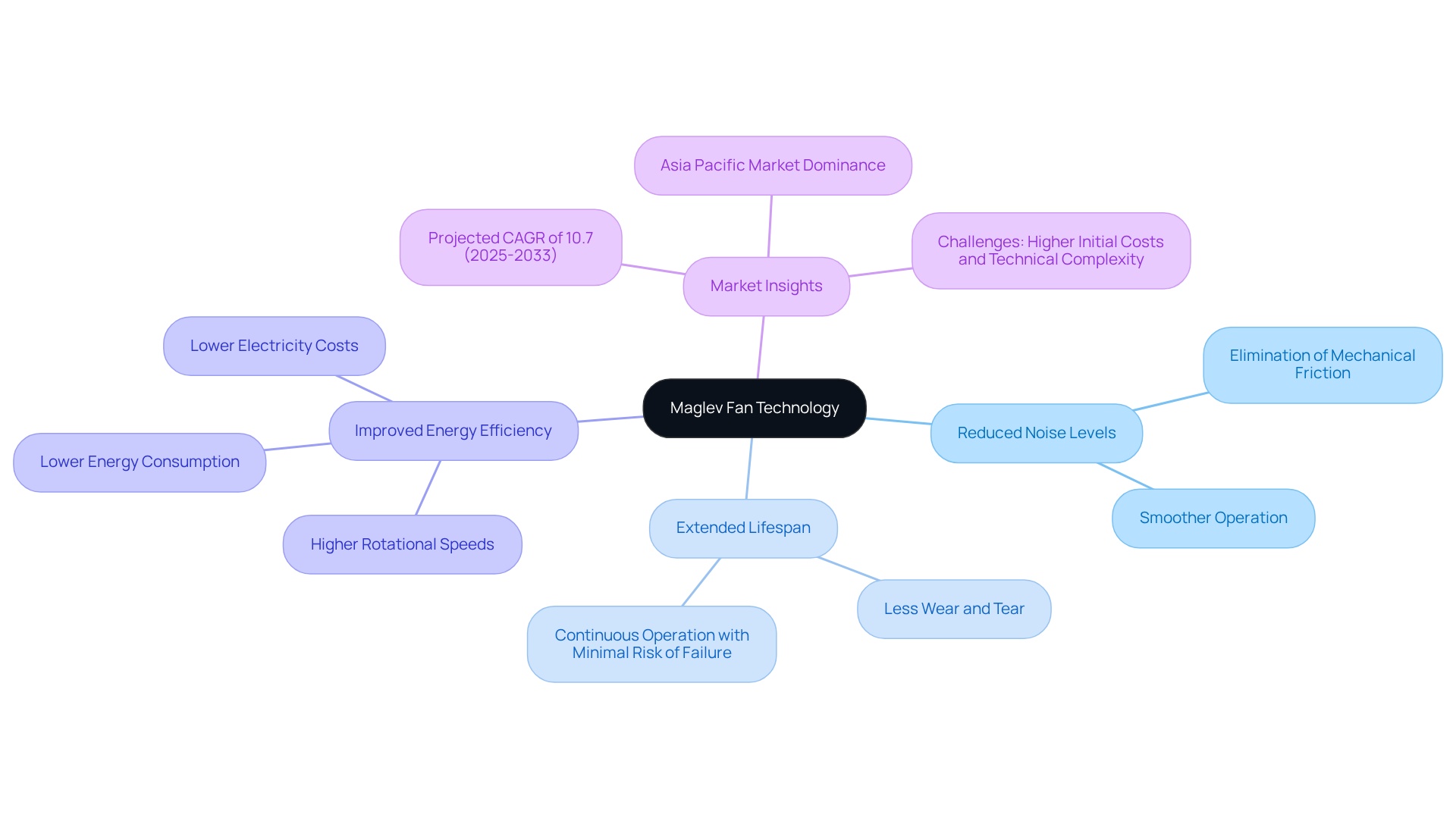

Explore Maglev Fan Technology: Operation and Advantages

Maglev fan devices operate by leveraging magnetic fields to elevate the rotor, thereby eliminating the need for traditional bearings. This contactless functionality offers several significant advantages:

- Reduced noise levels

- Extended lifespan

- Improved energy efficiency

Notably, the maglev fan can achieve higher rotational speeds while consuming less energy compared to its conventional counterparts. The absence of friction not only decreases wear but also facilitates smoother operation, which makes the maglev fan particularly suitable for applications that demand quiet and efficient cooling solutions.

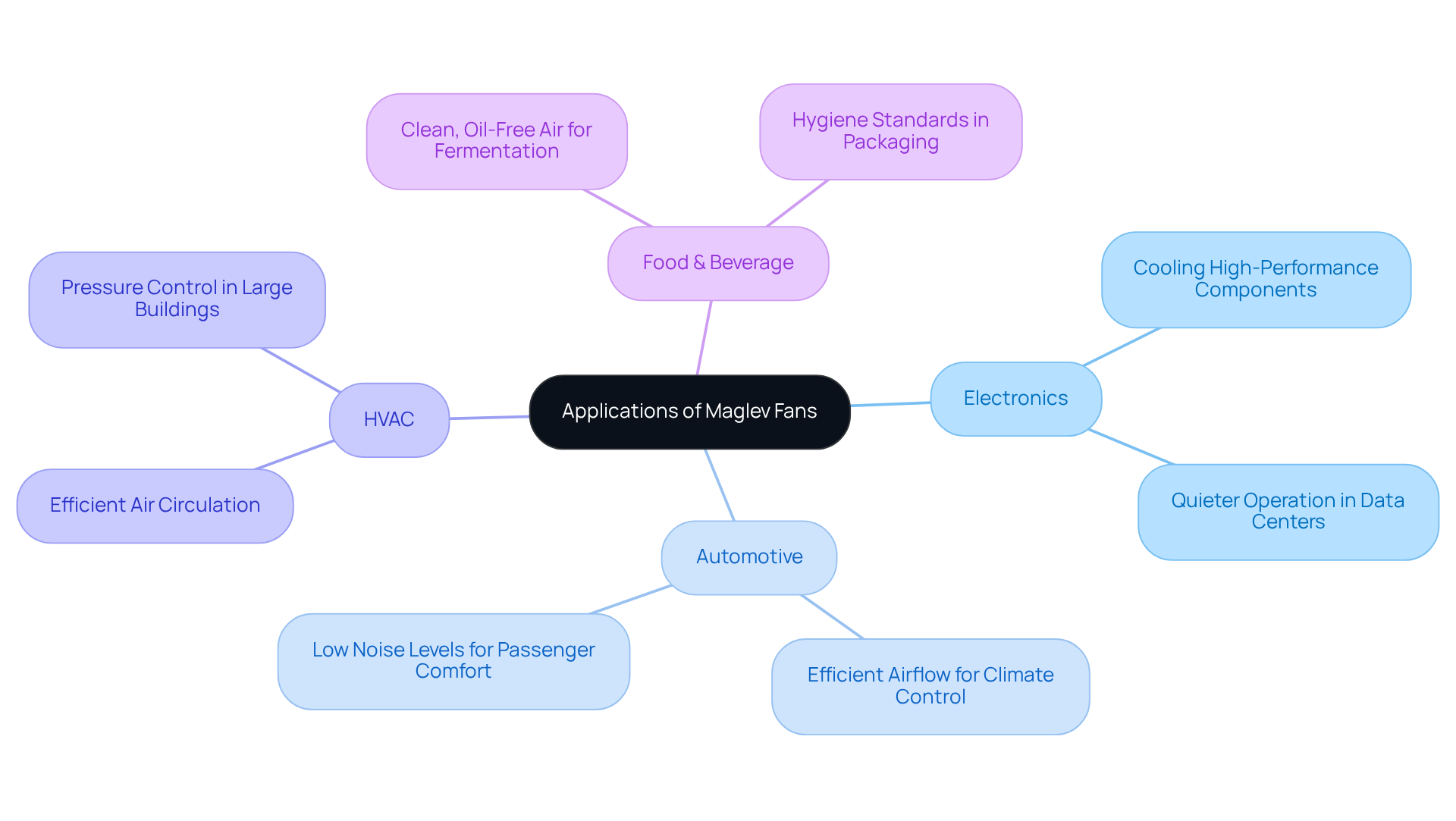

Examine Applications of Maglev Fans: Industries and Use Cases

Maglev devices are increasingly employed across various sectors, including electronics, automotive, and HVAC systems, owing to their advanced technology and efficiency. In the electronics industry, these devices are essential for cooling high-performance components in computers and servers, where effective heat dissipation is crucial for optimal performance. Their design enables quieter functioning, which is especially advantageous in settings demanding minimal sound, such as data centers.

In automotive applications, magnetic levitation blowers enhance climate control systems by delivering efficient airflow while maintaining a low noise level. This capability is vital for passenger comfort and overall vehicle performance. Furthermore, their robust construction allows them to thrive in harsh conditions, making them ideal for industrial applications, such as chemical processing and manufacturing, where reliability and durability are paramount.

The versatility of magnetic levitation devices extends across multiple sectors, with notable applications in the food and beverage industry, where they provide clean, oil-free air for processes such as fermentation and packaging. As industries increasingly prioritize energy efficiency and sustainability, the adoption of maglev fan technology is anticipated to rise, driven by their capacity to significantly reduce energy consumption and maintenance costs. With operational efficiencies often exceeding 90%, maglev systems are poised to become a standard in contemporary industrial applications.

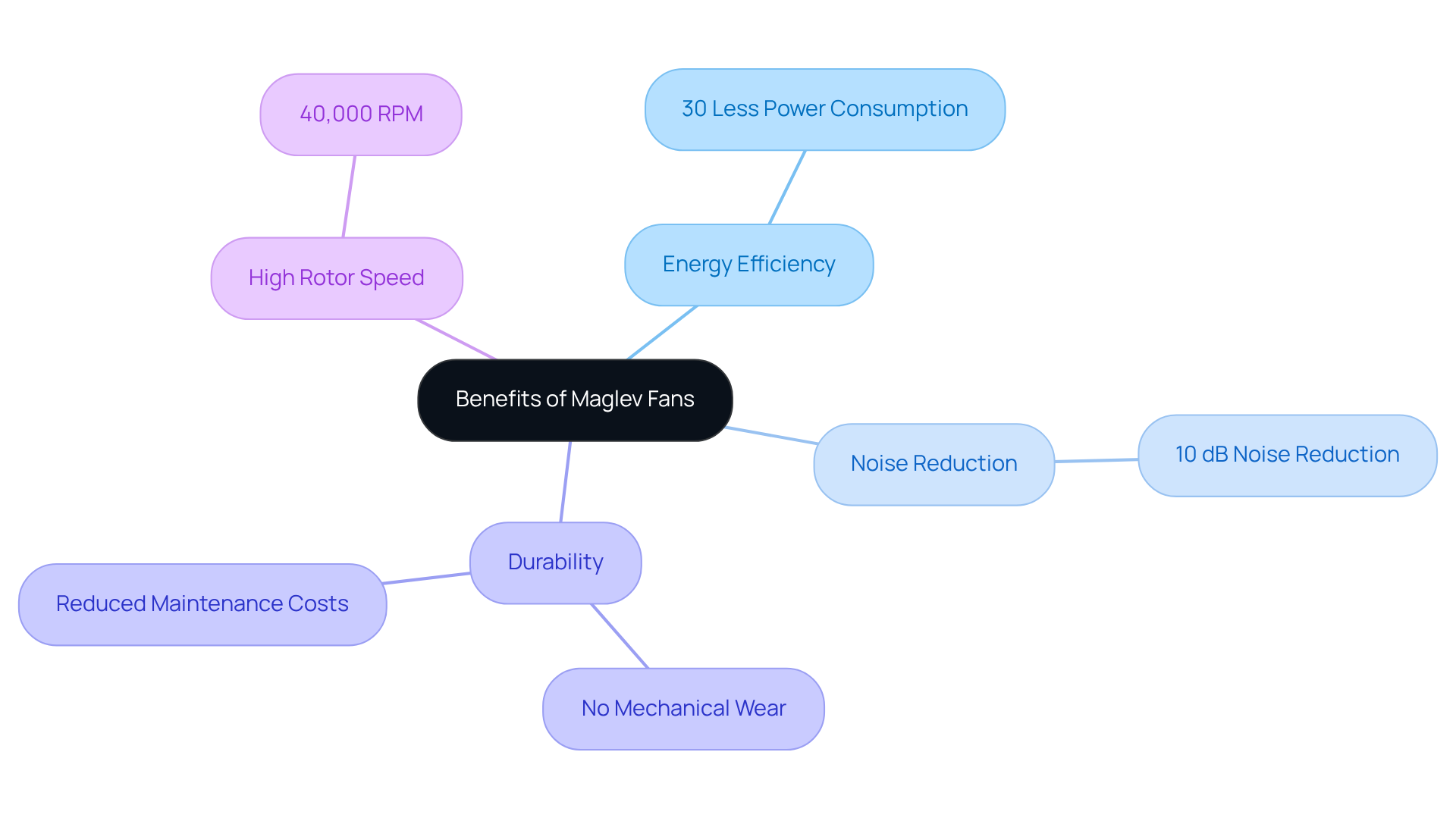

Assess Benefits of Maglev Fans: Efficiency and Performance

Maglev devices present a compelling solution to the challenges of energy efficiency, utilizing up to 30% less power than conventional models while delivering airflow that is either comparable or superior. Their innovative design significantly reduces sound levels, making them particularly well-suited for sound-sensitive environments such as offices and residential areas. For instance, magnetic levitation devices can achieve noise reductions of up to 10 dB compared to traditional models, creating a more pleasant atmosphere for users.

Additionally, the absence of mechanical wear in magnetic levitation devices, due to the use of magnetic bearings, enhances their durability. This allows them to operate efficiently for extended periods without the need for regular replacements. Such durability results in considerable savings on maintenance costs, as the frequency of repairs and part replacements is greatly diminished.

Furthermore, magnetic levitation fans can reach rotor speeds of up to 40,000 RPM, significantly surpassing traditional fans that typically rotate at around 8,000 RPM. Overall, the incorporation of the maglev fan technology represents a significant advancement in fan design, addressing the growing demand for energy-efficient and sustainable solutions across various applications.

Conclusion

The exploration of maglev fan technology unveils a groundbreaking advancement in air circulation systems, operating free from the friction and noise typically associated with traditional fans. By harnessing magnetic levitation, these devices not only enhance performance but also extend their lifespan, rendering them ideal for diverse applications where efficiency and quiet operation are paramount.

Key benefits such as reduced noise levels, improved energy efficiency, and enhanced durability have been underscored throughout this discussion. Maglev fans achieve remarkable rotational speeds while consuming significantly less power, positioning them as superior alternatives across industries ranging from electronics to automotive and beyond. Their ability to operate silently and reliably underscores their growing importance in environments demanding optimal performance with minimal disruption.

As industries increasingly pursue sustainable and energy-efficient solutions, the adoption of maglev fan technology is poised to rise. Embracing this innovative technology can yield substantial energy savings and reduced maintenance costs, making it a prudent investment for organizations striving to enhance operational efficiency. The future of cooling solutions lies in the advancement of maglev technology, paving the way for a quieter, more efficient, and environmentally friendly approach to air circulation.

Frequently Asked Questions

What is a maglev fan?

A maglev fan, or magnetic levitation fan, is a device that uses advanced magnetic levitation technology to operate without any physical contact between its moving components, allowing the fan blades to hover in the air.

How do maglev fans work?

Maglev fans work by using permanent magnets and electromagnets to create a magnetic field, which enables the blades to rotate freely, significantly reducing friction and wear.

What are the advantages of maglev fans compared to conventional air circulators?

Maglev fans operate quietly and efficiently without mechanical bearings, which are prone to deterioration and noise. This design enhances performance, prolongs lifespan, and is ideal for applications requiring silent operation.

How do recent advancements in magnetic levitation technology affect maglev fans?

Recent advancements have improved the energy efficiency of maglev fans, allowing them to maintain high speeds while consuming less power, resulting in smoother operation and reduced noise.

In what environments are maglev fans particularly beneficial?

Maglev fans are particularly beneficial in environments where sound reduction is critical, due to their quiet operation and lack of physical contact in their mechanisms.