Overview

PWM fans, or Pulse Width Modulation fans, operate by dynamically adjusting the speed of the fan motor through varying electrical pulse widths. This capability allows for precise temperature control and enhanced energy efficiency. Notably, this technology not only reduces operational noise but also significantly improves cooling performance. As a result, PWM fans are becoming increasingly essential in modern electronics. Projections indicate that by 2025, they will be utilized in approximately 70% of electronic devices, highlighting their growing importance in the industry.

Introduction

In the realm of modern electronics, where performance and efficiency reign supreme, Pulse Width Modulation (PWM) fans have emerged as a transformative solution for thermal management. These advanced cooling systems not only adjust their speed to accommodate fluctuating cooling demands but also operate with exceptional energy efficiency and minimal noise. As industries increasingly depend on cutting-edge cooling technologies, PWM fans are becoming essential across applications, from personal computers to industrial machinery. Given the anticipated rise in their adoption, grasping the mechanics, advantages, and applications of PWM fans is vital for anyone aiming to enhance electronic performance and ensure reliability in an ever-evolving technological landscape.

Define PWM Fans: Functionality and Purpose

PWM devices, or Pulse Width Modulation systems, represent an advanced thermal management solution, which leads to the question of what is a PWM fan and how it is widely adopted in the electronics sector. These devices employ a distinctive control technique that adjusts the width of electrical pulses delivered to the motor, enabling accurate speed regulation. Unlike conventional models that function at a steady voltage, PWM units can modify their speed dynamically, operating at reduced rates when temperature control needs are minimal. This capability not only enhances energy efficiency but also significantly reduces operational noise, making them ideal for environments where sound levels are critical.

Gagner-Toomey Associates, the world’s largest producer of standard and custom air-movers for cooling, provides a wide range of DC input Tube Axial devices and Centrifugal Blowers, optimized for performance, efficiency, and low noise. Their supporters vary in dimensions from 15 to 280mm, while the blowers are offered from 15 to 225mm, with IP protection accessible in most models upon request. To understand what is a PWM fan, it’s important to note that they are typically equipped with a 4-pin connector, which includes a dedicated pin for the PWM signal that communicates the desired speed to the device. This design enables smooth incorporation into , where optimal temperature management is crucial for sustaining performance and avoiding overheating. In fact, as of 2025, approximately 70% of electronics use PWM cooling systems, leading to the question of what is a PWM fan and its increasing significance in thermal management. The market for what is a PWM fan is expected to expand considerably, driven by the increasing demand for effective temperature control solutions in various applications.

Recent advancements in what is have led to innovations such as improved blade designs and enhanced motor efficiency, resulting in a technique that is now reported to be seven times more effective than standard methods. Gagner-Toomey’s extensive portfolio encompasses not only miniature blower and fan solutions for consumer applications but also a complete range of thermal management solutions, including:

- Extruded aluminum heatsinks

- Copper-based and full copper heat sinks

- Heat sinks with embedded heat pipes

- Vapor chambers

- Cold plates

- Open and closed liquid refrigeration solutions

Case studies emphasize the importance of PWM fan control in improving stability by dynamically modifying temperature management based on heat and load, thereby reducing the risk of thermal failures. For instance, the case study titled “Improved System Stability with PWM Fan Control” illustrates how effective PWM fan management can prevent overheating and system failures, showcasing Gagner-Toomey’s products in action.

Experts highlight that what is a PWM fan in electronics is its main function to ensure dependable cooling while enhancing energy efficiency. As Matt Safford, a technology writer, observes, “PWM units are crucial for contemporary electronics, balancing performance and efficiency in a manner that conventional counterparts cannot.” As the market for PWM devices continues to grow, many are asking what is a PWM fan, and their functionality and advantages are becoming more evident in various applications, from personal computers to industrial setups. Furthermore, a recent manual on strategically arranging case ventilators for optimal temperature regulation within a PC emphasizes what is a PWM fan and its practical significance in achieving effective thermal control.

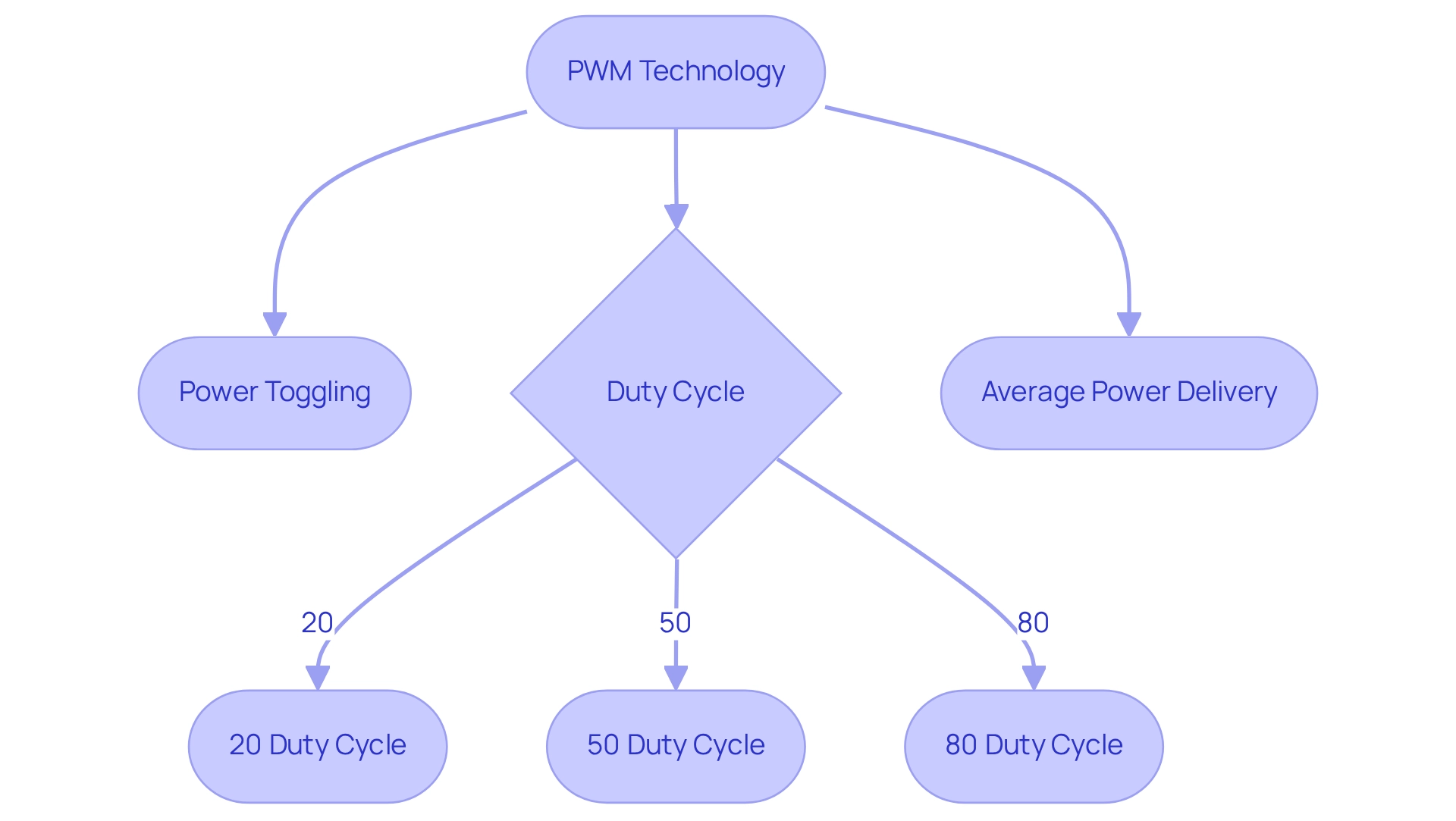

Explore PWM Technology: Operation and Mechanisms

To understand what is , it’s important to know that Pulse Width Modulation (PWM) operates by rapidly toggling the power supplied to a fan on and off at high frequencies. The duty cycle, defined as the ratio of ‘on’ time to ‘off’ time, is crucial in determining the average power delivered to the fan. For instance, a 50% duty cycle signifies that the fan receives power half the time, resulting in a moderate speed. This technique not only facilitates smoother speed transitions but also reduces wear on the fan motor compared to traditional voltage regulation methods.

In understanding what is a PWM fan, we see that PWM technology proves especially advantageous in scenarios requiring precise temperature control, such as in computer temperature regulation systems. By modulating power through pulse duration, PWM devices achieve higher efficiency and minimize energy waste, making them indispensable in modern electronics. As Edvard König, founder of EK, articulates, “We want to thank you for considering EK as your temperature control solutions provider.” EK is committed to excellence in every aspect—from our products to our service. Should you find yourself unsatisfied or in need of assistance, we encourage you to reach out.

The typical duty cycle percentages for PWM devices in electronics, specifically in the context of what is a PWM fan, generally span from 20% to 80%, contingent upon temperature management requirements. This versatility empowers engineers to customize fan performance to meet specific operational needs, ensuring optimal thermal management across a range of electronic devices.

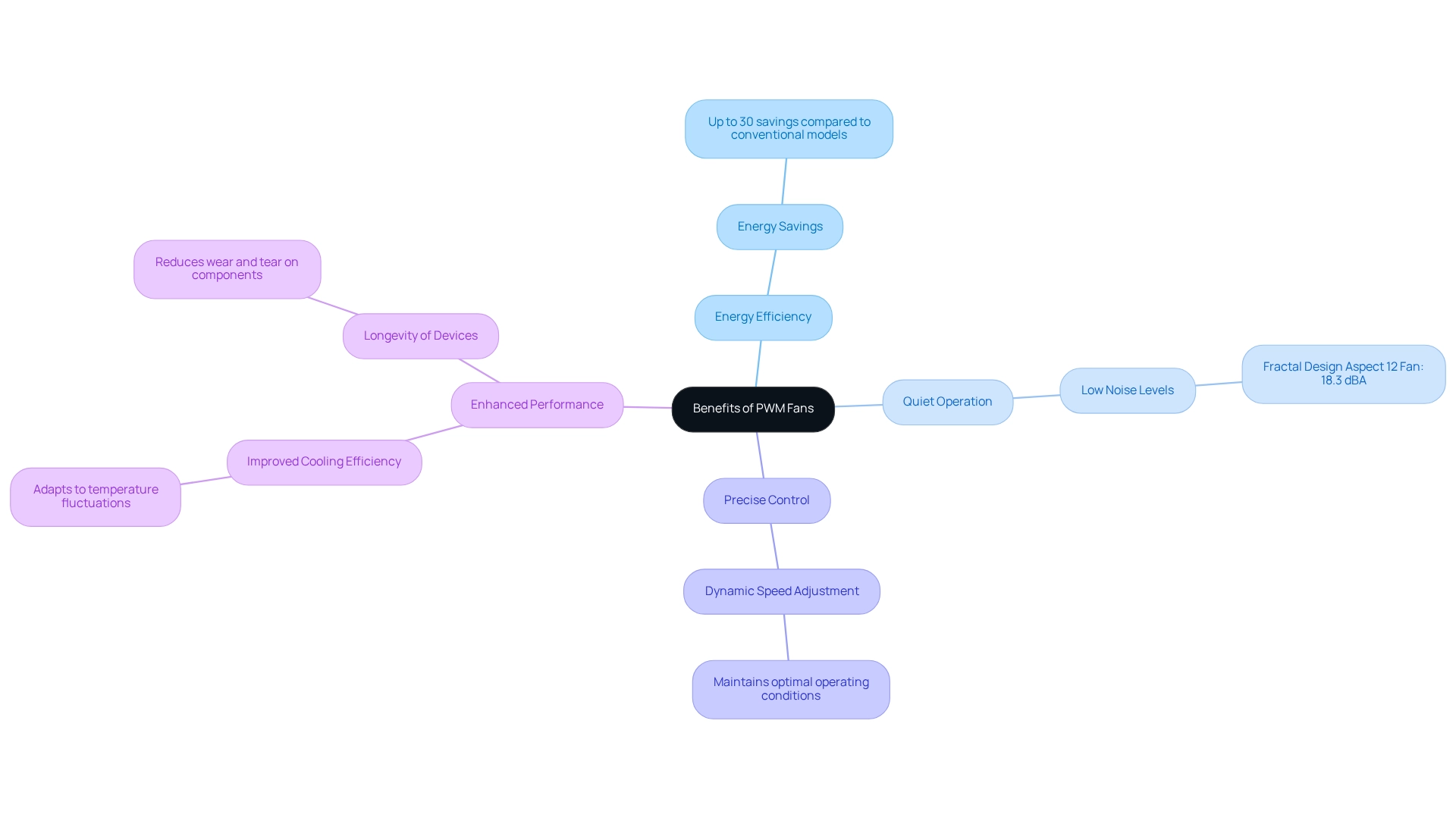

Evaluate Benefits: Why Choose PWM Fans for Electronics

What is a pwm fan, and why do PWM devices present a multitude of compelling advantages, establishing them as the preferred choice in various electronic applications? At the forefront, they demonstrate exceptional energy efficiency, functioning at reduced speeds during minimal cooling demands, which significantly curtails power consumption. Research indicates that PWM devices can achieve energy savings of up to 30% compared to conventional models, marking them as an environmentally responsible option.

In addition, PWM devices are engineered for quiet operation, dynamically adjusting their speed to minimize noise in low-load situations. This characteristic is particularly advantageous in settings where noise reduction is paramount, such as high-performance computing environments. For instance, exemplifies this capability, operating at a maximum speed of 2000 RPM and delivering an airflow of up to 56 CFM while maintaining a remarkably low noise level of just 18.3 dBA.

The precise control afforded by PWM technology not only enhances cooling efficiency but also contributes to greater stability and longevity. By adeptly responding to temperature fluctuations, PWM units help maintain optimal operating conditions, which is vital for sensitive electronic devices. This adaptability proves especially beneficial in applications demanding rigorous thermal management, ensuring systems remain reliable and efficient over time.

To fully appreciate this, one must understand what is a pwm fan, as integrating PWM devices within electronic applications yields enhanced performance, reduced energy costs, and quieter operation, establishing them as a crucial component in modern electronics. Understanding advancements in temperature regulation technologies empowers engineers to design both practical and aesthetically pleasing solutions, further underscoring the importance of PWM devices within the industry.

Applications of PWM Fans in Electronics

In understanding what is , it’s important to note that PWM devices play a crucial role in a variety of electronic applications, particularly in personal computers, servers, and industrial equipment. In personal computers, they are essential for cooling CPUs and GPUs, where maintaining optimal temperatures is vital for performance and reliability. In server settings, PWM fans effectively regulate airflow, dynamically responding to the thermal load of various components. This adaptability is increasingly crucial as power guidelines tighten and setups produce more heat. Notably, the controller attempts to restart a stalled fan for up to five attempts before acknowledging a catastrophic fan failure, showcasing advancements in .

Recent advancements in temperature measurement and fan-speed control techniques are being developed to improve the efficiency of these setups. As David Hanrahan observes, “As power regulations grow stricter, and PCs operate considerably hotter, more advanced temperature-monitoring and fan-speed-regulating methods are being created to manage the technologies of the future more efficiently.” PWM blowers are essential to HVAC setups, where accurate temperature regulation is crucial for energy efficiency and occupant comfort. Their ability to integrate into automated systems allows for real-time adjustments based on environmental conditions, further optimizing performance.

A significant percentage of industrial equipment now employs PWM units, reflecting their growing importance across various sectors. Case studies reveal that 4-wire PWM devices, which enable continuous speed monitoring and functioning at low speeds, are particularly effective in minimizing noise and power usage. This makes them ideal for contemporary electronic applications requiring efficient thermal management. This aligns with findings from the case study titled “Fan Types and Control Methods,” which emphasizes the benefits of 4-wire units regarding their advanced control capabilities. As the demand for sophisticated cooling solutions continues to rise, understanding what is a PWM fan highlights their versatility and efficiency, positioning them as a key component in the future of electronics.

Conclusion

The significance of Pulse Width Modulation (PWM) fans in modern electronics is paramount. Their capacity to dynamically adjust speed according to cooling demands not only enhances energy efficiency but also minimizes noise levels, establishing them as an ideal choice for various applications. From personal computers to industrial machinery, PWM fans are increasingly vital in maintaining optimal temperatures and ensuring system stability.

The operational mechanism of PWM technology, characterized by its precise control over power delivery, facilitates smoother speed transitions and reduces wear on fan components. This results in a more reliable cooling solution that adapts to fluctuating thermal loads, ultimately contributing to the longevity and performance of electronic devices. Studies indicate potential energy savings of up to 30% compared to traditional fans, reinforcing the eco-friendly nature of PWM technology.

As the demand for effective thermal management escalates across industries, the versatility of PWM fans positions them as a cornerstone of future cooling solutions. Their integration into sophisticated electronic systems not only enhances cooling efficiency but also aligns with the trend towards quieter and more energy-conscious technology. It is imperative for engineers and designers to understand and leverage the advantages of PWM fans to optimize performance and reliability in an ever-evolving technological landscape.

Frequently Asked Questions

What is a PWM fan?

A PWM fan, or Pulse Width Modulation fan, is a type of cooling device that uses a control technique to adjust the width of electrical pulses to the motor, allowing for precise speed regulation. This enables the fan to operate at varying speeds based on temperature needs, enhancing energy efficiency and reducing operational noise.

How do PWM fans differ from conventional fans?

Unlike conventional fans that operate at a steady voltage, PWM fans can dynamically modify their speed, running at reduced rates when less cooling is needed. This capability improves energy efficiency and lowers noise levels, making them suitable for environments where sound is a concern.

What are the typical features of a PWM fan?

PWM fans typically have a 4-pin connector, which includes a dedicated pin for the PWM signal that communicates the desired speed to the fan. This design allows for smooth integration into modern electronic systems, ensuring effective temperature management.

What is the significance of PWM fans in the electronics sector?

PWM fans are increasingly significant in the electronics sector, with about 70% of electronics expected to use PWM cooling systems by 2025. They play a crucial role in maintaining optimal temperature control, which is essential for sustaining performance and preventing overheating.

What advancements have been made in PWM fan technology?

Recent advancements include improved blade designs and enhanced motor efficiency, making PWM fans reportedly seven times more effective than standard cooling methods.

What products does Gagner-Toomey Associates offer related to PWM fans?

Gagner-Toomey Associates offers a range of products, including miniature blowers and fans, extruded aluminum heatsinks, copper-based heat sinks, heat sinks with embedded heat pipes, vapor chambers, cold plates, and liquid refrigeration solutions.

How does PWM fan control improve system stability?

PWM fan control enhances system stability by dynamically adjusting temperature management based on heat and load, thus reducing the risk of thermal failures. Case studies demonstrate that effective PWM management can prevent overheating and system failures.

What are the practical applications of PWM fans?

PWM fans are used in various applications, including personal computers and industrial setups, where dependable cooling and energy efficiency are crucial. They are essential for achieving effective thermal control in these environments.