Overview

EC fans, or Electronically Commutated fans, represent a significant advancement in fan technology. Utilizing a brushless DC motor paired with an integrated electronic controller, these fans dynamically adjust their speed in response to varying airflow requirements. This capability not only leads to substantial energy savings but also minimizes noise levels, addressing common concerns in various applications.

The efficiency of EC fans is remarkable; they consume up to 70% less power than traditional AC units. This reduction in energy consumption is crucial for sectors such as HVAC, data centers, and medical equipment, where operational costs and environmental impact are paramount. Additionally, the precise airflow regulation offered by EC fans allows for adaptability across diverse applications, making them a superior choice for modern facilities.

In conclusion, the integration of EC fans into operational systems not only enhances efficiency but also provides a sustainable solution to airflow management challenges. By considering the implementation of this technology, industries can achieve both cost savings and improved performance.

Introduction

Electronically Commutated (EC) fans are revolutionizing the approach to energy efficiency and operational performance across various industries. By merging the advantages of traditional AC and DC motors, these advanced devices not only optimize airflow but also significantly reduce energy consumption and noise levels. As the demand for sustainable solutions intensifies in sectors such as HVAC, automotive, and data centers, it becomes crucial to understand what makes EC fans the preferred choice for modern applications. This understanding leads us to explore how they deliver such remarkable benefits.

Define EC Fan Technology

When considering what is an ec fan, it is important to note that Electronically Commutated (EC) devices represent a significant advancement in technology, employing a brushless DC motor paired with an integrated electronic controller to optimize performance and efficiency. In contrast to traditional AC units, EC devices dynamically adjust their speed according to airflow requirements, resulting in improved energy efficiency and reduced noise levels. This cutting-edge design merges the advantages of both AC and DC units, facilitating precise operational control and enabling adaptation to fluctuating environmental conditions.

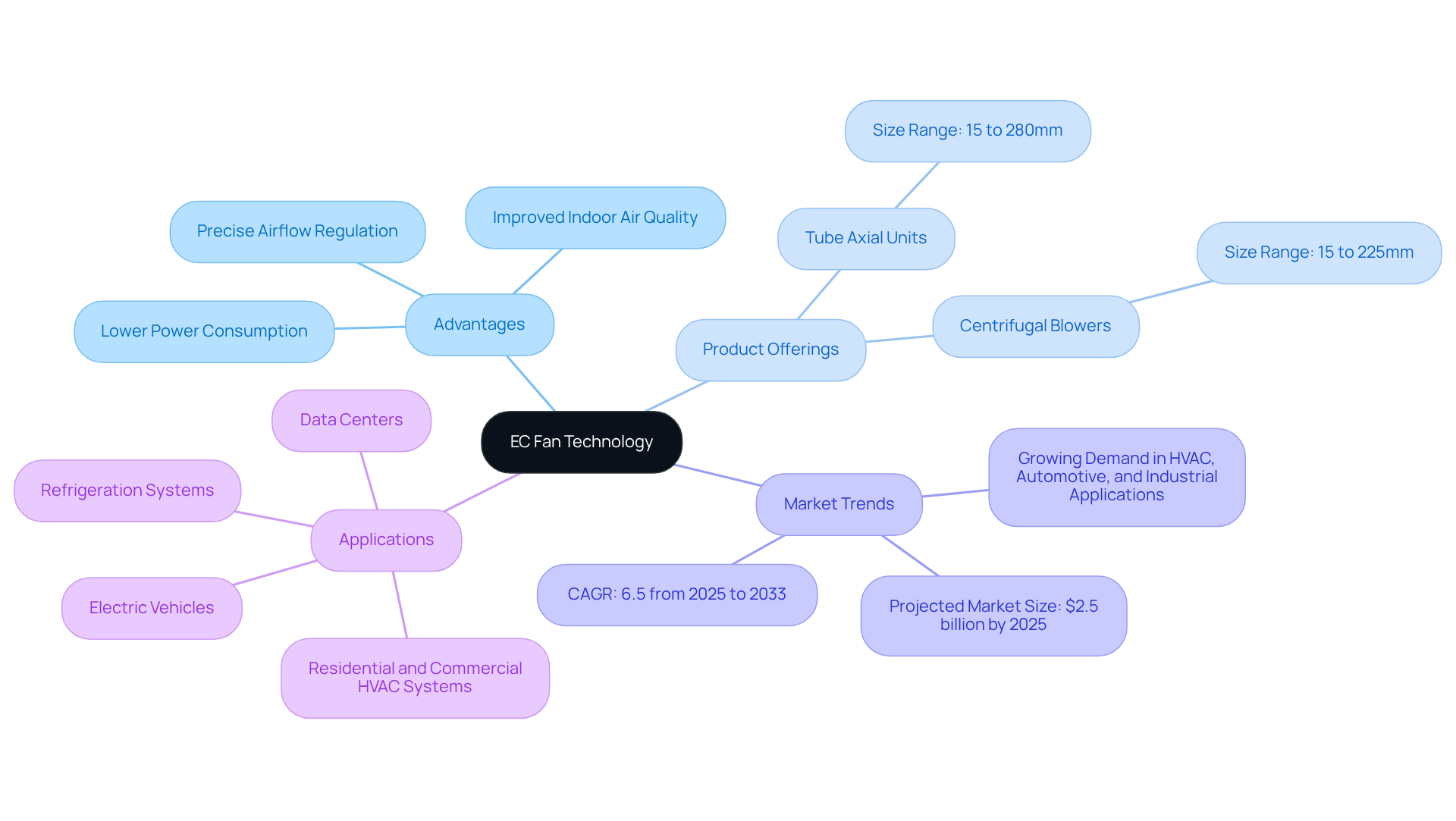

As the world’s largest producer of standard and custom air-movers, the company offers an extensive product line of DC input EC devices designed for superior performance, efficiency, and low noise. Their offerings include:

- Tube Axial units ranging from 15 to 280mm

- Centrifugal Blowers from 15 to 225mm, with IP protection available upon request

Furthermore, Gagner-Toomey Associates provides comprehensive thermal management solutions that feature extruded aluminum heatsinks, copper-based heat sinks, cold plates, and integrated cooling solutions incorporating blowers, heat pipes, and radiators.

The global market for EC devices is projected to reach approximately $2.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.5%. This growth is fueled by escalating demand for energy-efficient solutions across diverse sectors, including HVAC, automotive, and industrial applications. Notably, EC motors are extensively utilized in data centers, refrigeration systems, and electric vehicles, where their efficiency and performance are paramount.

Recent innovations in EC fan technology raise the question of what is an ec fan, encompassing advancements in motor design that enhance power efficiency and minimize operational noise. Gagner-Toomey Associates is at the forefront of these developments, offering high-efficiency EC devices tailored for various applications.

The benefits of EC units are manifold:

- They provide precise airflow regulation

- Significantly lower power consumption

- Contribute to improved indoor air quality

As awareness of energy conservation rises, the adoption of EC devices is expected to increase, particularly in residential and commercial sectors where energy efficiency is critical.

Explain How EC Fans Operate

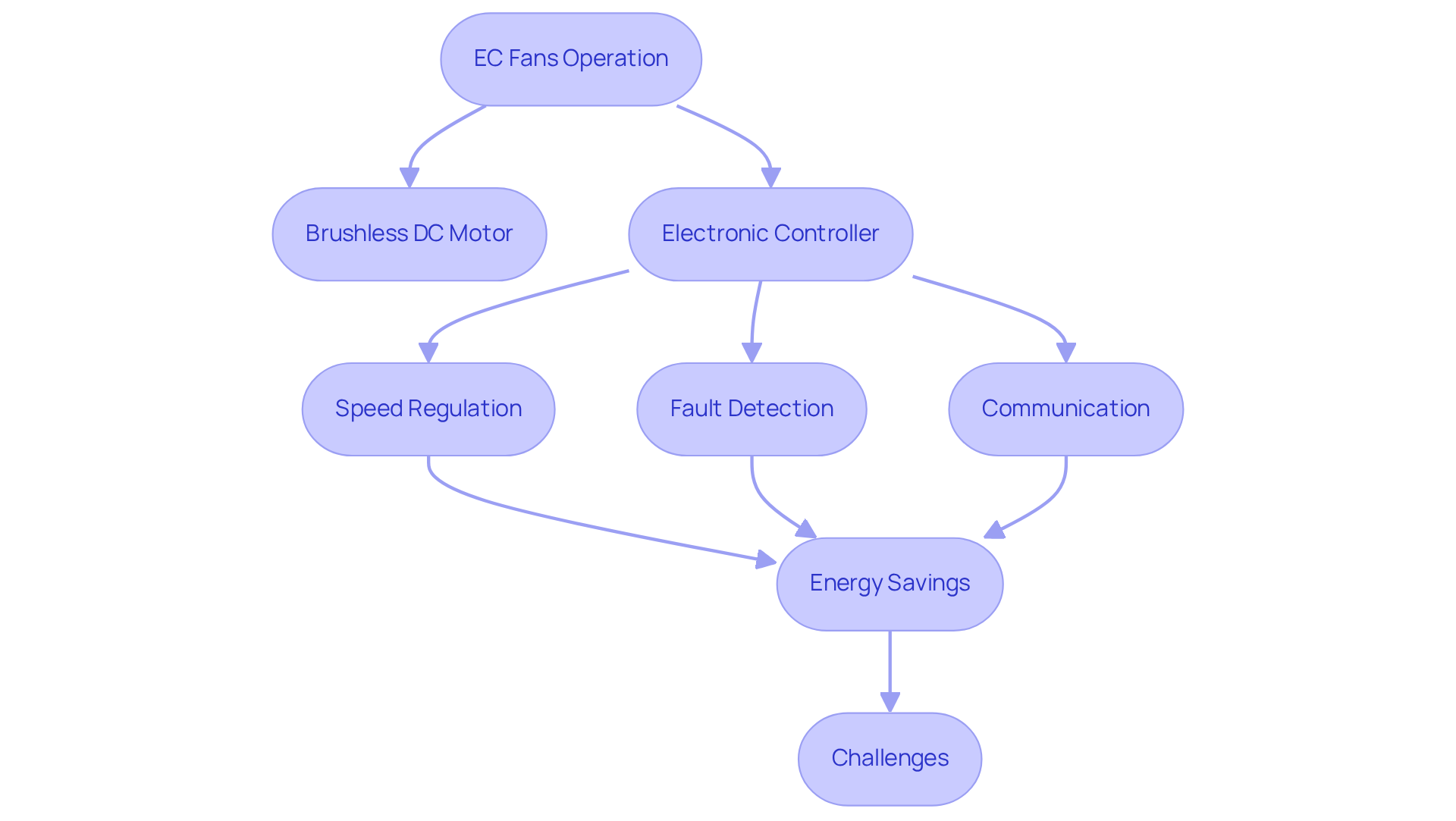

EC enthusiasts are increasingly turning to brushless DC motors, which eliminate the need for conventional brushes, significantly reducing friction and wear. This innovative design not only enhances longevity—typically 10 to 15 years—but also contrasts sharply with traditional models that last only 5 to 8 years, resulting in lower maintenance expenses. The integrated electronic controller is pivotal, as it modulates the power supplied to the motor, allowing the fan to adjust its speed based on real-time feedback from sensors. This dynamic capability enables EC devices to improve airflow while consuming up to 70% less power than conventional AC units, seamlessly adapting to the system’s cooling requirements.

Furthermore, the electronic control system amplifies functionality with features such as:

- precise speed regulation

- fault detection

- communication with other components

This ensures efficient operation and reliability. Case studies have illustrated that EC units can save $42,000 in energy expenses over eight years, reinforcing their value in energy-efficient applications. However, potential challenges in implementing EC devices, such as control system incompatibility and the necessity for skilled technicians, must be considered during the planning phase.

Outline the Advantages of EC Fans

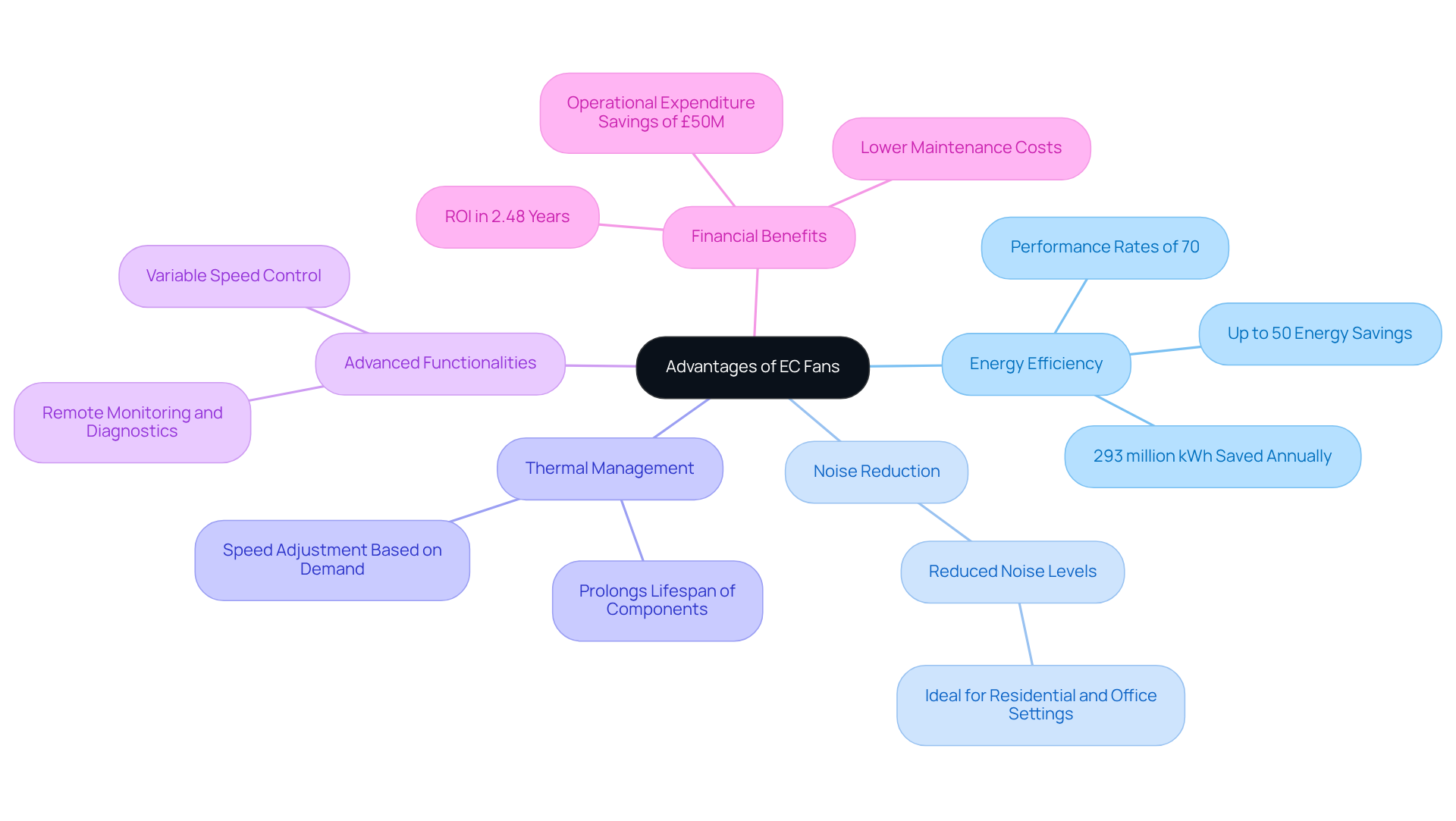

EC supporters present a multitude of significant advantages that warrant attention. Primarily, they enhance energy efficiency, achieving reductions in energy consumption of up to 50% compared to conventional AC units. This remarkable effectiveness not only lowers operational costs but also diminishes the carbon footprint, positioning EC devices as an environmentally friendly option. Furthermore, these devices operate at reduced noise levels, making them ideal for environments where sound management is essential, such as residential and office settings.

Their ability to adjust speed based on demand optimizes thermal management, consequently prolonging the lifespan of electronic components. The integration of electronic controls enables advanced functionalities, including remote monitoring and diagnostics, significantly enhancing usability in complex systems. Case studies reveal that data centers utilizing EC motors can achieve performance rates of up to 70% while consuming approximately 50% less energy, leading to substantial energy savings and reductions in operational costs.

The return on investment for these systems is often realized within a short timeframe, typically around 2.48 years, underscoring their long-term economic advantages. Moreover, the implementation of Adiabatic units in data centers has resulted in operational expenditure savings of £50 million per year, further emphasizing what is an ec fan and its financial benefits.

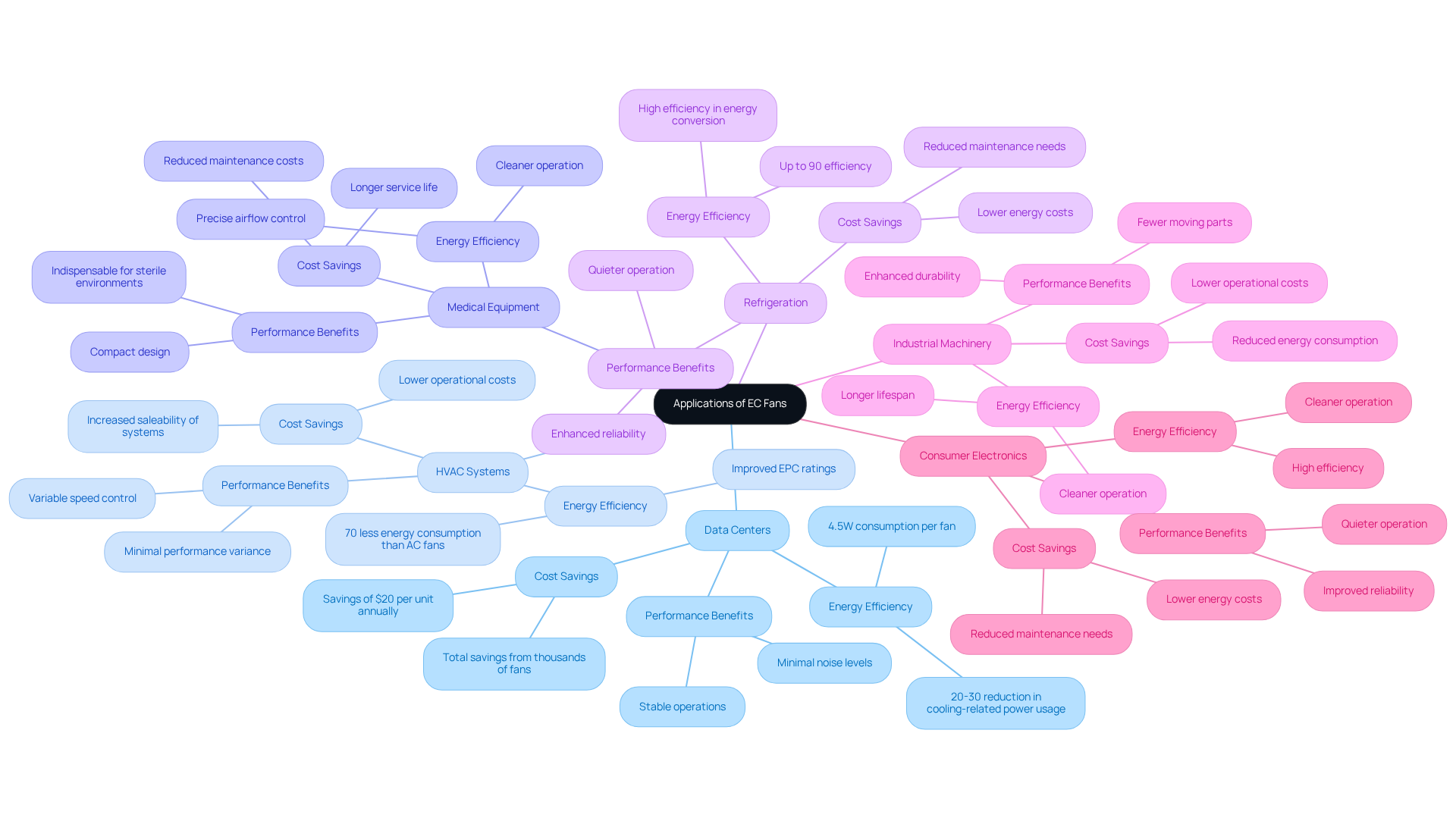

Identify Common Applications of EC Fans

What is an ec fan is becoming increasingly recognized among enthusiasts for their efficiency and adaptability across multiple sectors. The world’s largest producer of standard and custom air-movers offers a comprehensive range of DC input Tube Axial units and Centrifugal Blowers, optimized for performance and low noise.

In data centers, these devices are crucial for cooling servers and maintaining optimal operating temperatures, significantly reducing energy consumption. A case study highlighted that by transitioning to EC axial units, a data center manager saved nearly $20 per unit annually, leading to substantial total savings. Additionally, Mr. Li’s enhancement to the EC inline units resulted in savings of $55 per unit each year, underscoring the potential for significant cost reductions across various types of units.

In HVAC systems, when considering what is an ec fan, it is important to note that these units maintain minimal performance variance across the speed range, facilitating effective air circulation and ventilation while contributing to energy savings in both heating and cooling processes. Their combined variable speed controllers allow for real-time adjustments based on demand, further enhancing performance.

Moreover, in medical equipment, knowing what is an ec fan is essential for maintaining precise airflow control and sterile environments, making Gagner-Toomey’s EC fans an indispensable component. Their compact design and high efficiency also render them suitable for refrigeration systems, industrial machinery, and consumer electronics, where they improve performance and reliability while minimizing energy costs.

Conclusion

Electronically Commutated (EC) fans epitomize a revolutionary advancement in airflow technology, seamlessly integrating the advantages of both AC and DC motors to achieve exceptional energy efficiency and operational flexibility. By dynamically adjusting their speed to meet real-time airflow demands, these fans not only optimize performance but also yield significant energy savings and noise reduction. This makes them an exemplary choice for a diverse range of applications.

The exploration of EC fan technology reveals its core components, particularly the operation through brushless DC motors and integrated electronic controllers. The discussion highlights key benefits such as:

- Reduced energy consumption

- Enhanced indoor air quality

- An extended lifespan

Additionally, the growing market potential for EC fans across sectors like HVAC, data centers, and medical equipment underscores their relevance. The financial advantages, including substantial energy cost savings and a rapid return on investment, further accentuate the value of adopting EC fans.

In light of the escalating demand for energy-efficient solutions, the significance of integrating EC fan technology is paramount. The adoption of these advanced devices not only facilitates considerable cost savings but also aligns with broader environmental objectives by minimizing carbon footprints. Industries and consumers are thus urged to consider the implementation of EC fans to enhance operational efficiency and contribute to a sustainable future.

Frequently Asked Questions

What is EC fan technology?

EC fan technology refers to Electronically Commutated devices that utilize a brushless DC motor combined with an integrated electronic controller to enhance performance and efficiency. These devices adjust their speed based on airflow requirements, leading to improved energy efficiency and reduced noise levels.

How do EC fans differ from traditional AC units?

Unlike traditional AC units, EC fans dynamically adjust their speed according to airflow needs, which allows for better energy efficiency and lower noise levels. They combine the benefits of both AC and DC motors for precise operational control.

What types of EC devices are offered by Gagner-Toomey Associates?

Gagner-Toomey Associates offers a variety of EC devices, including Tube Axial units ranging from 15 to 280mm and Centrifugal Blowers from 15 to 225mm, with options for IP protection available upon request.

What are the market trends for EC devices?

The global market for EC devices is projected to reach approximately $2.5 billion by 2025, with a compound annual growth rate (CAGR) of 6.5%. This growth is driven by increasing demand for energy-efficient solutions across various sectors, including HVAC, automotive, and industrial applications.

In which applications are EC motors commonly used?

EC motors are commonly used in data centers, refrigeration systems, and electric vehicles, where their efficiency and performance are critical.

What are the benefits of using EC units?

The benefits of EC units include precise airflow regulation, significantly lower power consumption, and contributions to improved indoor air quality.

Why is the adoption of EC devices expected to increase?

The adoption of EC devices is expected to increase due to rising awareness of energy conservation, particularly in residential and commercial sectors where energy efficiency is essential.