Overview

Revolution per minute (RPM) serves as a fundamental unit of measurement that quantifies the frequency of rotation, indicating the number of complete revolutions an object makes around a fixed axis in one minute. This metric is crucial across various fields, particularly in engineering and automotive. The significance of RPM extends to assessing the performance and efficiency of rotating machinery.

The article delves into the historical evolution of RPM, elucidating its key characteristics, including its intrinsic relationship with torque and power output. These elements are essential for optimizing system performance, making RPM a vital consideration for professionals aiming to enhance operational efficacy.

Introduction

In the realm of engineering and technology, revolutions per minute (RPM) stands as a crucial metric for assessing the performance of rotating machinery. This unit of measurement quantifies the frequency of rotation and provides insights into the efficiency and operational capabilities of various devices, ranging from automotive engines to electronic motors.

As industries evolve, the significance of RPM becomes increasingly pronounced, particularly in fields such as electronics engineering, where it plays a vital role in optimizing performance and reliability.

This article will explore the definition of RPM, its historical evolution, and its key characteristics, illuminating its indispensable role in modern engineering practices.

Define Revolution Per Minute (RPM)

What is revolution per minute (RPM)? This unit of measurement quantifies the frequency of rotation, specifically indicating how many complete revolutions an object makes around a fixed axis in one minute. In various domains, including engineering, automotive, and manufacturing, the question of what constitutes revolution per minute is prevalent, as this metric is essential for evaluating the functionality and efficiency of rotating machinery.

For example, an engine operating at 3,000 RPM exemplifies this concept by completing 3,000 full rotations in one minute, thereby providing a clear indication of its operational speed and capability.

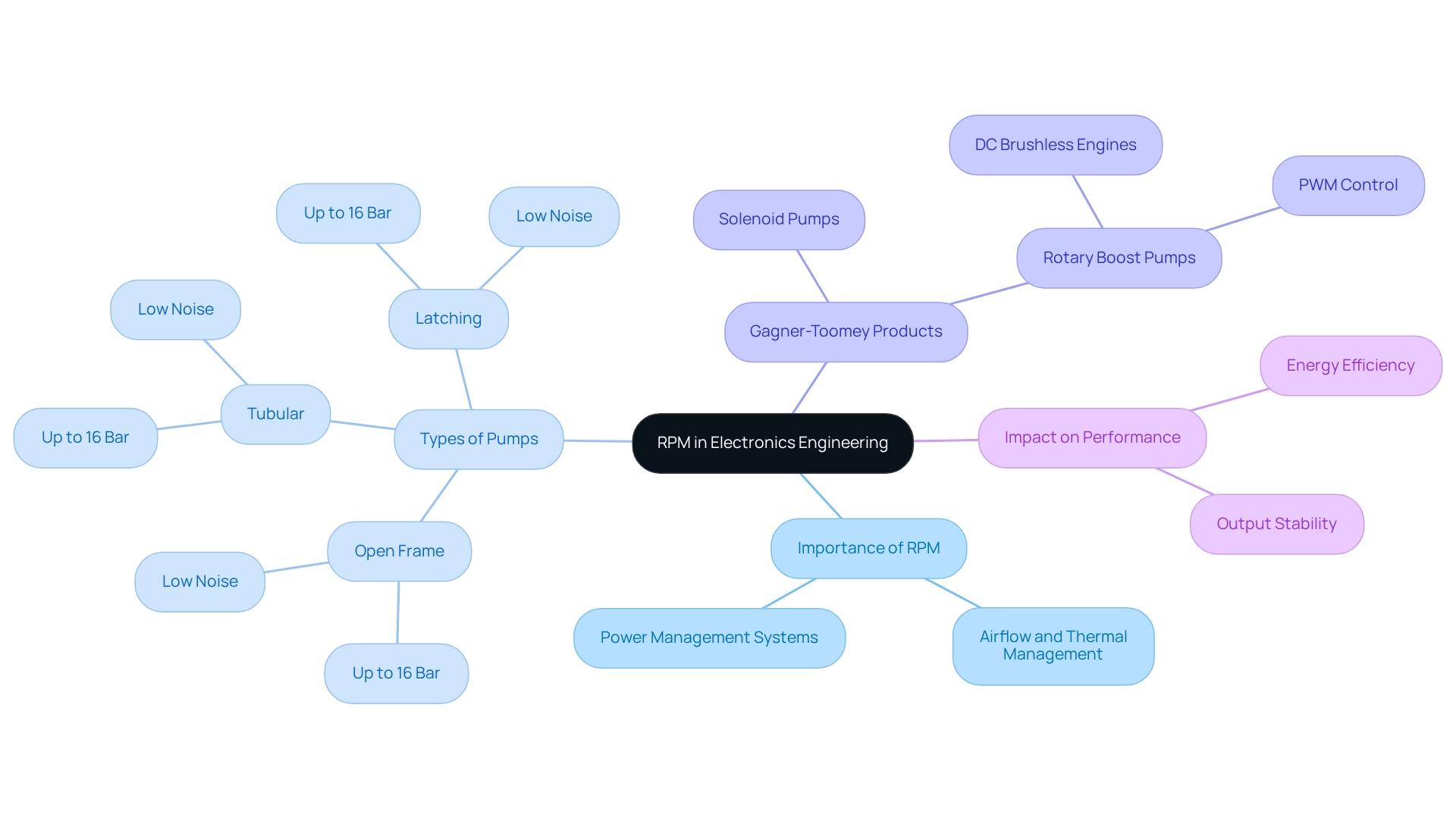

Contextualize RPM in Electronics Engineering

In electronics engineering, revolution per minute (RPM) is a crucial factor for assessing the performance of engines, fans, and other rotating elements, including solenoid and rotary boost pumps. The influence of fan RPM on airflow and thermal management is significant, as these elements are vital for maintaining optimal operating conditions for electronic devices.

Gagner-Toomey Associates offers cutting-edge solenoid pumps, such as:

- Open frame

- Tubular

- Latching varieties

These pumps are capable of functioning up to 16 Bar. Additionally, their rotary boost pumps are equipped with DC brushless engines and feature PWM control for precision pumping, allowing for fine-tuning of RPM to meet specific application requirements. These pumps also provide flexible input options and operate with low noise, enhancing their suitability for a variety of applications.

In power management systems, the RPM of generators and motors directly impacts energy efficiency and output stability. By understanding revolution per minute, engineers can enhance designs for improved efficiency and reliability, ensuring that electronic systems operate effectively under various operational conditions.

Gagner-Toomey’s facility is certified with IATF 16969 standards and complies with Automotive Standards SAE and VDA, further ensuring the quality and reliability of their products.

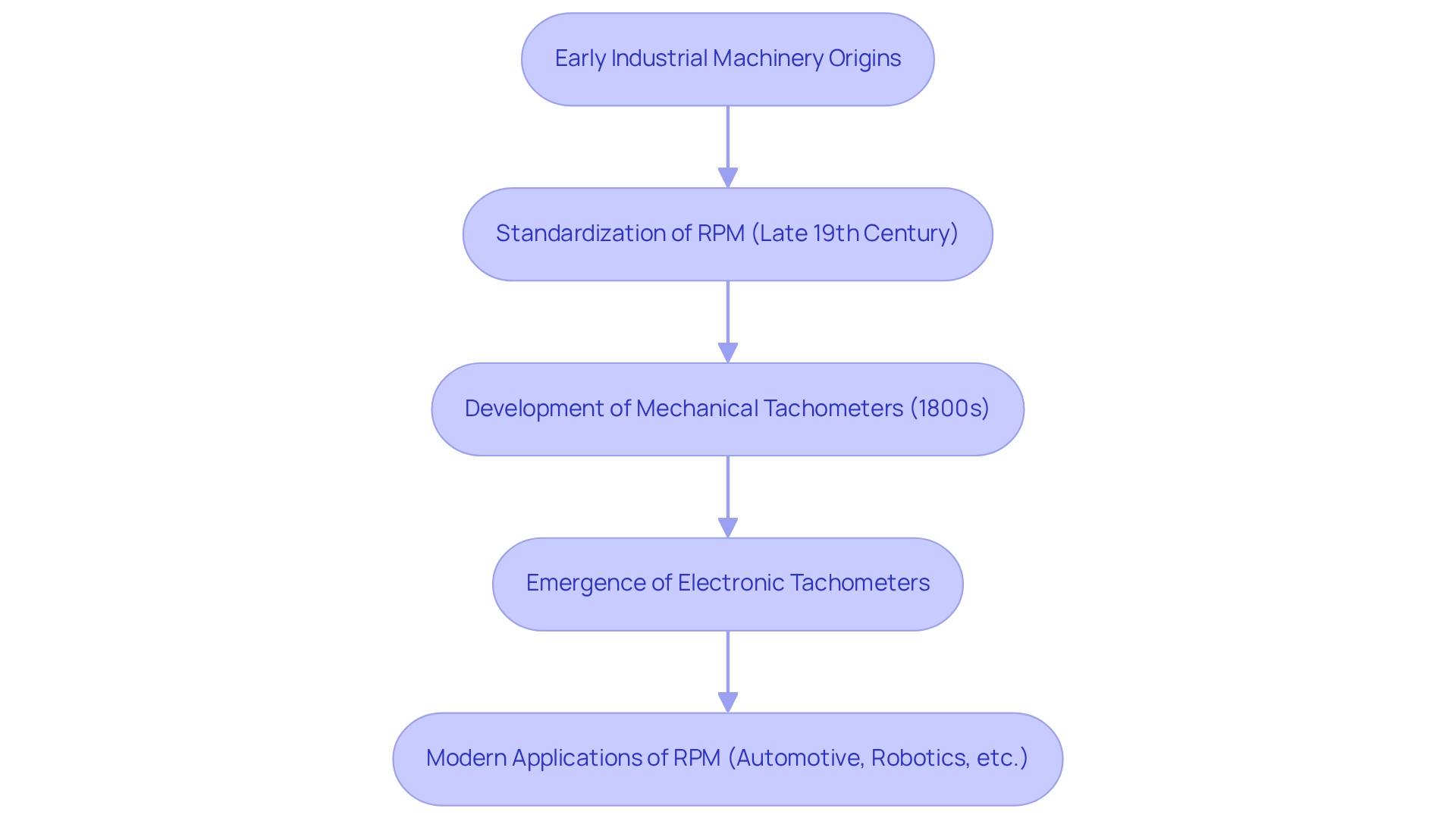

Trace the Origin and Evolution of RPM

The measurement of rotational speed has its origins in the early days of industrial machinery. The standardization of the term ‘revolution per minute’ occurred in the late 19th century, as engineers endeavored to quantify the performance of engines and turbines. Early tachometers, developed in the 1800s, were mechanical devices that measured RPM through direct contact with rotating shafts. With advancements in technology, electronic tachometers emerged, offering more accurate and reliable measurements. Today, a comprehensive understanding of what constitutes revolution per minute (RPM) is essential across various applications, ranging from automotive engineering to robotics. This metric not only reflects the enduring significance of RPM in the evolution of mechanical and electronic systems but also underscores its critical role in modern engineering practices.

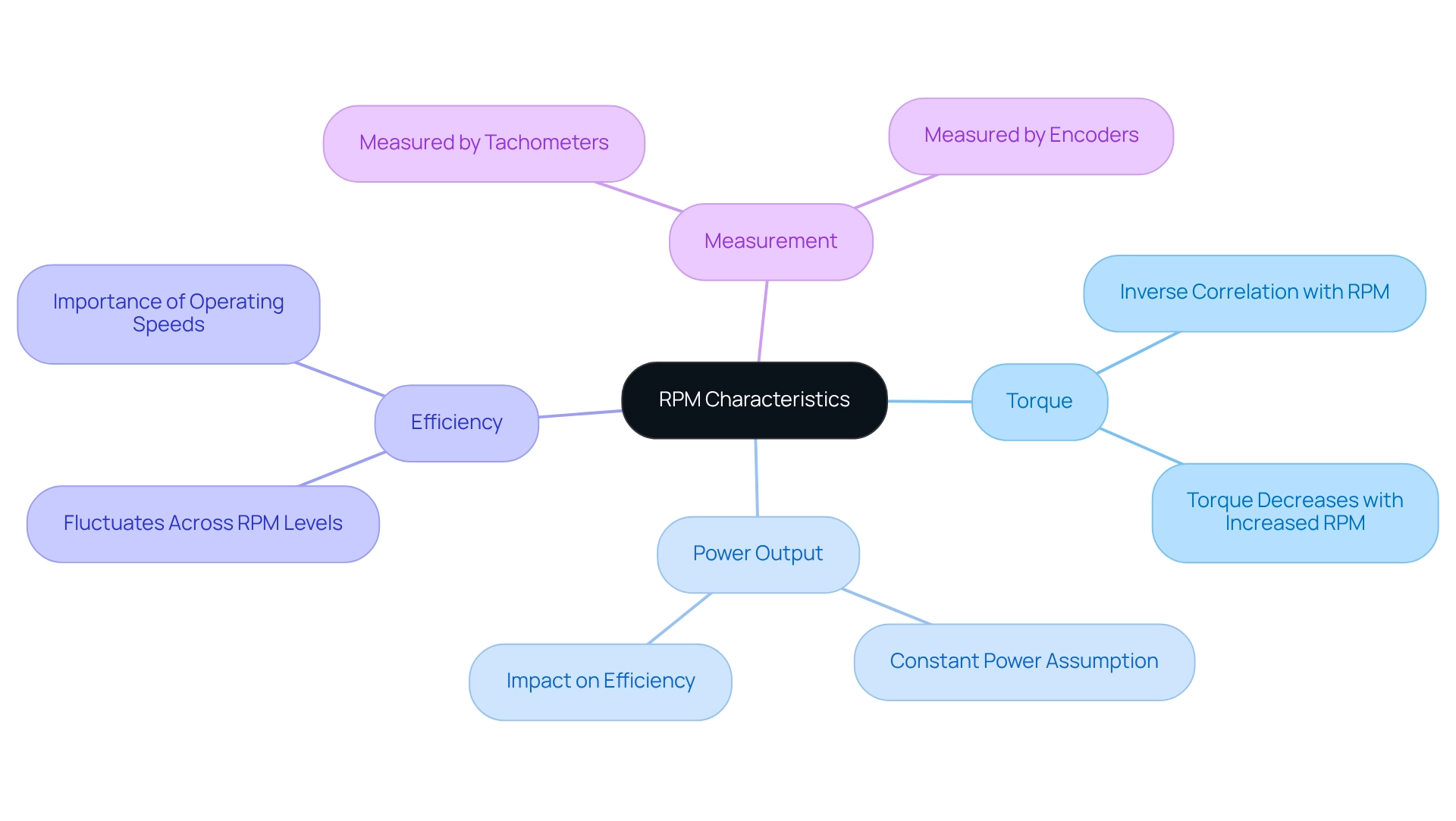

Identify Key Characteristics and Components of RPM

Key characteristics of revolutions per minute (RPM) encompass its relationship with torque, power output, and efficiency. In electric machines, for instance, an understanding of RPM reveals an inverse correlation with torque; as RPM increases, torque typically decreases, assuming constant power. This relationship underscores the importance of RPM for engineers, as motor efficiency can fluctuate significantly across various RPM levels. Selecting appropriate operating speeds for specific applications is therefore crucial. RPM, commonly referred to as revolutions per minute, is measured through devices such as tachometers and encoders, which deliver real-time feedback on rotational speed. Grasping these characteristics empowers engineers to optimize system performance and guarantees that machinery operates within safe and efficient parameters.

Conclusion

The exploration of revolutions per minute (RPM) underscores its indispensable role within the engineering and technology sectors. By defining RPM as a measure of rotational frequency, this discussion highlights its significance in assessing the performance and efficiency of machinery across various fields, particularly in electronics engineering. From automotive engines to advanced electronic motors, a thorough understanding of RPM is essential for optimizing operational capabilities and ensuring reliability.

Tracing the historical evolution of RPM illuminates its longstanding relevance, from early mechanical tachometers to today’s sophisticated electronic measurement devices. This evolution illustrates how advancements in technology have refined our ability to monitor and enhance the performance of rotating components. Furthermore, the relationship between RPM, torque, and power output emphasizes the importance of selecting appropriate operating speeds to maximize efficiency.

In conclusion, RPM transcends being merely a numerical value; it encapsulates a vital aspect of engineering that influences design, functionality, and efficiency. As industries continue to innovate, the understanding and application of RPM will remain crucial for developing reliable and high-performing systems. Embracing this knowledge empowers engineers to push the boundaries of technology and ensure that machinery operates at its peak, ultimately driving progress across various sectors.

Frequently Asked Questions

What does RPM stand for?

RPM stands for revolutions per minute, which is a unit of measurement that quantifies the frequency of rotation.

What does RPM measure?

RPM measures how many complete revolutions an object makes around a fixed axis in one minute.

Why is RPM important in various fields?

RPM is essential for evaluating the functionality and efficiency of rotating machinery in fields such as engineering, automotive, and manufacturing.

Can you provide an example of RPM in use?

An example of RPM is an engine operating at 3,000 RPM, which means it completes 3,000 full rotations in one minute, indicating its operational speed and capability.