Overview

Electronics engineers must consider mini box fans for cooling solutions, given their compact design, energy efficiency, and effectiveness in heat management. These factors are essential for maintaining the performance and reliability of electronic devices. The article elaborates on how mini box fans integrate seamlessly into constrained environments, consuming significantly less power than traditional cooling systems while providing essential airflow. This functionality mitigates the risk of overheating and extends the lifespan of electronic components, making them an indispensable choice for engineers.

Introduction

Effective thermal management stands as a critical concern in electronics engineering, particularly as the shrinking size of components and escalating power levels result in increased heat generation. As engineers endeavor to uphold optimal performance and reliability in their designs, the selection of cooling solutions becomes paramount. Mini box fans present a compelling option, offering energy efficiency, low noise, and seamless integration into diverse applications. However, amidst the multitude of cooling technologies available, what distinguishes mini box fans as the superior choice for electronics engineers confronting the challenges of contemporary thermal management?

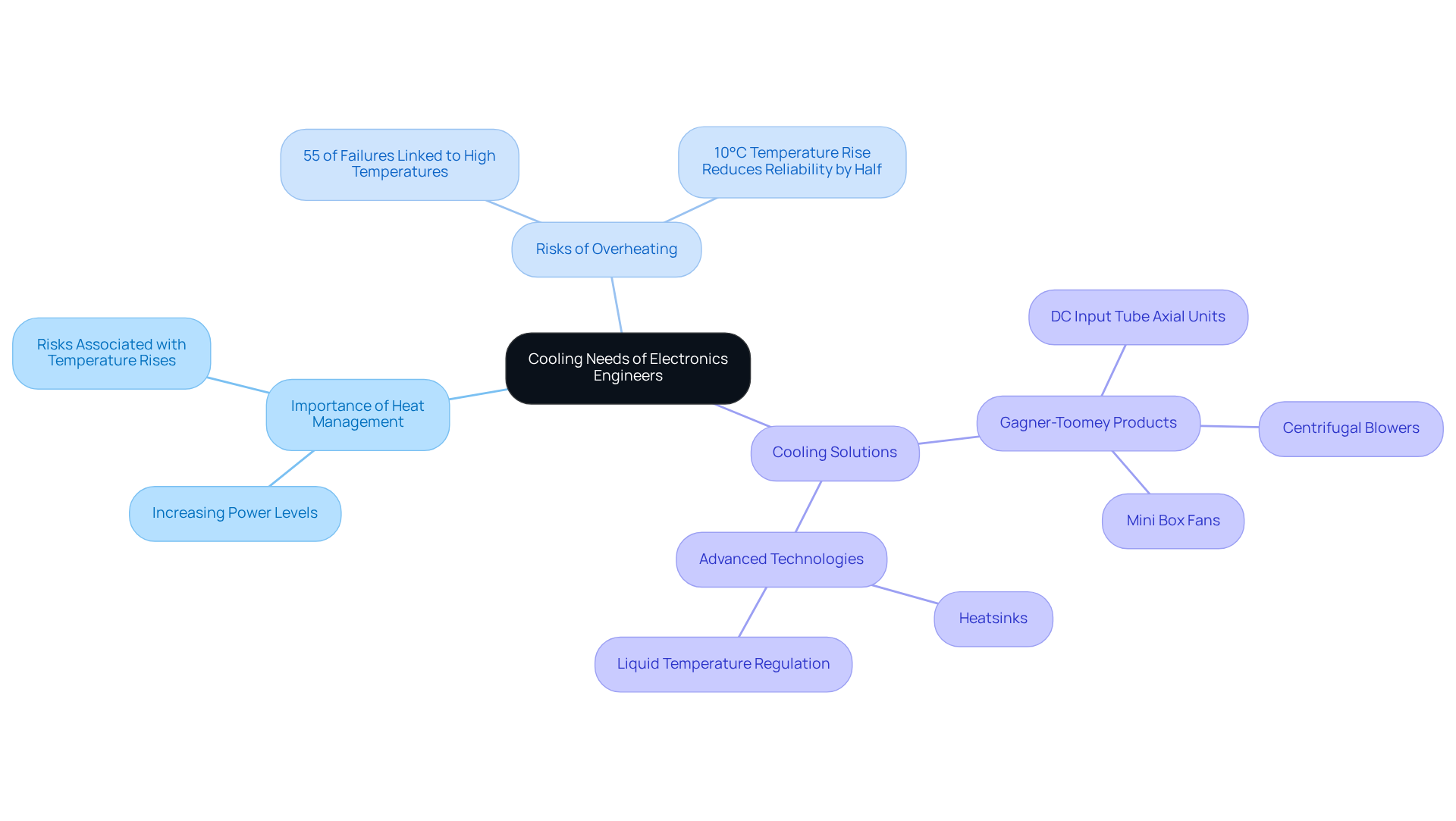

Understand the Cooling Needs of Electronics Engineers

In the realm of electronics engineering, effective heat management is crucial. As components shrink and power levels rise, the heat generated during operation escalates, necessitating a comprehensive grasp of thermal management principles. Engineers must account for ambient temperature, component placement, and airflow dynamics to mitigate overheating risks, which can lead to significant performance degradation or even catastrophic failure. Notably, approximately 55% of electronic equipment failures are linked to high temperatures, underscoring the urgency of addressing thermal issues. Each 10°C rise in temperature can reduce system reliability by half, making effective thermal management essential for the longevity and dependability of electronic devices.

Gagner-Toomey Associates stands out as the world’s largest manufacturer of standard and custom air-movers, offering a comprehensive portfolio of cooling solutions tailored for electronics and beyond. Their extensive range includes:

- DC input tube axial units

- Centrifugal blowers

These products are optimized for performance, efficiency, and low noise, with sizes ranging from 15mm to 280mm for units and 15mm to 225mm for blowers. Mini box fans from Gagner-Toomey are particularly effective in enhancing airflow and efficiently dissipating heat. Integrating a mini box fan into electronic designs is not merely advantageous; it is essential for maintaining optimal performance and ensuring the operational reliability of modern electronics.

Furthermore, engineers should consider advanced temperature regulation technologies, such as spray systems, which can manage heat fluxes up to 1000 W/cm², to further enhance thermal management strategies. Gagner-Toomey’s innovative solutions, including:

- Extruded aluminum heatsinks

- Copper-based heat sinks

- Integrated liquid temperature regulation solutions

These empower electronics engineers to ensure the operational reliability of modern electronics.

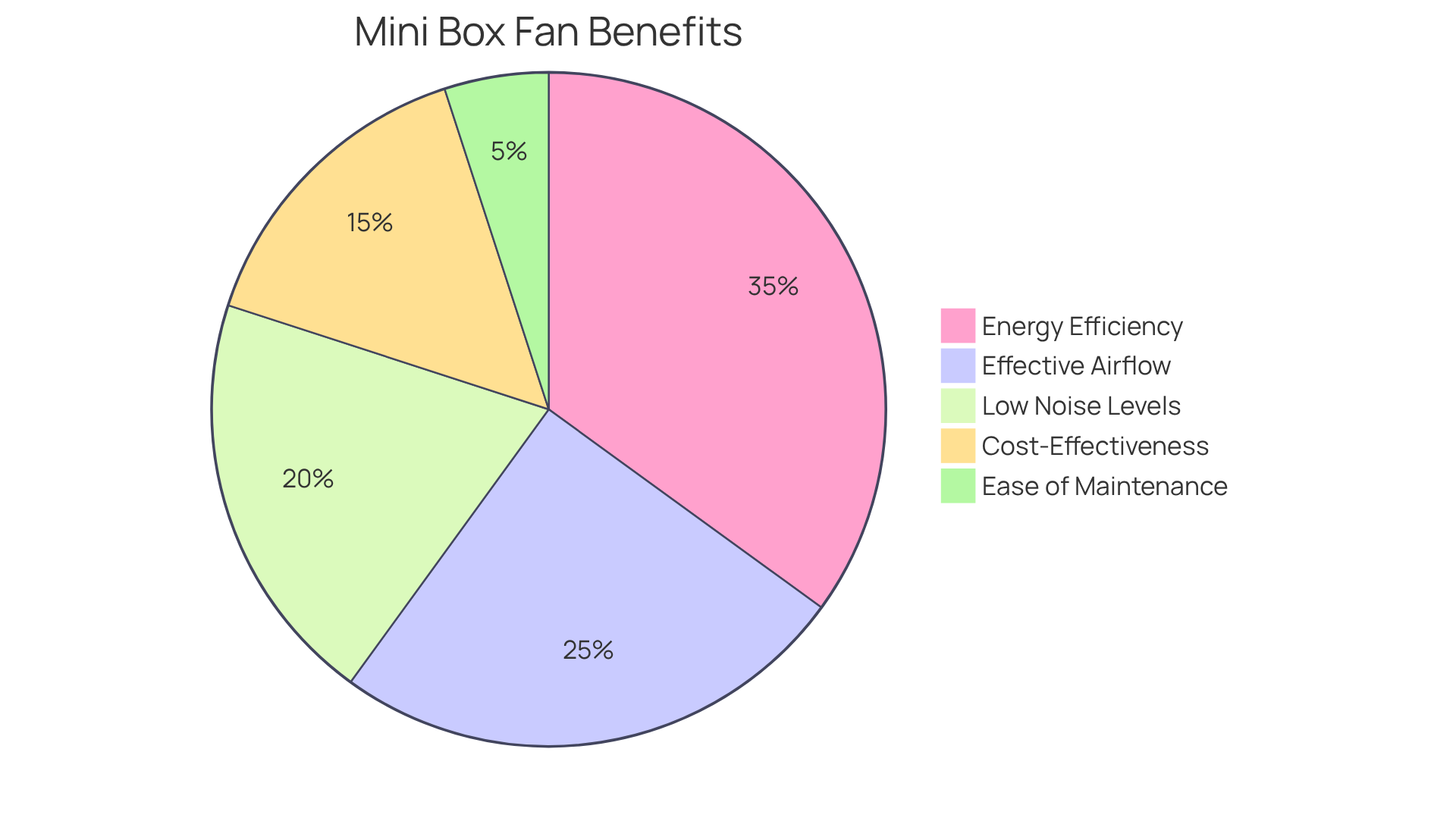

Explore the Advantages of Mini Box Fans

Mini box fans present a multitude of advantages, making them an optimal choice for electronics engineers. Their compact design allows for seamless integration into constrained environments, a frequent necessity in electronic applications. Notably, these devices are remarkably energy-efficient, consuming significantly less power than traditional temperature regulation systems—an essential feature for battery-operated devices. For instance, small box ventilators typically draw around 500 watts per hour, in stark contrast to 3,000 to 3,500 watts required by conventional air conditioning systems. This efficiency not only lowers operational costs but also mitigates the environmental impact linked to energy consumption.

Moreover, mini box fans excel in providing effective airflow, capable of moving substantial volumes of air while maintaining low noise levels—often quieter than many alternative ventilation solutions. This quality is vital in settings where sound levels must be minimized, such as offices or laboratories. Their cost-effectiveness and ease of maintenance further enhance their appeal, enabling engineers to implement efficient cooling solutions without incurring prohibitive expenses. Real-world applications demonstrate that small box ventilators can be seamlessly integrated into compact electronic designs, ensuring optimal performance while adhering to spatial constraints.

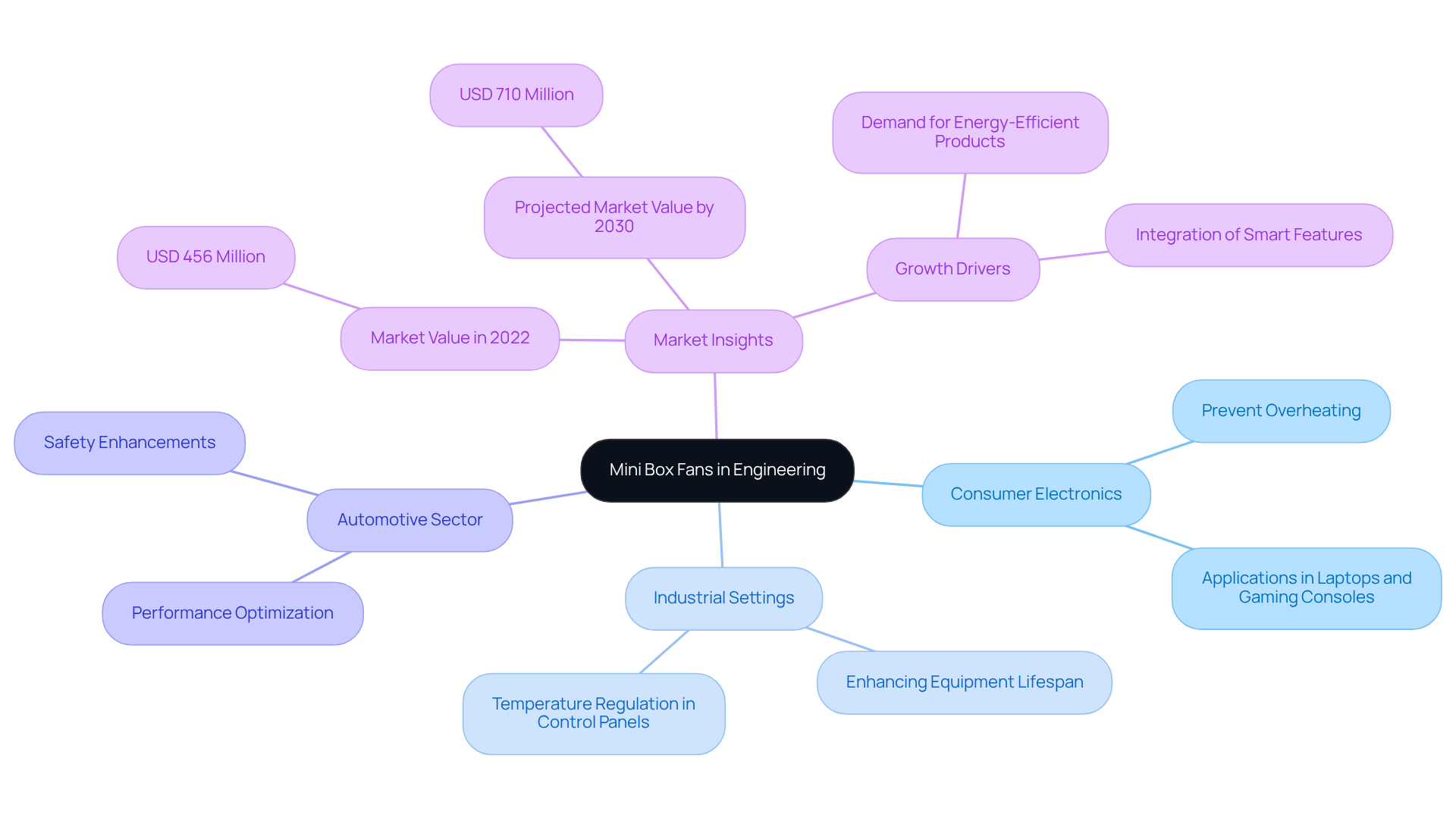

Examine Practical Applications of Mini Box Fans in Engineering

Mini box fans are indispensable in numerous engineering applications, particularly within industrial settings. They are crucial in consumer electronics, preventing overheating in devices such as laptops and gaming consoles during high-performance tasks. In industrial environments, small box ventilators play a vital role in maintaining optimal temperatures within control panels and enclosures, which is essential for the reliability of critical components. Their application extends to the automotive sector, where effective temperature regulation is paramount for both performance and safety.

The versatility of mini box fans empowers engineers to devise tailored cooling solutions for both portable and stationary devices, aligning with specific project requirements. Data reveals that the global personal portable fan market was valued at approximately USD 456 million in 2022 and is projected to reach around USD 710 million by 2030, indicating a growing demand for energy-efficient products. Furthermore, the integration of intelligent features in compact box devices appeals to tech-savvy consumers, enhancing their relevance in modern engineering applications.

Expert insights suggest that effective temperature regulation in industrial settings can significantly enhance equipment lifespan and operational efficiency, making mini box fans a prudent choice for engineers prioritizing reliability and performance.

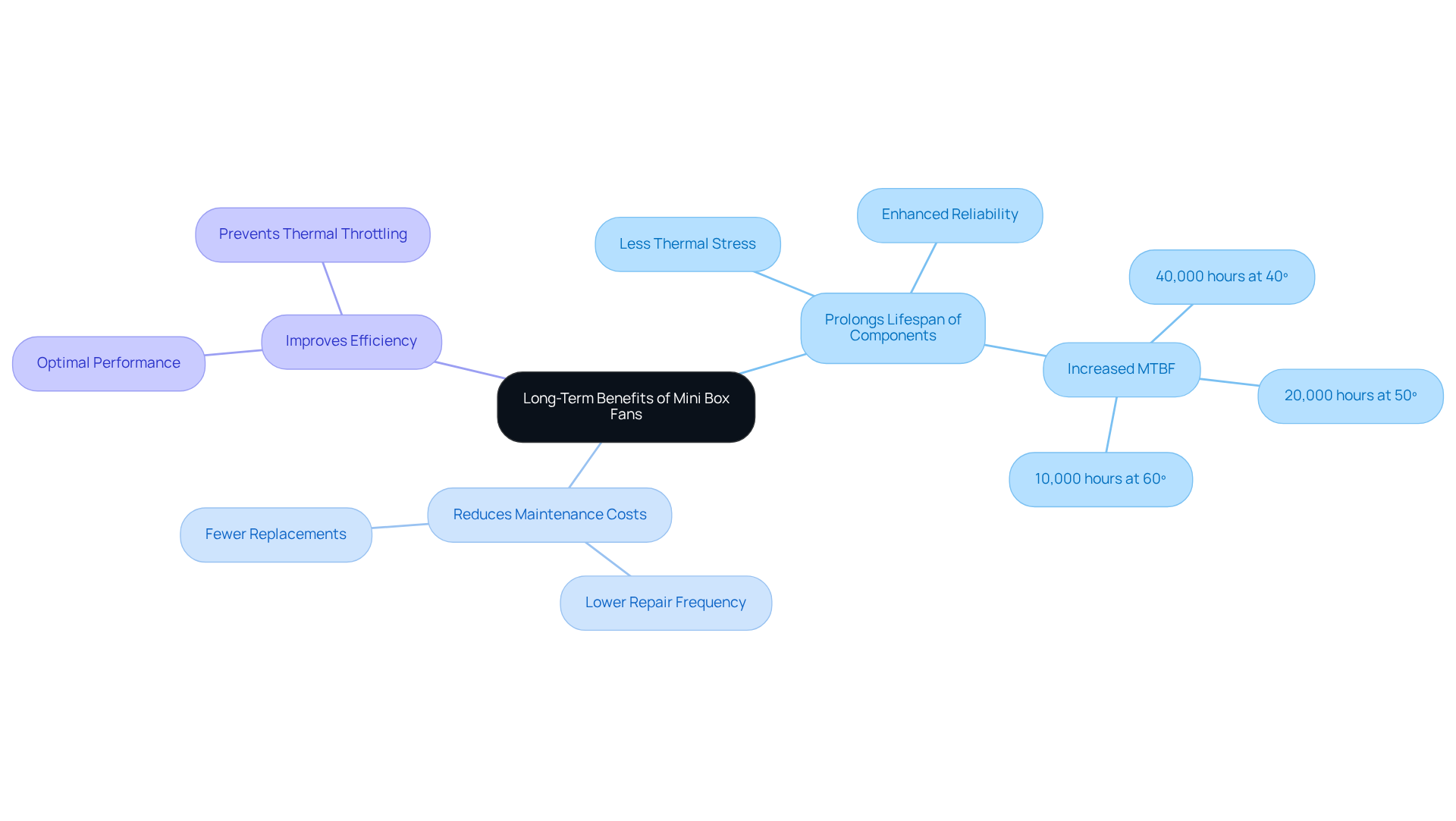

Assess the Long-Term Benefits of Mini Box Fans

Investing in small box ventilators for temperature regulation presents significant long-term benefits. These devices efficiently manage heat, which not only prolongs the lifespan of electronic components but also reduces the likelihood of early failures. This enhancement in reliability directly correlates with lower maintenance costs related to repairs and replacements. Moreover, consistent cooling performance contributes to improved efficiency, enabling devices to function at optimal levels without the threat of thermal throttling. As the demand for high-performance electronics escalates, the importance of mini box fans for maintaining sustained performance and reliability becomes increasingly paramount.

Conclusion

The choice of mini box fans for cooling in electronics engineering transcends mere preference; it is a necessity propelled by the escalating demands for effective thermal management. As electronic components become increasingly compact and power-intensive, the imperative for efficient cooling solutions that seamlessly integrate into designs is paramount. Mini box fans emerge as an exemplary solution, offering a fusion of performance, energy efficiency, and reliability that is essential for sustaining optimal functionality in contemporary electronic devices.

Throughout this discussion, the advantages of mini box fans have been thoroughly examined. Their compact design facilitates easy installation in space-constrained environments, while their energy efficiency markedly reduces operational costs compared to traditional cooling systems. Furthermore, the low noise levels of these fans render them suitable for sensitive settings, such as laboratories and offices. Practical applications across various industries underscore their versatility, demonstrating that mini box fans are not only effective in preventing overheating but also enhance the lifespan and reliability of electronic equipment.

In light of these insights, it is evident that mini box fans embody a forward-thinking choice for electronics engineers. As the industry continues to evolve, the adoption of innovative cooling solutions will be crucial for maintaining performance and reliability. By prioritizing effective thermal management with mini box fans, engineers can ensure that their designs remain competitive and resilient in an ever-changing technological landscape. The integration of such solutions not only addresses immediate cooling needs but also contributes to long-term operational efficiency and cost savings, positioning it as a strategic investment in the future of electronics engineering.

Frequently Asked Questions

Why is effective heat management important in electronics engineering?

Effective heat management is crucial in electronics engineering because as components shrink and power levels rise, the heat generated during operation increases. Poor thermal management can lead to performance degradation or catastrophic failure, with approximately 55% of electronic equipment failures linked to high temperatures.

What are the consequences of high temperatures on electronic systems?

Each 10°C rise in temperature can reduce system reliability by half, making effective thermal management essential for the longevity and dependability of electronic devices.

What cooling solutions does Gagner-Toomey Associates offer?

Gagner-Toomey Associates offers a range of cooling solutions, including DC input tube axial units and centrifugal blowers, optimized for performance, efficiency, and low noise.

What sizes are available for Gagner-Toomey cooling units and blowers?

Gagner-Toomey cooling units range in size from 15mm to 280mm, while blowers range from 15mm to 225mm.

How can mini box fans improve thermal management in electronics?

Mini box fans from Gagner-Toomey are effective in enhancing airflow and efficiently dissipating heat, making them essential for maintaining optimal performance and operational reliability in modern electronics.

What advanced temperature regulation technologies should engineers consider?

Engineers should consider advanced temperature regulation technologies such as spray systems, which can manage heat fluxes up to 1000 W/cm², to enhance thermal management strategies.

What types of heat sinks are available from Gagner-Toomey?

Gagner-Toomey provides innovative solutions including extruded aluminum heatsinks, copper-based heat sinks, and integrated liquid temperature regulation solutions to aid in thermal management for electronics engineers.