Introduction

Understanding the various axial fan sizes is crucial for electronics engineers aiming to optimize cooling solutions across a range of applications. Each fan size, from compact 12-inch models to robust 48-inch units, presents unique airflow capabilities tailored to specific environments and cooling demands.

With such a wide array of options, how can engineers pinpoint the ideal fan size to ensure efficient thermal management while balancing performance and noise levels? This article explores the key axial fan sizes that every engineer should know, offering insights into their applications, benefits, and essential considerations for selection.

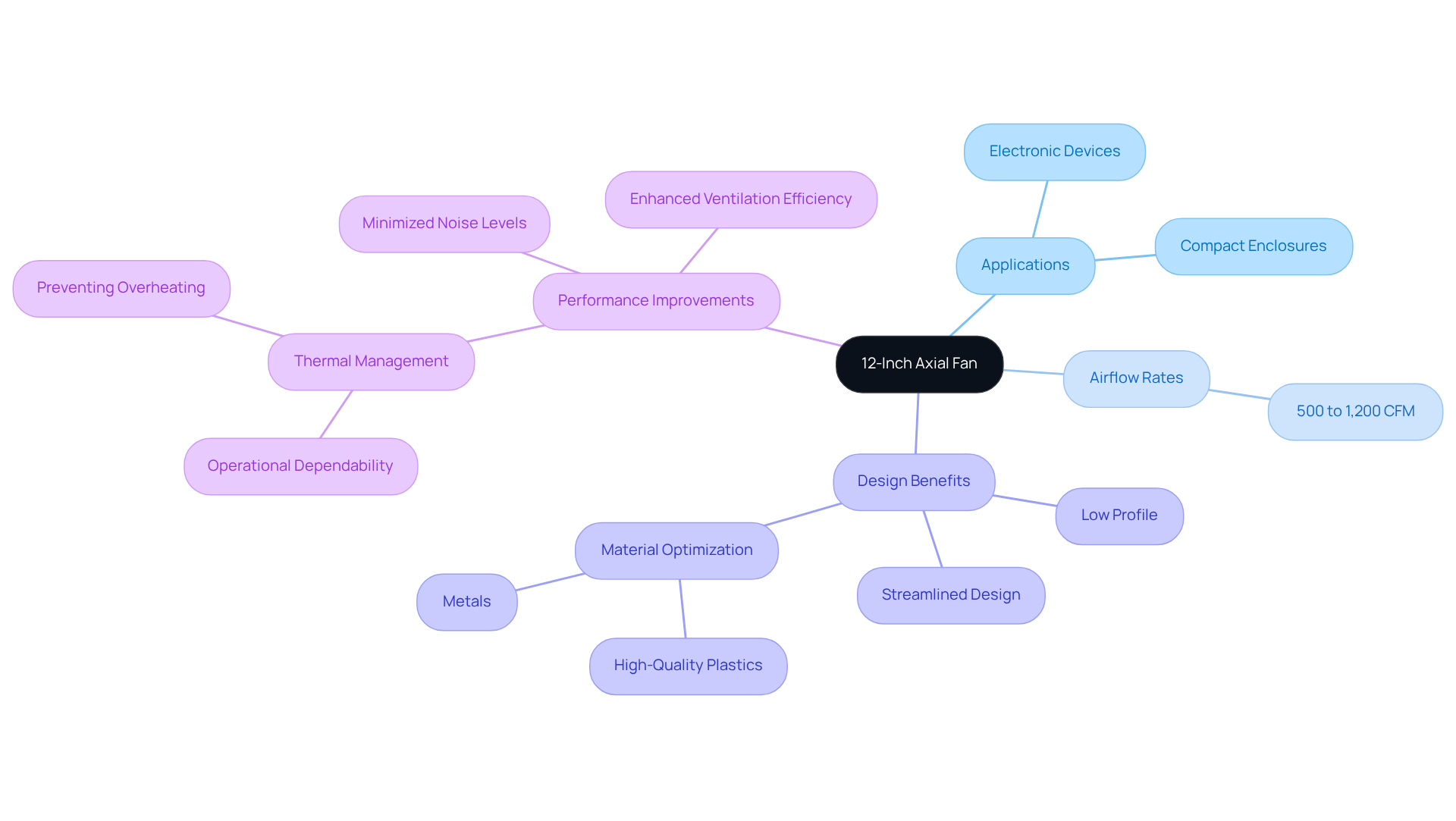

12-Inch Axial Fan Size: Ideal for Small Spaces

The 12-inch axial fan stands as a crucial element in applications where space is at a premium, such as compact enclosures and electronic devices. Its streamlined design facilitates effective air movement while maintaining a low profile, making it an ideal choice for various settings. Typically, this fan size achieves airflow rates ranging from 500 to 1,200 CFM, perfectly suited for cooling small components without occupying excessive space.

Recent advancements in blade design and materials have significantly optimized performance, enhancing ventilation efficiency and minimizing noise levels. Engineers must prioritize axial fan sizes when designing systems that require efficient thermal management in confined spaces. Adequate ventilation is vital for preventing overheating and ensuring reliable operation. By integrating the 12-inch axial fan into their designs, engineers can achieve superior thermal control and operational dependability.

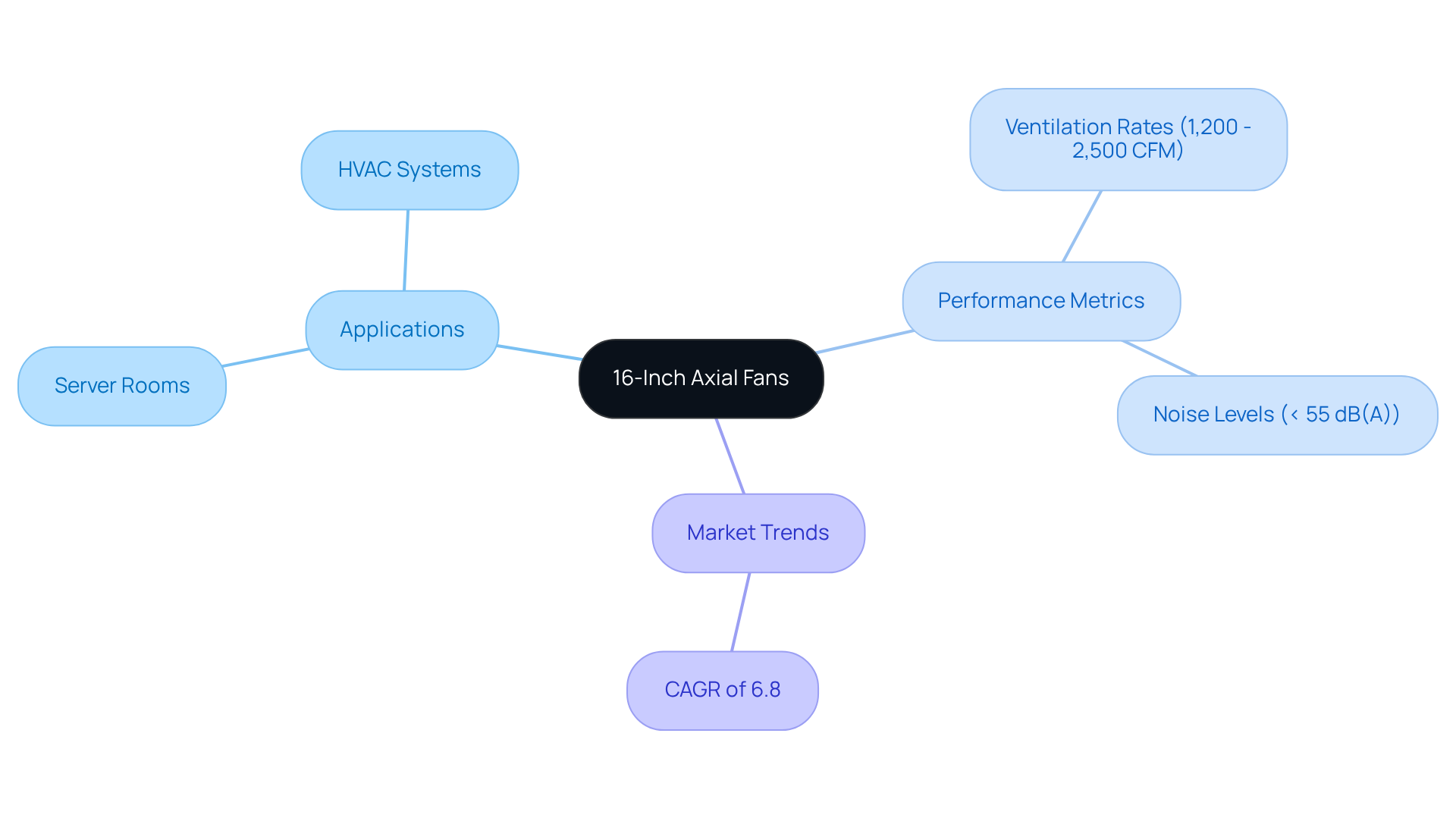

16-Inch Axial Fan Size: Perfect for Medium Applications

The 16-inch axial fan sizes make it an exceptional choice for medium-sized applications, such as server rooms and HVAC systems. With ventilation rates typically ranging from 1,200 to 2,500 CFM, these fans effectively cool larger components and spaces. These axial fan sizes achieve an optimal balance between ventilation efficiency and noise reduction, making them particularly suitable for environments where sound levels are crucial. For instance, in HVAC systems, keeping noise levels below 55 dB(A) is vital for ensuring comfort and productivity.

Gagner-Toomey Associates, recognized as the world’s largest producer of both standard and custom air-movers, guarantees that their ventilation units are designed for peak performance and minimal noise. This commitment ensures that the specific airflow requirements of various projects are met while adhering to noise regulations.

Moreover, the market for axial fan sizes is projected to grow at a CAGR of 6.8% from 2023 to 2030, driven by the increasing demand for energy-efficient solutions. Case studies have demonstrated that the installation of 16-inch ducted units can significantly reduce noise levels in sensitive environments, reinforcing their suitability for medium applications. For example, one study illustrated the effectiveness of these fans in maintaining optimal sound levels in server rooms, highlighting their role in enhancing operational efficiency.

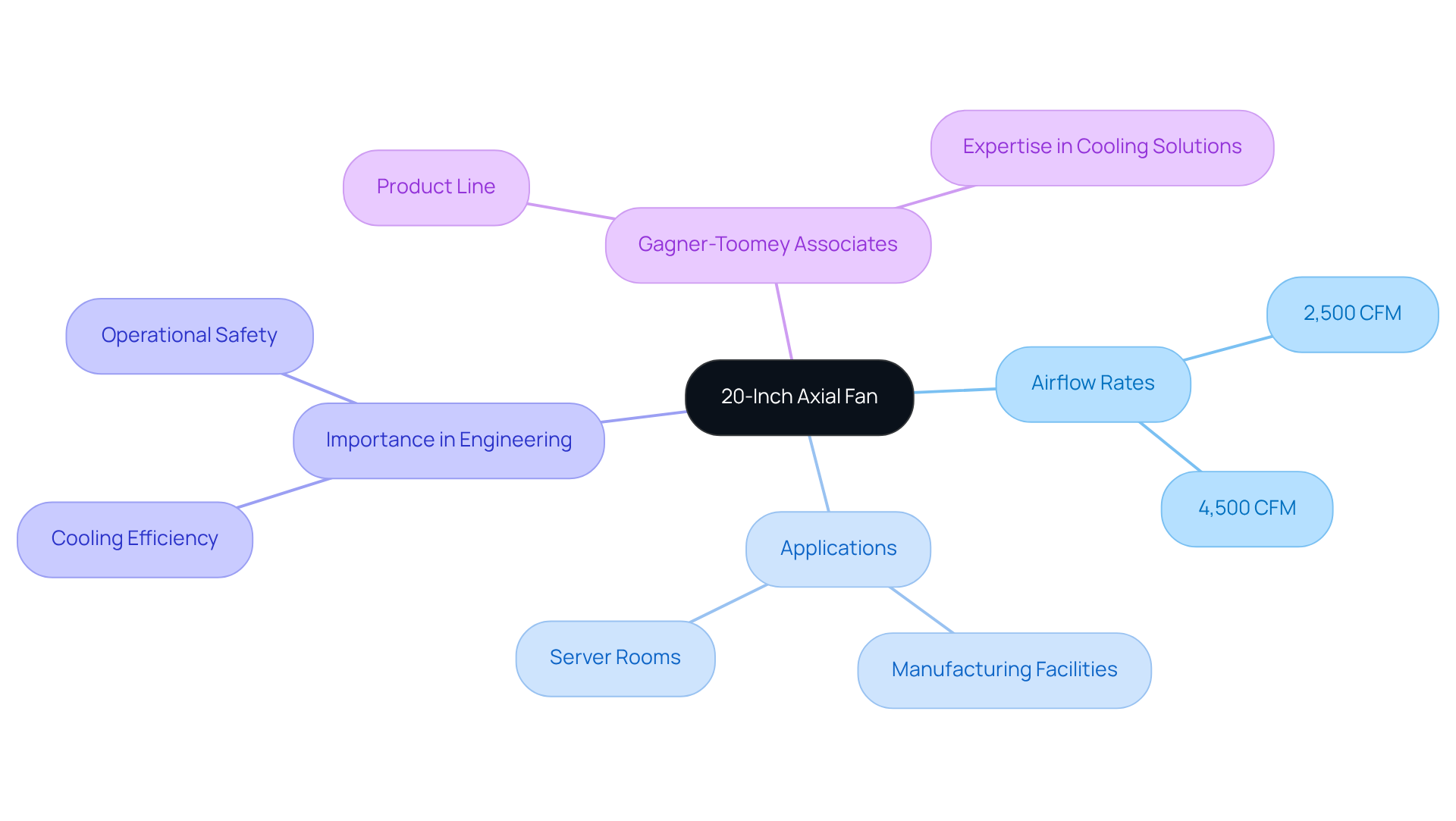

20-Inch Axial Fan Size: Best for Industrial Cooling Needs

The 20-inch axial fan stands out as a premier solution for industrial applications, boasting airflow rates that range from 2,500 to 4,500 CFM. In environments where substantial cooling is essential – such as manufacturing facilities and expansive server rooms – this fan dimension excels. Its ability to move large volumes of air makes it an optimal choice for effectively cooling machinery and equipment.

In production environments, these fans are crucial for maintaining ideal temperatures, ensuring that machinery operates efficiently and safely. Engineers should prioritize axial fan sizes when designing systems intended to manage heat in larger spaces, as their robust performance directly enhances operational efficiency.

Gagner-Toomey Associates provides a comprehensive line of cooling solutions, featuring both standard and custom fans and blowers tailored for diverse applications. This reinforces their expertise in power conversion and EMI solutions. Their offerings include specific product specifications designed to meet various industrial needs, ensuring optimal performance and reliability.

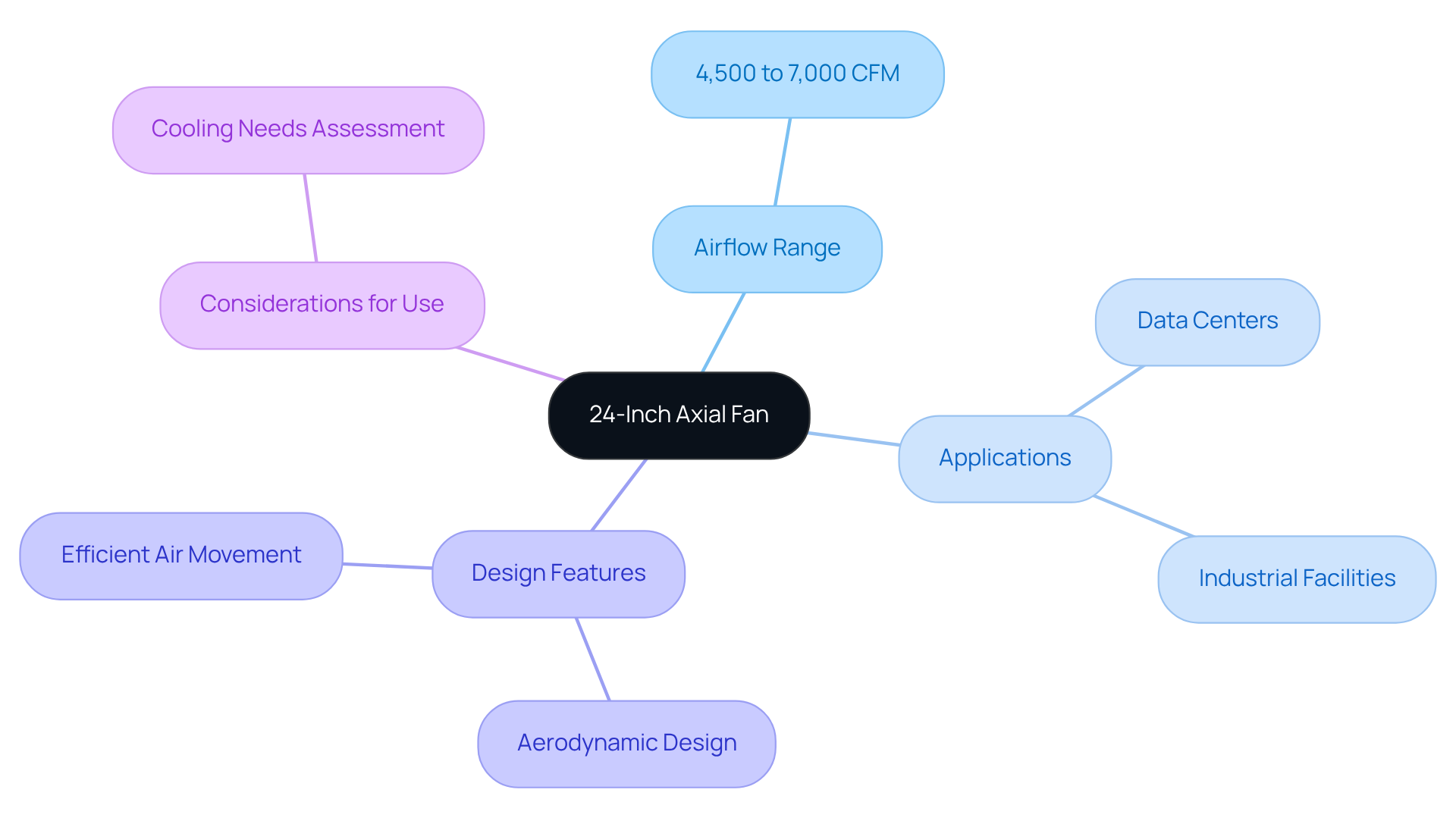

24-Inch Axial Fan Size: High Airflow for Demanding Environments

The 24-inch fan from Gagner-Toomey Associates stands out in high airflow applications, delivering an impressive range of 4,500 to 7,000 CFM. This axial fan size is particularly effective in environments requiring substantial cooling, such as data centers and large industrial facilities. Its aerodynamic design not only facilitates efficient air movement but also makes it an ideal choice for applications where effective heat dissipation is essential.

Current statistics reveal a growing trend in the utilization of axial fan sizes, especially the 24-inch fans, within industrial settings, underscoring their capability to meet the demanding cooling requirements of modern operations. Engineers must conduct a thorough assessment of their systems’ cooling needs to determine if the required axial fan sizes can provide the necessary ventilation for optimal performance. By leveraging the power of this fan, facilities can enhance their operational efficiency and ensure reliable cooling solutions.

30-Inch Axial Fan Size: Specialized for Large-Scale Ventilation

The axial fan sizes, particularly the 30-inch model from Gagner-Toomey Associates, stand out in large-scale ventilation, boasting airflow rates between 7,000 and 12,000 CFM. This axial fan size excels in applications like warehouse ventilation and extensive industrial processes, where maintaining optimal temperatures is essential. Its ability to move significant volumes of air is crucial for effective cooling in expansive environments.

Gagner-Toomey’s diverse product line of DC input Tube Axial devices, ranging from 15 to 280mm, underscores their commitment to performance, efficiency, and low noise levels, with IP protection available upon request. Recent trends reveal an increasing reliance on axial fan sizes, especially 30-inch devices, for large-scale solutions, showcasing their adaptability across various industrial settings. For instance, in production plants, these devices are commonly employed to enhance air circulation, thereby improving overall air quality and operational effectiveness.

Engineers should prioritize axial fan sizes in their designs to ensure robust air movement and effective thermal management, especially in light of current market trends emphasizing the importance of efficient ventilation solutions. Furthermore, Gagner-Toomey offers a range of thermal management solutions, including heat sinks and liquid cooling systems, which further optimize the performance of their fans.

36-Inch Axial Fan Size: Heavy-Duty Solutions for Industrial Use

The 36-inch axial fan sizes from Gagner-Toomey Associates are designed for heavy-duty applications, providing airflow rates between 12,000 and 20,000 CFM. This dimension is particularly suited for environments demanding robust cooling solutions, such as expansive manufacturing plants and industrial facilities. Its design facilitates efficient air movement, making it ideal for scenarios where effective heat dissipation is essential.

As the world’s largest manufacturer of standard and custom air-movers, Gagner-Toomey Associates provides a comprehensive portfolio of DC input Tube Axial fans. This ensures that engineers can identify the optimal solution tailored to their specific cooling requirements. To maximize performance, engineers should carefully evaluate the cooling needs of their projects to determine if the axial fan sizes are suitable for their objectives.

48-Inch Axial Fan Size: Optimal for Large Commercial Spaces

The 48-inch fan from Gagner-Toomey Associates stands out as a premier solution for large commercial environments, delivering airflow rates that impressively range from 20,000 to 30,000 CFM. In settings where substantial cooling is essential – think shopping malls and expansive warehouses – these axial fan sizes truly excel. Its ability to circulate vast volumes of air makes it a top choice for maintaining optimal temperatures across these extensive areas.

Gagner-Toomey’s extensive range of DC input tube cooling devices is optimized for both performance and efficiency. Among these, models with IP protection are available upon request, making them particularly suitable for commercial cooling solutions. As industries increasingly prioritize energy efficiency and effective ventilation, the adoption of various axial fan sizes, particularly 48-inch fans, is on the rise, especially in large-scale applications.

For engineers, considering axial fan sizes is crucial when designing systems aimed at effectively managing heat in commercial environments. By integrating these fans into their designs, they can ensure optimal performance and energy efficiency, addressing the growing demand for effective cooling solutions.

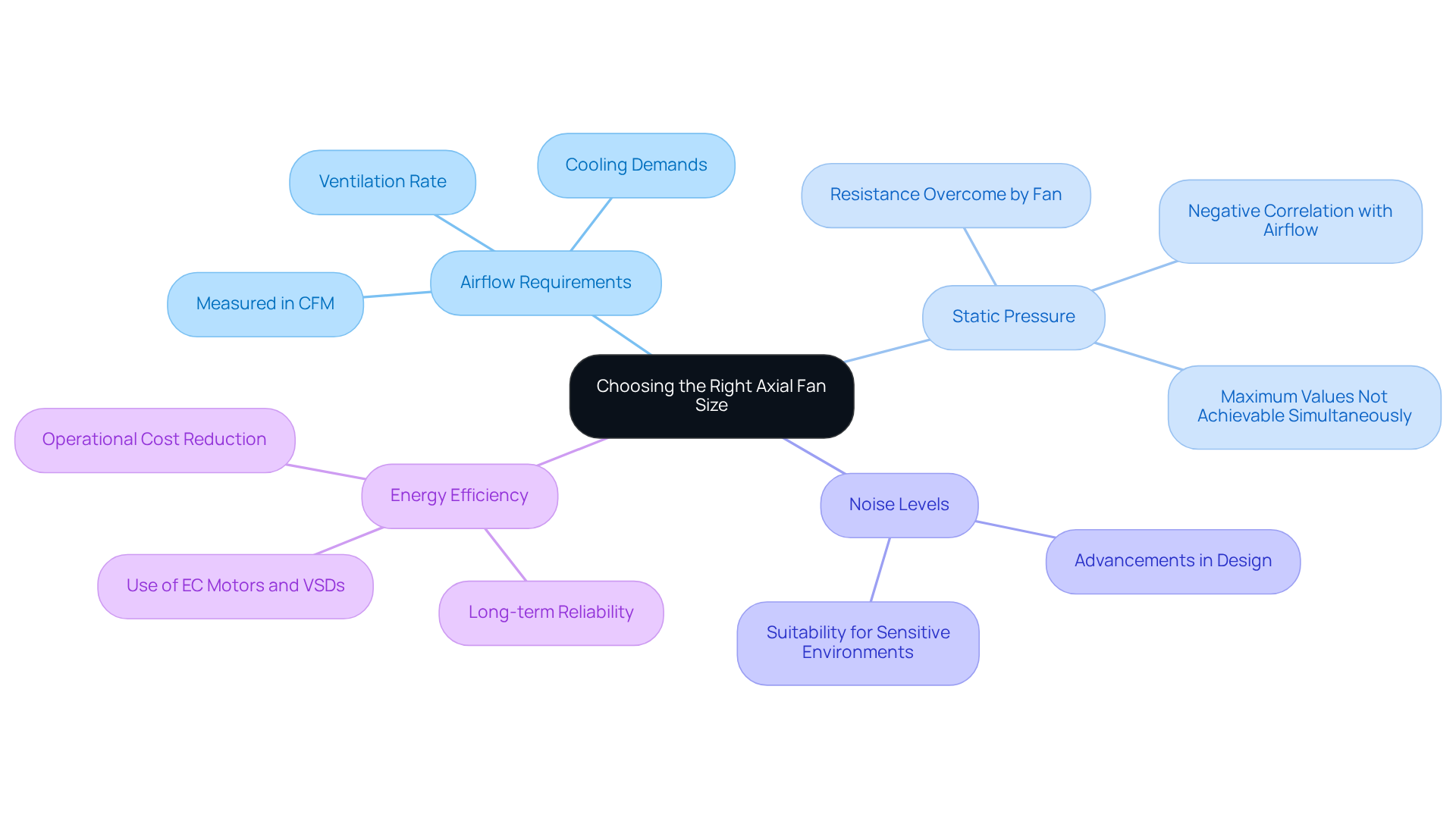

Choosing the Right Axial Fan Size: Understanding Airflow Requirements

Choosing the correct axial fan sizes is crucial for meeting specific ventilation requirements in any application. Understanding the dimensions of the space, the heat load generated, and the desired ventilation rate – typically measured in cubic feet per minute (CFM) – is essential. Engineers must accurately calculate the necessary ventilation to satisfy cooling demands, ensuring optimal performance and efficiency.

Static pressure is another critical factor to consider. It represents the resistance the fan must overcome, and there is a negative correlation between airflow and static pressure; as one increases, the other decreases. Additionally, evaluating the noise levels associated with various axial fan sizes is vital. Recent advancements in impeller and motor designs have significantly reduced noise, making modern ventilation devices suitable for sensitive environments like offices and healthcare facilities.

By thoroughly assessing these parameters, including the advantages of energy-efficient fans that can lower operational costs, engineers can make informed decisions. This not only enhances system reliability but also boosts energy efficiency, ultimately leading to better performance in various applications.

Gagner-Toomey Associates: Expert Guidance on Axial Fan Sizes

Gagner-Toomey Associates provides essential resources and expert guidance for engineers tasked with selecting the right axial fan sizes tailored to their specific applications. Their experienced team aids engineers in comprehensively understanding project requirements, ensuring that the selected fan dimensions meet ventilation and cooling needs effectively.

As Jeff Smoot, VP of Engineering at Gagner-Toomey Associates, states, “Choosing the appropriate fan is vital for guaranteeing that the ventilation setup functions effectively and efficiently.” By leveraging Gagner-Toomey’s expertise, engineers can optimize their designs, significantly boosting system performance and reliability.

Moreover, Gagner-Toomey offers miniature blower options for compact consumer applications, expanding the range of available solutions. Key factors such as:

- Ventilation capacity

- Efficiency in maintaining stable temperatures

- Axial fan sizes

are crucial considerations during the fan selection process. This makes Gagner-Toomey a valuable partner in achieving optimal thermal management solutions.

Key Considerations for Selecting Axial Fan Sizes for Optimal Cooling

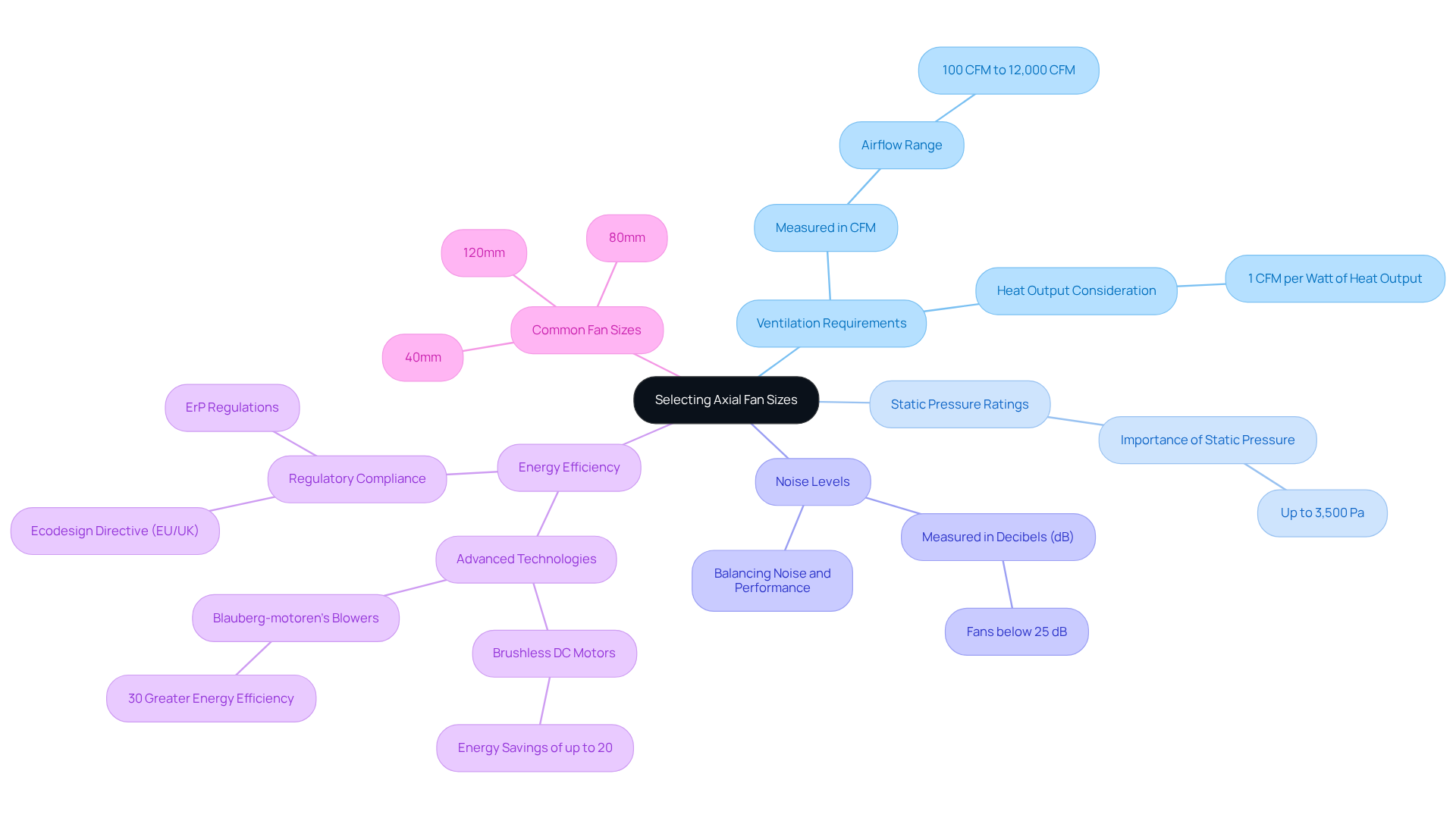

Choosing the right axial fan sizes is crucial for achieving optimal cooling performance in electronic systems. Engineers must evaluate several key factors, including:

- Ventilation requirements measured in cubic feet per minute (CFM)

- Static pressure ratings

- Noise levels

- Energy efficiency

To ensure compatibility, the installation space must align with common axial fan sizes, such as 40mm, 80mm, and 120mm.

Understanding the specific cooling needs of the application and the operational environment is vital for making informed decisions that enhance system performance and reliability. For instance, contemporary ducted fans can achieve air movement rates ranging from 100 CFM to 12,000 CFM, with static pressure enhancements reaching as high as 3,500 Pa. This capability is particularly significant in environments where effective airflow management is critical, such as data centers, where high server density generates substantial heat.

Current trends highlight a growing emphasis on energy efficiency in axial fan selection, driven by stricter environmental regulations and rising energy costs. Engineers are increasingly prioritizing fans that utilize advanced technologies, such as brushless DC motors, which can deliver energy savings of up to 20% compared to traditional AC motors. Notably, Blauberg-motoren’s blowers offer 30% greater energy efficiency than traditional models, making them an attractive option for engineers. Furthermore, advancements in blade design, featuring airfoil shapes that minimize turbulence, lead to improved air movement and quieter operation.

Real-world examples underscore the importance of evaluating airflow and energy efficiency. For example, a system with a total heat output of 300 watts would require approximately 300 CFM under standard conditions, emphasizing the necessity for precise calculations in fan selection. By prioritizing energy efficiency and selecting appropriately sized fans, engineers can significantly enhance the reliability and longevity of electronic systems, ultimately supporting sustainability initiatives and reducing operational costs. Additionally, compliance with regulations such as the Ecodesign Directive (EU/UK) and ErP regulations is essential in the selection process. Regular maintenance practices, including inspections every 6-12 months, are critical for prolonging fan life and ensuring optimal performance.

Conclusion

Understanding the various axial fan sizes is crucial for electronics engineers aiming to optimize cooling solutions across diverse applications. Each fan size, from the compact 12-inch model to the robust 48-inch variant, plays a distinct role in ensuring effective air movement and thermal management. By selecting the appropriate fan size, engineers can significantly enhance system reliability and operational efficiency, addressing the varied cooling needs inherent in modern electronic designs.

Key insights regarding the specifications and applications of various axial fan sizes have been shared. The 12-inch fan excels in small spaces, while the 16-inch fan is ideal for medium applications like server rooms. Larger models, such as the 20-inch and 24-inch fans, cater to industrial and high airflow needs, respectively. The 30-inch and 36-inch fans are tailored for extensive ventilation requirements, while the 48-inch fan stands out in large commercial environments. Each size brings specific benefits, including improved airflow rates, energy efficiency, and noise reduction, which are essential for maintaining optimal operational conditions.

Given the increasing emphasis on energy efficiency and effective ventilation solutions, engineers must prioritize axial fan sizes in their designs. Conducting thorough assessments of airflow requirements, static pressure, and noise levels enables informed decisions that enhance performance and sustainability. Embracing advancements in fan technology will not only lead to improved cooling solutions but also align with environmental regulations and operational cost reductions. The journey toward optimal thermal management begins with understanding and selecting the right axial fan sizes for each unique application.

Frequently Asked Questions

What is the purpose of a 12-inch axial fan?

The 12-inch axial fan is designed for applications where space is limited, such as compact enclosures and electronic devices. It facilitates effective air movement while maintaining a low profile, making it ideal for cooling small components.

What are the airflow rates for a 12-inch axial fan?

A 12-inch axial fan typically achieves airflow rates ranging from 500 to 1,200 CFM.

Why is adequate ventilation important in small spaces?

Adequate ventilation is vital for preventing overheating and ensuring reliable operation of components in confined spaces.

What advancements have been made in 12-inch axial fan design?

Recent advancements in blade design and materials have optimized performance, enhancing ventilation efficiency and minimizing noise levels.

What applications are 16-inch axial fans suitable for?

The 16-inch axial fan is suitable for medium-sized applications, such as server rooms and HVAC systems.

What are the typical airflow rates for a 16-inch axial fan?

A 16-inch axial fan typically achieves ventilation rates ranging from 1,200 to 2,500 CFM.

How do 16-inch axial fans balance ventilation efficiency and noise?

These fans are designed to achieve an optimal balance between ventilation efficiency and noise reduction, making them suitable for environments where sound levels are important.

What is the projected market growth for axial fan sizes from 2023 to 2030?

The market for axial fan sizes is projected to grow at a CAGR of 6.8% during this period, driven by the increasing demand for energy-efficient solutions.

What is the airflow capacity of a 20-inch axial fan?

The 20-inch axial fan boasts airflow rates ranging from 2,500 to 4,500 CFM.

In what environments are 20-inch axial fans most effective?

These fans are particularly effective in industrial applications, such as manufacturing facilities and expansive server rooms, where substantial cooling is essential.

Why should engineers prioritize axial fan sizes in their designs?

Engineers should prioritize axial fan sizes to ensure efficient thermal management in spaces requiring cooling, as their robust performance enhances operational efficiency.