Overview

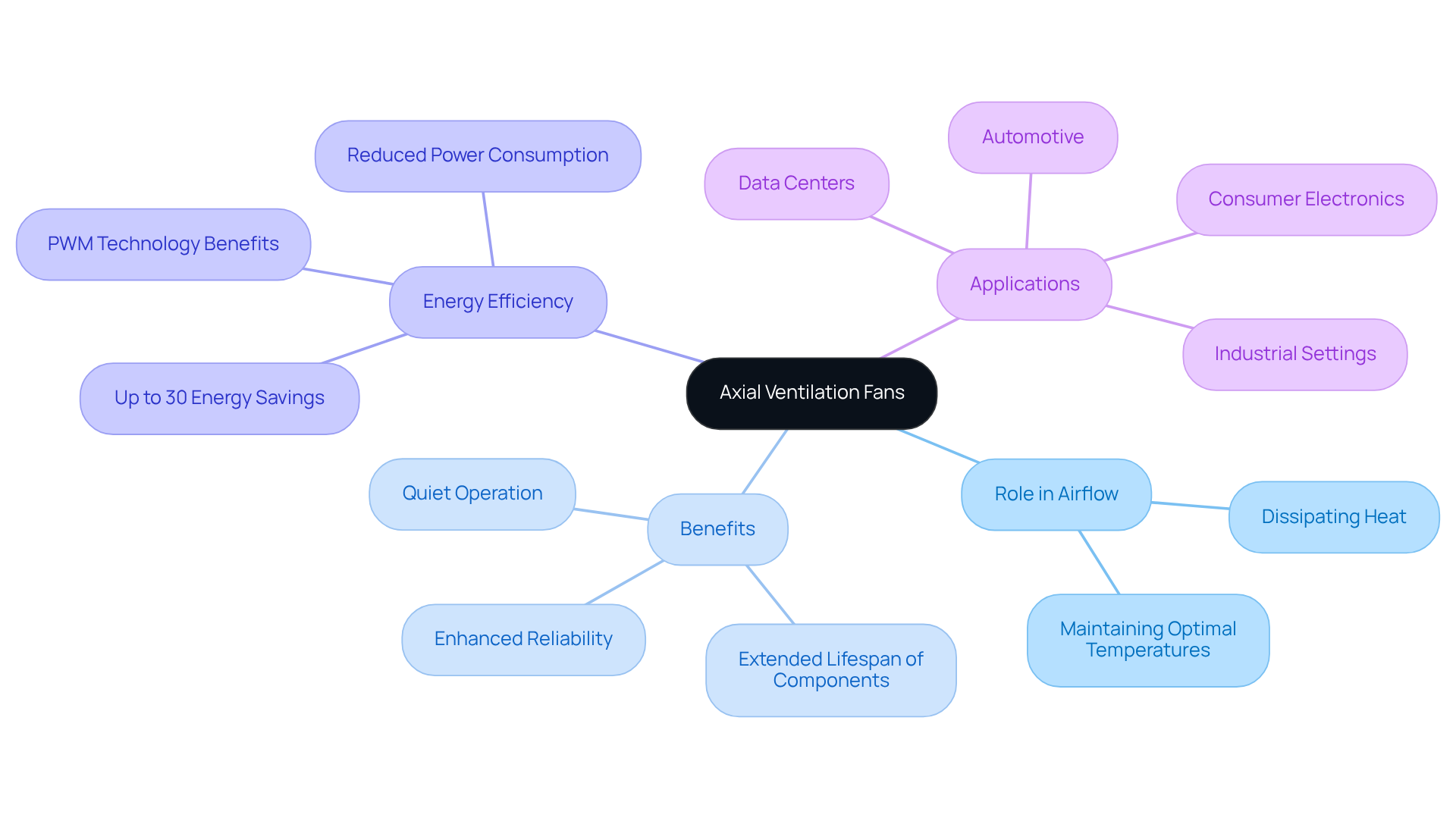

Axial ventilation fans are pivotal in the realm of electronics cooling, offering a range of benefits that are hard to overlook. These fans ensure efficient airflow, operate quietly, and boast a compact design, making them versatile and energy-efficient. Their ease of installation further enhances their appeal, particularly in environments where space and noise are critical considerations.

The necessity of these fans cannot be overstated. They play a crucial role in maintaining optimal temperatures within electronic systems, which is essential for enhancing reliability and minimizing operational costs. This combination of factors positions axial ventilation fans as a preferred choice among engineers in the electronics industry, who seek solutions that not only perform well but also contribute to the overall efficiency of their systems.

In summary, the integration of axial ventilation fans into electronic systems is not just beneficial; it is essential. By choosing these fans, engineers can ensure that their systems operate at peak performance, ultimately leading to greater reliability and reduced costs.

Introduction

The rapid evolution of electronic devices presents a pressing challenge: the need for innovative cooling solutions that effectively manage heat without sacrificing performance. Axial ventilation fans have emerged as a pivotal solution in this landscape, delivering a range of benefits tailored to the thermal demands of modern electronics. Yet, with a plethora of options at their disposal, how can engineers discern which cooling solution aligns best with their specific requirements? By delving into the advantages of axial fans, we uncover not only their efficiency and versatility but also their essential role in enhancing the reliability and longevity of electronic components.

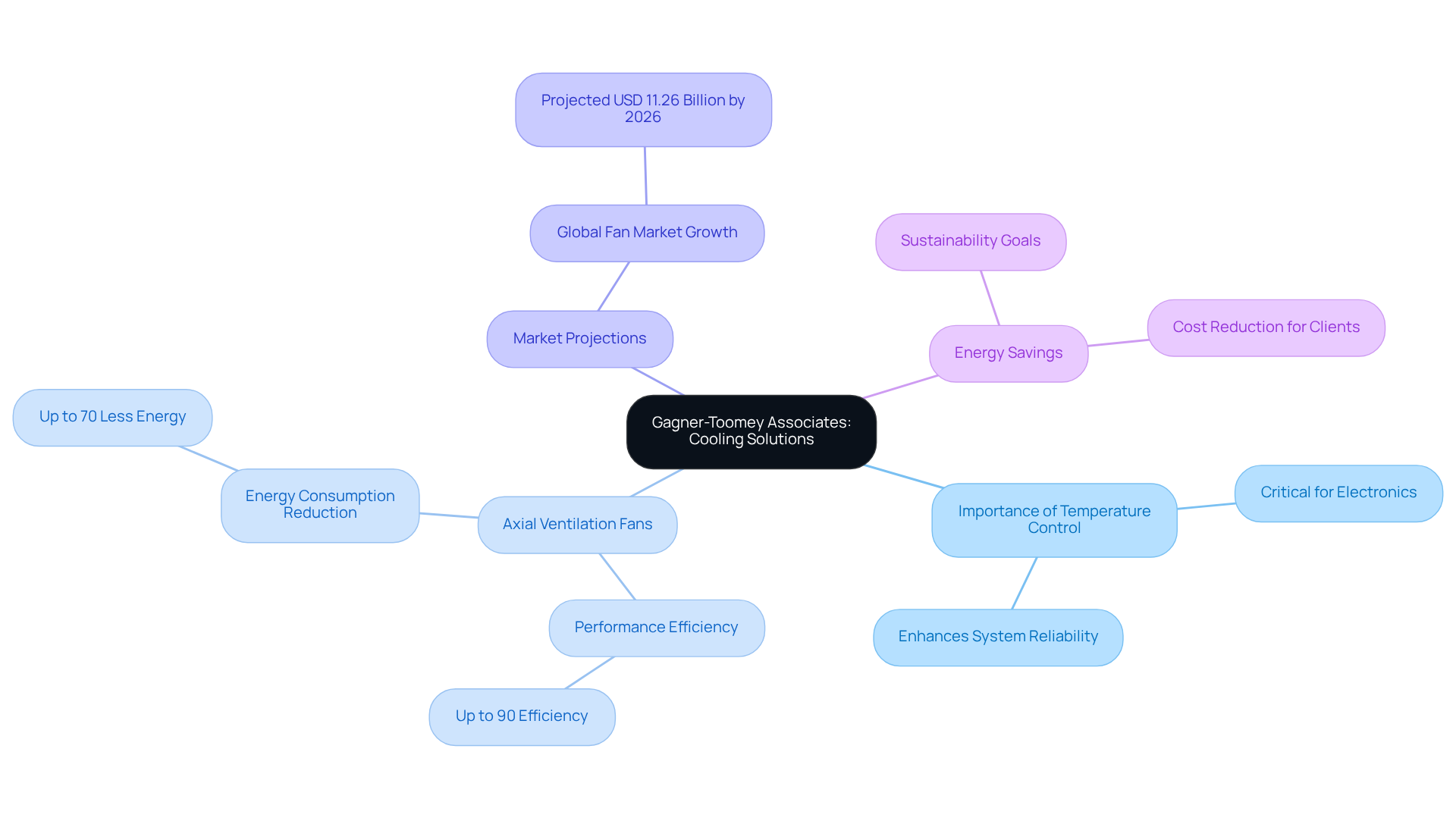

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics

Gagner-Toomey Associates stands at the forefront of temperature control solutions tailored for the electronics industry. As the demand for efficient thermal management grows, the need for advanced solutions becomes increasingly critical. By prioritizing performance optimization and energy efficiency, Gagner-Toomey collaborates with a diverse array of manufacturers known for their cutting-edge technologies.

Central to their offerings are axial ventilation fans, which play a crucial role in regulating the temperature of electronics. These devices achieve remarkable performance levels, boasting efficiency rates of up to 90%. With the global fan market projected to reach USD 11.26 billion by 2026, Gagner-Toomey’s expertise in temperature regulation, power management, and interconnect technologies positions them as an indispensable partner for engineers facing complex thermal challenges in electronic systems.

Recent trends indicate a rising demand for energy-efficient solutions, with the axial ventilation fan capable of reducing energy consumption by as much as 70% compared to traditional AC units. This commitment to innovative temperature management technologies not only enhances system reliability but also aligns with sustainability goals. As the landscape of electronics temperature regulation evolves, Gagner-Toomey Associates emerges as a trusted ally, ready to meet the challenges of tomorrow.

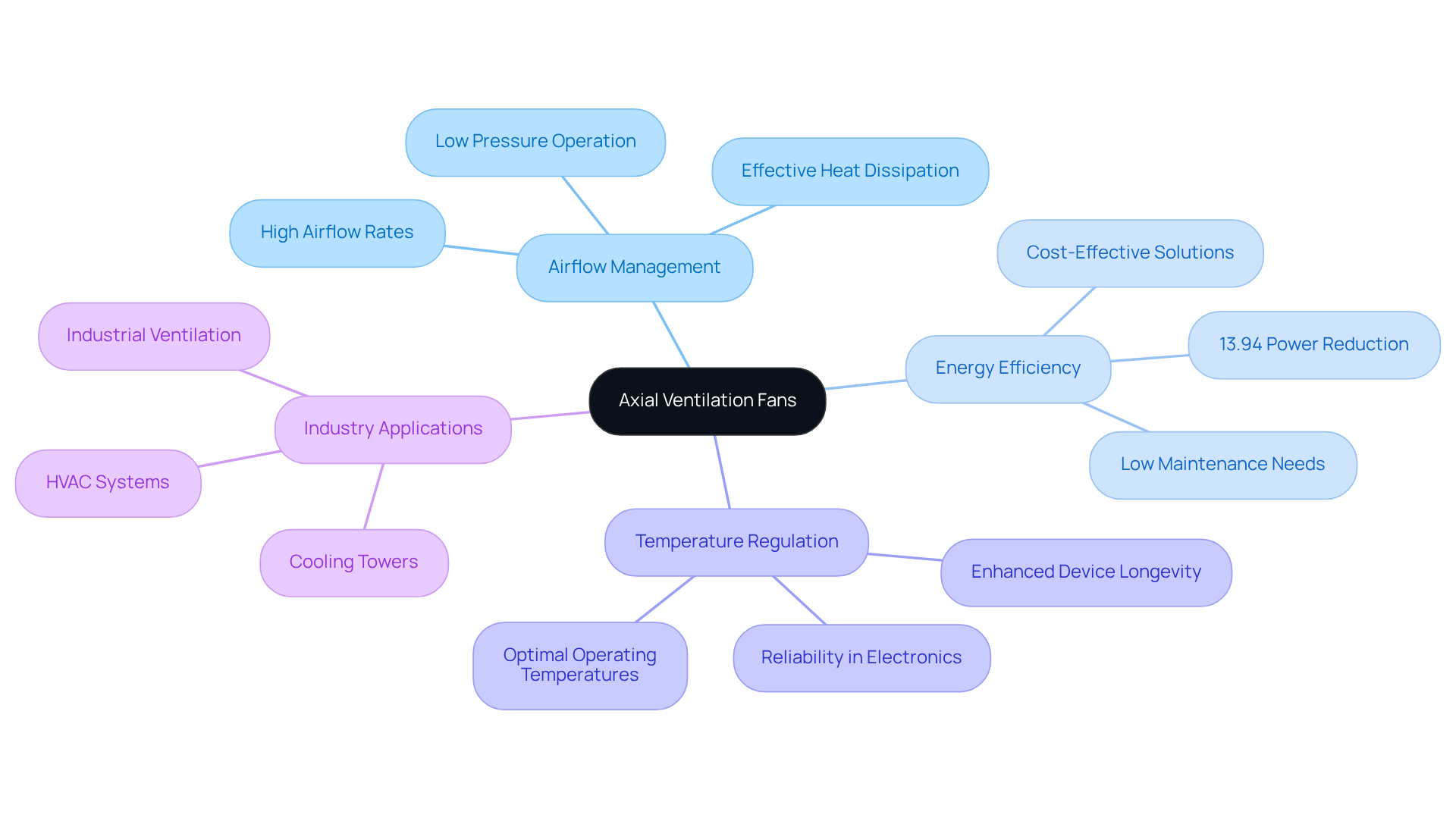

Efficient Airflow: Enhancing Cooling Performance with Axial Fans

The axial ventilation fan plays a critical role in managing airflow parallel to its axis, delivering a significant volume of air while keeping energy consumption low. This efficient airflow is essential for regulating electronic components, as it effectively dissipates heat and maintains optimal operating temperatures. Research indicates that these devices can reduce power usage by up to 13.94% under specific conditions, highlighting their energy-efficient capabilities.

By employing cylindrical blowers, engineers can significantly enhance the temperature regulation of their systems, ensuring the reliability and longevity of electronic devices. Industry leaders emphasize that directional blowers are particularly effective in applications requiring high airflow rates at low pressure, making them indispensable in modern electronic cooling solutions.

As noted by Gagner-Toomey Associates, the company excels in offering innovative solutions for axial ventilation fans specifically designed for the electronics sector. This statement underscores the importance of these devices in optimizing airflow and boosting overall system performance.

In conclusion, the integration of an axial ventilation fan not only addresses the challenges of heat management but also contributes to energy savings and improved device reliability, making it a vital component in the design of contemporary electronic systems.

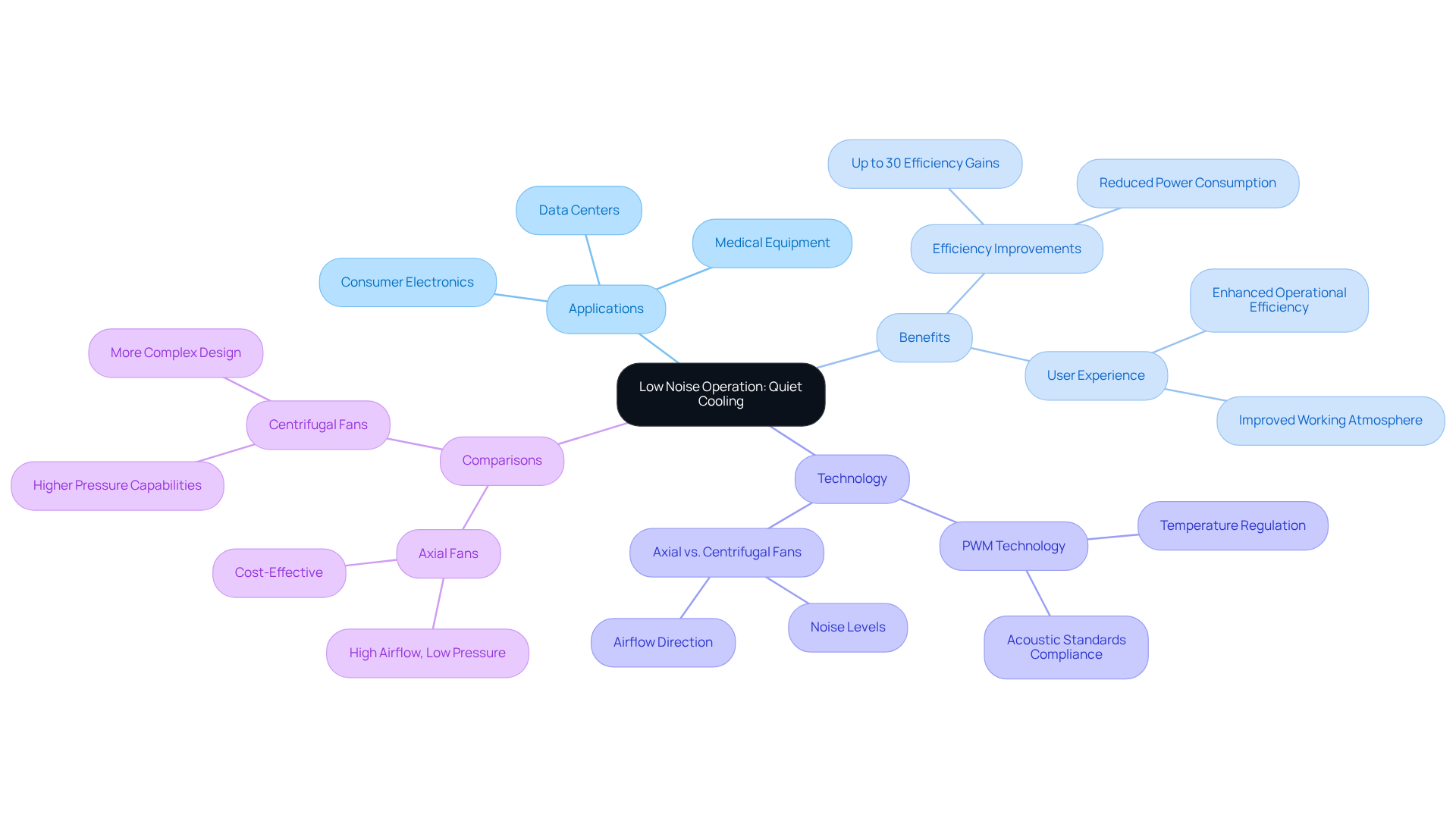

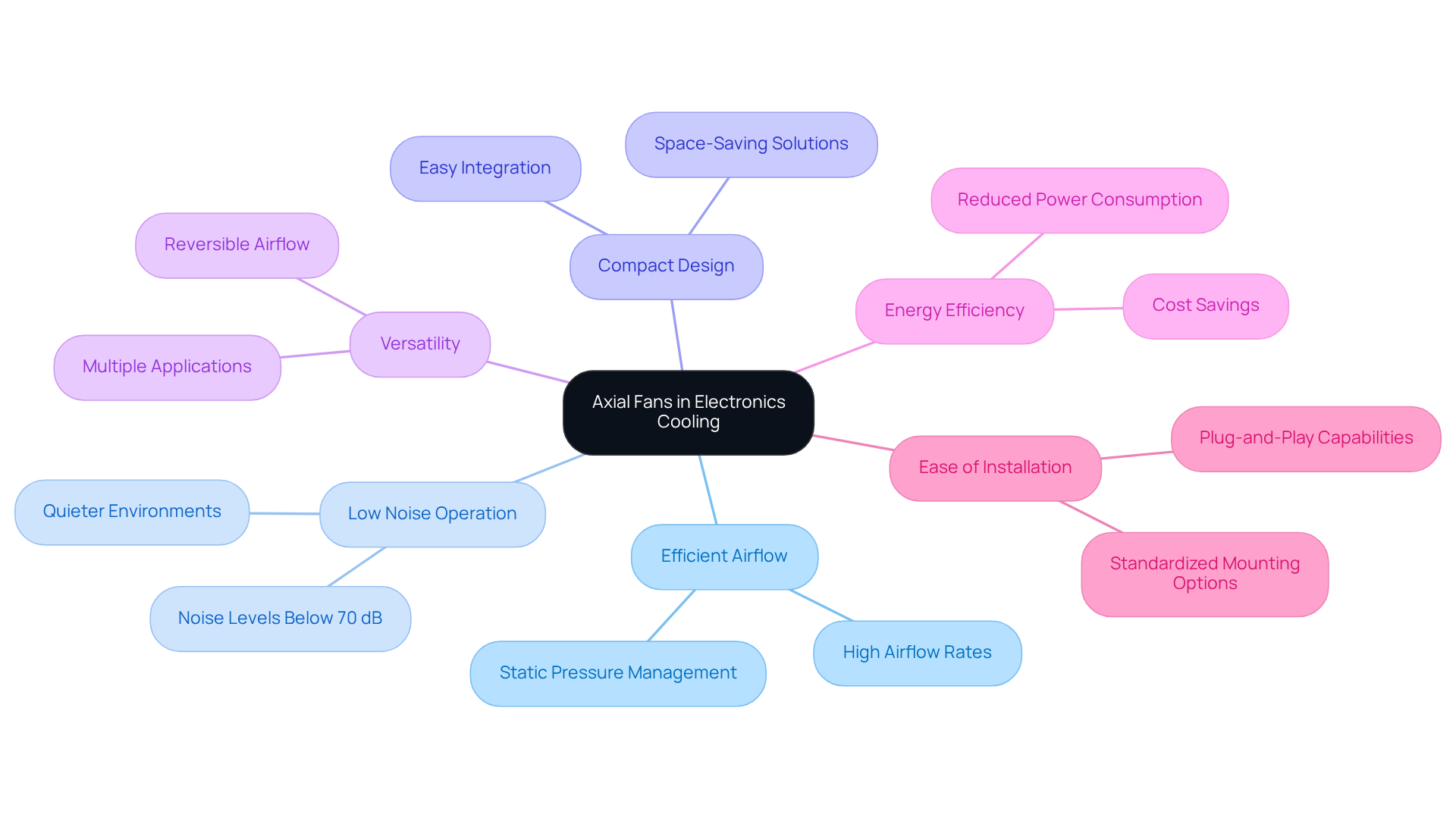

Low Noise Operation: Quiet Cooling for Sensitive Electronics

Axial blowers stand out for their ability to operate with minimal noise, making them particularly suitable for sensitive electronic applications. These devices are engineered to reduce noise levels while ensuring effective thermal management, a critical requirement in environments such as data centers, medical equipment, and consumer electronics. In these contexts, excessive noise can disrupt operations and adversely affect user experience. For example, data centers that employ low-noise axial ventilation fans have reported enhanced operational efficiency and a more favorable working atmosphere.

Moreover, data centers utilizing PWM technology have experienced efficiency improvements of up to 30%, underscoring the benefits of integrating silent temperature management solutions. Engineers focusing on silent thermal management technologies can guarantee that their designs not only fulfill performance criteria but also comply with acoustic standards, thereby boosting the overall functionality of electronic systems. As one engineer remarked, “the integration of quiet cooling technologies is essential for maintaining optimal operating conditions in sensitive electronics, particularly as the demand for silent operation continues to grow in 2025.”

Additionally, it is important to note that axial ventilation fans generally produce less noise than centrifugal models, further solidifying their role in applications where noise reduction is paramount.

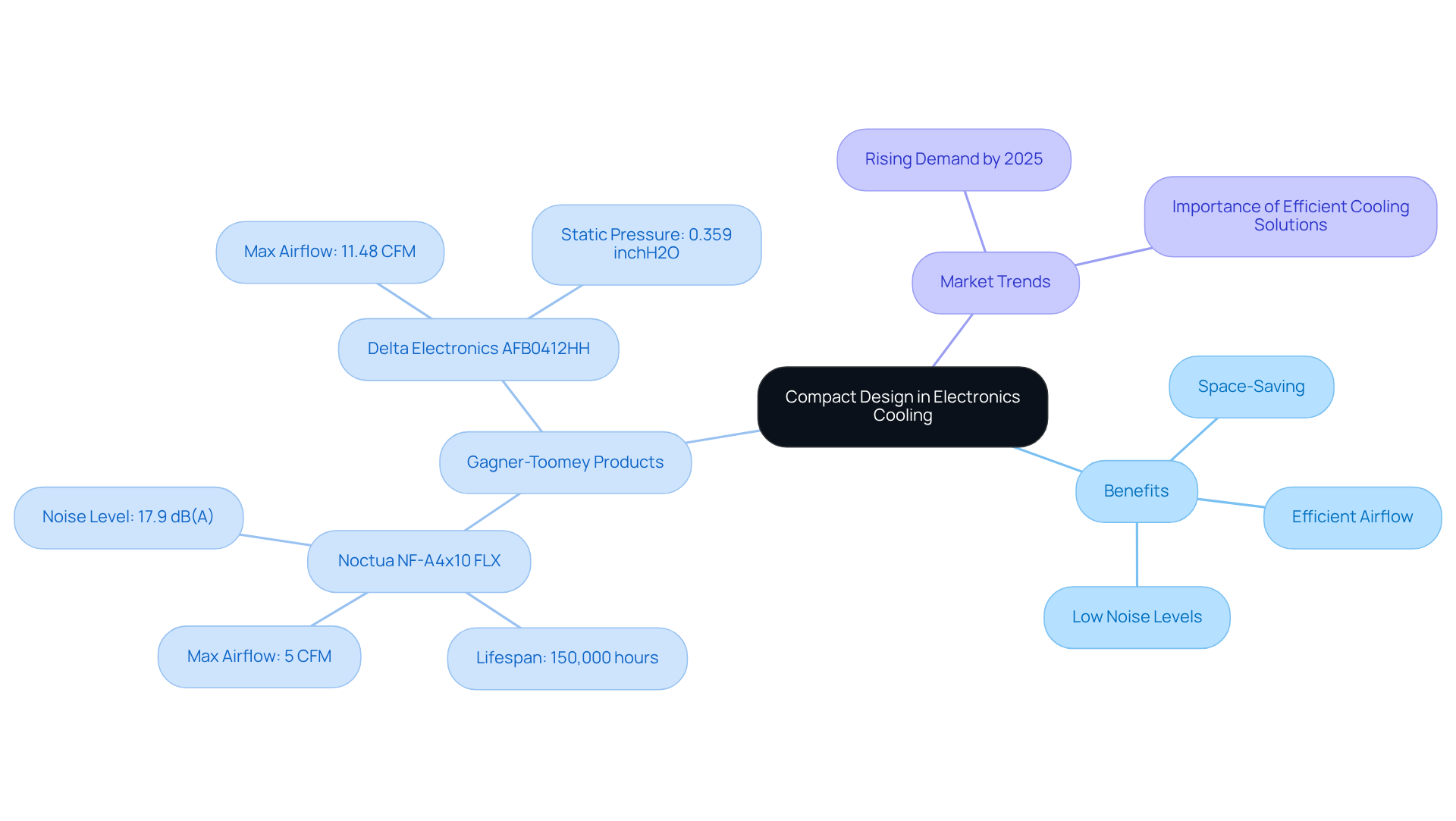

Compact Design: Space-Saving Solutions for Electronics Cooling

Axial blowers stand out for their compact design, making them ideal for tight spaces within electronic enclosures. This space-saving capability is essential in today’s electronics landscape, where miniaturization is a growing trend. By integrating ventilators from Gagner-Toomey Associates, engineers can significantly enhance airflow without sacrificing valuable space, ensuring that temperature regulation solutions are both efficient and discreet.

Gagner-Toomey offers a diverse range of DC input tube models, spanning from 15 to 280mm, all engineered for optimal performance, efficiency, and low noise levels, with IP protection available upon request. Take, for instance, the Noctua NF-A4x10 FLX—a high-quality miniature fan boasting a lifespan of over 150,000 hours and achieving a maximum airflow of 5 CFM at a mere 17.9 dB(A). This compact design not only streamlines installation but also simplifies maintenance, with regular upkeep recommended every 6-12 months to ensure longevity and reliable operation.

As we approach 2025, the demand for innovative temperature regulation solutions is expected to rise, with the axial ventilation fan playing a pivotal role in overcoming the challenges posed by space-limited environments. Efficient temperature regulation technologies, such as those offered by Gagner-Toomey, are crucial for ensuring the reliability and longevity of high-performance electronic systems.

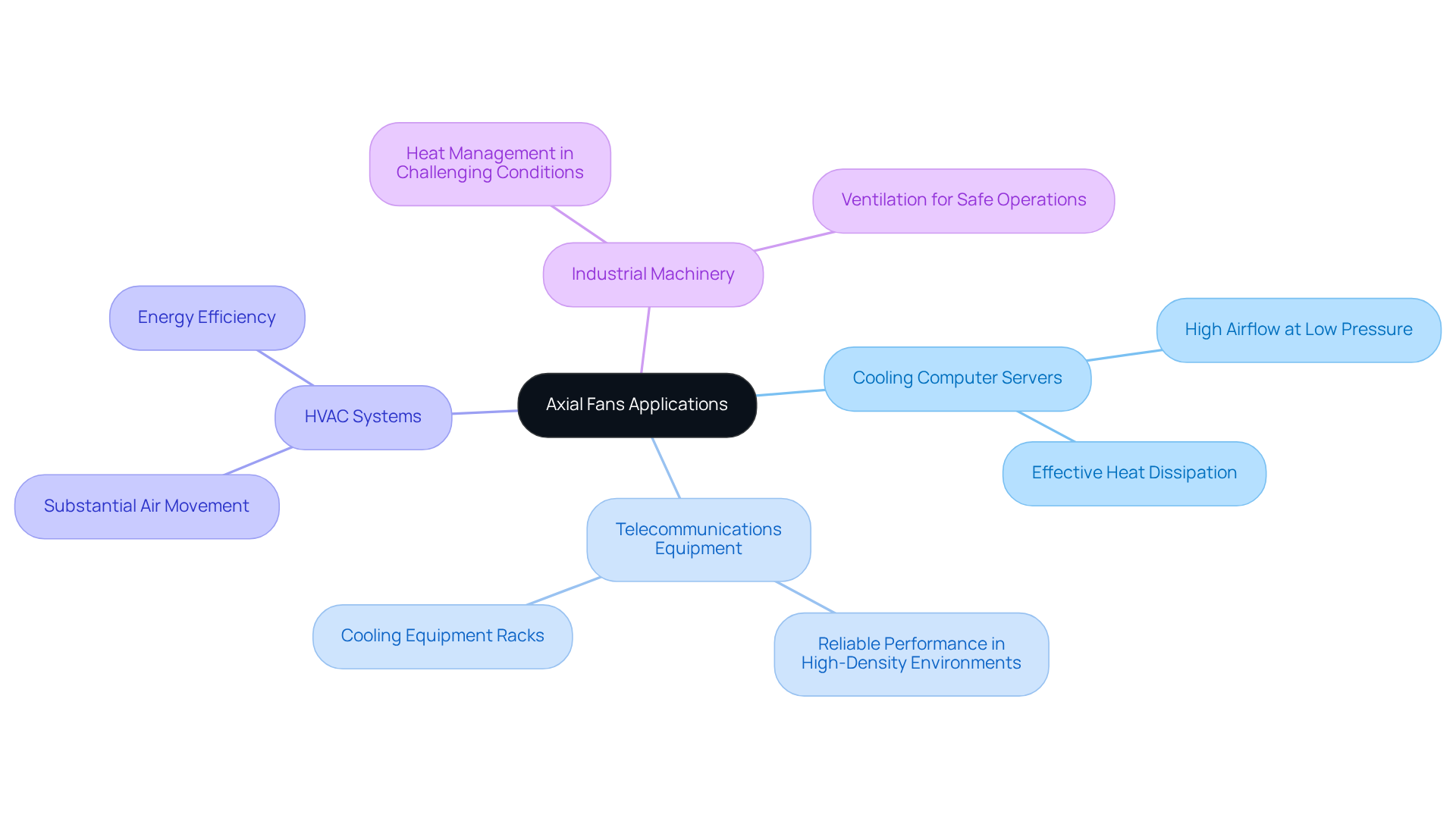

Versatile Applications: Axial Fans in Diverse Electronics Cooling Scenarios

Axial blowers demonstrate remarkable adaptability, making them essential in a wide range of electronic temperature regulation applications. Their effectiveness shines in cooling computer servers and telecommunications equipment, where maintaining optimal temperatures is vital for performance. In data centers, cylindrical blowers excel at delivering high airflow at low pressure, ensuring effective heat dissipation and preventing overheating. This adaptability extends to HVAC systems and industrial machinery, where they facilitate substantial air movement, crucial for maintaining safe operational environments.

The market demand for directional ventilators is on the rise, driven by their efficiency and effectiveness across various settings. For instance, in telecommunications, columnar ventilators are employed to cool equipment racks, ensuring reliable performance in high-density environments. Furthermore, their application in industrial machinery underscores their capability to manage heat in challenging conditions, reinforcing their significance in modern engineering practices.

Industry leaders emphasize the importance of the axial ventilation fan in meeting diverse temperature control needs. Their design allows for seamless integration into existing systems, positioning them as a preferred choice for engineers seeking reliable and effective temperature control solutions, particularly those involving an axial ventilation fan across multiple sectors. As the demand for efficient temperature regulation technologies continues to grow, the axial ventilation fan remains at the forefront, providing innovative strategies that meet the evolving requirements of the electronics industry.

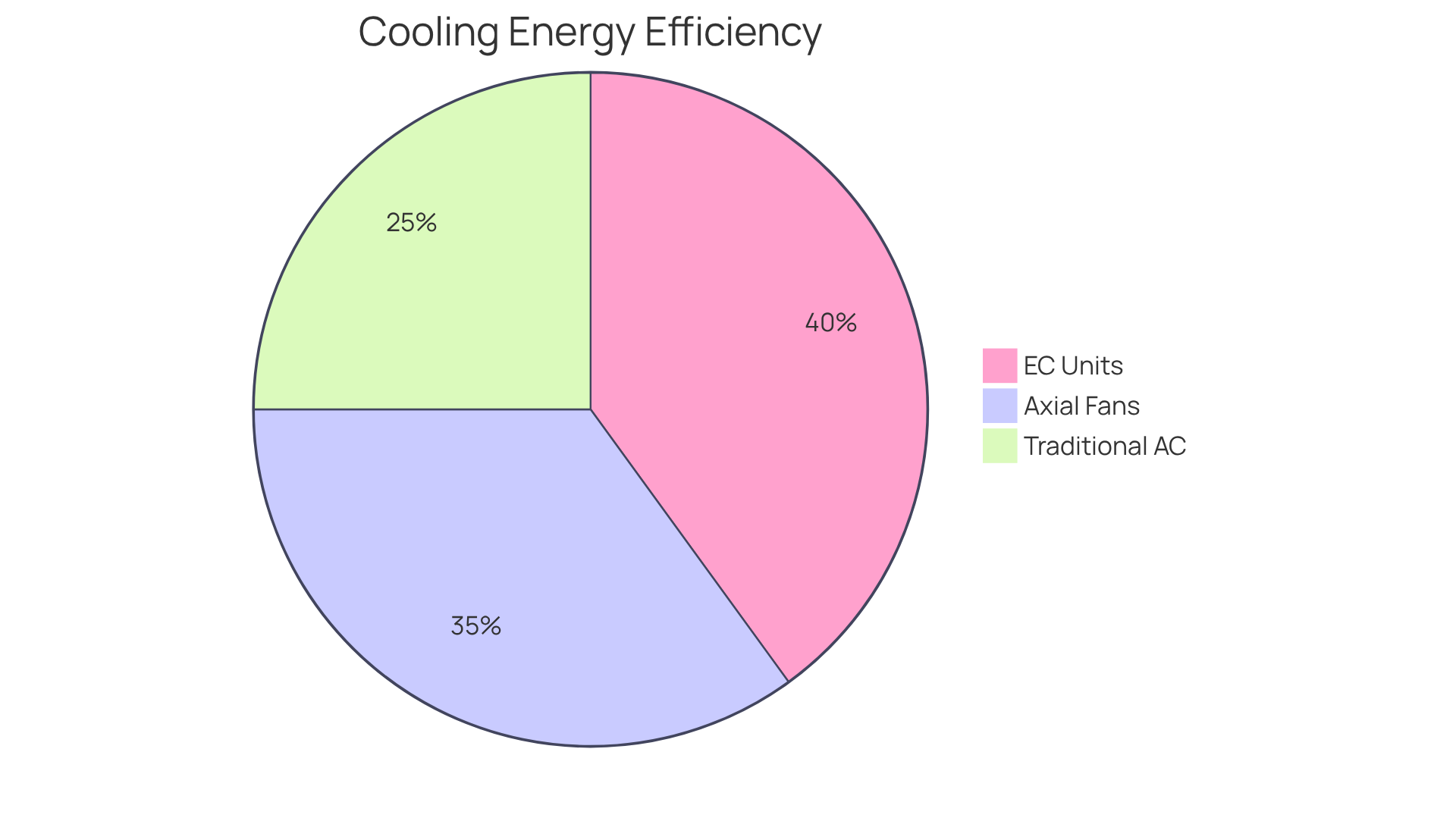

Energy Efficiency: Cost-Effective Cooling with Axial Fans

Axial blowers stand out for their energy efficiency, consuming significantly less power while delivering high airflow rates. This efficiency translates into reduced operational expenses, positioning them as a cost-effective solution for temperature regulation in electronic systems. For instance, data centers that upgrade their cooling systems with energy-saving airflow devices can achieve a remarkable reduction in cooling energy usage—up to 35%—which directly lowers their operational costs. In large setups, these energy savings can substantially impact the overall budget, making these ventilation devices an attractive choice for engineers focused on sustainability and cost control.

Moreover, the integration of advanced technologies in airflow design has led to notable performance improvements while simultaneously cutting energy consumption. EC units, for example, utilize 30-50% less energy compared to traditional AC units, reflecting the industry’s shift towards more sustainable solutions. As the demand for efficient cooling solutions continues to rise, the axial ventilation fan emerges as a reliable option for optimizing energy usage and ensuring effective thermal management in electronic applications.

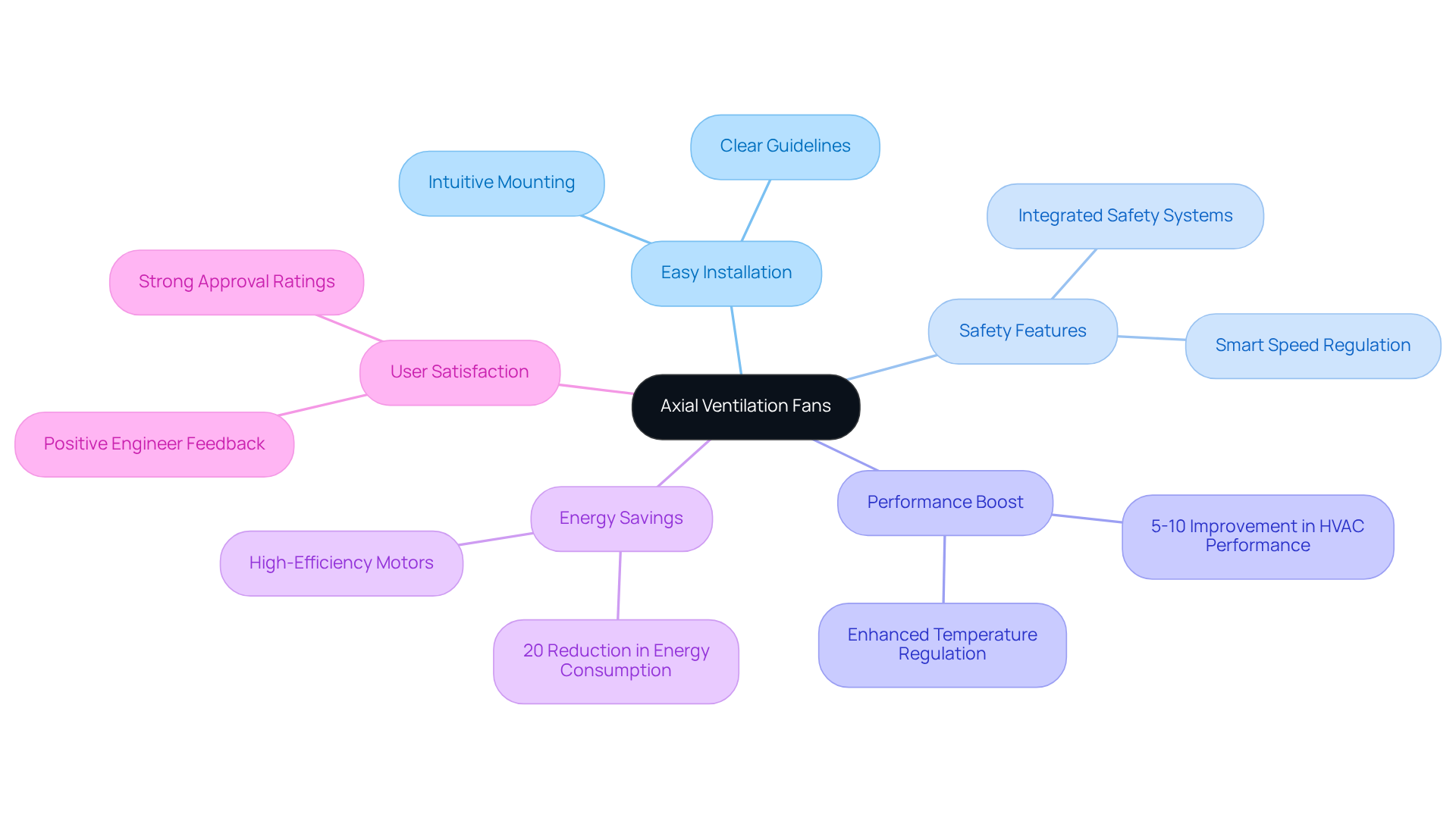

Easy Installation: Simplifying Cooling Solutions with Axial Fans

Axial ventilation fans are designed for effortless setup, offering intuitive mounting options and clear guidelines that facilitate rapid integration into various designs. This simplicity not only minimizes downtime but also significantly cuts labor costs, making them an appealing choice for engineers.

Many ventilation devices come equipped with integrated safety features and smart speed regulation, which streamline the installation process and enhance system reliability. Statistics indicate that FRP models can boost HVAC system performance by 5-10% while reducing energy consumption by 20% compared to metallic units. User satisfaction ratings reflect a strong approval for these features, with engineers frequently noting how specific ventilators simplify temperature regulation in their projects. As one engineer stated, “The simplicity of setup and effectiveness of these devices have changed our method for temperature management.”

With the demand for effective and user-friendly temperature control systems projected to rise in 2025, axial ventilation fans emerge as a preferred choice for engineers seeking to enhance performance while ensuring ease of use.

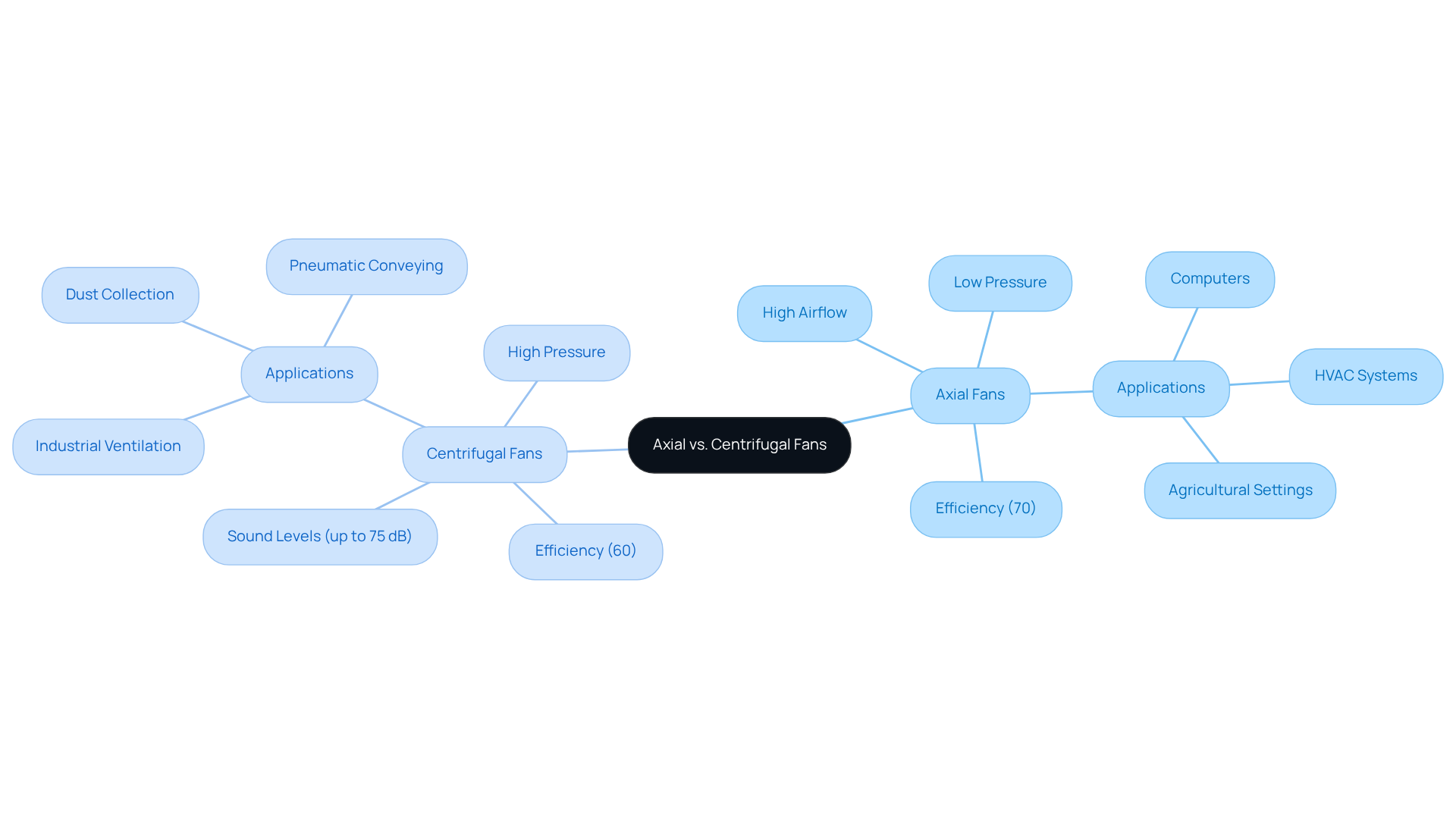

Axial vs. Centrifugal Fans: Choosing the Right Cooling Solution

When selecting a temperature regulation method, engineers often face the critical choice between using an axial ventilation fan and centrifugal blowers. Axial ventilation fans excel in applications that require high airflow at low pressure, making them ideal for ventilating electronic components. Conversely, centrifugal blowers are designed for high-pressure scenarios where airflow must be directed through ducts or filters. By comprehensively understanding the strengths and weaknesses of each fan type, engineers can make informed decisions tailored to their specific cooling requirements.

Axial blowers typically achieve efficiencies around 70%, while centrifugal units operate at approximately 60%. This efficiency gap can significantly influence energy consumption and operational costs, underscoring the importance of informed decision-making in today’s energy-conscious environment. Additionally, centrifugal fans can produce sound levels reaching up to 75 dB, whereas other fan types generally operate around 60 dB. This difference is crucial for applications sensitive to noise.

Industry experts stress the necessity of recognizing these distinctions. As one specialist noted, “Choosing the optimal choice will genuinely rely on the intended use, available space, and overall thermal demands of the final system.” Another expert, David Long, remarked, “If your application requires significant airflow with low resistance, a propeller fan is likely the suitable tool for the job.” These insights emphasize the need for engineers to carefully assess their specific temperature regulation needs.

Practical examples illustrate the effectiveness of ventilation systems in electronic temperature regulation. Engineers frequently opt for axial ventilation fans in scenarios where high airflow is essential, such as ventilation systems for computers and control panels. Their capability to maintain performance in confined spaces is invaluable, ensuring the reliable operation of sensitive electronic equipment.

Moreover, the market for centrifugal and similar fans is projected to reach USD 7,715.55 million by 2033, highlighting the significance of this topic and the necessity for informed decision-making in a growing market.

In conclusion, understanding the advantages and applications of axial versus centrifugal blowers is vital for engineers aiming to enhance cooling solutions. By aligning fan selection with specific operational needs, they can improve system performance and contribute to energy-efficient practices across various sectors.

Improved Airflow: Maintaining Optimal Temperatures in Electronics

The axial ventilation fan plays a vital role in enhancing airflow within electronic systems, effectively dissipating heat generated by components. By maintaining optimal temperatures, these devices are essential in preventing overheating, which can lead to performance degradation or even failure of electronic equipment. Engineers depend on directional blowers to establish a consistent airflow pattern that significantly boosts cooling efficiency.

For instance, high-efficiency airflow devices, particularly PWM models, can achieve energy savings of up to 30% compared to traditional direct current units, all while moving substantial volumes of air with minimal power consumption. This capability not only enhances the reliability of critical components but also extends their lifespan, making these devices indispensable in modern electronic applications.

With technological advancements, axial blowers are now designed to operate quietly, improving the working environment while ensuring effective thermal management. As highlighted by Gagner-Toomey Associates, “Cooling fan modules are integral to maintaining optimal operating temperatures and play a pivotal role across diverse applications, from automotive to consumer electronics.”

In conclusion, investing in high-quality axial ventilation fans is crucial for any engineer looking to optimize system performance and reliability.

Comprehensive Benefits: Why Axial Fans are Essential for Electronics Cooling

In summary, blowers play a crucial role in electronics temperature management, offering a range of advantages that make them indispensable. Their efficient airflow, low noise operation, compact design, versatility, energy efficiency, and ease of installation position them as the preferred choice for engineers. By integrating directional blowers into their designs, engineers can ensure optimal cooling efficiency, reduce operational costs, and enhance the reliability of electronic systems.

As technology advances, the importance of axial fans in effective thermal management will only grow. Engineers must recognize the value of these blowers and consider their implementation to stay ahead in the rapidly evolving landscape of electronics.

Conclusion

The essential role of axial ventilation fans in electronics cooling is paramount. These advanced cooling solutions are pivotal in managing thermal performance, enhancing energy efficiency, and ensuring the reliability of electronic systems. By prioritizing high airflow rates and low noise operation, axial fans emerge as the preferred choice for engineers navigating the complexities of modern electronics.

Key benefits of axial fans include:

- Their efficient airflow capabilities

- Compact designs that save space

- Versatility across various applications

The significant energy savings they provide, along with their ease of installation, further solidify their importance in the electronics industry. As engineers increasingly seek innovative cooling solutions, axial fans become indispensable tools for optimizing performance and sustainability.

In a rapidly evolving technological landscape, the demand for effective thermal management solutions will continue to grow. Embracing the advantages of axial ventilation fans not only enhances the functionality of electronic devices but also aligns with broader sustainability goals. Engineers are encouraged to integrate these fans into their designs to ensure they remain at the forefront of efficient and reliable electronics cooling solutions.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates specializes in innovative temperature control solutions for the electronics industry, focusing on performance optimization and energy efficiency.

What type of fans does Gagner-Toomey offer for temperature regulation?

Gagner-Toomey offers axial ventilation fans, which are essential for regulating the temperature of electronic components.

How efficient are axial ventilation fans?

Axial ventilation fans can achieve efficiency rates of up to 90% and can reduce energy consumption by as much as 70% compared to traditional AC units.

What is the projected growth of the global fan market?

The global fan market is projected to reach USD 11.26 billion by 2026.

How do axial fans enhance cooling performance?

Axial fans manage airflow parallel to their axis, delivering a significant volume of air while maintaining low energy consumption, which is crucial for dissipating heat in electronic components.

What are the benefits of using cylindrical blowers in cooling solutions?

Cylindrical blowers enhance temperature regulation, ensuring the reliability and longevity of electronic devices, particularly in applications requiring high airflow rates at low pressure.

Why are low-noise axial blowers important for sensitive electronics?

Low-noise axial blowers are engineered to minimize noise levels while effectively managing heat, making them ideal for environments such as data centers and medical equipment where excessive noise can disrupt operations.

What efficiency improvements have data centers experienced by using PWM technology?

Data centers utilizing PWM technology have reported efficiency improvements of up to 30%.

How do axial ventilation fans compare to centrifugal models in terms of noise production?

Axial ventilation fans generally produce less noise than centrifugal models, making them preferable for applications where noise reduction is important.