Overview

The primary objective of the article titled “10 Essential Insights on Axial HVAC Fans for Engineers” is to equip engineers with crucial information regarding axial HVAC fans. This includes:

- An exploration of their features

- Applications

- Advantages

- Key considerations for selection

The article emphasizes the fans’ high airflow efficiency, energy savings, and versatility across a multitude of industries. Additionally, it addresses limitations such as noise levels and maintenance requirements, thereby providing engineers with the essential insights needed to make informed decisions in their applications.

Introduction

Axial HVAC fans stand as a cornerstone in the engineering domain, seamlessly merging efficiency with versatility across a spectrum of applications. These fans are distinguished not only by their capacity to move substantial volumes of air but also by their potential for significant energy savings, positioning them as a premier choice for engineers intent on optimizing performance in heating, ventilation, and air conditioning systems. As the demand for enhanced airflow management escalates, the complexity of selecting the appropriate fan for specific requirements also intensifies.

How can engineers effectively navigate the intricate balance between performance, cost, and maintenance when it comes to axial HVAC fans? This article explores ten essential insights that illuminate the features, applications, and considerations crucial for making informed decisions in this vital area of engineering.

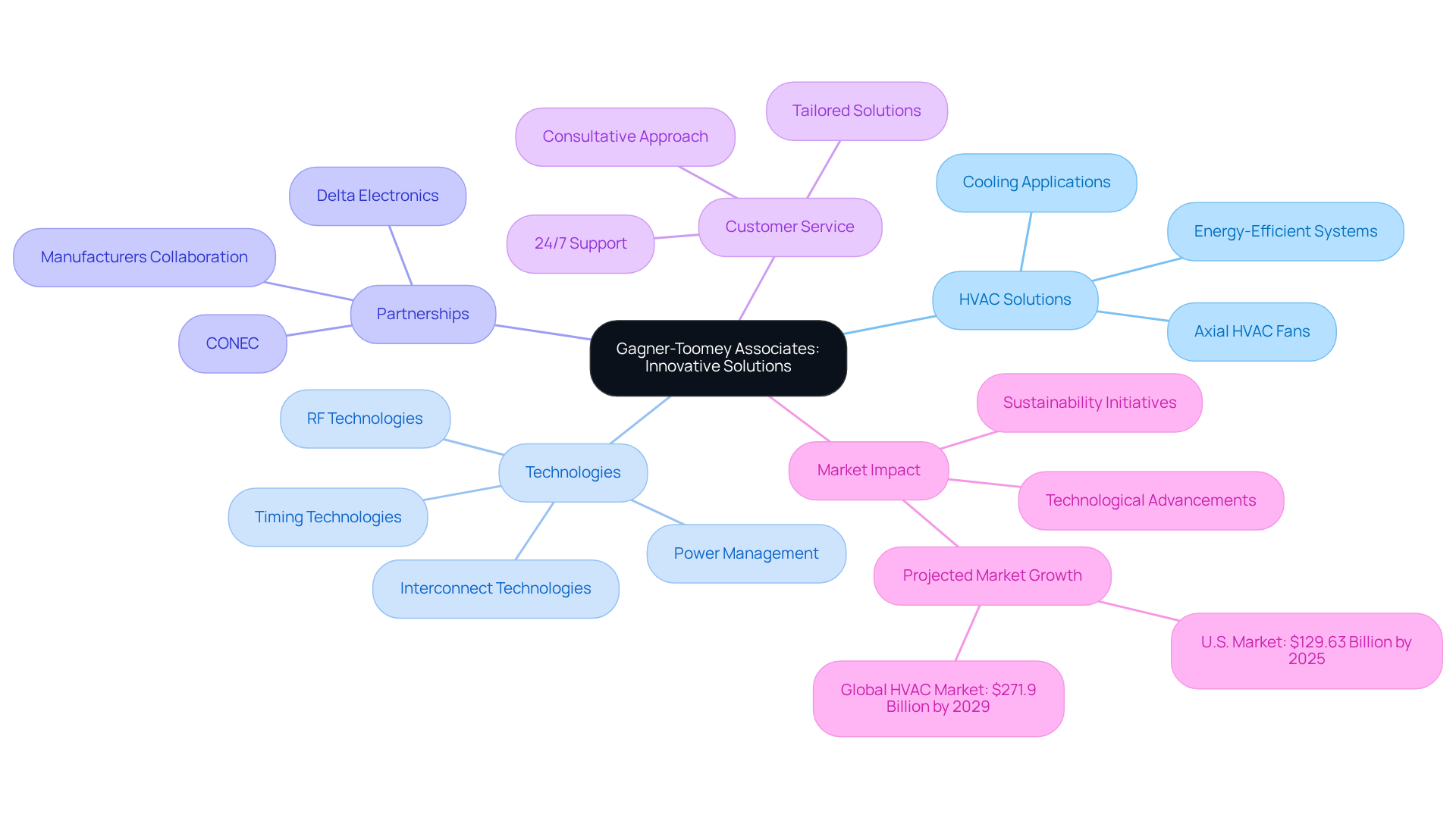

Gagner-Toomey Associates: Innovative Solutions for Axial HVAC Fans

Gagner-Toomey Associates stands at the forefront of the heating, ventilation, and air conditioning sector, delivering innovative solutions specifically designed for axial HVAC fans. Their comprehensive portfolio encompasses advanced cooling, power management, timing, RF, and interconnect technologies, all designed to optimize fan performance. This empowers engineers with the needed for success.

By partnering with exceptional manufacturers, Gagner-Toomey guarantees that engineers gain access to cutting-edge products that address the dynamic demands of the market. Their consultative approach and commitment to attentive customer service reflect a culture that values the time and needs of their clients, solidifying Gagner-Toomey as a trusted ally for engineers seeking reliable solutions, including axial HVAC fans, within the HVAC industry.

Moreover, Gagner-Toomey Associates plays a pivotal role in assisting clients in bringing transformative ideas to market, further affirming their status as a leader in the electronics industry.

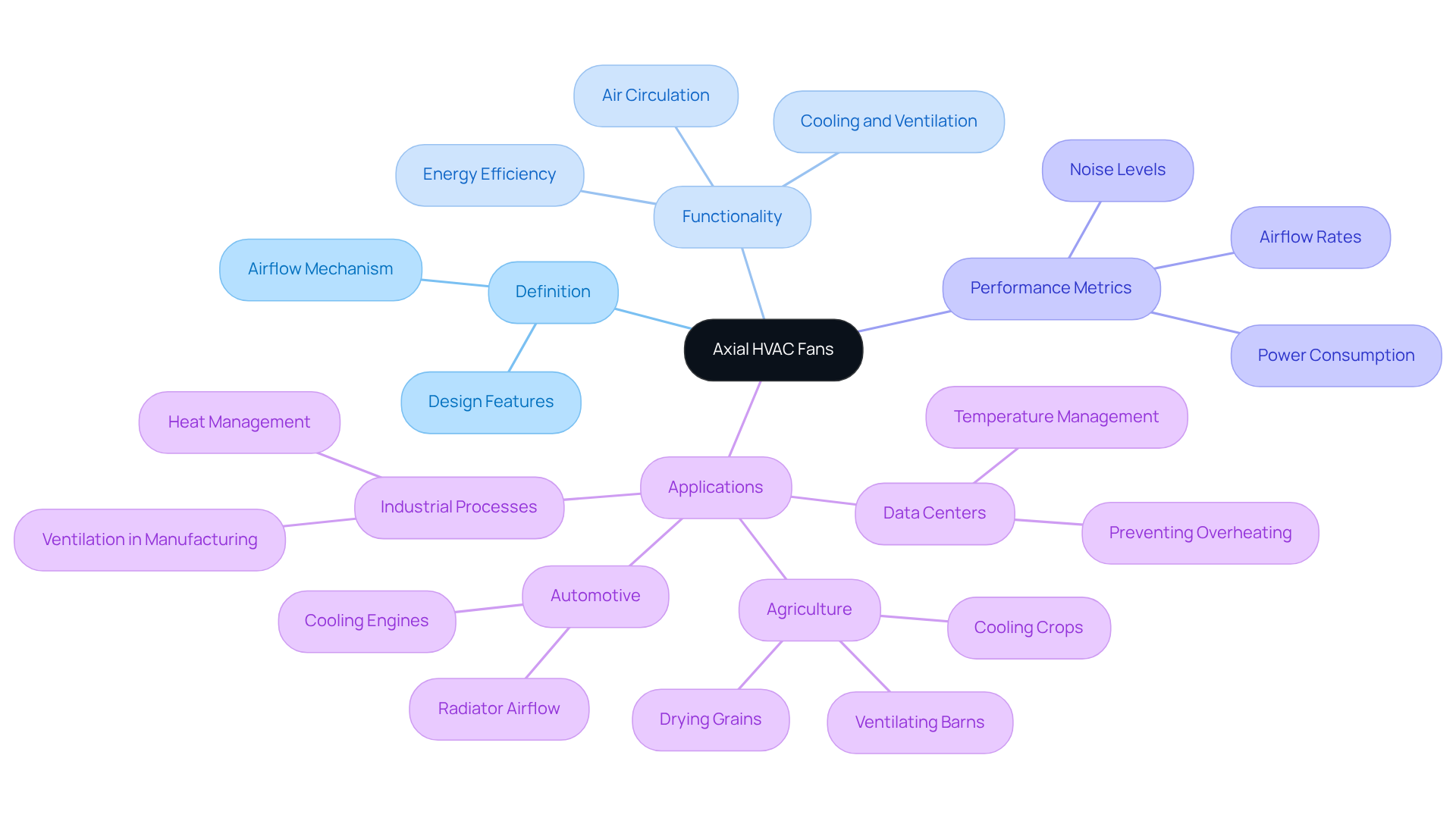

Understanding Axial HVAC Fans: Definition and Functionality

Axial air circulation units are engineered to move air parallel to the device’s axis, employing blades mounted on a rotating shaft to generate airflow. This mechanism efficiently draws air in from one side and expels it from the other, enabling these devices to deliver substantial volumes of air at low pressure. Their design is particularly effective for applications requiring efficient ventilation and cooling, making a preferred choice across various heating, ventilation, and air conditioning systems, from residential buildings to expansive industrial facilities.

Performance metrics indicate that directional blowers excel in high airflow efficiency, often achieving airflow rates that significantly enhance indoor air quality. In commercial heating and cooling applications, for instance, ducted blowers can effectively remove stale air and improve circulation, fostering a healthier environment. Their straightforward design not only simplifies installation and maintenance but also reduces operational costs, as they typically consume less power compared to other fan types.

Real-world applications underscore their versatility:

- In agricultural settings, horizontal blowers are vital for drying grains and ventilating barns.

- In data centers, they manage temperatures by moving substantial quantities of air to prevent overheating of sensitive equipment.

Recent studies emphasize that the efficiency of inline air circulation devices can be optimized by ensuring smooth airflow at the inlet, which minimizes turbulence and noise, further enhancing their operational effectiveness. In summary, axial HVAC fans serve as a reliable solution for engineers seeking to improve air circulation across multiple applications.

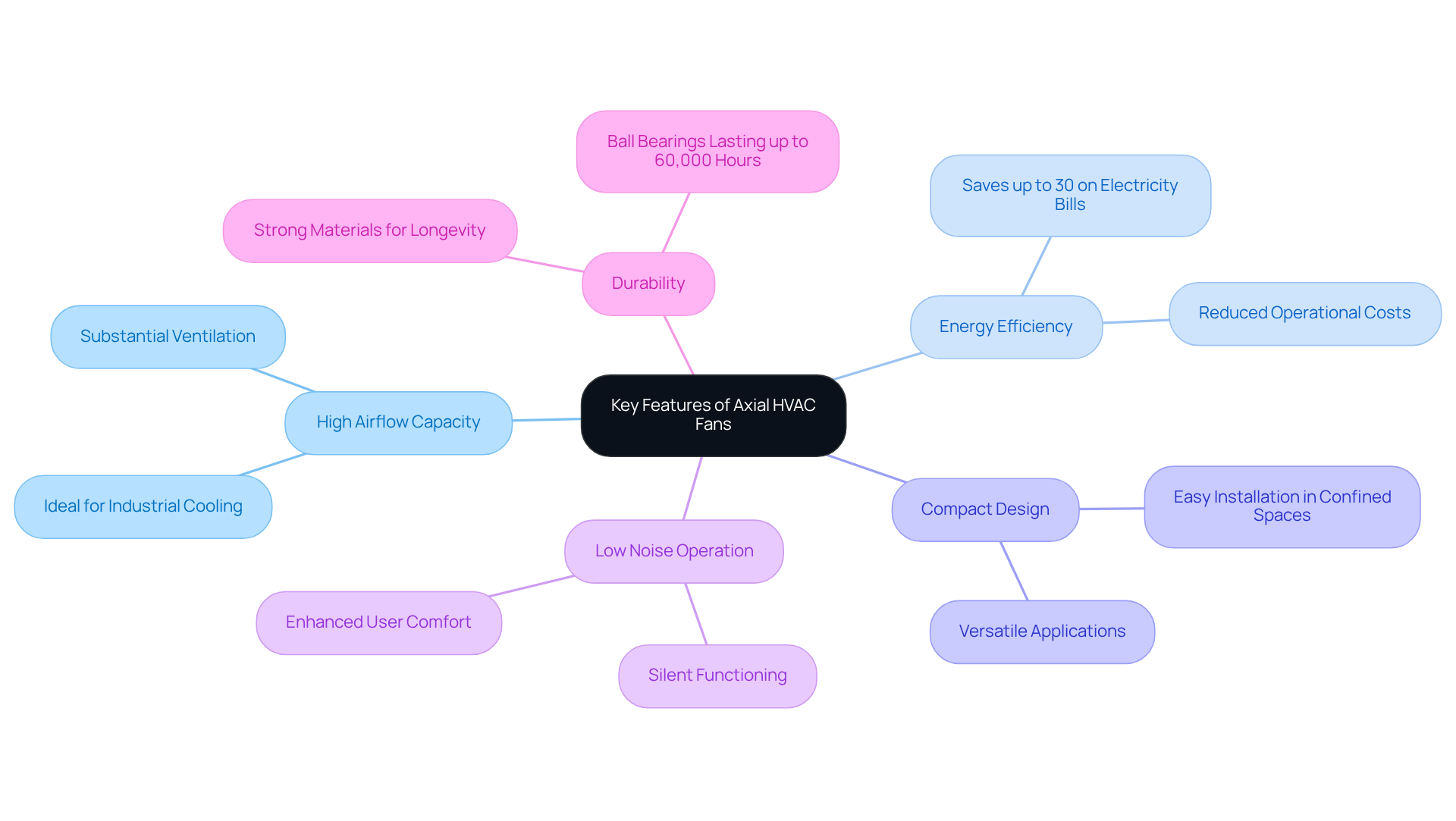

Key Features of Axial HVAC Fans: Performance and Efficiency

Axial HVAC fans are defined by several essential features that significantly enhance their performance and efficiency.

- High Airflow Capacity: These fans excel at moving large volumes of air, making them ideal for applications that demand substantial ventilation, such as industrial cooling and HVAC systems.

- Energy Efficiency: Axial blowers are designed to consume significantly less power than traditional types, leading to reduced operational costs. Axial HVAC fans are energy-efficient models that can save businesses up to 30% on electricity bills, making them a cost-effective choice for long-term use.

- Compact Design: Their streamlined structure facilitates easy installation in confined spaces, allowing for versatile applications across various environments, from residential settings to large industrial facilities.

- Low Noise Operation: Numerous ducted ventilators are designed for silent functioning, which is essential in environments where sound reduction is a priority, such as workplaces and residential zones. Advanced designs often incorporate features that minimize noise levels, enhancing user comfort.

- Durability: Constructed from strong materials, these cooling devices are designed to withstand severe operating conditions, guaranteeing longevity and dependability. With proper upkeep, ball bearings can endure for up to 60,000 hours, making these devices a for ongoing use.

Expert Insights: Industry specialists highlight the significance of choosing energy-efficient airflow devices, including axial HVAC fans, to satisfy contemporary requirements for sustainability without sacrificing performance. For example, Hae-Ji Kim observed that the dual-blade design consumes less energy and generates less noise in comparison to single-blade models, emphasizing the advantages of innovative designs.

In 2025, the emphasis on energy efficiency in axial heating and cooling systems continues to increase, with producers creating sophisticated technologies that improve performance while reducing energy usage. This evolution not only supports operational efficiency but also aligns with global sustainability goals.

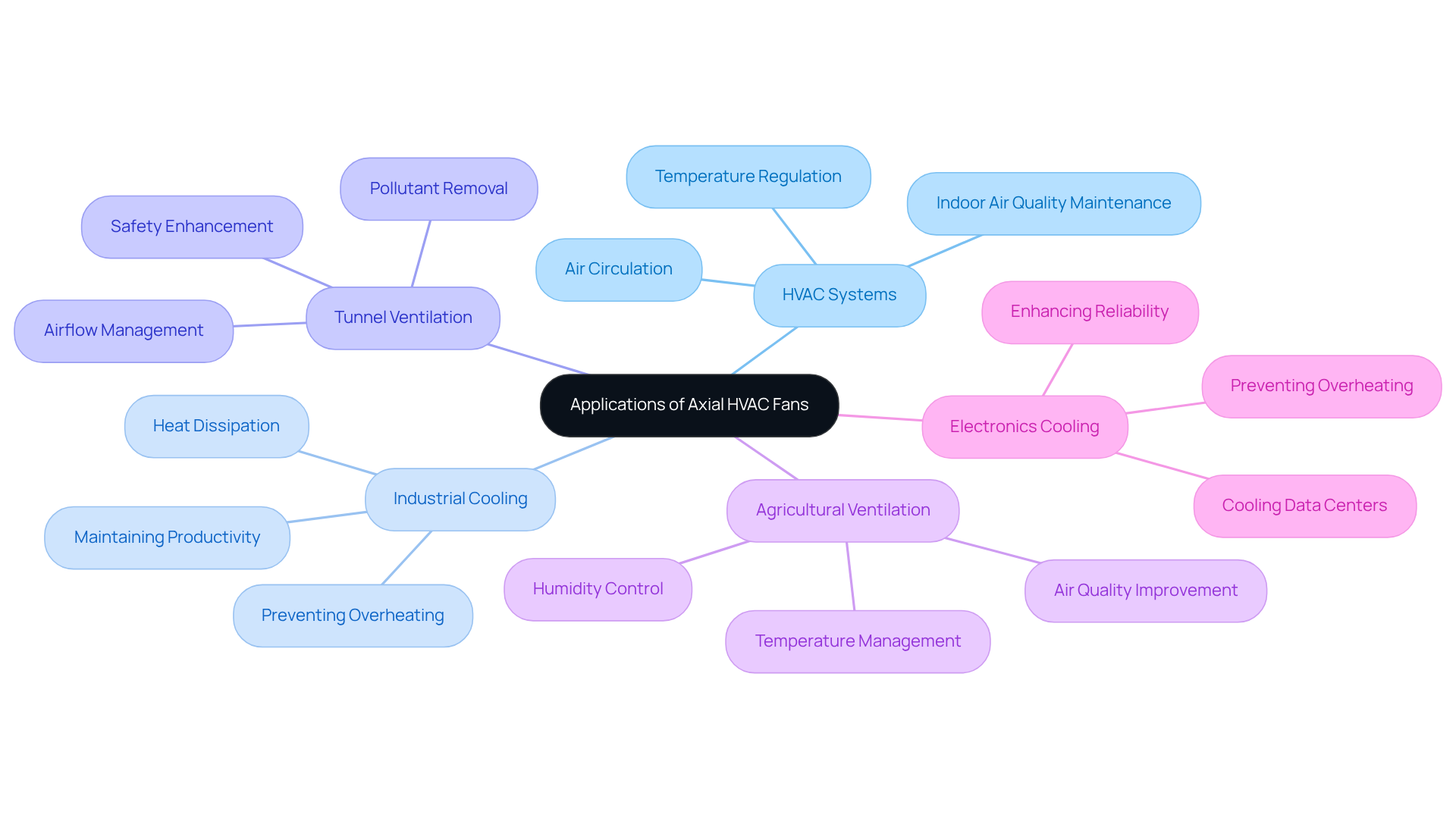

Common Applications of Axial HVAC Fans in Various Industries

Axial ventilation fans are indispensable across a multitude of industries, recognized for their efficiency and effectiveness. Their applications are extensive and critical:

- HVAC Systems: These fans are integral to heating, ventilation, and air conditioning systems in both residential and commercial buildings, ensuring optimal climate control.

- Industrial Cooling: They play a vital role in cooling machinery and equipment within manufacturing plants, preventing overheating and maintaining productivity.

- Tunnel Ventilation: In tunnels and underground facilities, axial fans are employed to guarantee sufficient airflow, enhancing safety and operational efficiency.

- Agricultural Ventilation: These fans are utilized in barns and greenhouses to uphold optimal air quality and temperature, crucial for the health of crops and livestock.

- Electronics Cooling: They are essential for cooling electronic components in data centers and server rooms, preventing overheating and ensuring reliability.

In conclusion, axial ventilation fans are not merely components; they are critical systems that enhance operational efficiency and safety across various sectors.

Advantages of Axial HVAC Fans: Why Choose Them?

Axial HVAC fans offer numerous advantages that establish them as a preferred choice across various applications:

- Cost-Effectiveness: With initial costs ranging from $200 to $2,000, axial fans are generally more budget-friendly than centrifugal fans, which can cost between $500 and $5,000. Their energy-efficient design significantly reduces electricity bills, making them economical for long-term use. Additionally, inline blowers are more economical due to easier production methods and fewer parts, resulting in decreased manufacturing expenses.

- Simplicity: The clear design of these ventilators allows for easy setup and maintenance, often requiring fewer parts. This simplicity translates to , enabling quick setup and minimal disruption in operations. Furthermore, their design allows for easy access to fan blades for cleaning, simplifying maintenance tasks.

- Versatility: Available in a broad spectrum of sizes, from compact desktop units to large industrial models, these devices can be customized to meet specific ventilation needs across various applications, including HVAC systems, cooling electronic components, and industrial processes. This adaptability underscores their suitability for diverse applications.

- High Performance: Engineered to produce significant air movement even in low-pressure settings, these ventilators ensure efficient ventilation and cooling, making them ideal for heat-intensive tasks. They generate high-volume airflow with relatively low pressure, which enhances the performance of axial HVAC fans in demanding environments.

- Environmentally Friendly: Many axial fans are designed to minimize energy consumption, supporting sustainability initiatives. Their efficient operation not only lowers energy costs but also promotes eco-friendly practices across various industries. Axial blowers typically consume less energy compared to other types, leading to substantial energy savings over time.

- Real-World Applications: In the automotive sector, shaft-mounted blowers are crucial for cooling engines and radiators, thereby improving vehicle performance. Similarly, in agriculture, they are utilized for drying grains and ventilating barns, demonstrating their adaptability and effectiveness in maintaining product quality. Moreover, these ventilators play a vital role in regulating environmental temperatures in industrial settings, ensuring safe operational conditions.

Disadvantages of Axial HVAC Fans: Considerations for Engineers

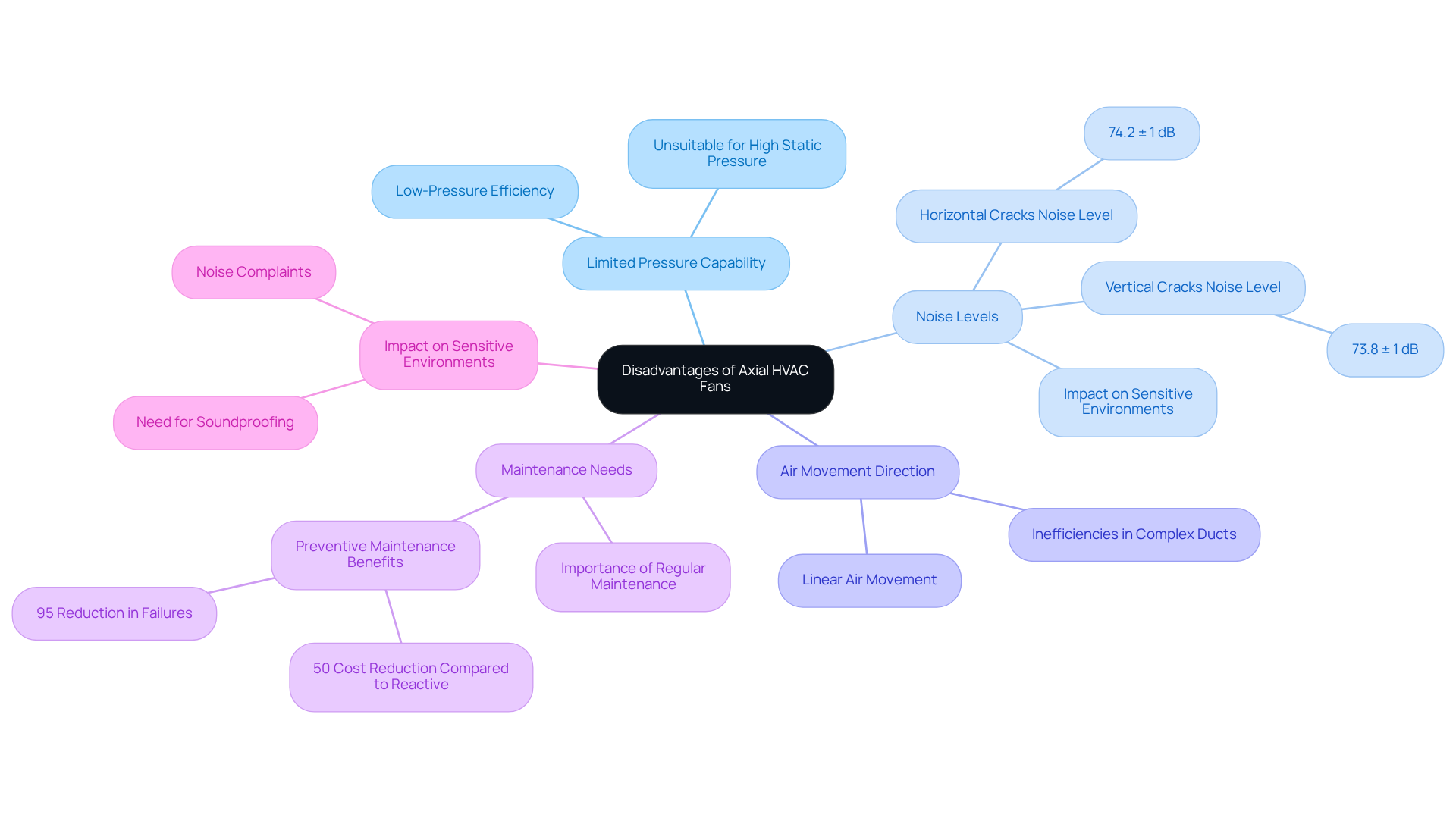

While axial HVAC fans present various advantages, it is imperative for engineers to recognize their limitations:

- Limited Pressure Capability: Axial fans are particularly proficient in low-pressure environments; however, they encounter challenges in applications that demand high static pressure. This limitation can significantly affect the performance of axial HVAC fans in specific industrial contexts.

- Noise Levels: Despite advancements in design aimed at reducing noise, certain blower types can generate sound levels that may be problematic in sensitive environments. For instance, noise levels from horizontal fissures in ventilators can reach 74.2 ± 1 dB, while vertical cracks may produce levels of 73.8 ± 1 dB, which could be unacceptable in residential or office settings.

- Air Movement Direction: The linear air movement produced by axial blowers may not fulfill the requirements of all ventilation systems, particularly those with complex duct configurations. This can result in inefficiencies in air distribution, especially in systems where fan enclosure design is critical for optimizing airflow.

- Maintenance Needs: Regular maintenance is vital for ensuring optimal performance, especially in environments susceptible to dust and debris accumulation. Neglecting maintenance can lead to increased vibrations and reduced lifespan of the devices. Research indicates that preventive maintenance can decrease HVAC system failures by up to 95%, and comprehensive planned maintenance programs can achieve a 50% reduction in total maintenance costs compared to reactive strategies, underscoring the necessity of routine inspections.

- Impact on Sensitive Environments: The noise generated by rotor devices can profoundly affect sensitive applications, such as those in healthcare or precision manufacturing. As noted by Husam Bakhtar, minimizing fan noise is crucial across residential, commercial, and industrial applications. Engineers must take into account the potential for noise complaints and the necessity for additional soundproofing measures.

Understanding these challenges is essential for engineers to make informed decisions when into HVAC systems.

Axial vs. Centrifugal Fans: Key Differences Explained

When selecting between , it is crucial to understand their fundamental differences.

- Airflow Direction: Axial HVAC fans move air parallel to their axis, making them ideal for applications requiring direct airflow. In contrast, centrifugal blowers direct air perpendicular to the intake, which is beneficial for ducted systems.

- Pressure Generation: Centrifugal blowers are designed for high-pressure applications, effectively producing significant static pressure of up to 10 inches of water gauge (inwg) while maintaining a volumetric flow of approximately 1,000 cubic feet per minute (CFM). Conversely, these types of blowers perform exceptionally well in low-pressure situations, reaching airflow rates of up to 5,000 CFM with a static pressure of 0.5 inwg, rendering them appropriate for ventilation and cooling duties.

- Size and Design: Generally, axial HVAC fans are more compact and lightweight, which aids installation in tight areas. This contrasts with the larger design of centrifugal blowers, which may require more space.

- Efficiency: In high-volume, low-pressure scenarios, axial HVAC fans demonstrate excellent energy efficiency, using less power while providing significant air movement. Centrifugal blowers, however, are more efficient in high-pressure environments, where their design allows for effective airflow management. As noted, “in comparison to a straight configuration, a centrifugal fan offers a broader range of static pressure abilities.”

- Sound Levels: Typically, straight-bladed ventilators function more silently than their centrifugal equivalents, rendering them more suitable in noise-sensitive environments, such as workplaces or residential zones.

Understanding these differences is essential for engineers to make informed decisions based on specific application requirements and operational contexts. For example, centrifugal blowers are frequently utilized in free-blow unit heaters and rooftop condenser areas, demonstrating their practical uses.

Maintenance Tips for Axial HVAC Fans: Ensuring Longevity

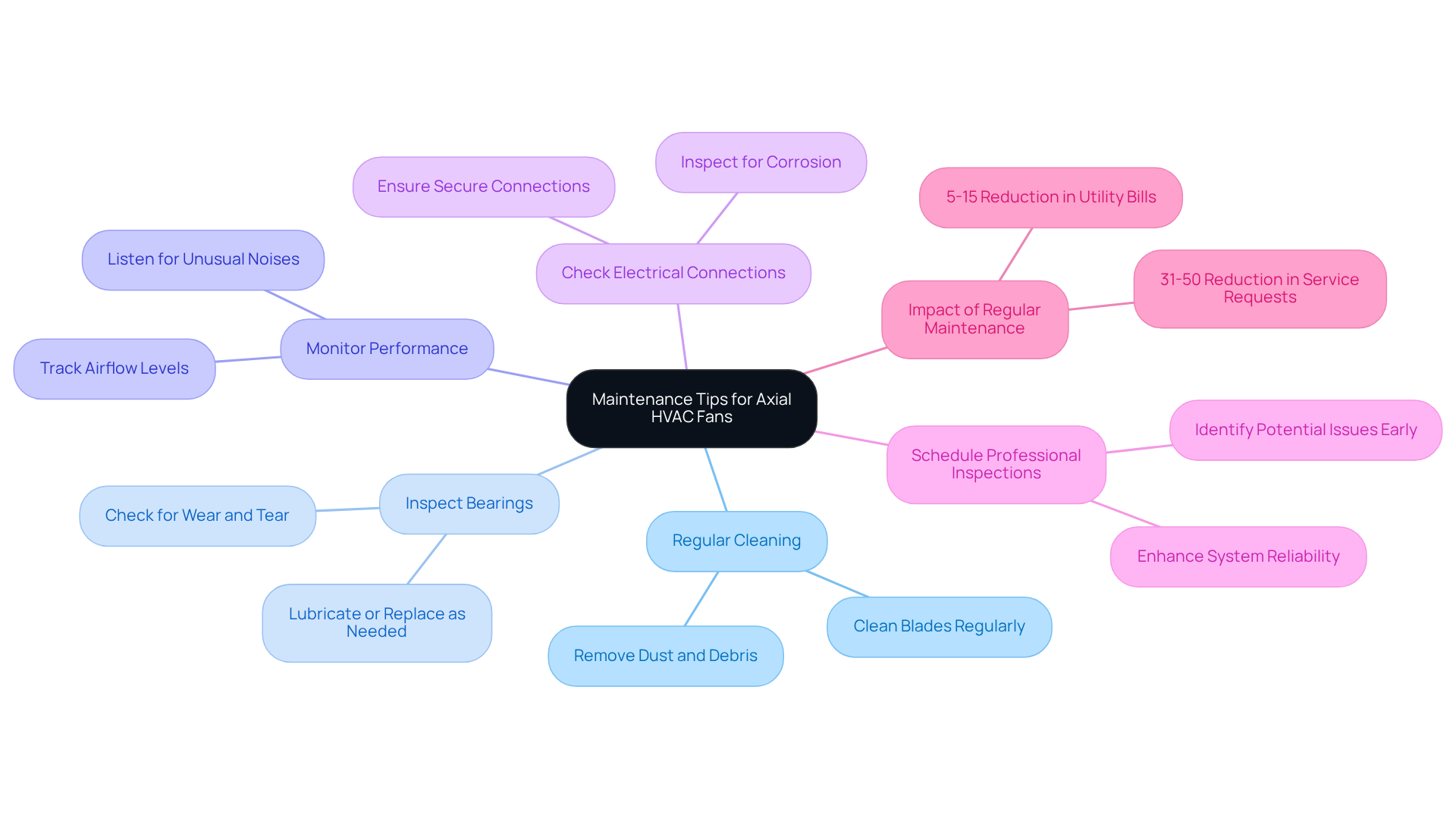

To ensure the longevity and optimal performance of axial HVAC fans, implementing is crucial.

Regular cleaning of axial HVAC fans is necessary, as accumulated dust and debris on their blades can significantly reduce efficiency. Therefore, regular cleaning of the blades of axial HVAC fans is essential to maintain optimal circulation and prevent overheating.

- Inspect Bearings: Regularly checking bearings for signs of wear and tear is vital. Proper lubrication or timely replacement of axial HVAC fans is crucial to avoid noise and operational disruptions, ensuring their smooth operation.

- Monitoring the performance of axial HVAC fans involves keeping track of airflow and noise levels, which is important. Any noticeable changes in the axial HVAC fans may signal the need for maintenance or repairs, allowing for proactive interventions.

- Check Electrical Connections: Ensuring all electrical connections are secure and free from corrosion helps prevent electrical failures that could compromise the performance of axial HVAC fans.

- Schedule Professional Inspections: Periodic professional inspections can identify potential issues with axial HVAC fans before they escalate into serious problems, thereby enhancing the reliability of the fan system.

- Impact of Regular Maintenance: Studies indicate that well-maintained systems achieve a 5-15% reduction in monthly utility bills through regular filter changes, highlighting the financial benefits of consistent maintenance practices.

- Best Practices for Upkeep: Incorporating a routine that includes cleaning, inspection, and monitoring can lead to a 31-50% reduction in heating, ventilation, and air conditioning service requests, as found in studies on preventive maintenance programs. This proactive strategy not only prolongs the lifespan of the devices, including axial HVAC fans, but also improves overall system efficiency.

Selecting the Right Axial HVAC Fan: Key Considerations

When selecting the right axial HVAC fans, engineers must consider several key factors to ensure in their applications.

- Airflow Requirements: It is essential to accurately determine the necessary airflow, measured in cubic feet per minute (CFM), for the specific application. This assessment guarantees sufficient ventilation and peak performance, as axial blowers can provide air movement rates ranging from 500 CFM for smaller units to over 100,000 CFM for industrial uses.

- Static Pressure: Evaluating the static pressure needs of the system is crucial, as it pertains to the resistance to air movement within the ventilation system. Axial HVAC fans are most suitable for applications requiring high flow rates with low to moderate static pressure, typically between 100-500 Pa. Neglecting static pressure considerations can lead to suboptimal airflow and increased energy consumption.

- Noise Levels: Assessing the acceptable noise levels for the installation environment is particularly important in residential or sensitive areas. Axial HVAC fans may produce higher noise levels than centrifugal units, particularly at increased speeds. Therefore, verifying the decibel (dB) rating is vital to select models that meet specific noise standards.

- Energy Efficiency: Prioritizing devices with high energy efficiency ratings is essential to minimize operational costs and reduce environmental impact. Energy-efficient axial HVAC fans consume less electricity while delivering the necessary air movement, resulting in lower overall ownership expenses.

- Size and Mounting Options: It is important to ensure that the fan’s dimensions and mounting options align with the available space and installation requirements. Proper sizing is critical for optimal performance and to prevent unnecessary strain on the system, with configurations available for wall-mounted, duct-mounted, ceiling-mounted, or portable setups.

- Maintenance: Regular maintenance is vital for extending the lifespan of directional blowers and ensuring optimal performance. This routine upkeep includes cleaning fan blades, checking bearings, and performing timely lubrication.

- Casing Functionality: The casing or housing of axial HVAC fans plays a significant role in directing airflow and protecting internal components. It often incorporates guide vanes for enhanced efficiency and acoustic insulation for noise reduction. Understanding the design of the casing can significantly improve the overall performance of the fan.

Essential Facts About Axial HVAC Fans: A Summary for Engineers

Axial HVAC fans are essential components in modern engineering, providing numerous advantages that enhance performance and efficiency. Here are some key insights:

- High Airflow Efficiency: Axial fans are adept at moving substantial volumes of air while consuming minimal energy, establishing them as a preferred option across various applications. Their design promotes effective air circulation, which is critical in environments demanding consistent temperature control.

These devices, including axial HVAC fans, find utility in multiple sectors, such as HVAC systems, industrial cooling, and ventilation. Their adaptability renders them suitable for diverse settings, from data centers to agricultural facilities, where they play a vital role in regulating temperature and humidity.

- Compact Design: The streamlined and compact architecture of these ventilators enables installation in constrained spaces, such as between walls or within ducts. This characteristic is particularly advantageous in environments with limited space, ensuring efficient airflow without compromising performance.

- Low Maintenance: Compared to other device types, these models typically require less upkeep, leading to reduced long-term operational costs. Routine maintenance practices, such as cleaning and lubricating bearings, can further prolong their lifespan and sustain optimal performance.

- Energy Savings: With motor efficiencies reaching up to 0.92 for 100 kW models, these blowers significantly contribute to . Notably, the energy-saving ratio of the adjustment strategy Str-2 achieved 13.94% at a wind speed of 12 m/s, showcasing their efficiency under varying conditions. This capability not only lowers energy expenses but also minimizes environmental impact, making them a sustainable choice for engineers.

- Real-World Applications: In industrial environments, axial blowers are indispensable for cooling machinery and ensuring adequate ventilation. For example, they are utilized in cooling towers and chillers, where effective airflow is crucial for maintaining equipment performance. Moreover, in agricultural contexts, these devices help create optimal conditions for livestock and crops by regulating air quality and temperature. As Wenhui Huang noted, “The fan adjustment strategy Str-2 could greatly reduce the power consumption of the fan array, especially at high wind speeds.”

- Current Efficiency Statistics: As of 2025, directional ventilators continue to demonstrate exceptional efficiency, with energy-saving ratios reaching as high as 13.94% under ideal conditions. This efficiency is particularly noteworthy in applications requiring high airflow at low pressures, such as heating and cooling systems and industrial ventilation.

In summary, axial HVAC fans are characterized by their high efficiency, versatility, and low maintenance requirements, making them an invaluable asset in various engineering applications.

Conclusion

Axial HVAC fans are essential in optimizing air circulation and efficiency across diverse engineering applications. Their capability to move substantial volumes of air at low pressure positions them as a premier choice for various environments, ranging from residential HVAC systems to industrial cooling setups. This article has delved into the fundamental characteristics, advantages, and limitations of axial fans, underscoring their critical role in contemporary engineering solutions.

Key insights reveal their high airflow capacity, energy efficiency, and compact design, which together lead to reduced operational costs and enhanced performance. Furthermore, comprehending the distinctions between axial and centrifugal fans empowers engineers to make informed decisions tailored to specific application requirements. The discussion surrounding maintenance strategies further emphasizes the necessity of regular upkeep to ensure longevity and optimal functionality.

Given these insights, engineers are urged to view axial HVAC fans not merely as components but as integral systems that can profoundly influence energy efficiency and operational effectiveness. By harnessing the latest trends and innovations in axial fan technology, professionals can optimize their designs and foster sustainable practices within the HVAC industry.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized for delivering innovative solutions specifically designed for axial HVAC fans, offering a comprehensive portfolio that includes advanced cooling, power management, timing, RF, and interconnect technologies to optimize fan performance.

How does Gagner-Toomey Associates support engineers?

Gagner-Toomey Associates partners with exceptional manufacturers to provide engineers with access to cutting-edge products that meet market demands. They employ a consultative approach and prioritize attentive customer service, making them a trusted ally for engineers in the HVAC industry.

What are axial HVAC fans and how do they work?

Axial HVAC fans are air circulation units designed to move air parallel to the device’s axis using blades mounted on a rotating shaft. They efficiently draw air in from one side and expel it from the other, making them effective for ventilation and cooling applications.

What are the key features of axial HVAC fans?

Key features of axial HVAC fans include high airflow capacity, energy efficiency, compact design, low noise operation, and durability. These features enhance their performance and make them suitable for various applications.

How do axial HVAC fans contribute to energy savings?

Axial HVAC fans are designed to consume significantly less power than traditional fan types, potentially saving businesses up to 30% on electricity bills, which reduces overall operational costs.

In what applications are axial HVAC fans commonly used?

Axial HVAC fans are used in various applications, including agricultural settings for drying grains and ventilating barns, as well as in data centers to manage temperatures by moving large quantities of air.

What are the benefits of the design of axial HVAC fans?

The compact design of axial HVAC fans allows for easy installation in confined spaces, and their low noise operation is beneficial in environments where sound reduction is important. Additionally, they are built from durable materials for longevity.

What trends are shaping the future of axial HVAC fans?

The emphasis on energy efficiency in axial heating and cooling systems is increasing, with manufacturers developing advanced technologies that enhance performance while reducing energy usage, supporting operational efficiency and global sustainability goals.