Overview

This article delineates ten significant benefits of axial blower fans tailored specifically for electronics cooling, underscoring their efficiency, compact design, high airflow capacity, and cutting-edge technology. Each benefit is substantiated by robust evidence illustrating performance enhancements, energy savings, and versatility across various applications. This comprehensive analysis demonstrates how these fans effectively improve thermal management within electronic systems, providing actionable insights for professionals seeking optimal cooling solutions.

Introduction

Axial blower fans have emerged as essential components in the realm of electronics cooling, providing a compelling blend of efficiency, versatility, and advanced technology. As industries confront the escalating heat generated by high-performance electronics, these fans offer a robust solution that not only enhances thermal management but also contributes to significant energy savings and reduced operational costs.

With a plethora of options available, engineers face the critical challenge of selecting the right axial blower fan for their specific applications. This article explores ten key benefits of axial blower fans, illuminating their vital role in optimizing cooling systems for electronics while addressing the challenges encountered by modern engineers.

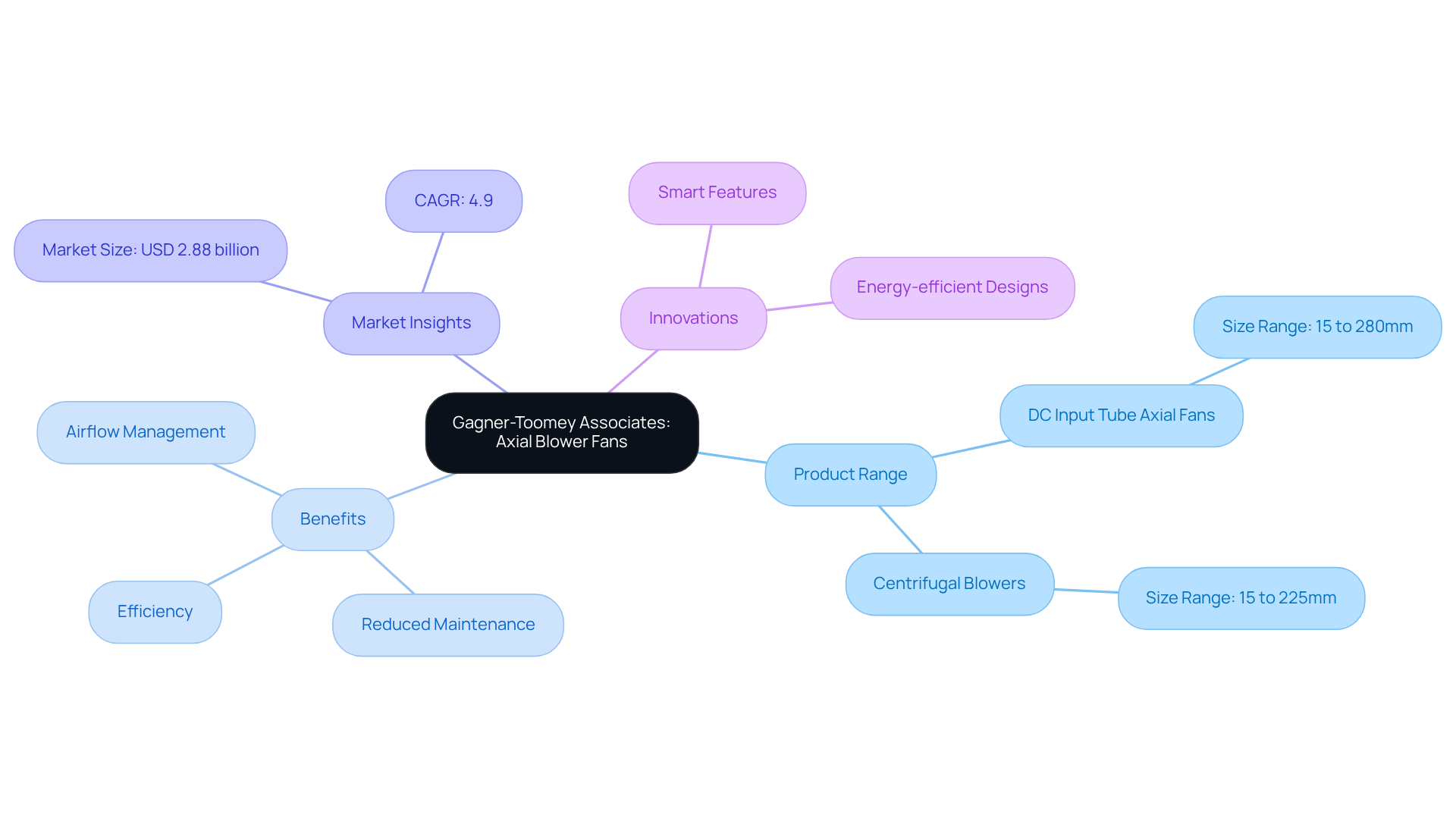

Gagner-Toomey Associates: Leading Provider of Axial Blower Fans for Electronics Cooling

Gagner-Toomey Associates excels in delivering ventilation devices meticulously crafted for electronics heat dissipation applications. As the world’s foremost producer of both standard and custom air-movers, Gagner-Toomey guarantees that engineers are equipped with cutting-edge temperature management solutions designed to meet the rigorous demands of the electronics industry. Their extensive product range encompasses:

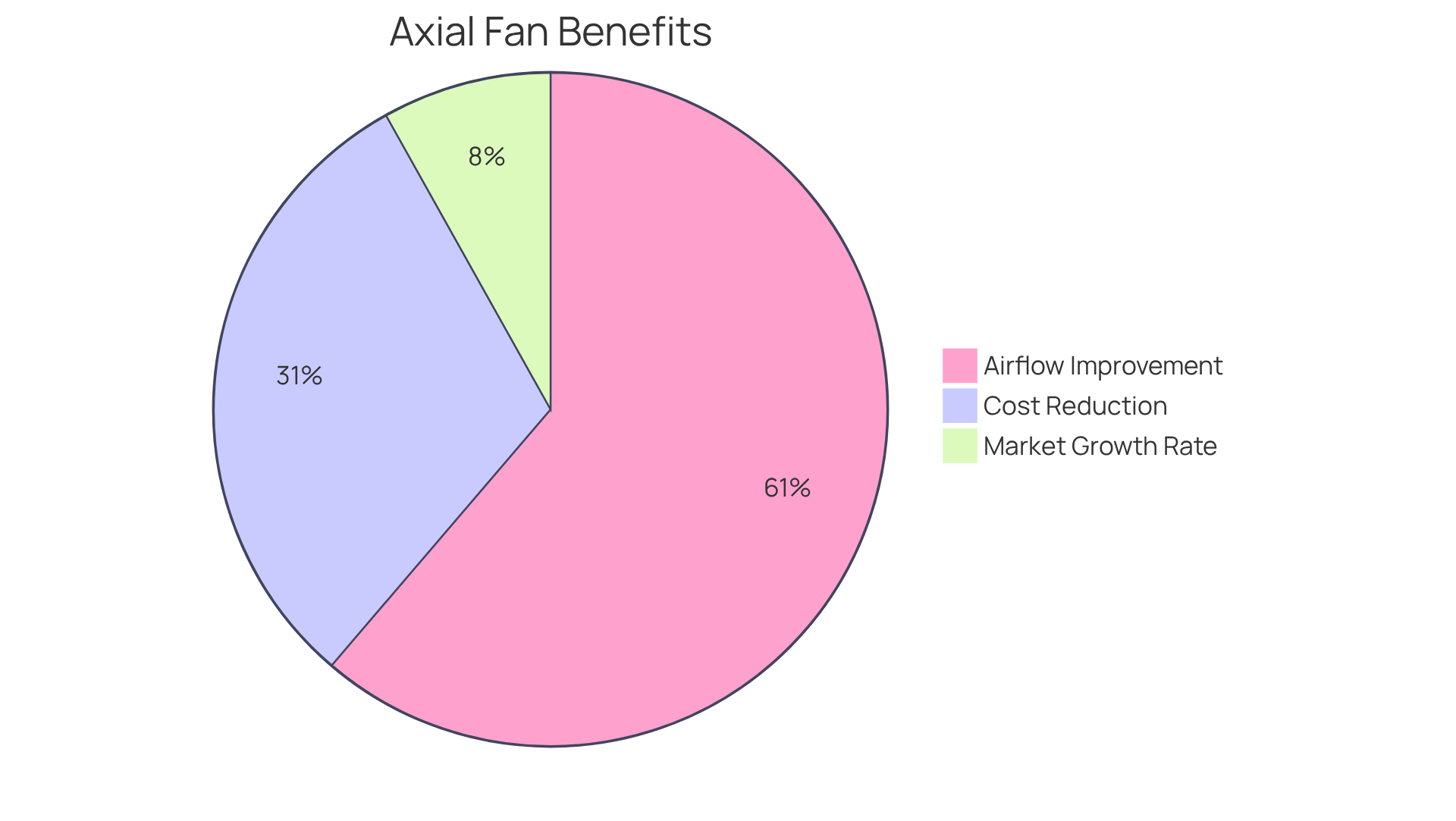

- DC input tube axial fans spanning from 15 to 280mm

- Centrifugal blowers ranging from 15 to 225mm

These products are engineered for optimal performance, efficiency, and minimal noise, with IP protection available in most models upon request. The benefits of these ventilation devices include exceptional efficiency, reduced maintenance costs, and the ability to manage diverse airflow and pressure requirements, making them ideal for critical cooling operations. Market analysis indicates that the fan market size was valued at USD 2.88 billion in 2024, with a projected CAGR of 4.9% from 2025 to 2030. As advancements in axial blower fan technology progress, innovations like smart features for remote monitoring and energy-efficient designs are becoming more prevalent. Gagner-Toomey’s unwavering commitment to quality is reflected in their comprehensive portfolio, which showcases advanced thermal management solutions, including extruded aluminum heatsinks and integrated temperature regulation systems. This steadfast dedication to exemplary customer service solidifies Gagner-Toomey’s position as a trusted partner for engineers seeking reliable and efficient .

Energy Efficiency: Reduce Power Consumption with Axial Blower Fans

Axial blower fans are engineered for optimal efficiency, leading to substantial reductions in power consumption when compared to traditional cooling methods. By leveraging advanced motor technologies alongside innovative aerodynamic designs, these units deliver impressive airflow rates while minimizing energy usage. For example, FläktGroup’s latest fan demonstrates a remarkable 15% enhancement in air movement capacity, highlighting significant advancements in this sector. This efficiency not only results in lower operational costs but also contributes to a diminished carbon footprint, which resonates with the objectives of environmentally conscious organizations.

While directional blowers can achieve , it is crucial to recognize that specific percentages may fluctuate depending on the application and design. Experts assert that the integration of smart technology further amplifies the operational efficiency of devices like the axial blower fan, facilitating real-time monitoring and adjustments to optimize energy use. Moreover, routine maintenance every 6-12 months is advisable to ensure the longevity and reliable performance of ventilation units.

As industries increasingly prioritize sustainability, the axial blower fan stands out as a viable solution for achieving both performance and ecological goals. Engineers must consider these factors when selecting axial devices, as doing so can lead to improved efficiency and effectiveness in refrigeration applications.

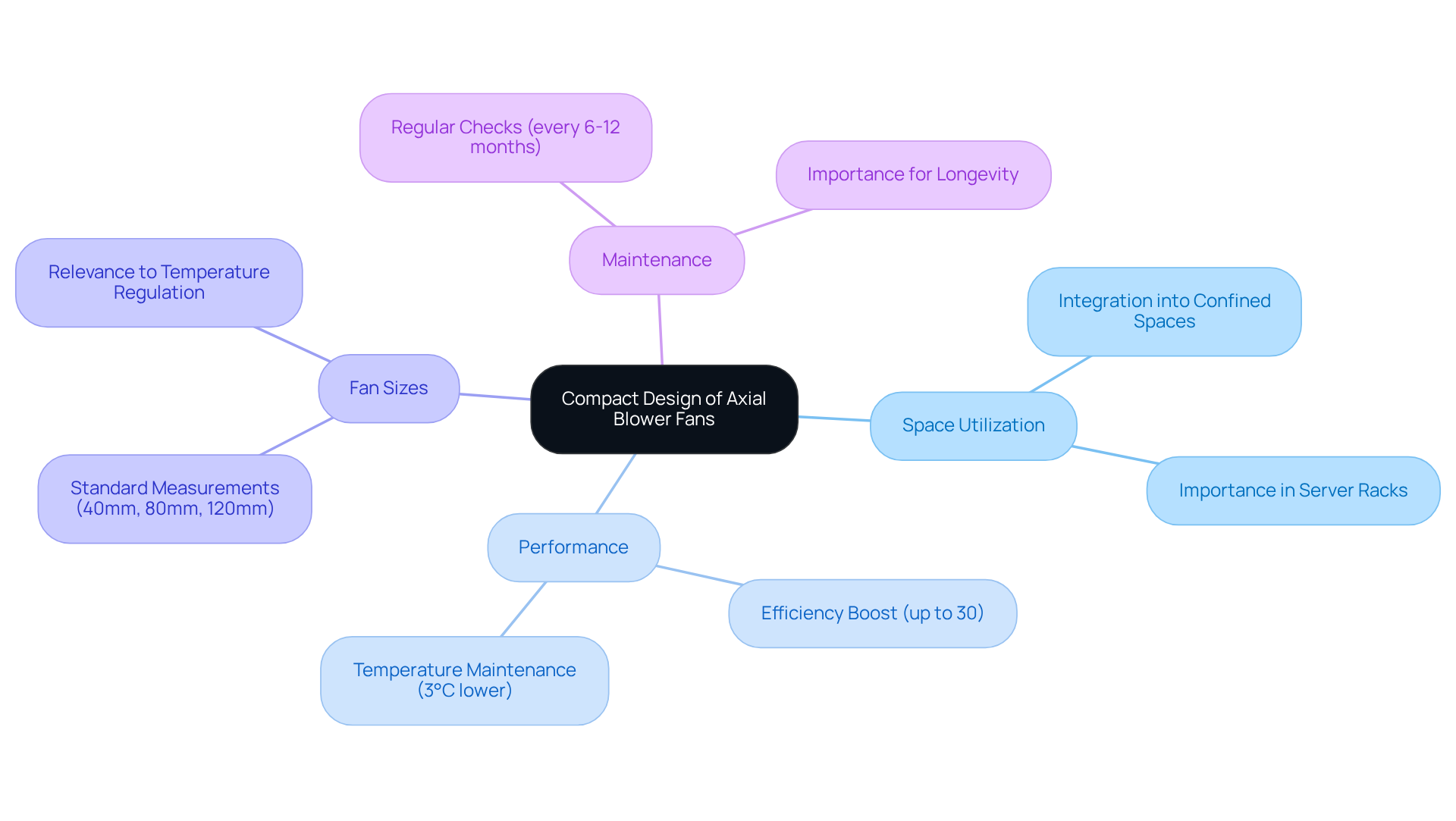

Compact Design: Maximize Space Utilization in Electronics Cooling

Axial blower fans are engineered with a compact structure that facilitates seamless integration into confined spaces within electronic systems. Their streamlined profiles empower engineers to optimize space utilization without compromising thermal performance. This advantage is particularly significant in environments such as server racks, where an axial blower fan is essential for maximizing every inch to ensure and maintain optimal operating temperatures.

For instance, optimizing fan size can result in an efficiency boost of up to 30%. Furthermore, static pressure fans can maintain CPU temperatures up to 3 degrees Celsius lower than ventilation fans, thereby enhancing performance. The ability to adjust fan sizes, including standard measurements like 40mm, 80mm, and 120mm, ensures that specific temperature regulation requirements are met, further bolstering the efficiency of thermal management strategies in electronics.

As emphasized by Gagner-Toomey Associates:

- “Choosing the appropriate axial blower fan is essential for ensuring optimal temperature regulation in electronic systems,” underscoring the critical importance of fan selection.

Additionally, it is advisable to conduct regular maintenance of axial units every 6-12 months to guarantee reliable operation and longevity.

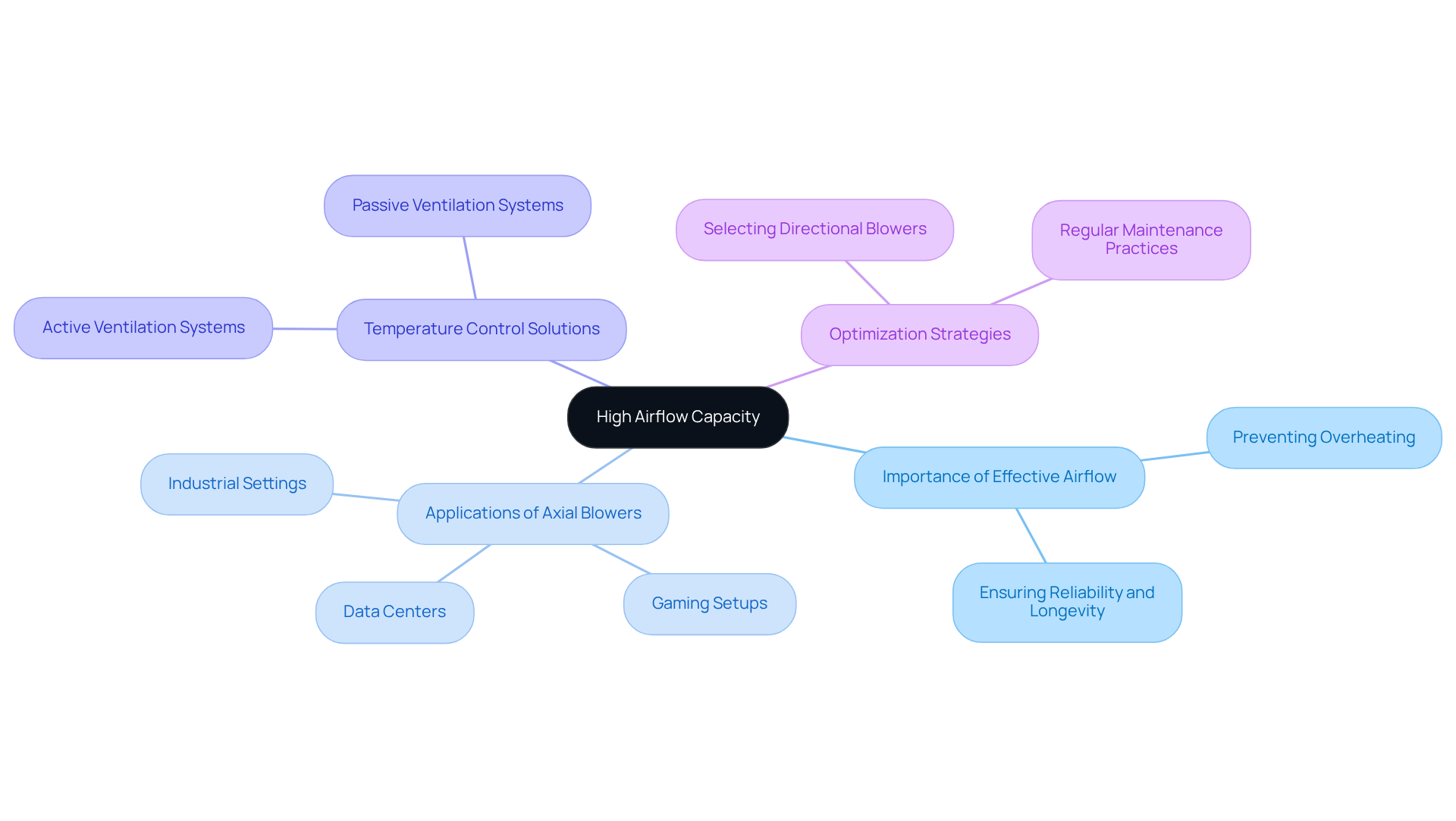

High Airflow Capacity: Enhance Cooling Performance in Electronics

Axial blowers are distinguished by their exceptional ability to deliver high airflow capacity, a critical attribute for ventilating high-performance electronics such as CPUs and GPUs that produce considerable heat during operation. These devices proficiently circulate substantial volumes of air, which is vital for maintaining optimal temperatures.

In high-performance computing environments, effective airflow is paramount for preventing overheating, a condition that can lead to premature component failure. Experts emphasize that robust temperature control solutions are indispensable for ensuring reliability and longevity.

Axial blower fans have proven their worth across various applications, including data centers and gaming setups, where maintaining low temperatures is essential for performance and stability. Notably, these devices can handle significant airflows at low to moderate pressures, making them versatile for diverse temperature regulation needs.

To optimize thermal performance, it is advisable to select directional blowers tailored to specific requirements, thereby ensuring in sophisticated electronic systems.

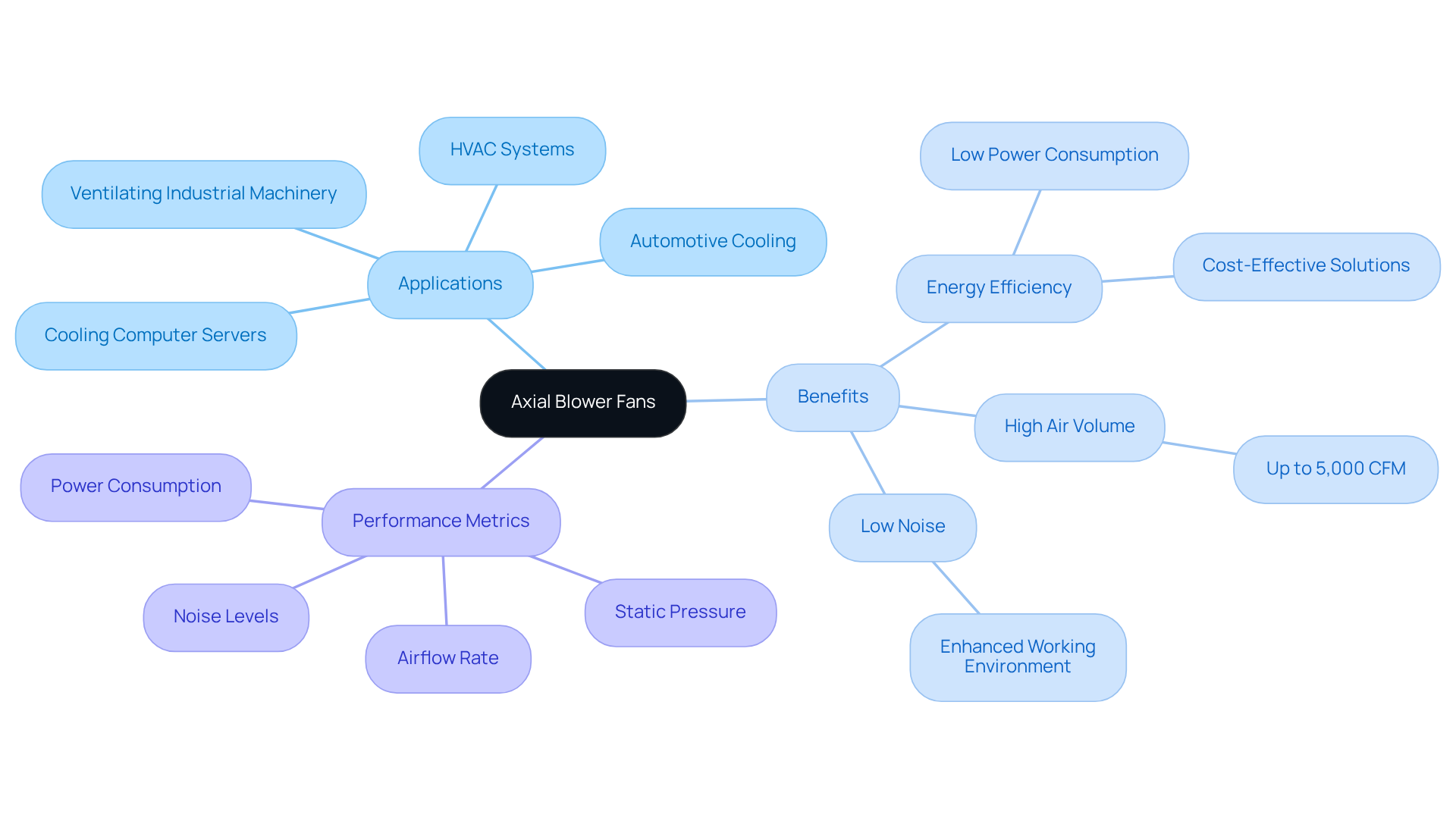

Versatility: Adapt Axial Blower Fans for Diverse Electronics Applications

The versatility of axial blower fans exemplifies their suitability as ideal solutions for a wide array of electronics applications, ranging from cooling computer servers to ventilating industrial machinery. Their innovative design facilitates effective operation across diverse environments, catering to both consumer electronics and heavy-duty industrial requirements.

In server rooms, for instance, cylindrical ventilators play a crucial role in maintaining optimal temperatures by ensuring a steady airflow across heat-producing components. Similarly, in manufacturing environments, these units enhance ventilation and exhaust, thereby fostering safe working conditions.

Notably, statistics indicate that these blowers can move up to 5,000 cubic feet of air per minute, underscoring their capability to manage substantial volumes efficiently. Furthermore, the axial blower fan is lauded for its energy efficiency; it can transport large air volumes with minimal power consumption, rendering it a cost-effective choice for engineers.

Additionally, they generate less noise than other fan types, which enhances their appeal in both consumer and industrial settings. This flexibility empowers engineers to tailored to specific temperature management needs, ultimately boosting performance and reliability across various applications.

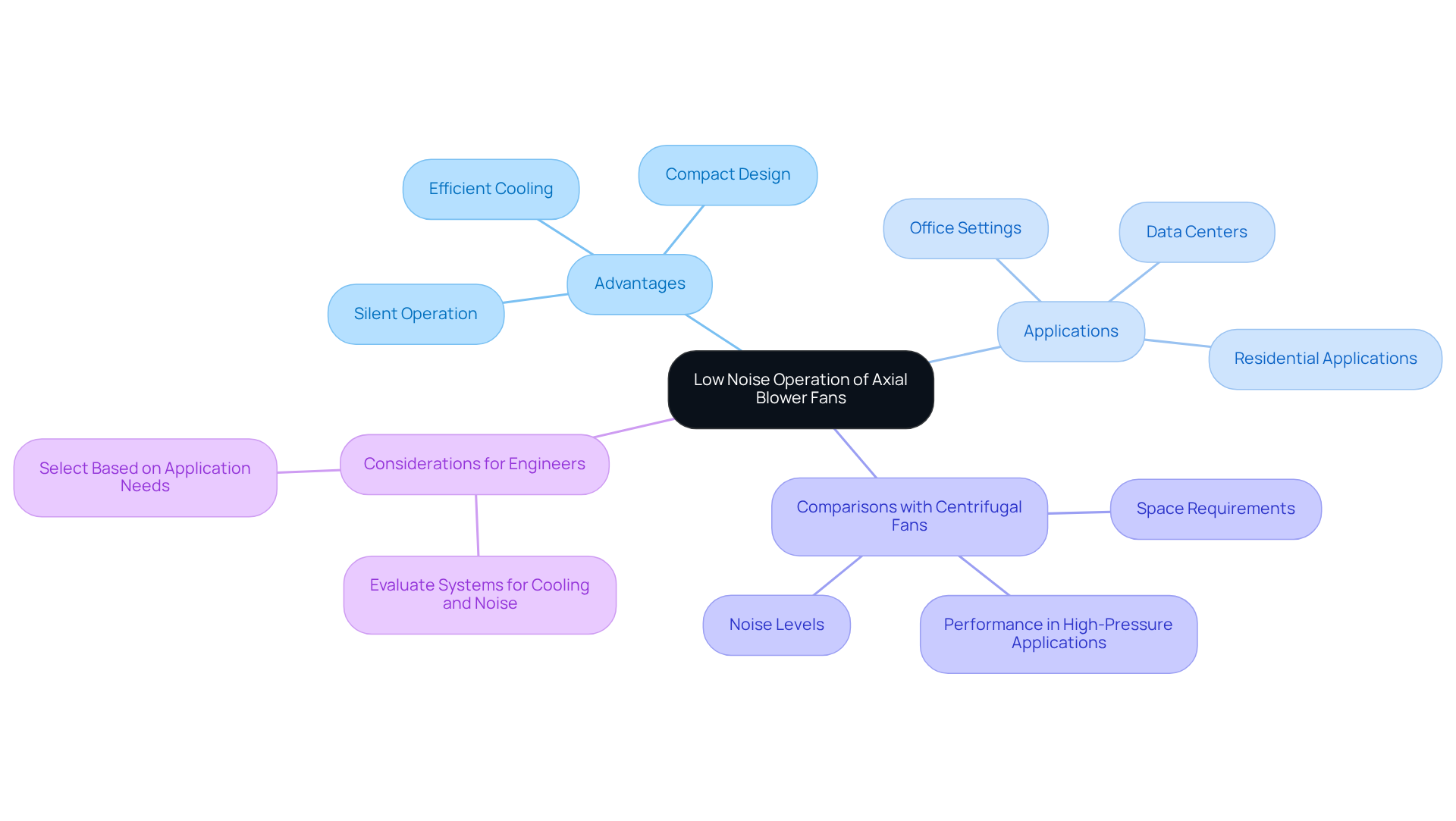

Low Noise Operation: Maintain Quiet Environments with Axial Blower Fans

Axial blower fans are engineered for silent operation, making them ideal for environments where noise reduction is paramount. With advanced motor control and aerodynamic designs, the axial blower fan units minimize turbulence and noise output, enabling effective cooling without disturbing the surrounding atmosphere. This characteristic is especially advantageous in office settings, data centers, and residential applications where a tranquil environment is crucial. Notably, the axial blower fan in EC ventilation systems has been proven to deliver quieter and more efficient performance, a necessity in noise-sensitive contexts.

Practical applications in data centers indicate that the implementation of specific ventilation devices has led to , enhancing overall operational efficiency and creating a more conducive working environment. In contrast to centrifugal units, which tend to produce more noise and require additional space, the axial blower fan and other straight-through ventilators offer a compact and quieter alternative, making them a preferred choice for engineers looking to optimize their temperature regulation systems.

Given these advantages, engineers should carefully evaluate ventilation systems for their specific applications to achieve both efficient cooling and noise minimization.

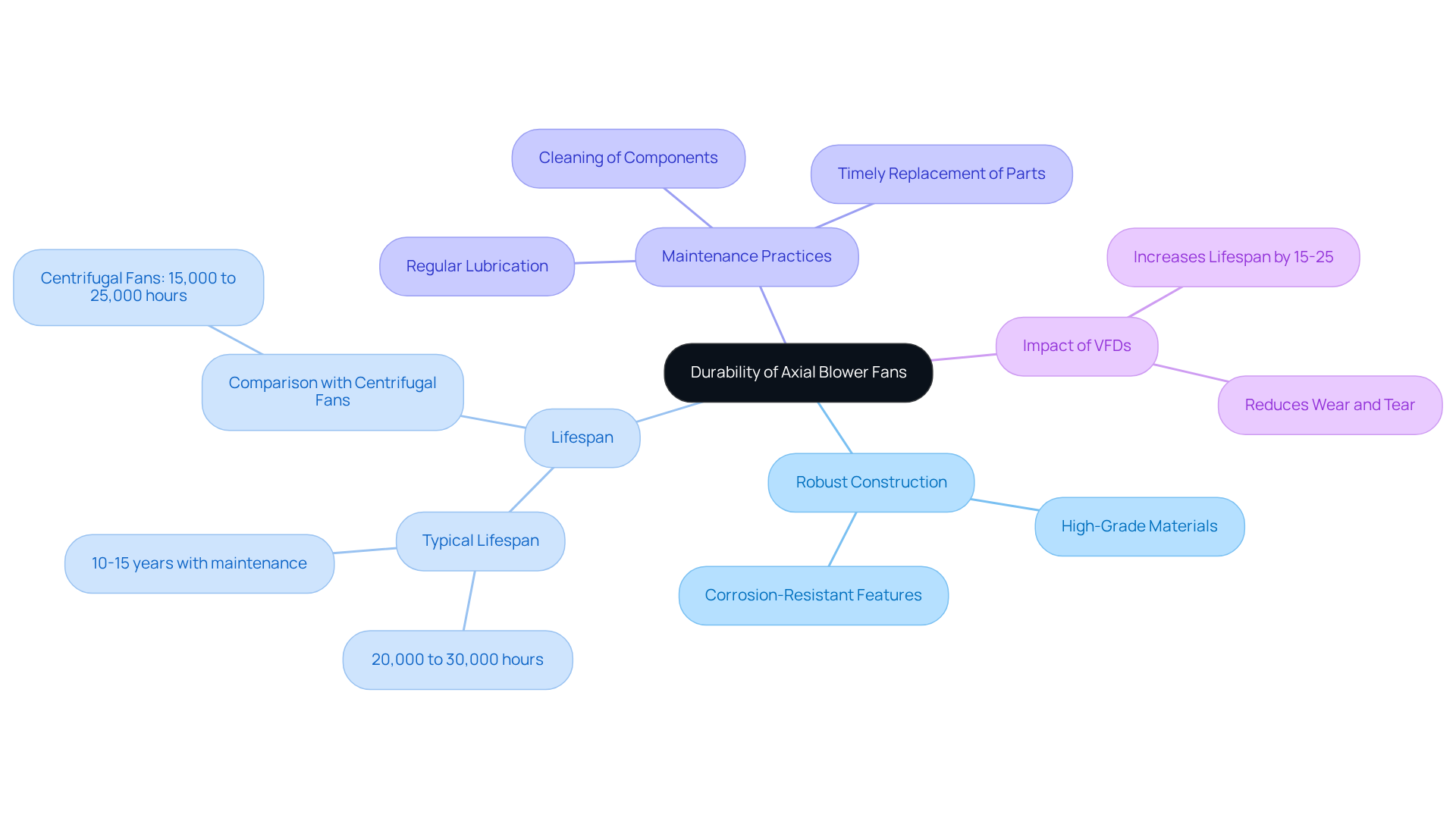

Durability: Ensure Long-Term Reliability with Axial Blower Fans

Axial ventilation devices exemplify durability, featuring robust construction and premium materials that guarantee long-term dependability. Their design significantly reduces wear and tear, facilitating consistent performance over extended periods. This durability is particularly essential in industrial environments, where equipment frequently endures harsh conditions and continuous operation.

For instance, tube-shaped blowers typically offer a lifespan of 20,000 to 30,000 hours, translating to approximately 2.3 to 3.4 years, which notably exceeds many alternatives. By investing in reliable ventilation devices, companies can enhance operational efficiency while reducing maintenance costs and downtime.

Regular maintenance practices, such as lubrication and cleaning, can further extend their lifespan, allowing these devices to operate efficiently for up to 10-15 years. Moreover, the integration of variable frequency drives (VFDs) can increase fan lifespan by 15-25%. This combination of longevity and positions the axial blower fan as an exceptional choice for temperature regulation in demanding settings.

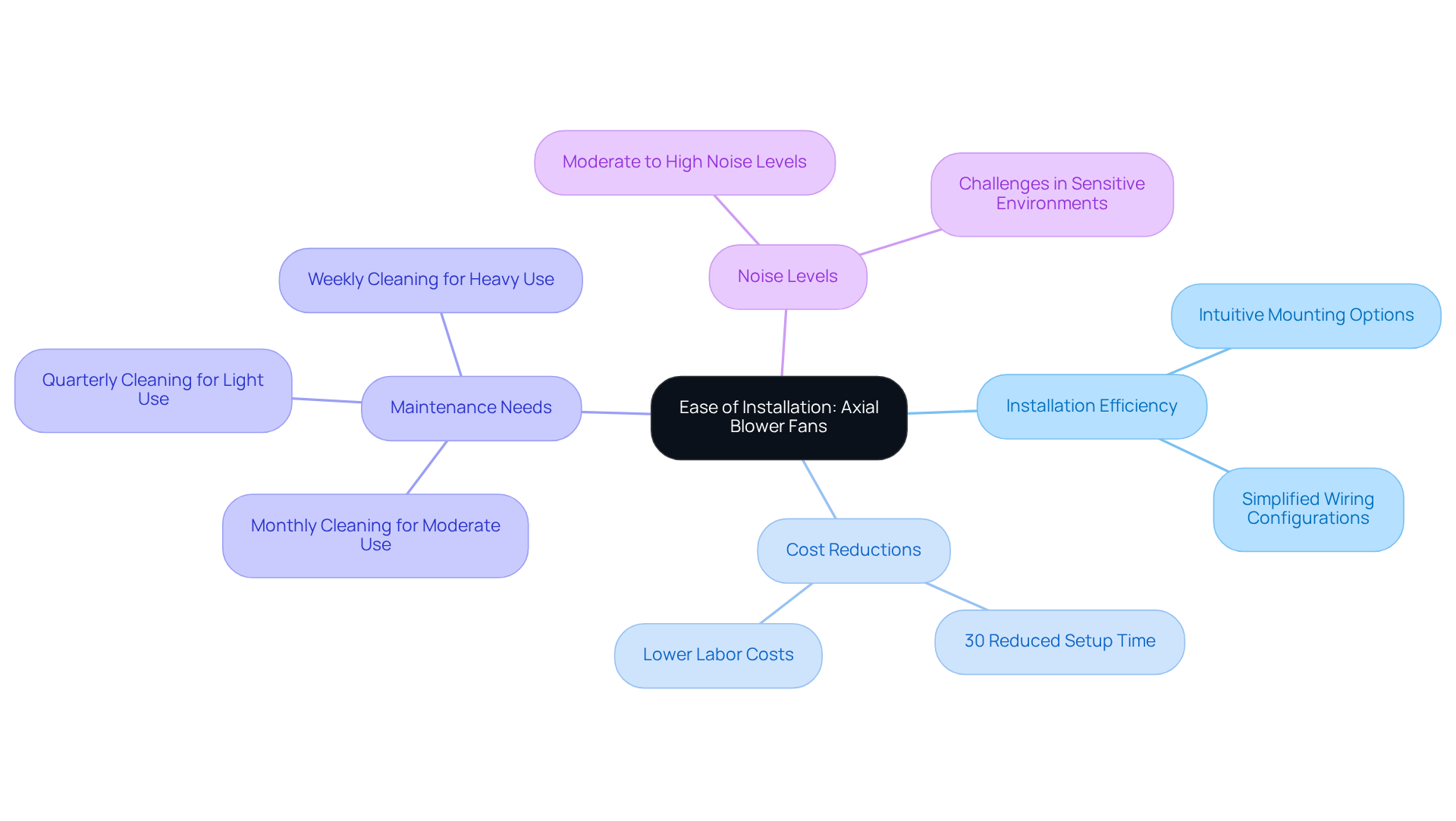

Ease of Installation: Simplify Setup with Axial Blower Fans

Axial blower fan units are engineered for effortless installation, featuring intuitive mounting options and simplified wiring configurations. This innovative design facilitates rapid setup, enabling engineers and technicians to with remarkable efficiency, thereby significantly reducing both installation time and labor costs. The straightforward characteristics of these devices, such as the axial blower fan, allow for seamless incorporation into new designs or modifications of existing systems, making them an exceptional choice for a wide range of applications.

Notably, the labor cost reductions associated with the deployment of these ventilation units can be substantial; practical instances demonstrate that businesses have successfully decreased setup durations by as much as 30% through their use. Furthermore, regular maintenance, including monthly cleaning cycles for moderate use, is crucial for maintaining optimal airflow and minimizing energy expenses.

It is also essential to recognize that noise levels may pose challenges in sensitive environments, underscoring the importance of operational efficiency in rotating devices when considering their application.

Cost-Effectiveness: Optimize Budget with Axial Blower Fans

Axial blower fans offer an exceptionally economical solution, delivering outstanding performance without straining budgets. Their can facilitate operational cost reductions of up to 20%, while their robust construction minimizes replacement frequency, further amplifying savings. Additionally, these ventilators typically produce less noise than air movers, rendering them suitable for noise-sensitive applications. Over time, organizations employing axial blower fans can realize substantial financial benefits, making them an ideal choice for engineers and managers focused on budget optimization.

The fan market is anticipated to grow at a rate of 5.3% from 2025 to 2032, reflecting an increasing demand for these efficient solutions. Moreover, the integration of EC technology in these devices can enhance airflow by as much as 40% compared to conventional AC models, providing even greater efficiency and value. By investing in directional air mover units, organizations not only enhance their temperature management capabilities but also secure long-term savings, reinforcing their position as a prudent choice in the electronics temperature regulation sector.

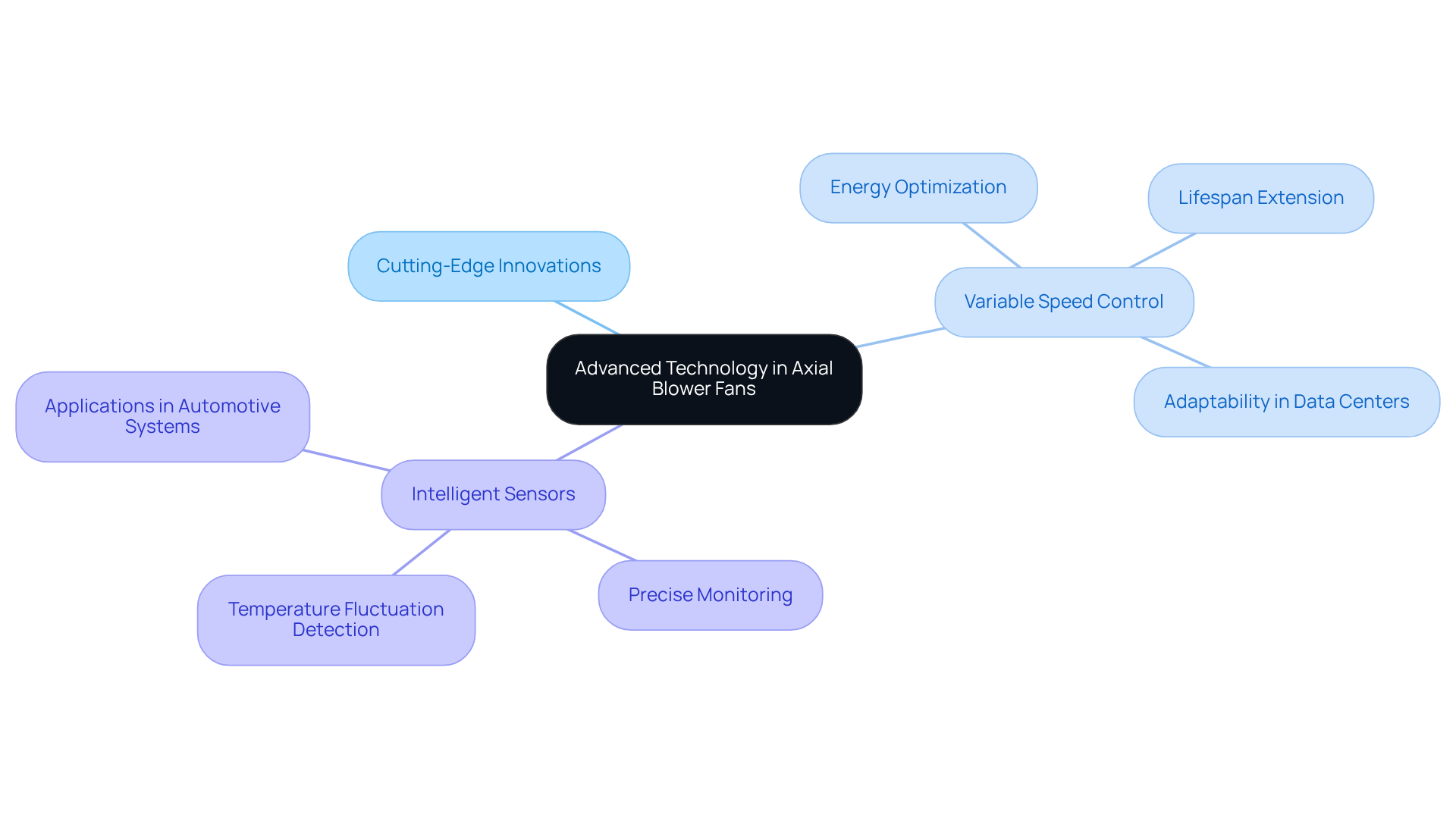

Advanced Technology: Leverage Cutting-Edge Features of Axial Blower Fans

Modern axial blower fans are at the forefront of technological advancement, featuring cutting-edge innovations such as variable speed control and intelligent sensors that significantly enhance their operational performance. empowers these devices to dynamically adjust their performance in response to immediate temperature requirements. This adaptability not only optimizes energy consumption but also extends the lifespan of electronic components by ensuring they operate within optimal temperature ranges. In environments with fluctuating temperature control needs, such as data centers, these devices can modulate their speed to provide the necessary airflow, effectively minimizing energy waste.

Intelligent sensors further elevate the performance of ventilation devices by facilitating precise monitoring of environmental conditions. These sensors detect temperature fluctuations and adjust fan speeds accordingly, ensuring that ventilation is activated only when necessary. This technology proves particularly advantageous in high-density electronic systems, where the risk of overheating can lead to performance degradation or system failure.

The practical applications of variable speed control are evident in automotive temperature management systems, where ventilation devices are crucial for regulating the thermal environment of engines and electronic components. By integrating these advanced features, engineers can create more efficient and reliable thermal solutions, ultimately enhancing the performance and longevity of electronic systems. The incorporation of these technologies positions the axial blower fan as an indispensable component in contemporary electronics cooling strategies.

Conclusion

Axial blower fans signify a crucial advancement in electronics cooling, presenting a range of benefits that meet the industry’s evolving demands. Their design not only boosts energy efficiency but also maximizes space utilization, ensuring optimal performance even in the most confined environments. By integrating advanced technology and innovative features, these fans provide exceptional airflow capacity while maintaining low noise levels, making them an ideal choice for both consumer and industrial applications.

Key points highlighted throughout this discussion include:

- The energy savings associated with axial blower fans

- Their durability and ease of installation

- Their versatility across various electronics applications

Their ability to adapt to different cooling requirements, combined with their cost-effectiveness, positions axial blower fans as a smart investment for engineers and organizations alike. Moreover, the commitment of providers like Gagner-Toomey Associates to quality and innovation guarantees that these solutions remain at the forefront of thermal management strategies.

In conclusion, adopting axial blower fans transcends a mere technical choice; it represents a strategic decision that can significantly enhance operational efficiency and sustainability in electronic systems. As industries increasingly prioritize performance and eco-friendliness, leveraging these advanced cooling solutions will be essential. Embracing the benefits of axial blower fans can lead to improved reliability, reduced costs, and a more effective approach to managing heat in electronic applications.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in delivering ventilation devices for electronics heat dissipation applications, particularly as a leading provider of axial blower fans.

What types of fans does Gagner-Toomey offer?

Gagner-Toomey offers DC input tube axial fans ranging from 15 to 280mm and centrifugal blowers ranging from 15 to 225mm.

What are the benefits of using Gagner-Toomey’s ventilation devices?

The benefits include exceptional efficiency, reduced maintenance costs, and the ability to manage diverse airflow and pressure requirements, making them ideal for critical cooling operations.

How large is the fan market, and what is its projected growth?

The fan market was valued at USD 2.88 billion in 2024, with a projected compound annual growth rate (CAGR) of 4.9% from 2025 to 2030.

What advancements are being made in axial blower fan technology?

Advancements include smart features for remote monitoring and energy-efficient designs, enhancing the overall performance and efficiency of the fans.

How do axial blower fans contribute to energy efficiency?

Axial blower fans are designed for optimal efficiency, leading to significant reductions in power consumption compared to traditional cooling methods, resulting in lower operational costs and a reduced carbon footprint.

What maintenance is recommended for axial blower fans?

Routine maintenance every 6-12 months is advisable to ensure the longevity and reliable performance of the ventilation units.

How do axial blower fans maximize space utilization in electronics cooling?

Their compact design allows for seamless integration into confined spaces within electronic systems, optimizing space without compromising thermal performance, particularly in environments like server racks.

What is the impact of optimizing fan size in electronic systems?

Optimizing fan size can lead to an efficiency boost of up to 30%, and static pressure fans can maintain CPU temperatures up to 3 degrees Celsius lower than ventilation fans.

What should engineers consider when selecting axial blower fans?

Engineers should consider the specific temperature regulation requirements and the importance of fan selection to ensure optimal temperature management in electronic systems.