Overview

This article delineates four best practices for the effective utilization of blowers in cooling systems:

- Proper sizing

- Strategic placement

- Advanced control systems

- Regular maintenance

These practices are essential for ensuring optimal thermal management and reliability in electronic applications. By enhancing airflow efficiency, reducing energy consumption, and prolonging the lifespan of cooling components, these strategies not only address critical challenges but also provide actionable insights for implementation.

Introduction

The efficiency of electronic cooling systems is fundamentally dependent on the effective utilization of blowers, which play a critical role in managing the heat generated by sensitive components. Understanding the unique roles and types of blowers allows engineers to optimize their cooling strategies, ensuring that devices operate at safe temperatures while enhancing both performance and longevity. However, a significant challenge persists: how can one adeptly navigate the complexities of blower selection and integration to circumvent common pitfalls that result in inefficiencies and increased costs?

Understand the Role of Blowers in Electronic Cooling

The blower for cooling plays a pivotal role in effective thermal management within electronics, generating high-pressure currents that efficiently dissipate heat from critical components. Unlike standard fans, which primarily circulate air, these devices are engineered to move air against resistance, rendering them particularly suitable for applications requiring . This capability is vital in electronics, where overheating can drastically affect performance and longevity.

Engineers must thoroughly comprehend the specific cooling requirements of their systems to select the appropriate blower for cooling and configuration for optimal thermal management. For instance, fans are frequently paired with heat sinks to enhance heat dissipation, ensuring that sensitive components maintain safe operating temperatures.

Case studies demonstrate that the consistent use of compact fans not only reduces maintenance costs but also prolongs the lifespan of electronic devices by effectively eliminating dust and debris, common culprits of overheating. Furthermore, energy-efficient fans can decrease energy consumption by as much as 30%, aligning with the industry’s growing emphasis on sustainability while simultaneously improving overall efficiency.

Explore Different Types of Blowers and Their Applications

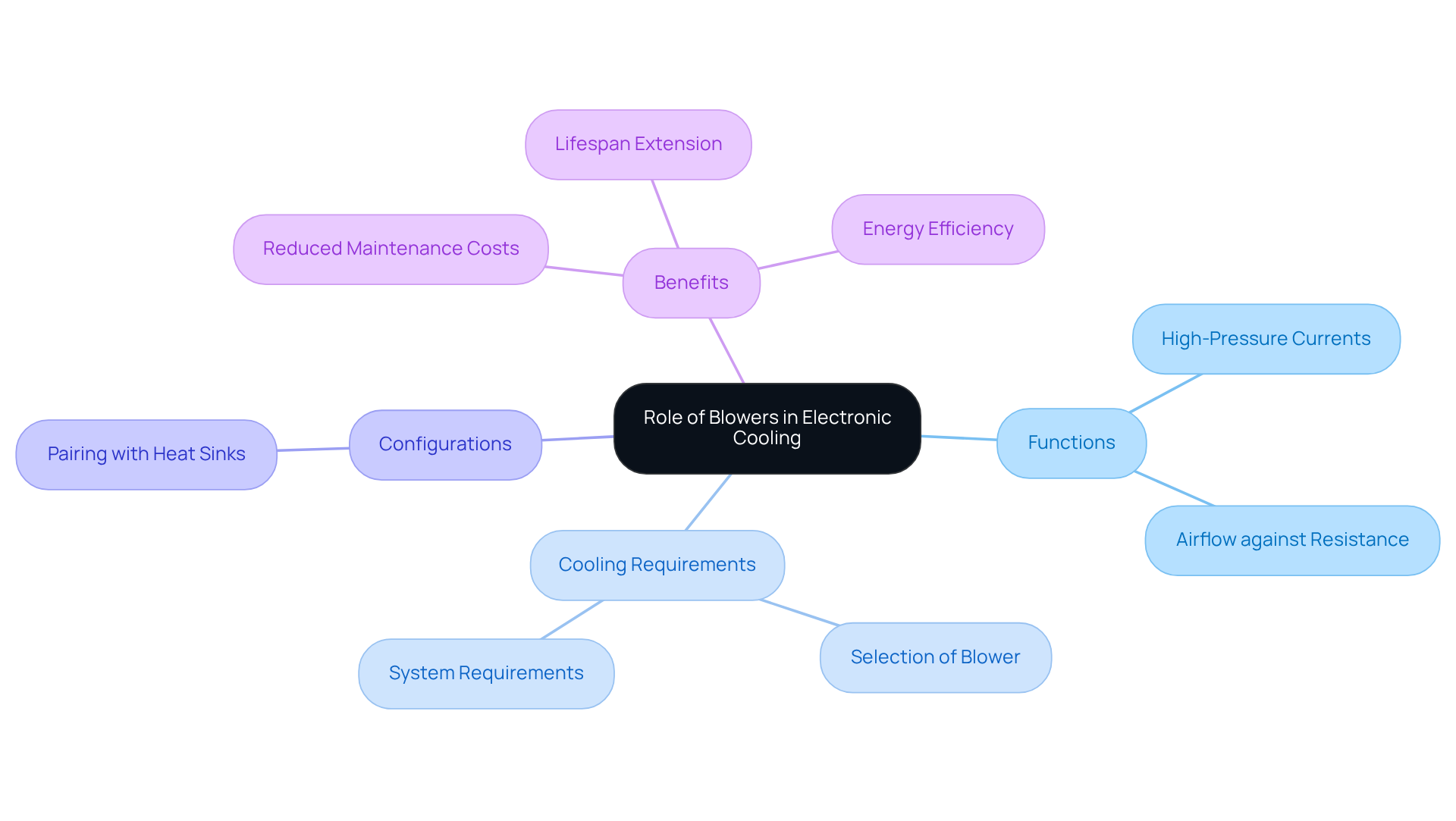

In electronic cooling systems, selecting the appropriate blower for cooling is essential for optimizing performance. The primary types of blowers include:

- Centrifugal Fans: Utilizing an impeller, these devices draw air in and expel it at a right angle, generating high pressure and velocity. They excel in applications that require significant movement of air against resistance, making them ideal for HVAC systems and industrial cooling environments. The MB Series S Type centrifugal fan, for example, achieves a maximum static pressure of 1.81 inH2O, supports air movement rates up to 184 CFM, and operates effectively within an intake air temperature range of -10°C to +90°C (14°F to 194°F), demonstrating its efficiency in challenging conditions.

- Axial Blowers: These blowers move air parallel to the fan’s axis, providing a high volume of air at low pressure. They are especially beneficial in applications with limited space where large amounts of air are required, such as in computer temperature management. The MRS Series axial fans can achieve a maximum air movement of 547 CFM and a static pressure of up to 1.06 inH2O, making them suitable for general ventilation and cooling of electronic components.

- Positive Displacement Devices: Designed to trap a fixed volume of air and force it into the system, these devices maintain consistent airflow regardless of pressure fluctuations. They are commonly employed in pneumatic conveying and material handling applications, ensuring reliable performance in various industrial settings.

- Regenerative Fans: Known for their energy efficiency, regenerative fans are ideal for low-noise applications requiring high reliability, such as aquaculture and wastewater treatment. Their design allows for effective air movement while minimizing energy consumption.

Understanding the unique features and applications of each fan type, such as the blower for cooling, enables engineers to make informed choices tailored to their specific . This knowledge is vital for extending the lifespan of electronic components, as efficient temperature management can significantly lower operating temperatures and enhance overall reliability. As Johann Tang noted, “This reduction in temperature has numerous advantages, including extended lifespan, reduced maintenance, decreased downtime, improved production throughput, and increased profitability for the company.” Furthermore, engineers must be cautious of common errors in fan selection, as choosing the incorrect type can lead to inefficiencies and increased operational costs.

Implement Best Practices for Blower Integration in Systems

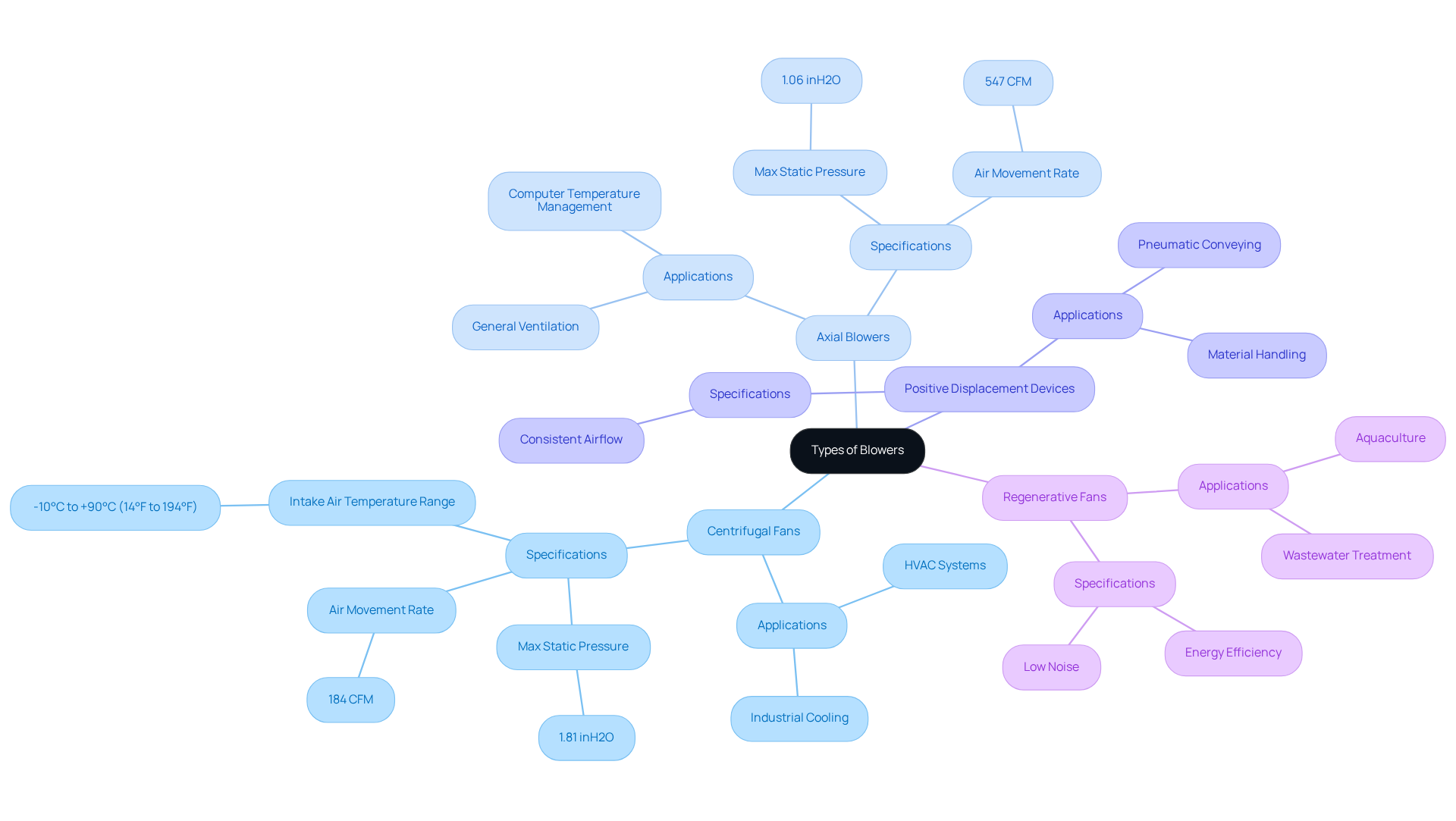

To achieve optimal performance when integrating blowers into electronic cooling systems, it is essential to consider the following best practices:

- Proper Sizing: Ensure that the fan is appropriately sized for the application. Oversized fans can result in excessive noise and energy use, while undersized units may not deliver sufficient cooling. Given that cooling systems account for approximately one-third of a data center’s overall energy usage, accurate calculations in sizing the blower for cooling are crucial.

- Strategic Placement: Position the blower to optimize the movement of air over essential components. This may involve utilizing ductwork or directing airflow to specific areas that generate the most heat. Case studies indicate that strategic placement can enhance cooling efficiency by as much as 25%, particularly in high-density environments.

- Control Systems: Implement advanced control systems, such as Model Predictive Control (MPC) and Reinforcement Learning (RL), which can adjust fan speed based on temperature readings. Blowers for cooling not only enhance energy efficiency but also reduce wear on components. Research suggests that employing these in refrigeration operations.

- Minimize Air Leaks: Ensure that all ductwork and connections are airtight to prevent air leaks, which can significantly diminish the efficiency of the refrigeration unit. Research indicates that even minor leaks can lead to a 10% reduction in cooling efficiency, underscoring the necessity of comprehensive sealing, especially since the blower for cooling and other cooling apparatuses consume nearly 50% of the energy in data centers.

- Regular Maintenance: Establish a maintenance schedule for the consistent cleaning and inspection of air movers. Dust and debris can severely impact performance, with neglected setups experiencing up to a 20% reduction in airflow efficiency. Regular maintenance is essential not only for performance but also to prevent mold and bacteria growth, which can compromise air quality and efficiency.

By adhering to these optimal methods, engineers can ensure that the blower for cooling is efficiently integrated into their setups, resulting in enhanced performance and reliability.

Maintain and Troubleshoot Blower Systems for Longevity

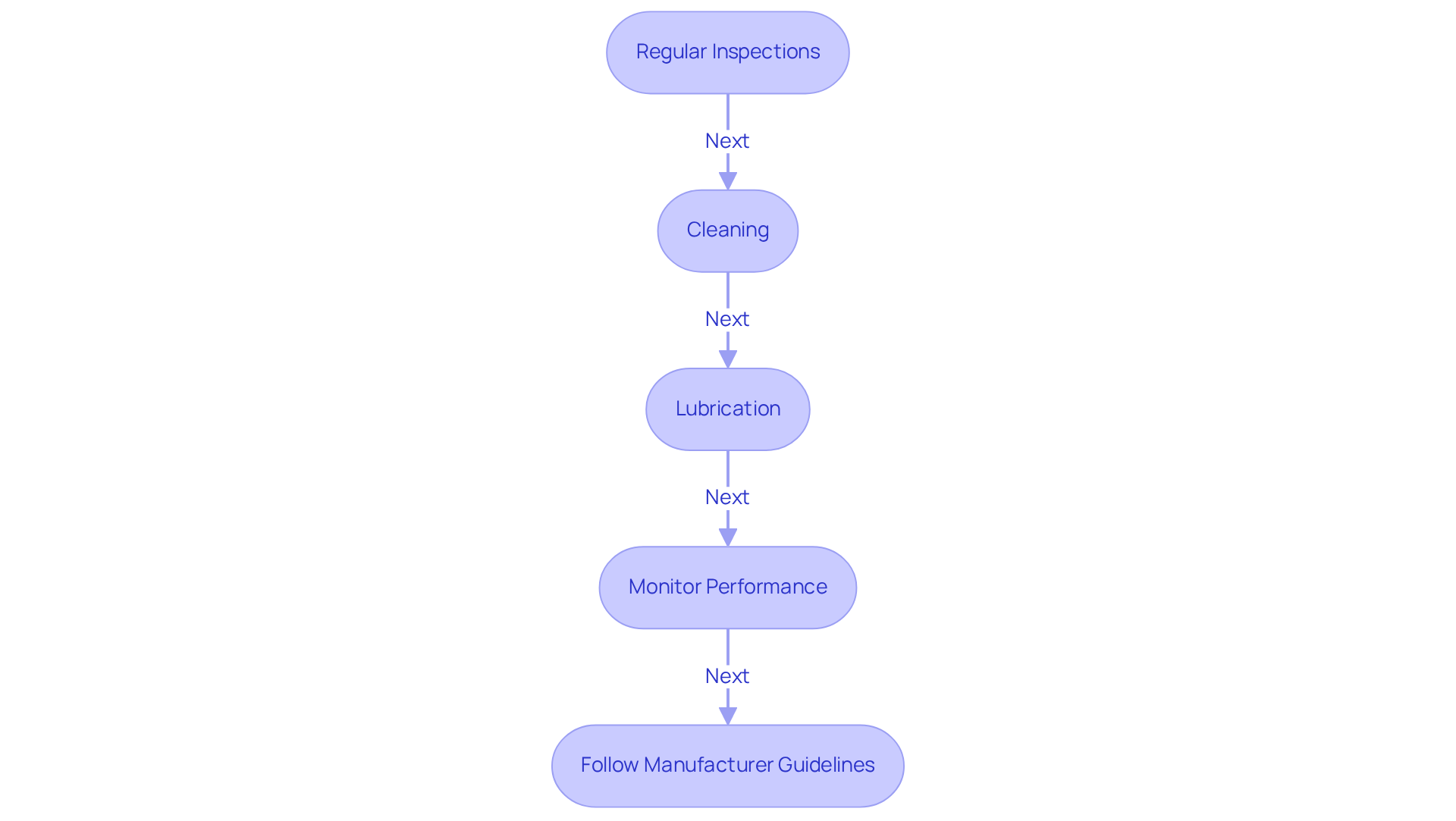

To effectively maintain and troubleshoot blower systems, it is essential to adhere to the following best practices:

- Regular Inspections: Conduct routine inspections to identify signs of wear, such as unusual noises, vibrations, or decreased airflow. Early detection is crucial; for instance, unusual sounds may indicate misalignment or internal issues that require immediate attention. Regular inspections can stop small issues from growing into major failures, ultimately prolonging the device’s lifespan.

- Cleaning: Regularly clean the blower and its components to eliminate dust and debris. This encompasses filters, impellers, and housing, which are essential for guaranteeing optimal ventilation and efficiency. Ignoring this can result in diminished performance and heightened energy usage, as blocked filters can significantly affect circulation.

- Lubrication: Ensure that all moving parts are lubricated according to the manufacturer’s specifications. Proper lubrication reduces friction and wear, significantly prolonging the device’s operational life. For example, well-lubricated bearings can reduce the risk of overheating and mechanical failure.

- Monitor Performance: Track key performance indicators, such as airflow and pressure. Significant deviations from normal operating conditions may signal a need for maintenance or adjustments. Regular monitoring can help identify issues before they lead to costly repairs, as increased energy costs without changes in consumption patterns often indicate diminished efficiency.

- Follow Manufacturer Guidelines: Adhere to the maintenance recommendations outlined in the device’s user manual, including service intervals and specific tasks. This organized method not only guarantees adherence to best practices but also improves the dependability of the ventilation device.

By implementing these maintenance and troubleshooting practices, engineers can significantly enhance the reliability and longevity of blower for cooling systems, ensuring consistent performance in electronic cooling applications. Regular maintenance not only improves efficiency but also contributes to a safer working environment by minimizing risks associated with dust accumulation and mechanical failures.

Conclusion

The effective use of blowers in cooling systems is crucial for maintaining optimal thermal management in electronic applications. Understanding the specific roles and types of blowers allows engineers to make informed decisions that enhance both performance and efficiency. This article outlines the importance of selecting the right blower, integrating it effectively, and implementing best practices for maintenance to ensure longevity and reliability.

Key insights discussed include the distinct functionalities of:

- Centrifugal fans

- Axial blowers

- Positive displacement devices

- Regenerative fans

Each serving unique applications in cooling systems. Furthermore, best practices such as:

- Proper sizing

- Strategic placement

- Advanced control systems

Are essential for maximizing cooling efficiency. Regular maintenance and troubleshooting techniques further contribute to the overall performance and lifespan of blower systems, preventing costly failures and inefficiencies.

In conclusion, the role of blowers in electronic cooling systems cannot be overstated. By prioritizing best practices and staying informed about the latest technologies and methods, engineers can significantly improve the reliability and efficiency of their cooling solutions. Embracing these strategies will not only enhance performance but also align with the industry’s growing focus on sustainability and energy efficiency. It is essential to take proactive steps in blower integration and maintenance to ensure that electronic systems operate at their best while minimizing energy consumption and extending equipment life.

Frequently Asked Questions

What is the primary function of blowers in electronic cooling?

The primary function of blowers in electronic cooling is to generate high-pressure currents that efficiently dissipate heat from critical components, aiding in effective thermal management.

How do blowers differ from standard fans?

Unlike standard fans, which primarily circulate air, blowers are engineered to move air against resistance, making them suitable for applications that require concentrated airflow.

Why is understanding cooling requirements important for engineers?

Understanding the specific cooling requirements of their systems is crucial for engineers to select the appropriate blower and configuration for optimal thermal management.

How are fans commonly used in conjunction with heat sinks?

Fans are frequently paired with heat sinks to enhance heat dissipation, ensuring that sensitive components maintain safe operating temperatures.

What benefits do compact fans provide in electronic devices?

Compact fans help reduce maintenance costs and prolong the lifespan of electronic devices by effectively eliminating dust and debris, which are common causes of overheating.

How can energy-efficient fans impact energy consumption?

Energy-efficient fans can decrease energy consumption by as much as 30%, which supports the industry’s focus on sustainability while improving overall efficiency.