Overview

The article delineates nine compelling benefits of centrifugal industrial fans specifically designed for electronics cooling, underscoring their efficiency, adaptability, and durability in sustaining optimal temperatures for electronic components. Each benefit—ranging from energy savings to consistent airflow and low noise operation—is substantiated by data and examples that illustrate how these fans not only enhance performance but also reduce operational costs and extend the lifespan of electronic devices across various applications.

Introduction

Centrifugal industrial fans are transforming the realm of electronics cooling, delivering a combination of efficiency, durability, and versatility that aligns with the demands of contemporary technology. As electronic devices grow increasingly compact and powerful, the necessity for effective thermal management has reached a critical juncture. This article delves into nine compelling advantages of centrifugal fans, ranging from energy savings that can substantially lower operational costs to their capability to sustain consistent airflow in high-pressure environments. However, with a plethora of options at hand, how can engineers and decision-makers ensure they are choosing the optimal cooling solutions for their specific applications?

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics

Gagner-Toomey Associates excels in delivering specifically designed for the electronics industry. By concentrating on and heat control, the company collaborates with a variety of producers to provide advanced . These devices are crucial in across diverse electronic applications, including power control cabinets and .

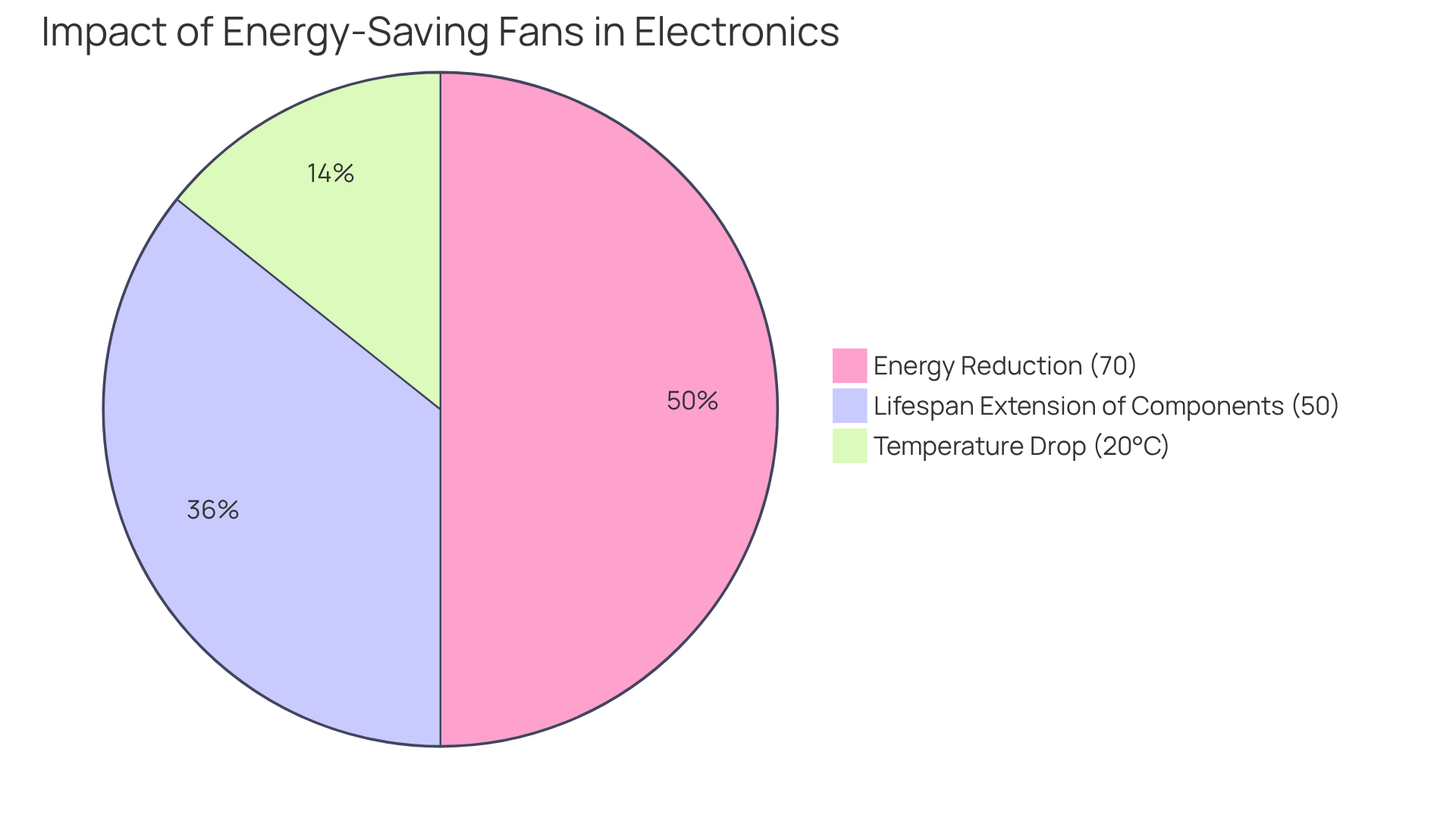

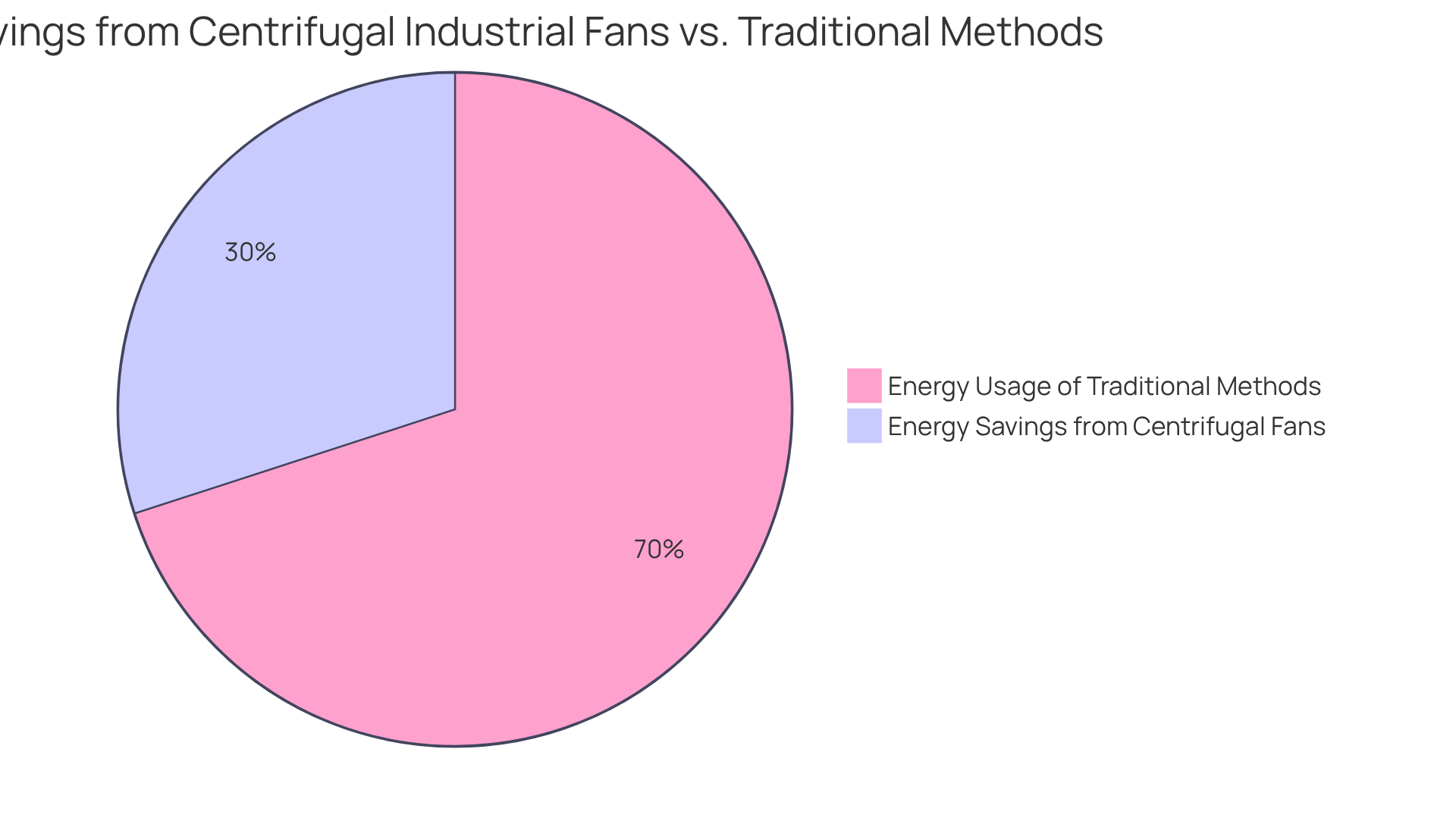

Statistics reveal that can reduce energy consumption by up to 70% compared to traditional models, underscoring their significance in enhancing system reliability and performance. Furthermore, the incorporation of has been shown to improve temperature regulation efficiency while significantly reducing power consumption, aligning with sustainability objectives.

Recent trends indicate a growing demand for innovative , such as the Cloud 3 fan, which can achieve remarkable . Successful applications of centrifugal industrial fans in electronics thermal management demonstrate their efficiency in preventing overheating, which can reduce the lifespan of electronic components by as much as 50%.

As the electronics industry continues to prioritize energy efficiency, Gagner-Toomey Associates remains at the forefront, providing essential insights and solutions that empower engineers to make informed decisions regarding fan selection.

Energy Efficiency: Reduce Operational Costs with Centrifugal Fans

are distinguished by their high efficiency, resulting in significant reductions in . By leveraging advanced motor technologies and optimized airflow designs, these devices can achieve . This remarkable decrease in energy usage not only lowers operational costs but aligns with , positioning these blowers as both a for electronics cooling applications.

A recent study highlighted that the use of resulted in substantial energy cost reductions, underscoring their practical efficiency. Furthermore, the industrial rotary blowers market is projected to grow from USD 2.5 Billion in 2024 to USD 4.1 Billion by 2033, reflecting the increasing demand for . Although the initial investment for centrifugal industrial fans may be elevated, the render them a strategic choice for industries prioritizing operational cost management and environmentally friendly practices.

Additionally, the enhances the efficiency of these devices, facilitating real-time performance monitoring and optimization. This combination of advanced technology and practical application makes centrifugal industrial fans an essential consideration for forward-thinking industries.

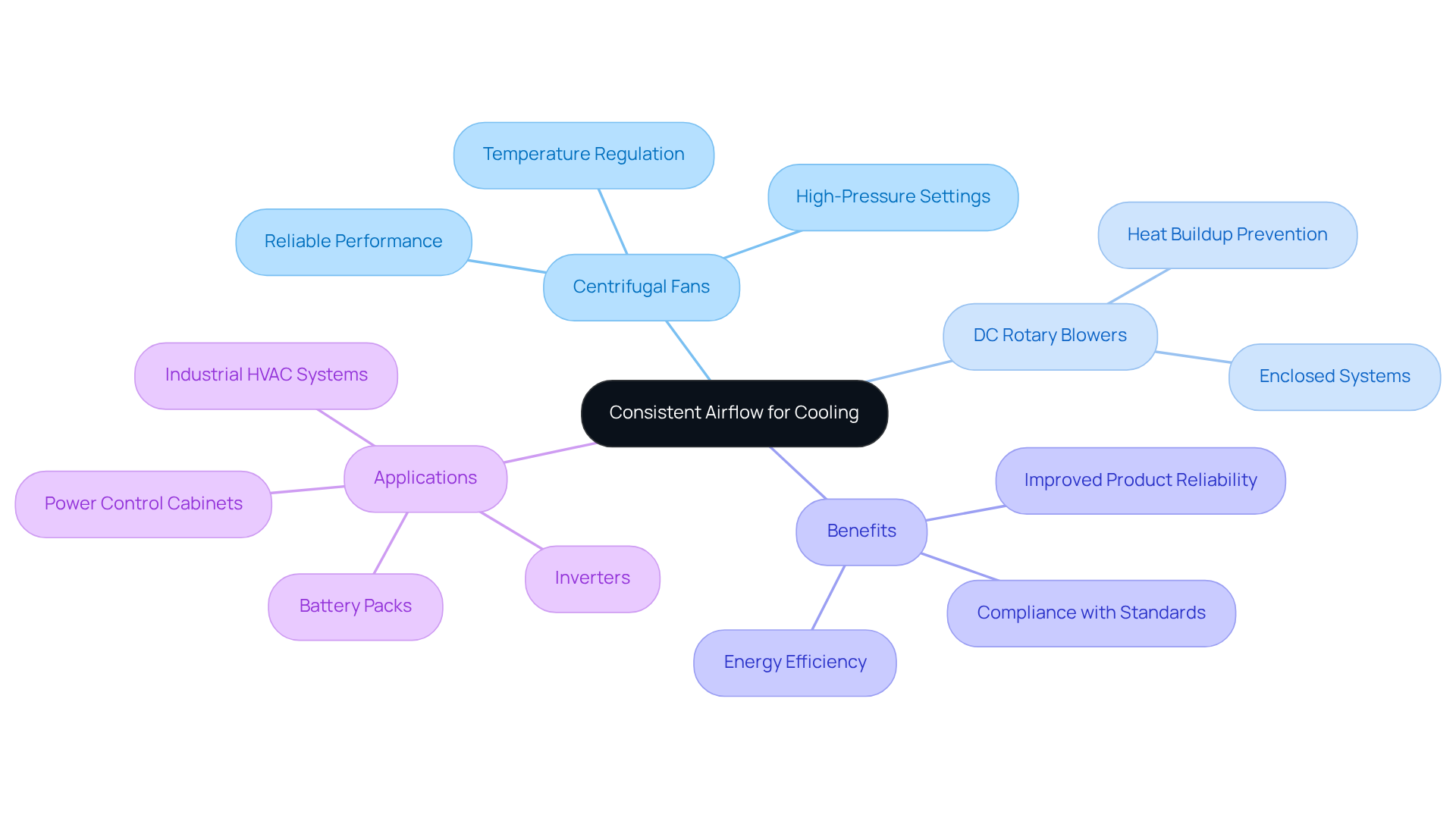

Consistent Airflow: Ensure Reliable Cooling for Electronics

are engineered to deliver a consistent and , which is essential for in electronic devices. Unlike axial types, which may struggle to sustain airflow under changing conditions, radial systems excel in providing even in high-pressure settings. This reliability is vital for maintaining electronic components within safe temperature ranges, thereby preventing thermal failure and significantly extending the lifespan of devices. can enhance product reliability by as much as 30%.

Furthermore, play a crucial role in industrial setups and HVAC configurations that require dependable airflow under pressure. They are particularly adept at , making them ideal for applications in power control cabinets, battery packs, and inverters. Additionally, centrifugal industrial fans support negative pressure environments and filtration efficiency to meet ISO, OSHA, or EPA standards.

Their capacity to ensure stable temperature control is crucial; insufficient can lead to operational interruptions in electronics, underscoring the significance of these devices in contemporary electronic design. As industry specialists assert, is imperative for the reliability of electronic devices.

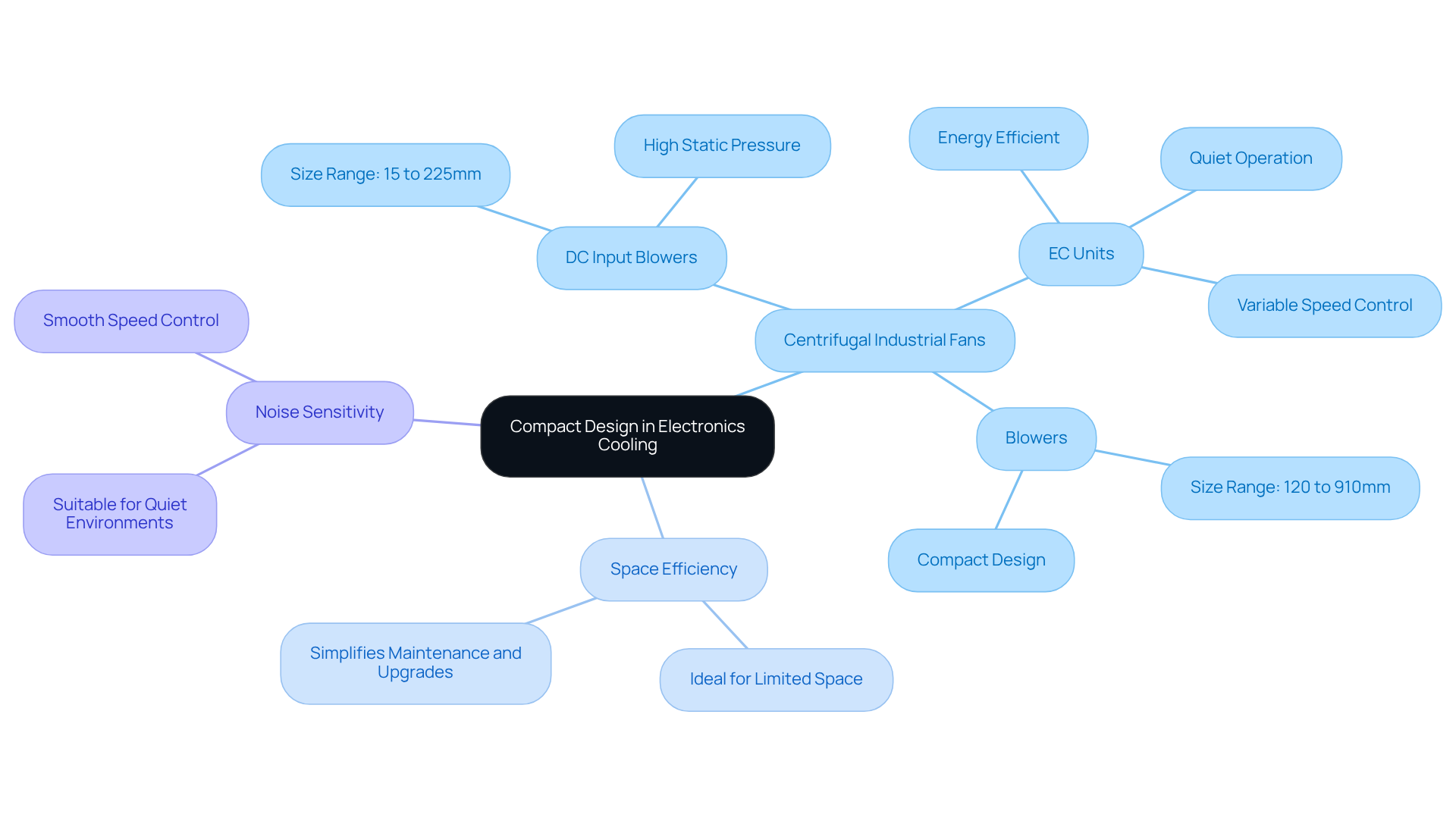

Compact Design: Maximize Space Efficiency in Electronics Cooling

from stand out due to their , making them ideal for environments where space is at a premium. As the world’s largest manufacturer of both standard and custom air-movers, they excel in generating within a smaller footprint, allowing for seamless integration into a variety of electronic systems, from compact servers to intricate circuit boards. This not only enhances the overall design of electronic devices but also simplifies maintenance and upgrades.

With an extensive array of centrifugal industrial fans, including:

- DC input blowers ranging from 15 to 225mm

- EC units

- Blowers from 120 to 910mm

Gagner-Toomey Associates ensures that engineers have access to innovative tailored to their specific needs. Furthermore, the and performance enhancement of these devices make them particularly suitable for , ensuring without compromising performance.

Versatility: Adapt Centrifugal Fans for Diverse Electronics Applications

exhibit remarkable adaptability, making them indispensable across various applications within the electronics industry. They play a crucial role in for environments, where is paramount. These devices can handle airflow ranges from 500 to 66,000 m³/h, addressing the diverse cooling needs of telecommunications equipment and industrial electronics. Their design facilitates , essential for overcoming resistance in complex networks.

As highlighted by PERFECT, “This unique geometry allows the fan to generate relatively high total pressure, making it ideal for applications where high resistance needs to be overcome.” Moreover, centrifugal industrial fans can be customized to meet specific requirements, such as size, voltage, and motor type, ensuring in both industrial and consumer electronics contexts. This adaptability is particularly beneficial in high-performance computing temperature regulation, where is vital to maintain system integrity.

By integrating advanced features, these devices not only enhance but also bolster the overall reliability of electronic systems, establishing them as a preferred choice for a range of applications. Furthermore, the that INFINAIR products undergo guarantee , reinforcing their effectiveness across diverse operational scenarios.

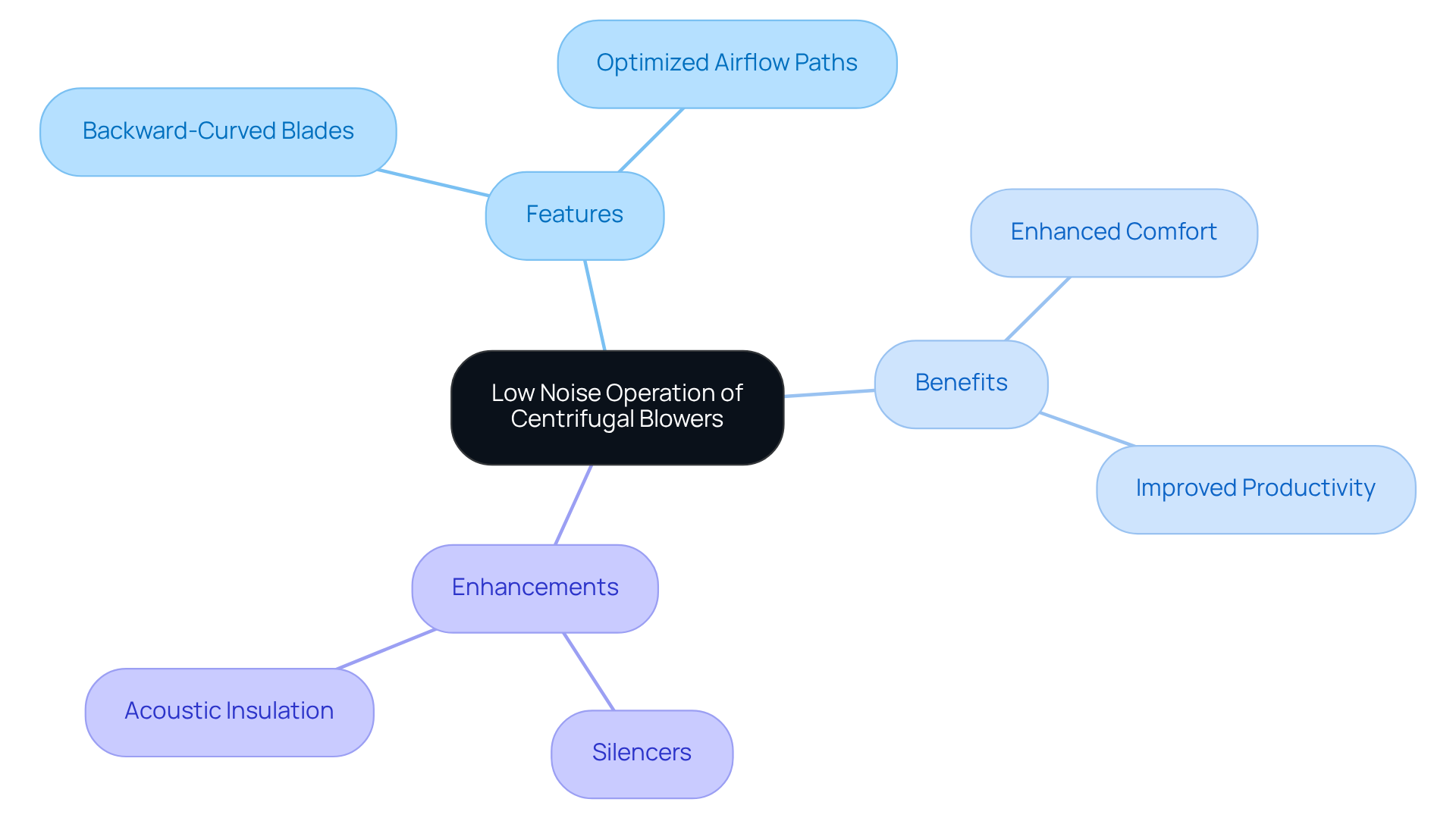

Low Noise Operation: Enhance Comfort in Electronics Environments

are renowned for their , a crucial attribute in environments where maintaining a serene atmosphere is essential. These devices, engineered with —such as backward-curved blades—and optimized airflow paths, significantly reduce sound levels. This makes them particularly well-suited for offices, laboratories, and residential areas.

Excessive noise can hinder focus and productivity, especially in spaces demanding concentration, like research labs or open office environments. By choosing , users can achieve while fostering a .

Furthermore, these devices can be enhanced with silencers or acoustic insulation to further diminish noise levels in . This equilibrium of performance and not only but also positively influences workplace productivity, as and efficiency.

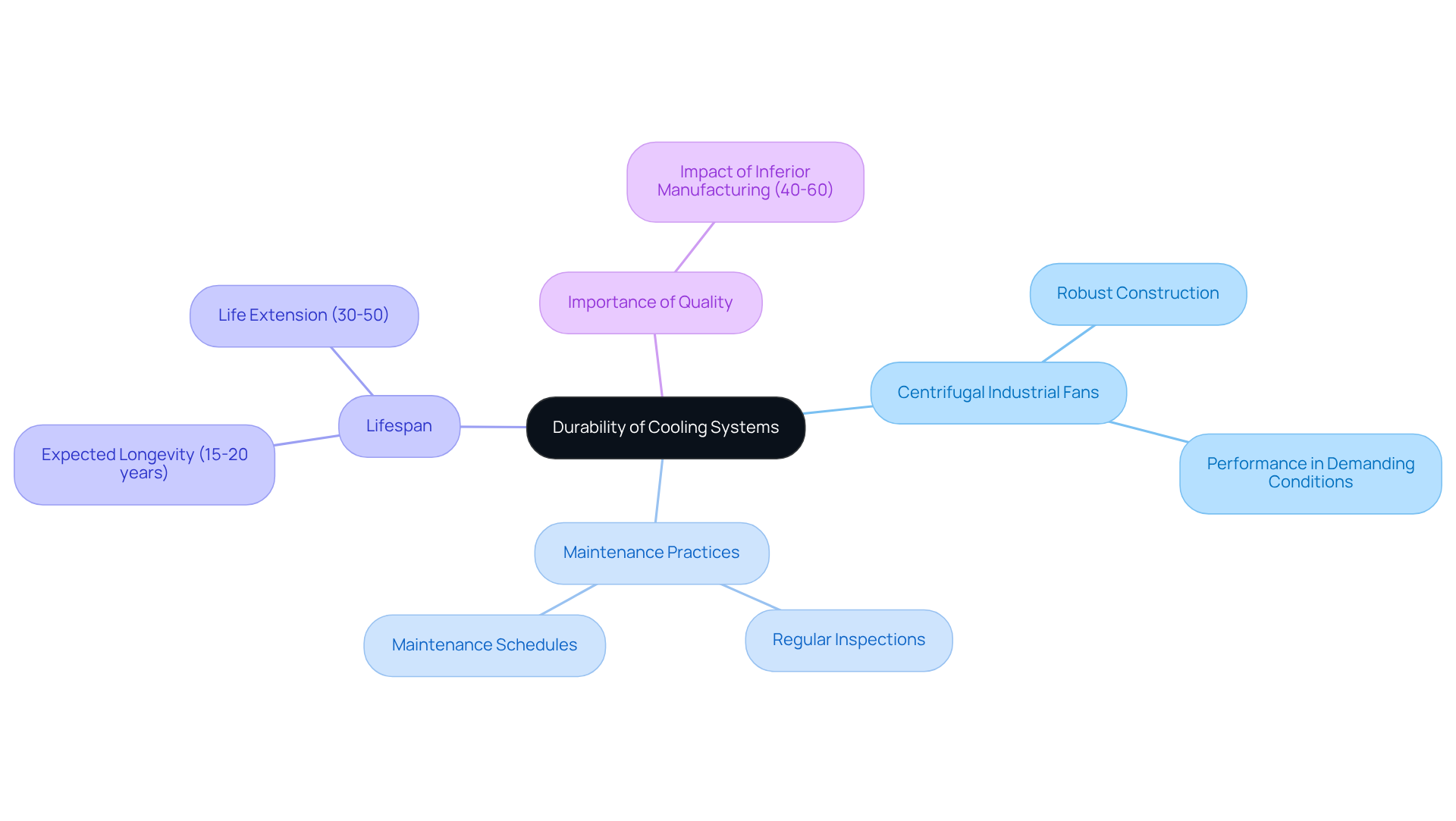

Durability: Ensure Long-Lasting Performance of Cooling Systems

are engineered for durability, featuring robust construction and premium materials that ensure consistent performance even in the most demanding conditions. Their design minimizes wear and tear, facilitating over extended periods. With appropriate maintenance practices, these devices can deliver for 15 to 20 years, representing a prudent investment for companies aiming to enhance the longevity of their electronic equipment.

For instance, centrifugal industrial fans are commonly utilized in HVAC systems for large commercial buildings, where they play a critical role in . Regular inspections can decrease fan-related downtime by 70-80%, while adherence to maintenance schedules can significantly lower operational costs; proper upkeep can by 30-50%. This not only reduces downtime but also ensures that remain efficient and effective, protecting the performance of sensitive electronic components.

As Mr. Bourne emphasizes, selecting is crucial, as inferior manufacturing processes can diminish their lifespan by 40-60%.

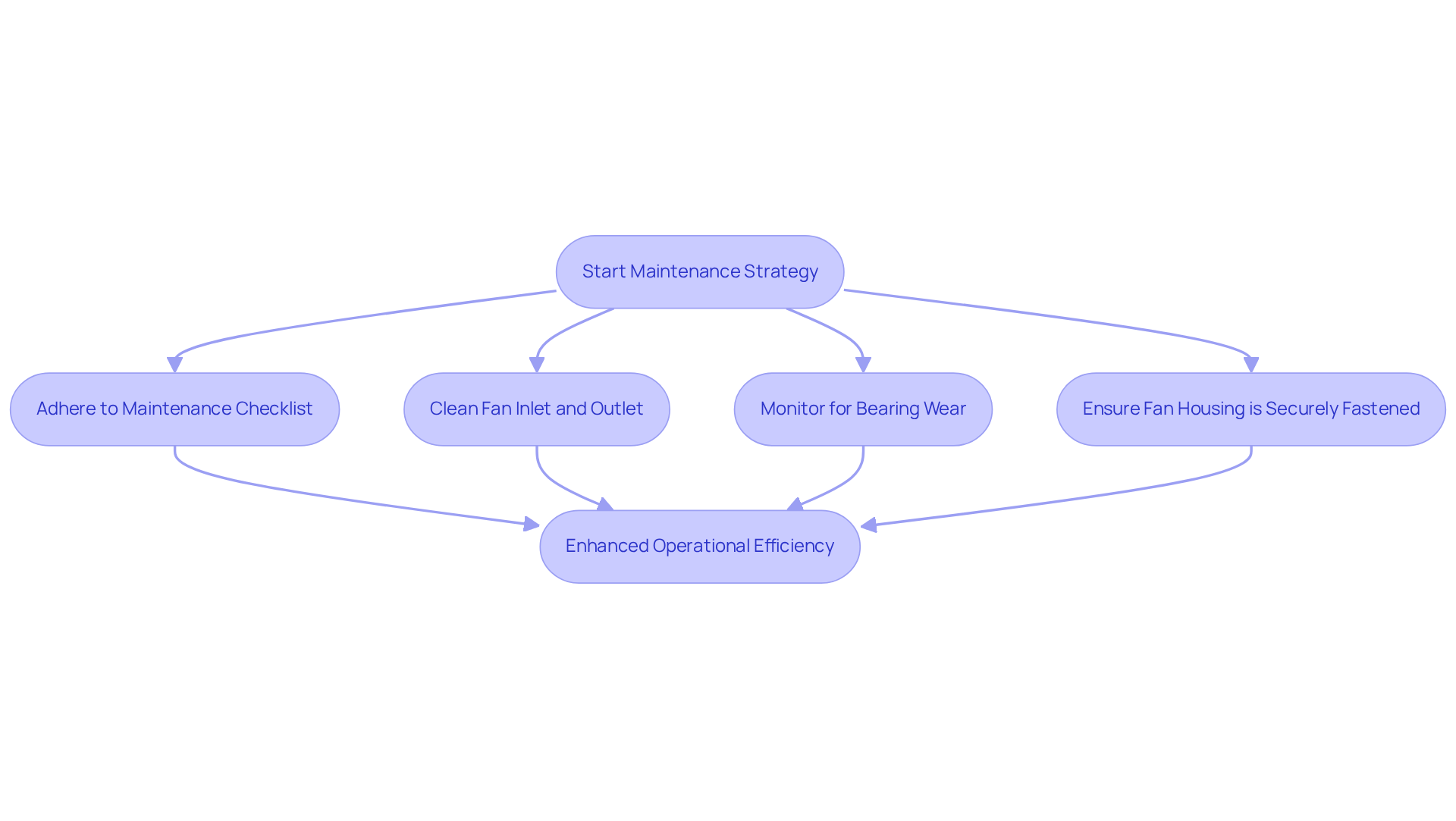

Ease of Maintenance: Simplify Upkeep of Cooling Solutions

are designed for straightforward maintenance, featuring accessible components that facilitate upkeep. Routine cleaning and inspections can be performed with minimal effort, thereby ensuring and efficiency. The ease of maintenance for centrifugal industrial fans not only minimizes downtime but also significantly , as expenses are generally less than those associated with repairs or replacements. For instance, consistent maintenance can prevent costly repairs and , positioning turbine blowers as an excellent choice for companies focused on reliable and efficient .

By adopting a structured maintenance strategy for centrifugal industrial fans, which includes tasks such as:

- Adhering to a

- Cleaning the fan’s inlet and outlet

- Monitoring for bearing wear

- Ensuring the fan housing is securely fastened

Companies can enhance the operational efficiency of their while mitigating the risk of unexpected breakdowns. Neglecting maintenance can result in problems such as unusual noises or overheating, highlighting the critical importance of proactive upkeep. Case studies have demonstrated that regular maintenance not only boosts performance but also extends the lifespan of turbines, ultimately saving businesses money by averting significant repairs and operational disruptions.

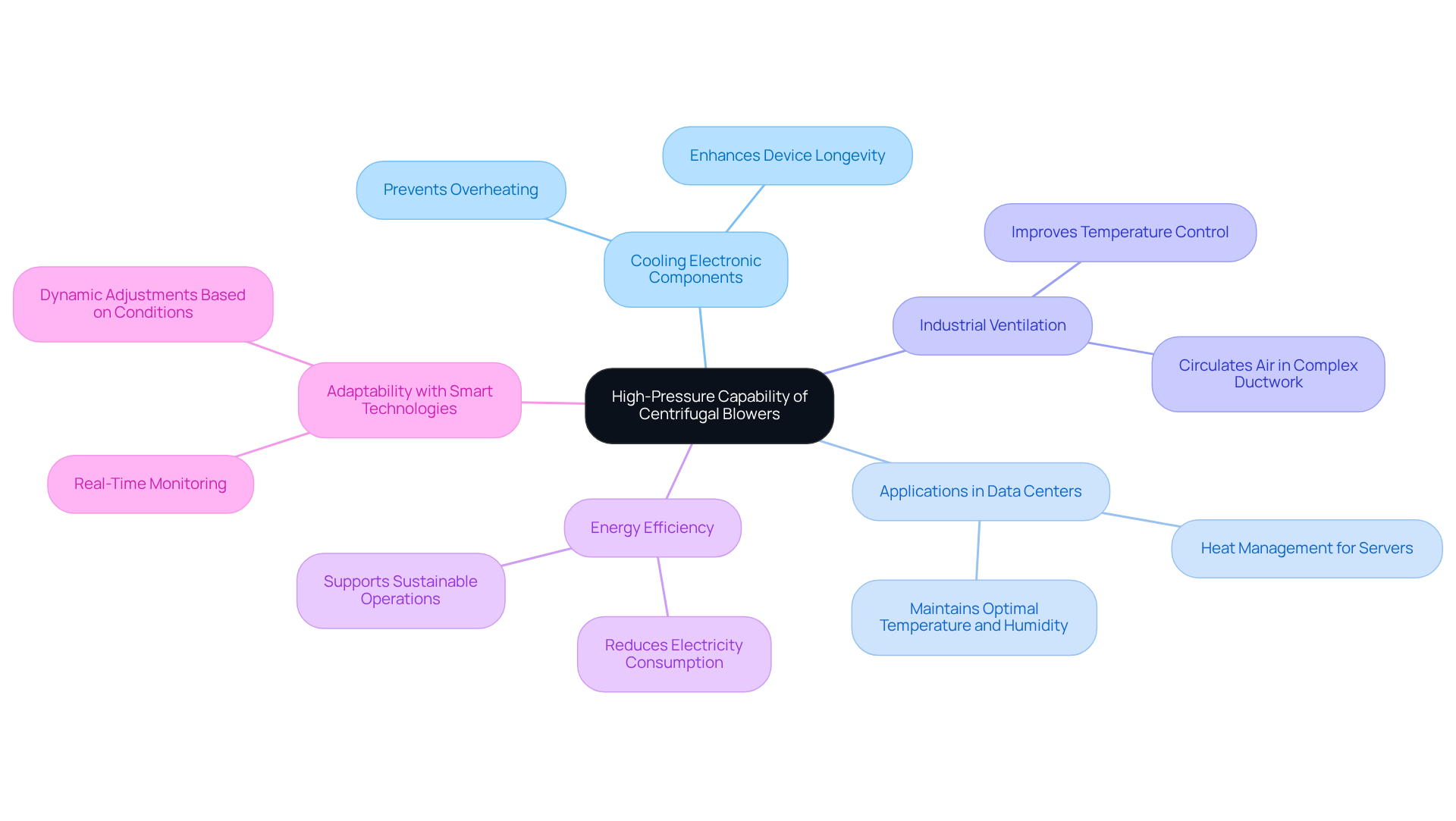

High-Pressure Capability: Optimize Cooling in Demanding Environments

Centrifugal blowers are recognized for their exceptional , making them indispensable in applications that demand substantial airflow against resistance. This feature is particularly beneficial in environments with or where air must traverse filters. By delivering consistent high-pressure airflow, rotating blowers are vital for sustaining , even in demanding conditions. Such reliability not only enhances the performance of electronic devices but also contributes to their longevity, ensuring that critical components operate within safe temperature thresholds.

For instance, in data centers, effectively manage the heat generated by servers, preventing overheating and ensuring uninterrupted operation. Furthermore, in industrial settings, these devices are essential for circulating air through intricate ventilation systems, improving temperature control and maintaining air quality. As industries increasingly prioritize , the demand for rotary blowers capable of adapting to specific temperature control needs continues to rise, underscoring their importance in modern .

Moreover, the anticipated surge in demand for tailored reflects the industry’s requirement for fans that satisfy distinct operational criteria. The integration of is projected to further enhance fan performance, enabling dynamic adjustments based on real-time operating conditions. This adaptability is crucial for addressing the evolving challenges of electronics cooling.

Conclusion

Centrifugal industrial fans are fundamental to the effective cooling of electronic devices, providing numerous benefits that enhance both performance and longevity. By emphasizing energy efficiency, consistent airflow, compact design, and adaptability, these fans not only optimize temperature control but also lead to substantial operational cost savings. As industries evolve and pursue sustainable solutions, the role of centrifugal fans becomes increasingly crucial in ensuring the reliability and efficiency of electronic systems.

The article has thoroughly examined the advantages of centrifugal fans. Their energy-saving capabilities can result in consumption reductions of up to 70%, while their ability to deliver consistent airflow guarantees that critical components remain within safe temperature ranges. The compact design facilitates seamless integration into various electronic applications, and their versatility renders them suitable for a wide array of environments. Additionally, low noise operation and durability enhance their appeal, making them ideal for both industrial and consumer electronics.

Given these insights, it is clear that investing in centrifugal industrial fans transcends merely enhancing cooling efficiency; it represents a strategic move towards sustainable and cost-effective operations. As the demand for innovative cooling technologies escalates, embracing these advanced solutions will empower businesses to confront the challenges of modern electronics cooling effectively. By prioritizing energy efficiency and reliable performance, organizations can protect their electronic investments and contribute to a more sustainable future.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in delivering innovative cooling solutions specifically designed for the electronics industry, focusing on energy management and heat control.

How do centrifugal industrial fans benefit the electronics industry?

Centrifugal industrial fans help maintain ideal temperatures in various electronic applications, such as power control cabinets and high-density computing environments, and can reduce energy consumption by up to 70% compared to traditional fans.

What are electronically commutated (EC) blowers, and why are they important?

Electronically commutated (EC) blowers improve temperature regulation efficiency and significantly reduce power consumption, aligning with sustainability objectives in the electronics industry.

What recent trends are observed in temperature regulation technologies?

There is a growing demand for innovative temperature regulation technologies, such as the Cloud 3 fan, which can achieve temperature drops of up to 20 degrees Celsius.

How do centrifugal industrial fans impact the lifespan of electronic components?

Centrifugal industrial fans efficiently prevent overheating, which can reduce the lifespan of electronic components by as much as 50%.

What advantages do centrifugal industrial fans offer in terms of energy efficiency?

Centrifugal industrial fans achieve energy savings of up to 30% compared to traditional temperature control methods, lowering operational costs and supporting sustainable cooling practices.

What is the projected growth of the industrial rotary blowers market?

The industrial rotary blowers market is projected to grow from USD 2.5 billion in 2024 to USD 4.1 billion by 2033, indicating increasing demand for energy-efficient solutions.

How do intelligent sensors and controls enhance the efficiency of centrifugal fans?

The integration of intelligent sensors and controls allows for real-time performance monitoring and optimization, enhancing the overall efficiency of centrifugal industrial fans.

Why is consistent airflow important for electronic devices?

Consistent airflow is essential for efficient cooling, preventing thermal failure, and significantly extending the lifespan of electronic devices.

In what applications are DC rotary blowers particularly effective?

DC rotary blowers are effective in industrial setups and HVAC configurations that require dependable airflow under pressure, particularly in power control cabinets, battery packs, and inverters.

How do centrifugal industrial fans support regulatory standards?

Centrifugal industrial fans support negative pressure environments and filtration efficiency to meet ISO, OSHA, or EPA standards, ensuring compliance in various applications.