Overview

The article delineates ten compelling benefits of backward inclined blower wheels for engineers, emphasizing their efficiency, durability, and versatility across diverse applications. These advantages are substantiated by robust evidence, including:

- Energy savings of up to 30%

- Diminished maintenance requirements

- Improved performance reliability

Consequently, backward inclined blower wheels emerge as a strategic choice for optimizing system design and reducing operational costs in engineering projects.

Introduction

Backward inclined blower wheels are transforming the engineering landscape, particularly within the electronics sector, by delivering substantial advantages in performance and efficiency. These innovative components not only minimize energy consumption but also bolster system reliability and longevity, establishing themselves as a vital choice for engineers aiming to optimize their designs.

As industries evolve and sustainability takes precedence, it is crucial to explore the specific benefits that backward inclined blower wheels can offer your projects. Consider how these components can effectively address the unique challenges encountered across various applications.

Gagner-Toomey Associates: Innovative Backward Inclined Blower Wheel Solutions

Gagner-Toomey Associates specializes in providing cutting-edge reverse-tilted wheel solutions specifically tailored for the electronics sector. By collaborating with a diverse range of manufacturers, the company ensures that engineers have access to state-of-the-art technologies that significantly enhance performance and energy efficiency.

The broad array of electronics solutions offered by Gagner-Toomey Associates positions them to meet the needs of engineers designing or building electronic systems. This growth is particularly evident in sectors such as manufacturing and food & beverage, where innovative air-moving designs are essential for meeting rigorous hygiene standards.

Gagner-Toomey’s commitment to innovation is reflected in their ability to address complex engineering challenges, making them a reliable partner for professionals seeking effective and sustainable air handling solutions. Recent advancements in reverse-angled fan technology, including IoT-enabled monitoring systems, further enhance operational efficiency and reliability. This positions Gagner-Toomey Associates at the forefront of industry developments, underscoring their role as a leader in the field.

Energy Efficiency: Reduce Operational Costs with Backward Inclined Blower Wheels

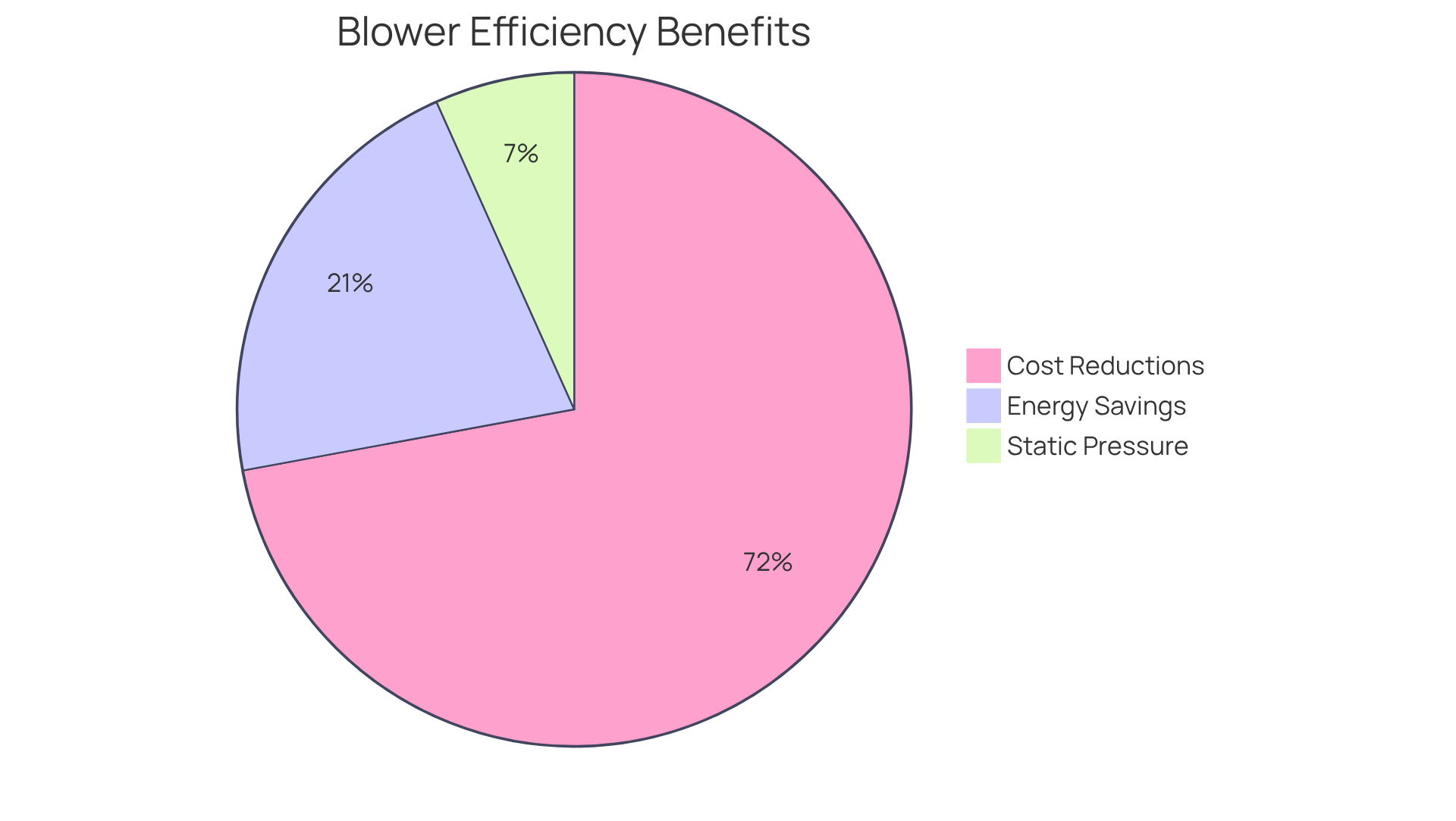

Backward inclined blower wheels are designed for optimal efficiency, significantly reducing energy usage compared to conventional fan designs. Their aerodynamic shape effectively minimizes airflow resistance, resulting in lower power requirements. This enhanced efficiency not only leads to substantial operational cost reductions but also aligns with sustainability goals, making them an appealing choice for engineers seeking to improve system performance within budget constraints.

Facilities utilizing a backward inclined blower wheel have reported energy savings of up to 25%, showcasing their effectiveness in lowering operational costs. Moreover, these devices can enhance static pressure by as much as 7.9%, further substantiating their efficiency claims. They require minimal maintenance, with recommendations for regular upkeep every few months, which contributes to cost efficiency by decreasing repair frequency and extending lifespan.

By investing in backward inclined blower wheel technology, organizations can achieve operational cost reductions of up to 85%, reinforcing their role in energy-efficient practices within the electronics sector. The market for backward-tilted fans is projected to expand at a CAGR of 6.2% from 2026 to 2033, underscoring their increasing significance in the industry.

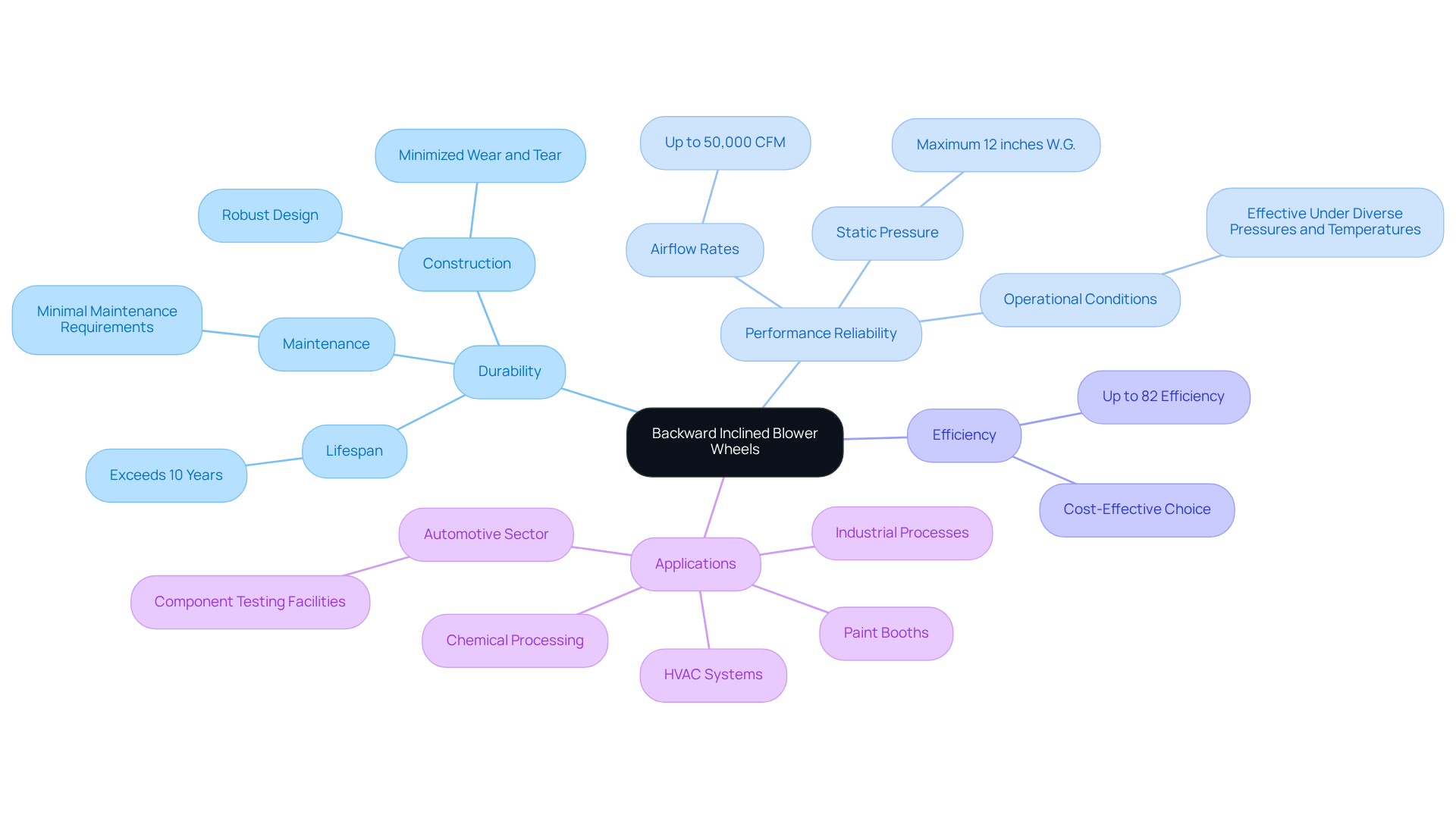

Performance Reliability: Enhance System Integrity with Backward Inclined Blower Wheels

Backward slanted fan components are engineered for exceptional durability, significantly enhancing performance reliability. Their robust construction minimizes wear and tear, a crucial factor for maintaining consistent operation over extended periods. This reliability is vital in critical applications, such as HVAC systems and industrial processes, where system integrity is paramount. Research indicates that these fan components can achieve lifespans exceeding 10 years in demanding environments, showcasing their ability to withstand varying operational conditions.

Experts in the field emphasize that the design of reverse sloped fan components not only facilitates high airflow rates—reaching up to 50,000 cfm—but also ensures that systems operate effectively under diverse pressures and temperatures, with a maximum static pressure of 12 inches W.G. Real-world applications, including paint booths, exhaust systems, and component testing facilities within the automotive sector, further demonstrate their durability. Many installations report minimal maintenance requirements and sustained performance over time.

Moreover, reverse sloped fans can achieve efficiencies of up to 82%, making them a cost-effective choice for engineers. This combination of longevity and reliability empowers engineers to confidently integrate reverse-angled fan components into their designs, assured that they will deliver consistent results even in the most challenging scenarios.

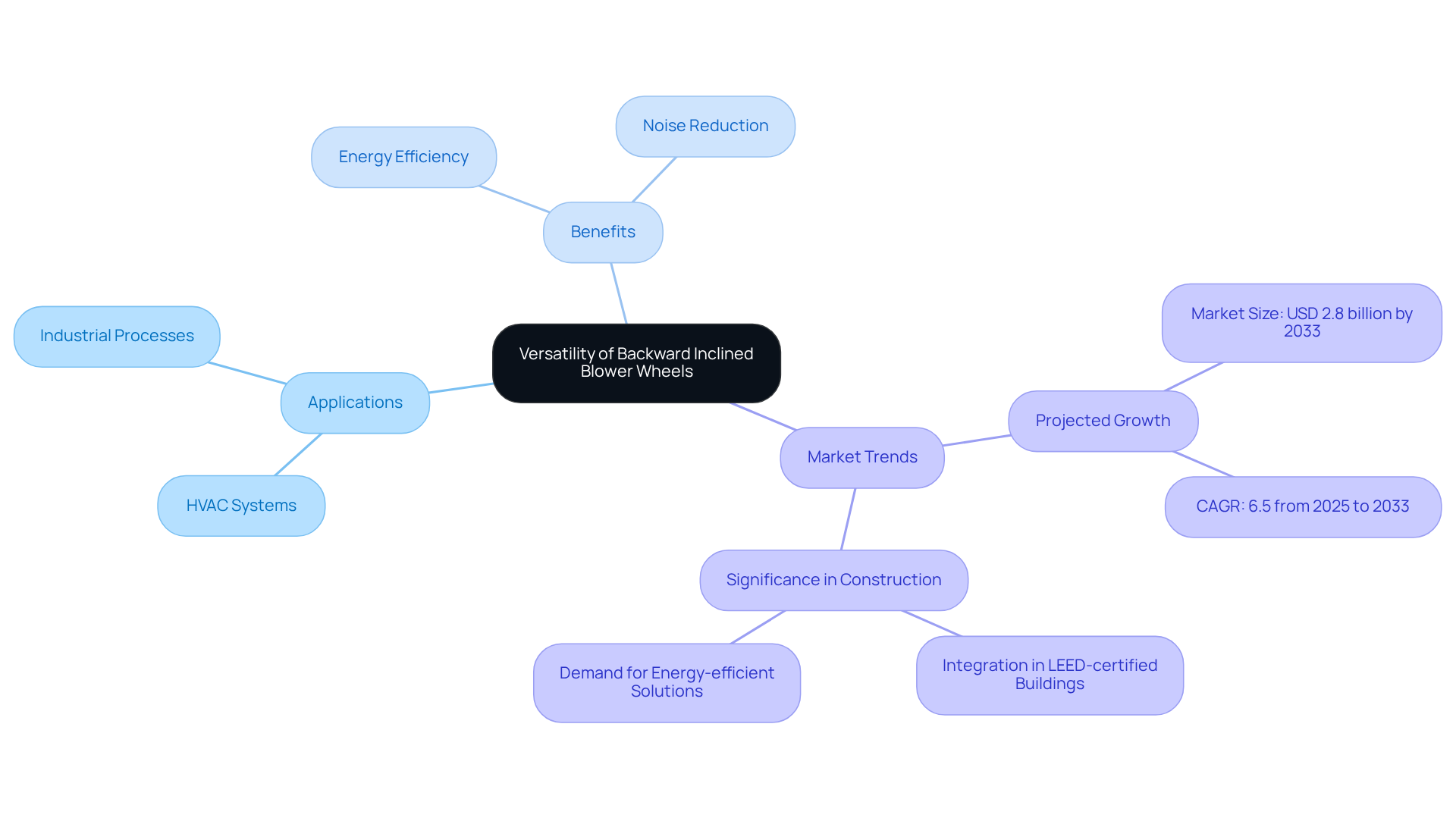

Versatility: Utilize Backward Inclined Blower Wheels Across Diverse Applications

Backward inclined blower wheels represent a highly versatile solution, effectively utilized across a spectrum of applications, including HVAC systems and various industrial processes. Their design allows for the management of a wide range of airflow requirements and pressures, making them ideal for diverse environments. This adaptability not only enables engineers to implement these solutions in multiple projects but also maximizes their investment by ensuring optimal performance in varying conditions.

In HVAC applications, the use of backward inclined blower wheels contributes significantly to enhanced energy efficiency and reduced noise levels. In industrial settings, they play a crucial role in improving airflow management and system dependability. The increasing movement towards energy-saving solutions further underscores the importance of these ventilation components, as they are becoming more frequently integrated into environmentally-friendly construction initiatives and LEED-certified structures.

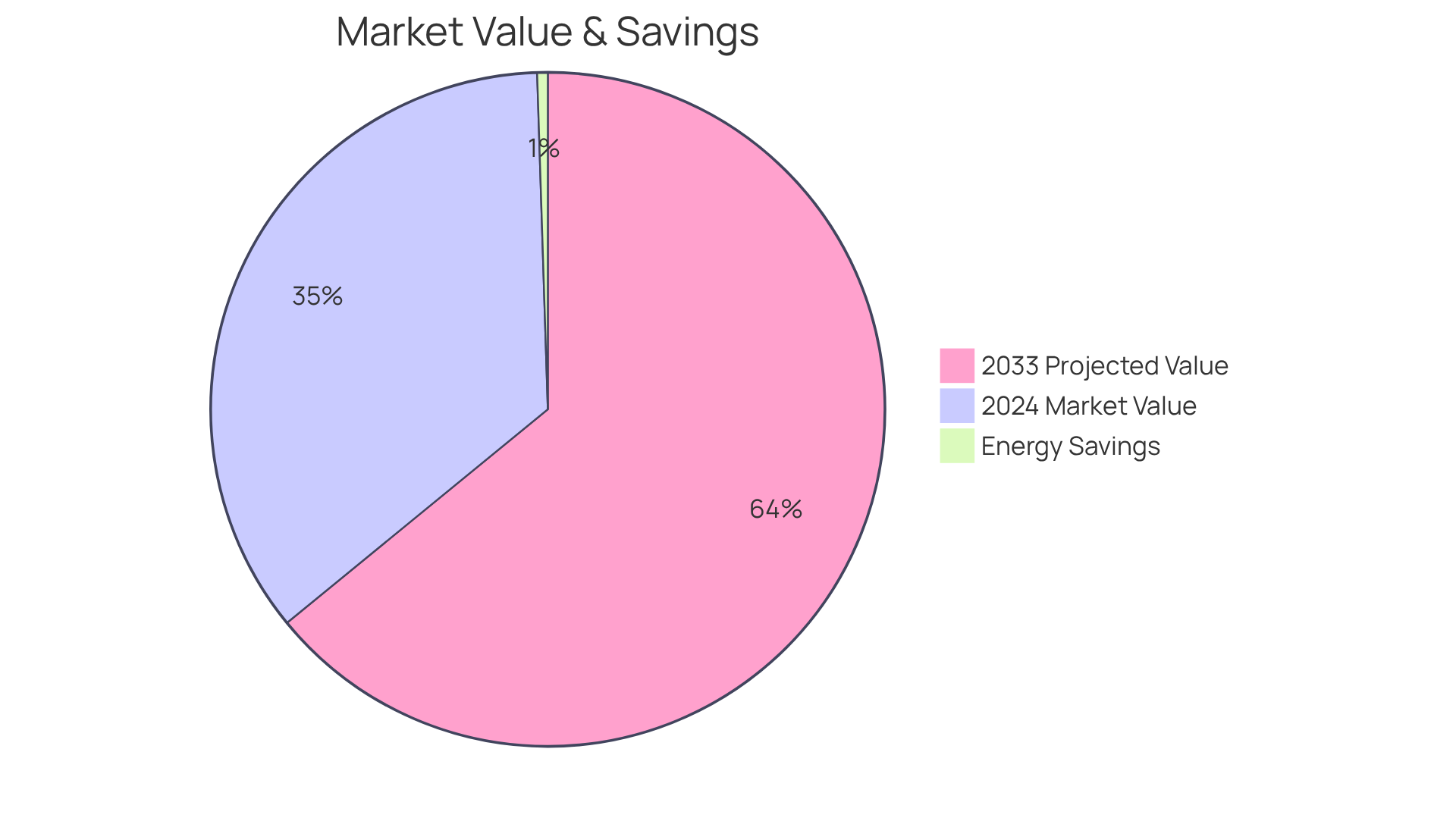

With the market for fan components projected to expand considerably, reaching USD 2.8 billion by 2033 with a CAGR of 6.5% from 2025 to 2033, the adaptability of the backward inclined blower wheel establishes it as a vital resource for engineers striving to meet contemporary requirements in both residential and commercial sectors.

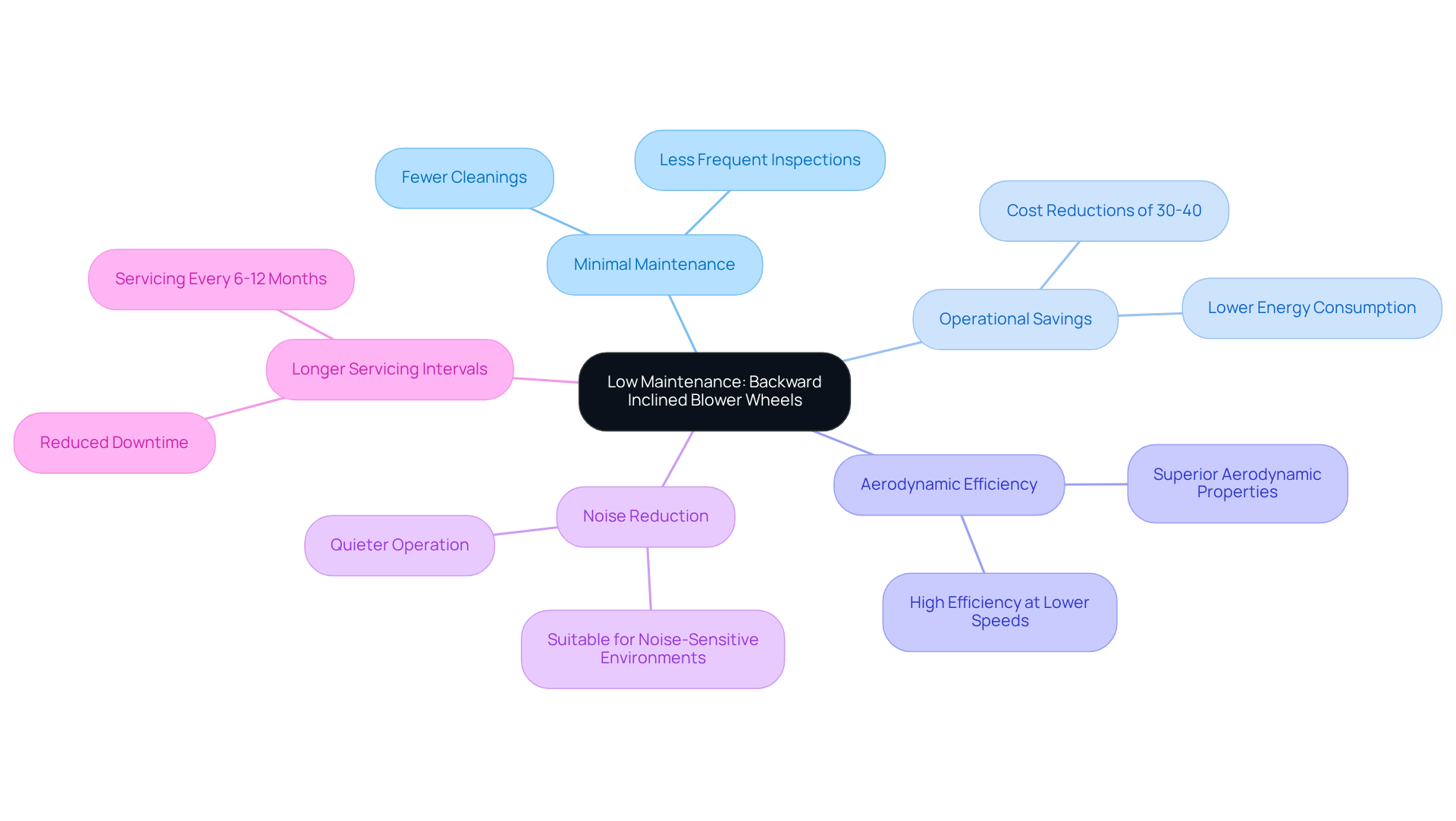

Low Maintenance: Simplify Operations with Backward Inclined Blower Wheels

Backward curved fans are recognized for their minimal maintenance requirements, a significant advantage across various applications. Their innovative design effectively mitigates dust accumulation, which subsequently reduces the need for frequent cleaning and part replacements. For example, these devices adeptly handle dust-laden air, leading to lower maintenance demands compared to traditional fan types. In environments where airborne particulates are common, this capability results in considerable operational savings and minimized downtime.

Typically, maintenance for rearward sloped air movers necessitates regular inspections and cleaning of the impeller and housing; however, the frequency is markedly less than that associated with forward curved devices. Reports suggest that maintenance intervals can be significantly extended, with some sources indicating that servicing can occur every 6 to 12 months. This allows engineers to redirect their time and resources toward other critical components of their projects.

Expert opinions emphasize that the aerodynamic efficiency of slanted fans not only enhances airflow but also contributes to their longevity and reliability. As one expert noted, “Backward curved blades are known for their high-efficiency levels, particularly at lower speeds.” This efficiency often translates to operational cost reductions of up to 30-40%, attributed to lower energy consumption and fewer maintenance interventions. Additionally, curved fans typically produce less noise compared to forward curved models, making them suitable for noise-sensitive environments. Ultimately, the low maintenance characteristics of reverse curved fans streamline operations, positioning them as an optimal choice for engineers seeking to improve performance while minimizing upkeep.

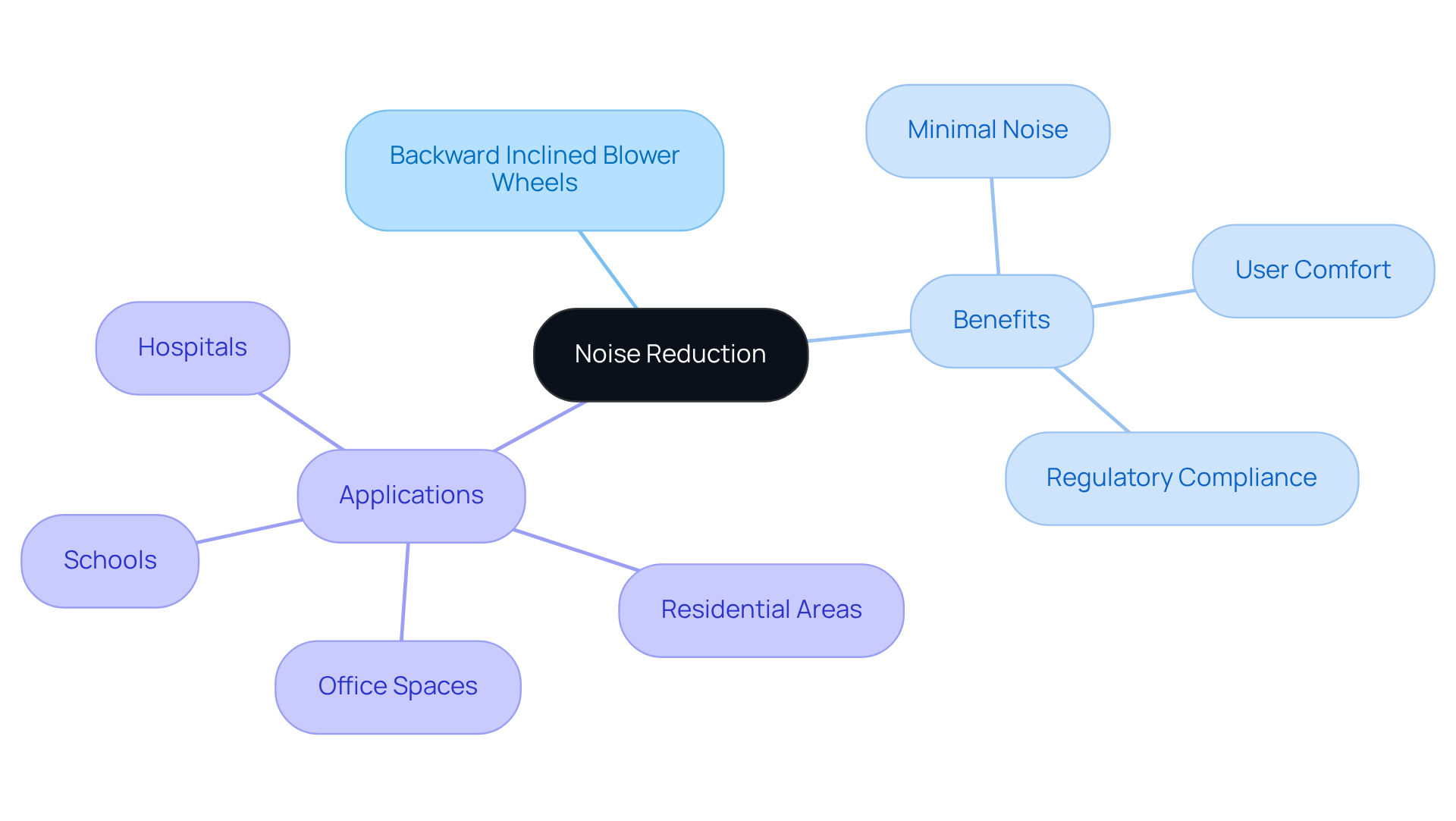

Noise Reduction: Achieve Quieter Operations with Backward Inclined Blower Wheels

Backward curved fans are meticulously designed to operate with minimal noise, resulting in a significant reduction in sound levels compared to traditional fan designs. This characteristic is particularly beneficial in environments where noise pollution is a concern, such as residential neighborhoods and office spaces. By utilizing these reverse-tilted fan components, engineers enhance user comfort and comply with regulatory noise standards.

Known for their lower noise levels, backward curved fans are ideally suited for applications that demand quiet operation. Furthermore, the aerodynamic design of these components minimizes turbulence, contributing to quieter performance. In environments like hospitals and schools, where maintaining a serene atmosphere is crucial, reverse-angled fan components prove to be a considerable advantage, delivering effective airflow while prioritizing noise reduction.

Improved Airflow: Optimize System Performance with Backward Inclined Blower Wheels

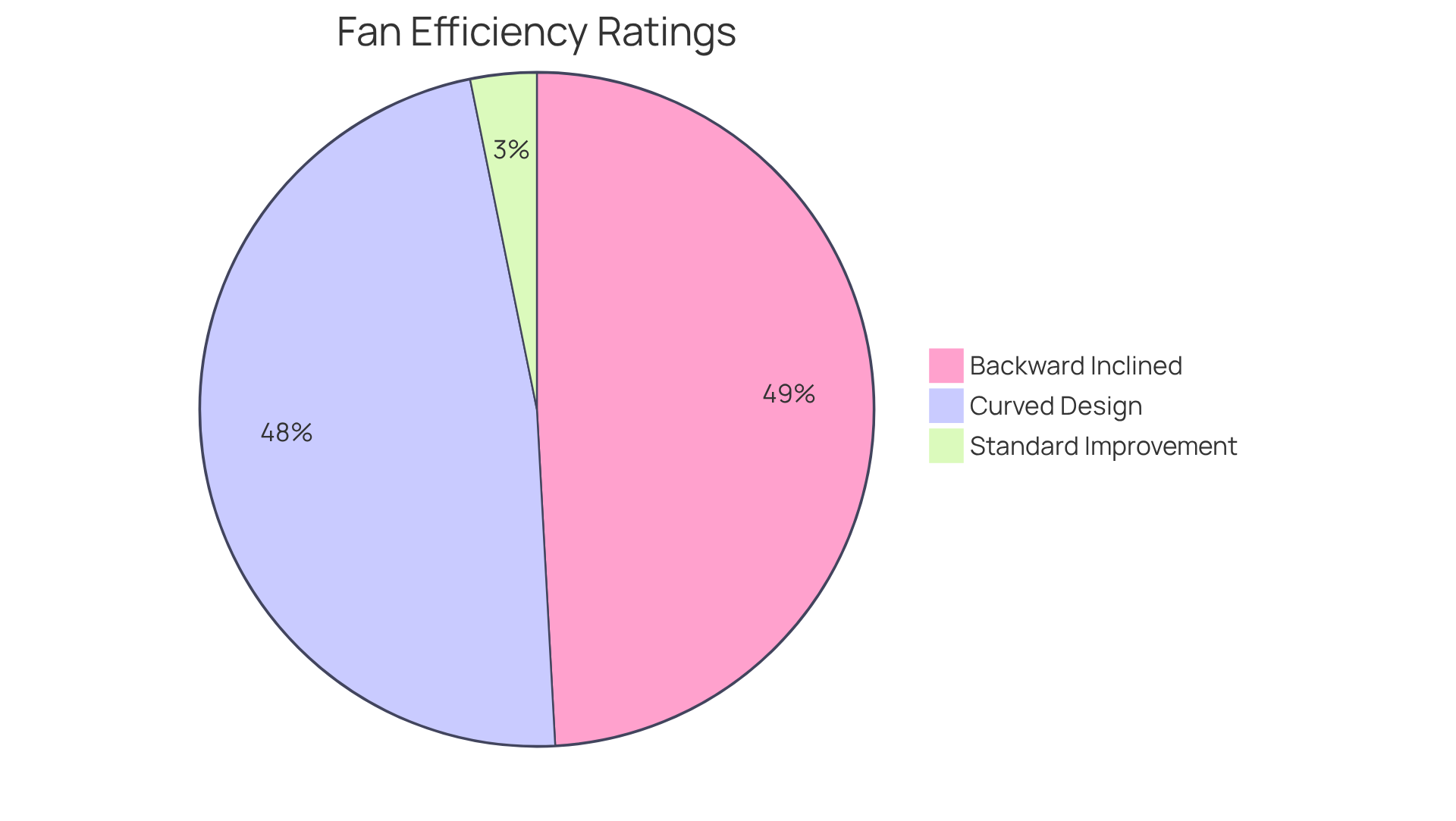

Backward inclined blower wheels are engineered to optimize airflow efficiency, resulting in a significant enhancement in system performance. Their unique blade configuration creates a streamlined airflow path that minimizes turbulence and maximizes efficiency. This innovative design not only boosts airflow rates but also plays a crucial role in better temperature regulation and an extended system lifespan.

Research indicates that fans with a rearward tilt achieve efficiencies ranging from 80% to 90%, while those with curved designs offer efficiency ratings between 80% and 85%, providing a useful comparative context. Furthermore, the incorporation of new design features has been demonstrated to improve fan efficiency by 3 to 8% across a broader airflow range compared to standard designs, underscoring their effectiveness in various applications.

The backward inclined blower wheel is particularly favored in HVAC systems and the automotive industry, where energy efficiency and performance are critical. Additionally, backward-tilted fans can handle a maximum static pressure of 12 inches W.G., further showcasing their capabilities. By reducing energy consumption and operational costs, these fans are increasingly becoming the preferred choice in sectors that prioritize energy efficiency and high performance.

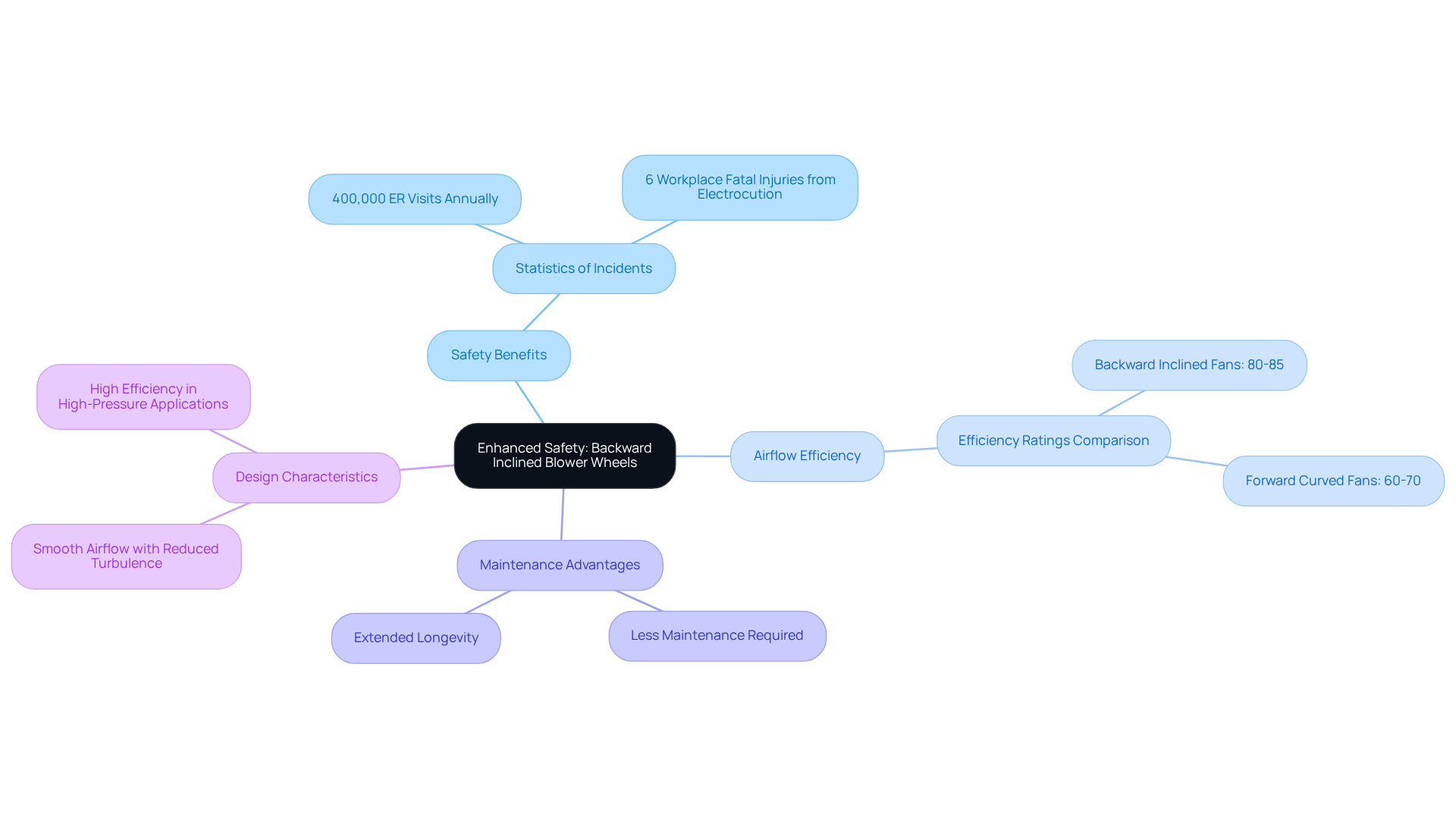

Enhanced Safety: Incorporate Backward Inclined Blower Wheels for Safer Operations

Integrating backward-leaning air circulation components into systems significantly enhances safety by mitigating the risk of component failure. This innovative design effectively diminishes the chances of overheating and mechanical breakdown, which can precipitate hazardous situations across various applications.

For instance, statistics reveal that improper ventilation and overheating incidents result in nearly 400,000 emergency room visits annually due to power tools, thereby underscoring the critical importance of reliable airflow management.

By employing rearward sloped fan blades, engineers achieve airflow efficiency ratings ranging from 80-85%, as opposed to the 60-70% commonly observed with forward curved fans. This heightened efficiency not only reduces energy consumption but also lessens the risk of overheating, thereby safeguarding users and ensuring consistent system performance.

The strategic design of these fan wheels facilitates smoother airflow with reduced turbulence, further decreasing the likelihood of mechanical failure. Additionally, reverse-angled fans require less maintenance due to their structural advantages, promoting easier care and extended longevity.

By prioritizing safety through the implementation of a backward inclined blower wheel, engineers can devise systems that operate reliably while protecting users from potential hazards.

Cost-Effectiveness: Maximize Value with Backward Inclined Blower Wheels

Backward inclined blower wheels offer exceptional cost-effectiveness, due to their energy-efficient design, minimal maintenance requirements, and superior performance. Although the initial investment may be higher, the long-term operational savings can be significant. For instance, these fan components can reduce energy consumption by up to 30%, resulting in substantial savings on electricity bills over time. Furthermore, their durable construction reduces downtime and maintenance needs, thereby enhancing their overall value proposition.

The global market for backward-angled fans, valued at $2.1 billion in 2024, is projected to reach $3.8 billion by 2033, indicating a strong demand for these technologies across various sectors, including HVAC, manufacturing, and food & beverage. Engineers opting for a backward inclined blower wheel design not only comply with stringent energy regulations but also contribute to more sustainable operations, ultimately keeping their projects within budget while achieving optimal performance.

Technological Advancements: Leverage Modern Backward Inclined Blower Wheels

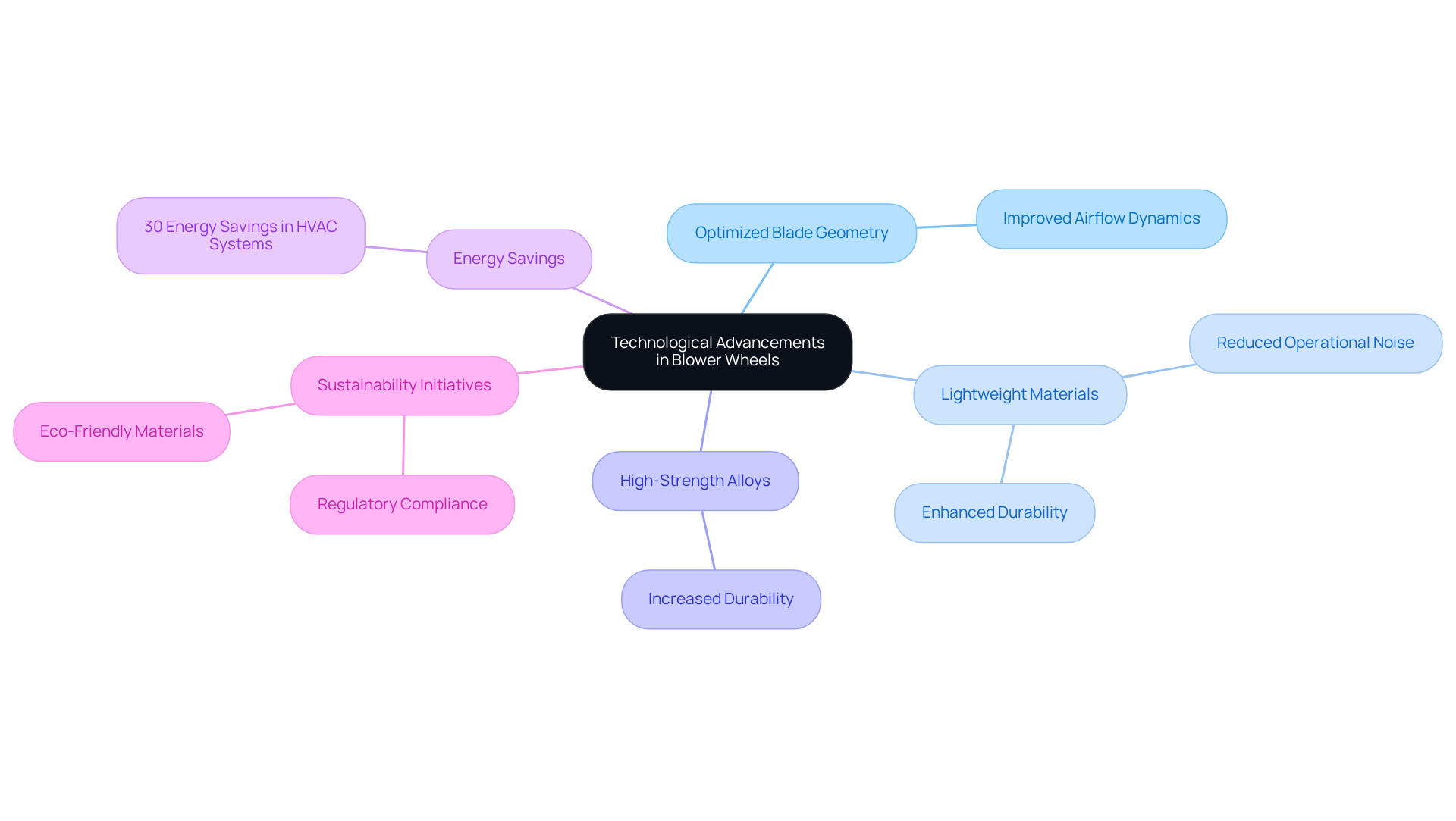

Contemporary designs of the backward inclined blower wheel stand at the forefront of engineering innovation, leveraging advanced materials and cutting-edge techniques to significantly enhance performance and efficiency. Innovations such as optimized blade geometry and the use of lightweight materials markedly improve airflow dynamics and reduce energy consumption.

For instance, the integration of high-strength alloys and composites not only increases durability but also contributes to a notable reduction in operational noise levels. Statistics indicate that these advancements can lead to energy savings of up to 30% in HVAC systems, underscoring the critical importance of selecting the right components.

By adopting these technological advancements, engineers can ensure their systems are equipped with backward inclined blower wheels, thereby fostering innovation and efficiency in their projects. The ongoing trend towards sustainability further drives the demand for eco-friendly materials, aligning with regulatory standards and consumer expectations within the industry.

Conclusion

Backward inclined blower wheels represent a transformative solution for engineers, offering a multitude of benefits that enhance both performance and efficiency across various applications. By prioritizing energy savings, reliability, and versatility, these innovative components empower engineers to optimize their designs while adhering to stringent operational standards.

The impressive energy efficiency, low maintenance requirements, and enhanced safety features of backward inclined blower wheels stand out as key advantages. Their ability to achieve significant operational cost reductions and improve airflow dynamics makes these blower wheels an ideal choice for diverse sectors such as HVAC, manufacturing, and food & beverage. Moreover, ongoing technological advancements in their design further solidify their role as a vital resource for engineers committed to innovation and sustainability.

Incorporating backward inclined blower wheels into engineering projects not only promotes cost-effectiveness but also aligns with the growing demand for eco-friendly solutions. As industries continue to evolve, leveraging these advanced technologies will be crucial for meeting operational goals while ensuring safety and efficiency. Embracing backward inclined blower wheels can pave the way for a more sustainable and economically viable future in engineering practices.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in providing innovative reverse-tilted wheel solutions tailored for the electronics sector, enhancing performance and energy efficiency.

How does Gagner-Toomey Associates support engineers in the electronics sector?

The company collaborates with various manufacturers to offer a broad array of electronics solutions, ensuring engineers have access to state-of-the-art technologies for designing or building electronic systems.

What industries benefit from Gagner-Toomey’s solutions?

Their solutions are particularly beneficial in sectors such as manufacturing and food & beverage, where innovative air-moving designs are crucial for meeting hygiene standards.

What recent advancements have been made in Gagner-Toomey’s technology?

Recent advancements include IoT-enabled monitoring systems in reverse-angled fan technology, enhancing operational efficiency and reliability.

What are backward inclined blower wheels designed for?

Backward inclined blower wheels are designed for optimal efficiency, significantly reducing energy usage compared to conventional fan designs.

How do backward inclined blower wheels contribute to energy savings?

These wheels minimize airflow resistance, leading to lower power requirements, and facilities using them have reported energy savings of up to 25%.

What are the maintenance requirements for backward inclined blower wheels?

They require minimal maintenance, with recommendations for regular upkeep every few months, which helps decrease repair frequency and extend lifespan.

What operational cost reductions can organizations achieve by using backward inclined blower wheels?

Organizations can achieve operational cost reductions of up to 85% by investing in this technology.

What is the projected market growth for backward-tilted fans?

The market for backward-tilted fans is projected to expand at a CAGR of 6.2% from 2026 to 2033.

What makes backward slanted fan components reliable?

Their robust construction minimizes wear and tear, allowing for exceptional durability and consistent operation over extended periods.

How long can backward slanted fan components last in demanding environments?

These components can achieve lifespans exceeding 10 years in challenging operational conditions.

What airflow rates can reverse sloped fan components achieve?

They can facilitate high airflow rates, reaching up to 50,000 cfm.

In what applications are reverse sloped fans commonly used?

They are commonly used in applications such as paint booths, exhaust systems, and component testing facilities within the automotive sector.

What efficiencies can reverse sloped fans achieve?

Reverse sloped fans can achieve efficiencies of up to 82%, making them a cost-effective choice for engineers.