Overview

The article delineates ten significant benefits of backward inclined blowers for electronics cooling, underscoring their energy efficiency, low maintenance requirements, versatility, and environmental merits. These advantages are substantiated by evidence illustrating substantial operational cost reductions, improved performance across a variety of applications, and a steadfast commitment to sustainability. Consequently, backward inclined blowers emerge as a compelling choice for the electronics industry.

Introduction

Backward inclined blowers are revolutionizing the landscape of electronics cooling. They offer a blend of efficiency and adaptability that meets the evolving demands of the industry. As the need for effective temperature regulation intensifies, these innovative devices emerge as key players. They promise significant energy savings, reduced maintenance, and enhanced performance reliability.

However, with numerous cooling solutions available, what sets backward inclined blowers apart? How can they be leveraged to optimize operations in a rapidly changing technological environment?

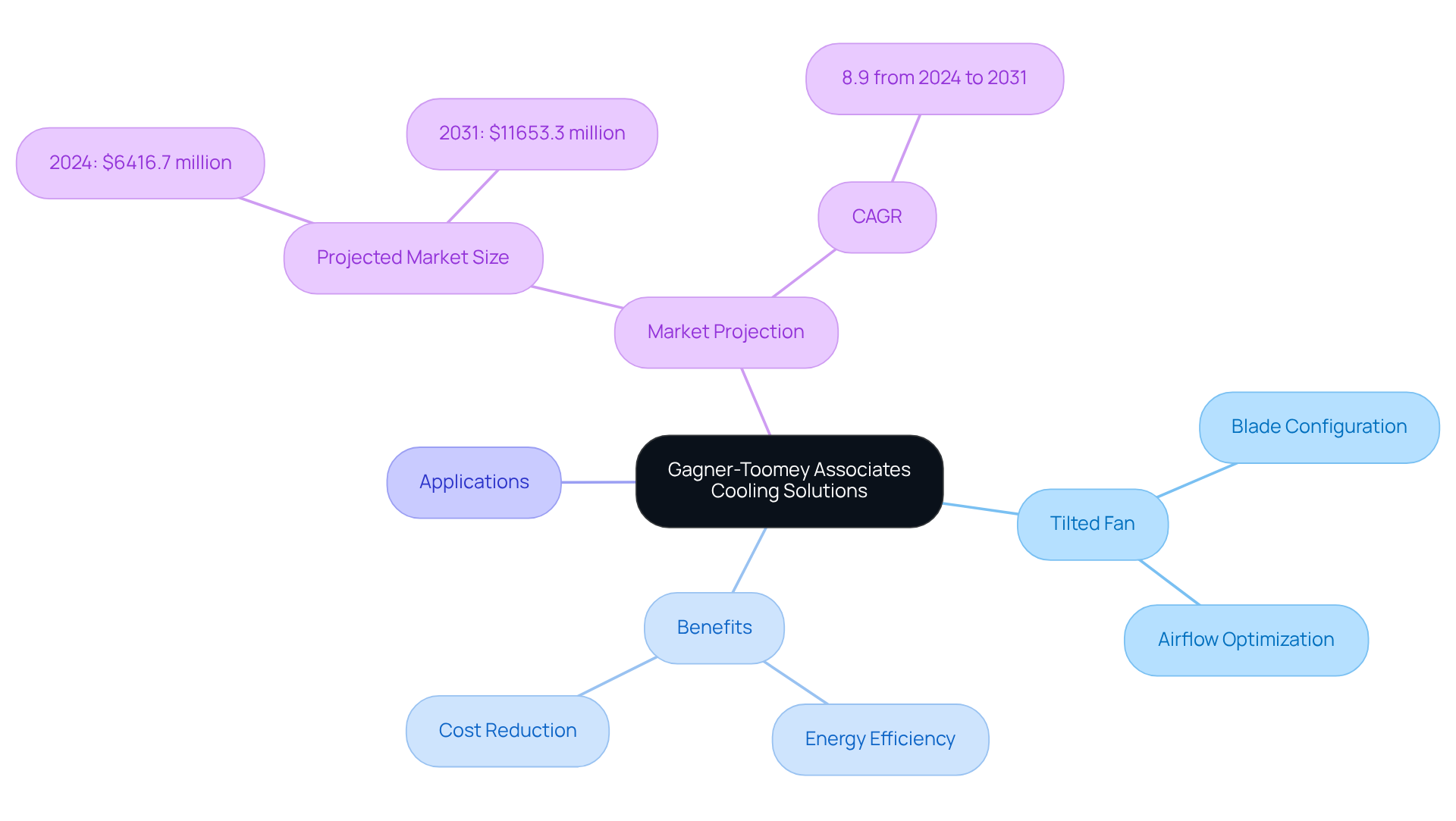

Gagner-Toomey Associates: Innovative Cooling Solutions with Backward Inclined Blowers

Gagner-Toomey Associates stands at the forefront of advanced temperature control solutions tailored specifically for the electronics industry. Among their innovative offerings, the tilted fan emerges as a standout option, significantly enhancing temperature management while effectively addressing the unique challenges faced by engineers in this sector.

These devices feature a specialized blade configuration that optimizes airflow, rendering them exceptionally suited for a variety of applications in electronics heat dissipation. As the demand for energy-efficient solutions escalates, reverse-angled devices are increasingly recognized for their ability to reduce operational costs and enhance system efficiency.

With the global market for projected to reach $11,653.3 million by 2031, the significance of cutting-edge cooling technologies, such as sloped fans, becomes increasingly critical in meeting industry demands.

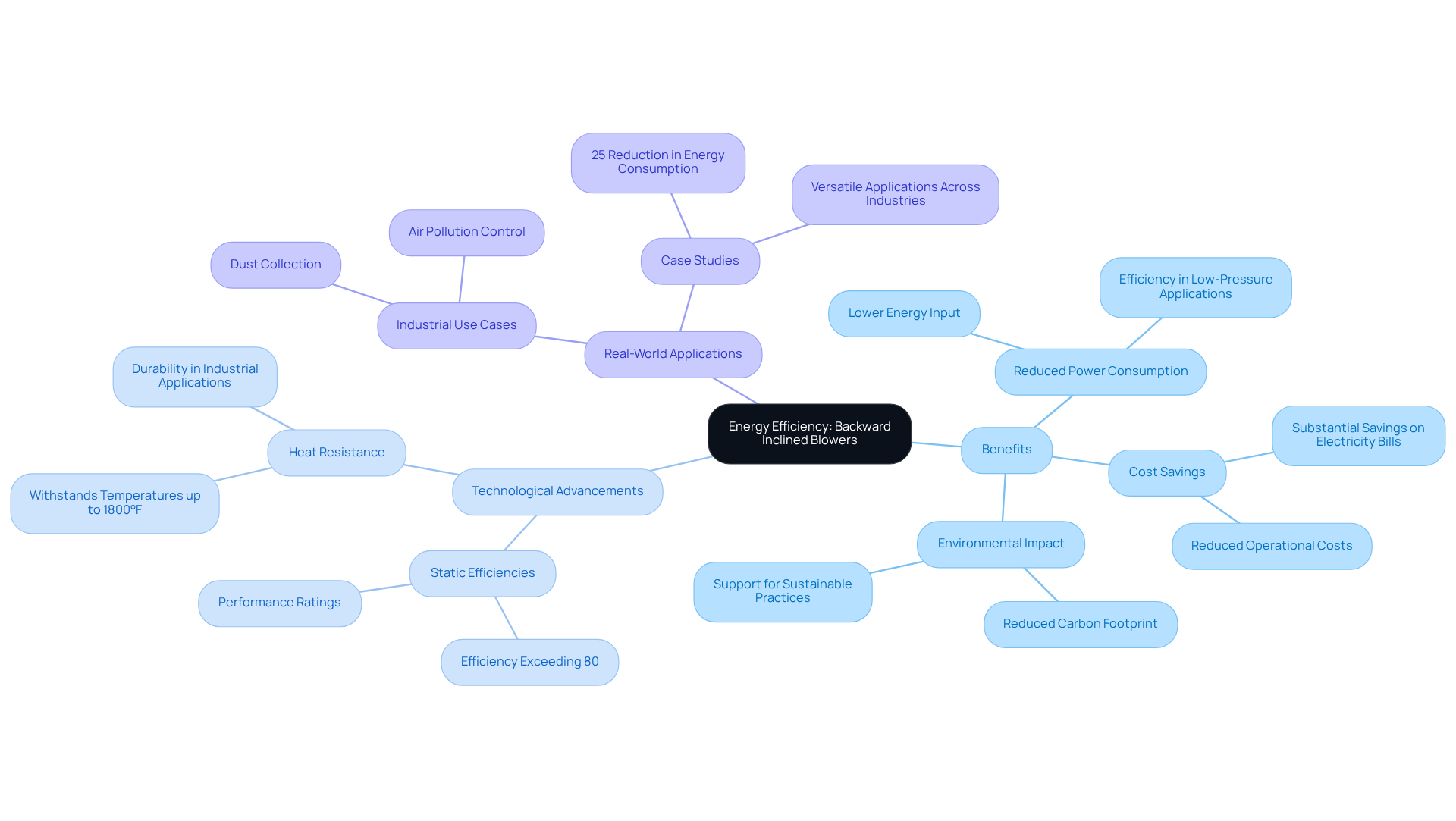

Energy Efficiency: Reduce Power Consumption with Backward Inclined Blowers

Backward inclined blowers represent a significant advancement in energy efficiency, significantly reducing power consumption when compared to traditional fan systems. Their aerodynamic blade design minimizes airflow resistance, which allows for optimal performance with lower energy input. This enhanced efficiency translates into and a reduced carbon footprint, positioning them as an appealing choice for environmentally conscious companies.

In 2025, innovations in backward inclined blowers technology have further elevated their efficiency, with static efficiencies surpassing 80% and reaching as high as 82%. Experts assert that backward inclined blowers not only diminish operational costs but also play a crucial role in promoting sustainable practices within industrial environments. Case studies reveal that facilities utilizing sloped fans for cooling systems have achieved a remarkable 25% reduction in energy consumption, underscoring their effectiveness in real-world applications.

Moreover, reverse-angled fans are capable of withstanding temperatures up to 1800°F, enhancing their suitability across various industrial applications. As industries increasingly prioritize energy efficiency, backward inclined blowers emerge as a reliable solution for firms committed to environmental stewardship.

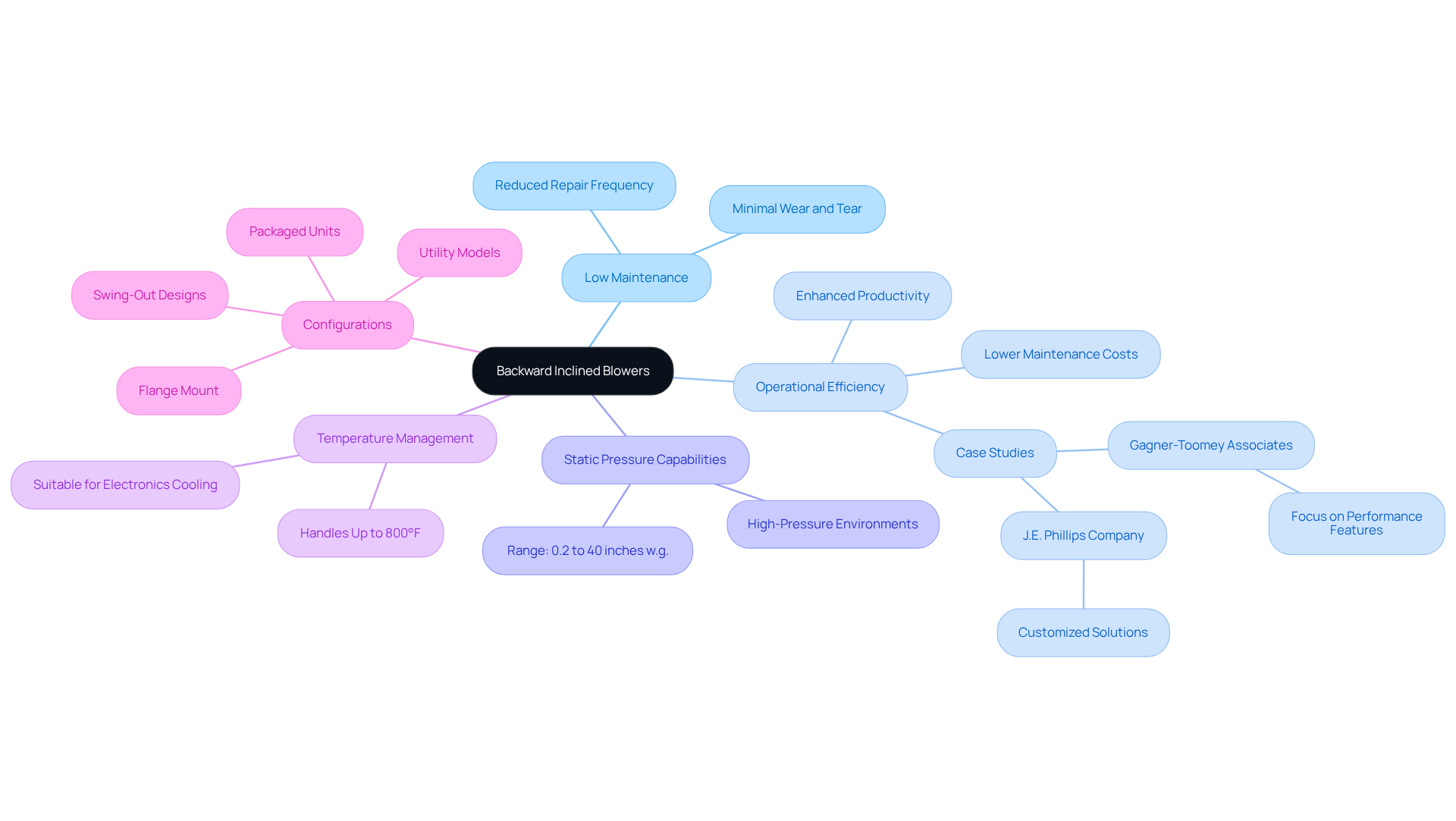

Low Maintenance: Simplify Operations with Backward Inclined Blowers

Backward inclined blowers are celebrated for their minimal maintenance requirements, significantly reducing wear and tear. This design not only extends the average lifespan of the devices but also decreases the frequency of repairs and replacements. With static pressure capabilities ranging from 0.2 to 40 inches w.g. and the ability to , these devices excel in high-temperature environments, particularly in electronics cooling applications. Consequently, engineers can focus on their core operations without the constant worry of equipment failure. The use of backward inclined blowers contributes to this reliability, resulting in smoother operations and a marked reduction in equipment downtime.

For instance, case studies indicate that facilities employing backward inclined blowers experience enhanced operational efficiency, as these systems can effectively manage polluted air with minimal maintenance. Companies have reported substantial improvements in productivity and lowered maintenance costs. Furthermore, rear-tilted fans are available in various configurations, such as flange mount and packaged units, allowing engineers to select the ideal fan for their specific requirements. By ensuring consistent airflow and performance, backward inclined blowers foster a more stable and productive working environment.

Versatility: Adapt Backward Inclined Blowers for Diverse Cooling Needs

Backward-tilted fans exemplify remarkable adaptability, positioning them as ideal solutions for a diverse range of temperature regulation applications within the electronics sector. This versatility enables effective operation in critical environments such as:

- Data centers

- Telecommunications equipment

- Industrial machinery

These devices can be tailored to meet specific airflow and pressure requirements, ensuring optimal performance across varying conditions. For instance, reverse-angled fans play a crucial role in maintaining effective temperature regulation in high-density server environments, where precise airflow control is essential to prevent overheating.

Statistics reveal that indoor air can be two to five times more polluted than outdoor air, underscoring the necessity for effective ventilation solutions. Furthermore, case studies demonstrate how customized backward inclined blowers significantly improve temperature regulation in industrial applications, showcasing their vital contribution to enhancing operational reliability and energy efficiency. By leveraging advanced design techniques, these devices not only address the unique demands of each application but also support sustainability initiatives within the electronics industry.

Performance Reliability: Ensure Consistent Cooling with Backward Inclined Blowers

Backward inclined blowers are recognized for their exceptional performance reliability, making them a crucial component in electronics refrigeration systems. Their sturdy construction and efficient design ensure consistent airflow, which is vital for maintaining optimal temperatures in sensitive electronic components. This reliability significantly mitigates the risk of overheating, thereby of equipment and reducing the likelihood of system failures.

Notably, various case studies illustrate that backward-angled fans excel in preserving air quality and regulating temperature in cleanrooms and laboratories, where stable airflow is imperative. Furthermore, their capacity to operate quietly and efficiently renders them ideal for environments where noise reduction is critical.

By ensuring consistent airflow, backward inclined blowers not only enhance the performance of electronic systems but also contribute to overall operational efficiency, making them a preferred choice for engineers seeking reliable temperature regulation solutions.

Compact Design: Optimize Space with Backward Inclined Blowers

Backward-leaning fans are engineered with a compact structure that allows them to seamlessly fit into constrained spaces, making them particularly advantageous in scenarios where space is at a premium. Their smaller footprint does not compromise performance; rather, it empowers engineers to implement effective cooling solutions without requiring extensive modifications to existing layouts. This adaptability is critical in settings such as telecommunications and medical facilities, where maintaining while managing limited space is paramount.

Case studies demonstrate that facilities transitioning to sloped fans have achieved significant improvements in airflow and noise reduction, with research indicating that DC motors can realize noise reductions of up to 10 dB compared to standard AC devices. This highlights their effectiveness in optimizing space while enhancing performance.

Furthermore, the robust design of these devices ensures longevity, as they are constructed to operate reliably in extreme temperatures and harsh conditions, thus extending their lifespan and reducing the need for replacements. By leveraging the advantages of backward inclined blowers, engineers can achieve improved temperature regulation while maximizing available space, ultimately leading to more efficient and effective electronic systems.

Noise Reduction: Achieve Quieter Operations with Backward Inclined Blowers

Backward inclined blowers are engineered for quiet operation, significantly diminishing noise levels in comparison to conventional fan systems. This feature is vital in environments where can disrupt workflows or compromise comfort, such as offices and residential areas. The reduction in noise not only enhances user experience but also contributes to heightened workplace productivity; studies indicate that lower noise levels can foster better concentration and efficiency among employees.

Furthermore, these units are recognized for their high efficiency, particularly at lower speeds, sustaining effective temperature regulation while moving substantial volumes of air with minimal energy consumption. This ensures that temperature regulation systems operate effectively while curtailing operational expenses.

In various case studies, backward inclined blowers have demonstrated their capability in maintaining optimal airflow and energy efficiency, solidifying their status as a preferred option for engineers and facility managers seeking quieter ventilation solutions.

Enhanced Airflow: Improve Cooling Efficiency with Backward Inclined Blowers

Backward inclined blowers are specifically designed to optimize airflow, which is a critical factor in enhancing temperature management for electronic systems. Gagner-Toomey Associates provides innovative solutions that facilitate the movement of larger air volumes, essential for effectively dissipating heat from electronic components. Their not only aids in maintaining optimal operating temperatures but also significantly enhances overall system performance.

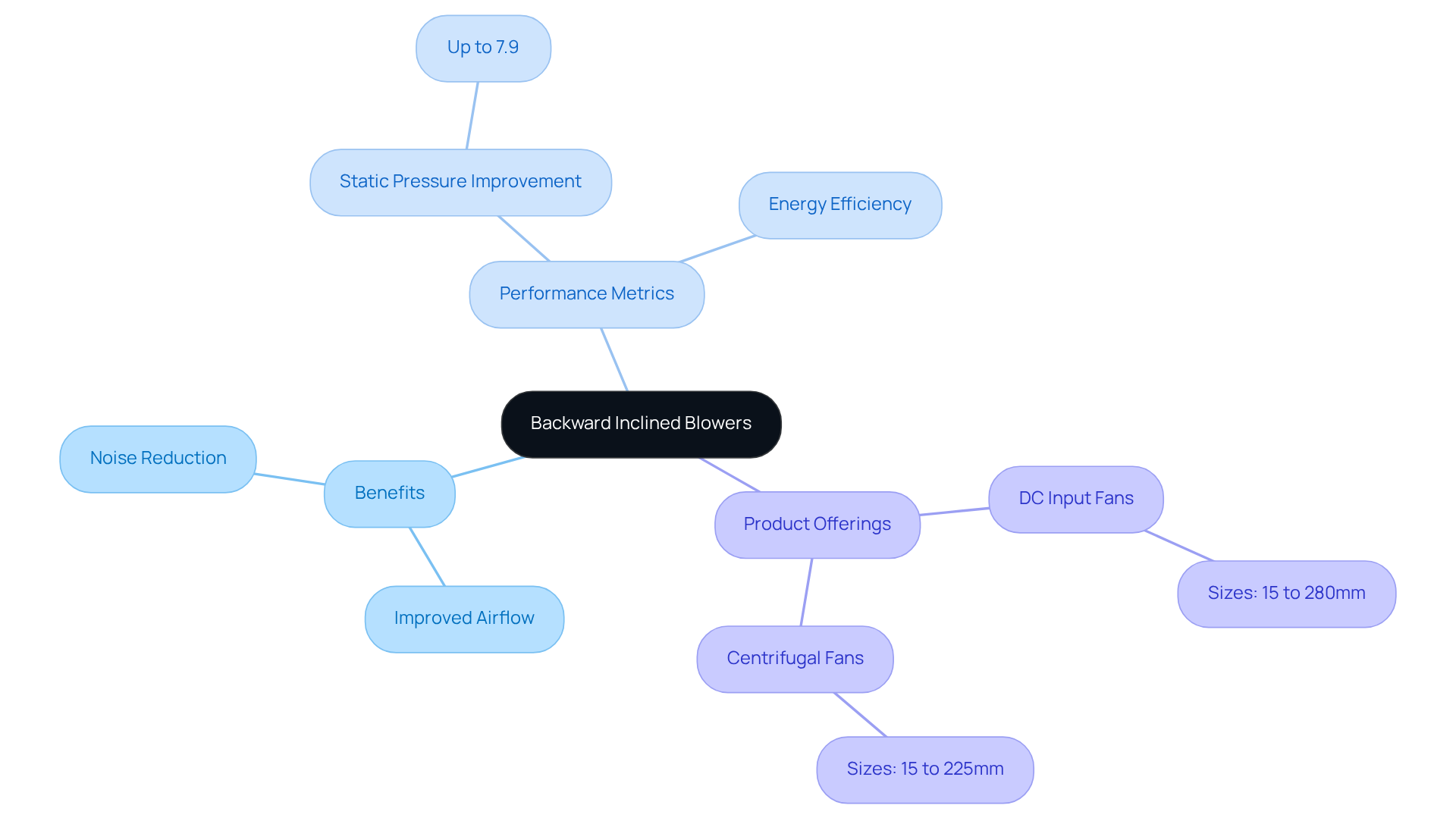

Research indicates that backward inclined blowers can improve static pressure by as much as 7.9%, leading to better temperature regulation across various applications. Furthermore, their design minimizes turbulence, resulting in quieter operation—an essential feature in environments where noise reduction is crucial, such as data centers, hospitals, and laboratories.

In light of the challenges posed by the global energy crisis in 2023, the integration of backward inclined blowers into temperature control systems has become increasingly vital for achieving significant enhancements in energy efficiency and reliability. Moreover, Gagner-Toomey’s extensive portfolio of temperature regulation solutions includes:

- DC input fans ranging from 15 to 280mm

- Centrifugal fans from 15 to 225mm

This underscores the importance of proper installation and maintenance to maximize the benefits of these devices, ultimately contributing to the durability and efficiency of electronic equipment.

Cost-Effectiveness: Maximize Value with Backward Inclined Blowers

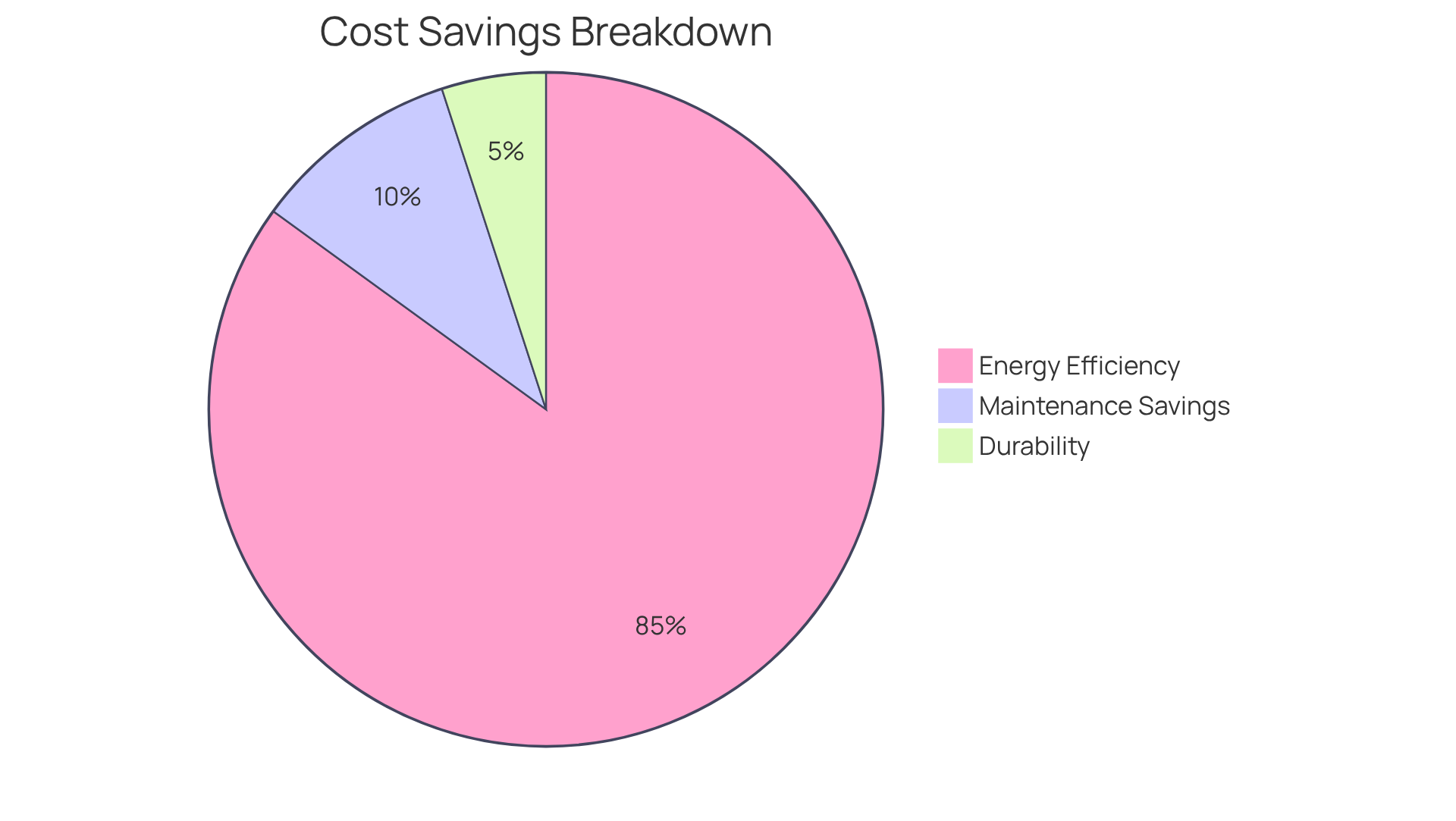

Investing in backward inclined blowers presents substantial long-term financial benefits. Their remarkable energy efficiency can lead to operational cost reductions of up to 85%, significantly lowering energy bills compared to traditional systems. This efficiency results directly in , establishing these devices as a financially prudent choice for cooling systems.

Moreover, their robust design necessitates less frequent upkeep, which mitigates unforeseen repair expenses and minimizes downtime. Case studies highlight that companies utilizing inclined fans experience fewer replacements due to their durability and reduced maintenance needs, further enhancing overall cost-efficiency.

The combination of reliability and durability ensures that these devices not only operate efficiently but also contribute to long-term savings. Additionally, backward inclined blowers are recognized for their quieter operation, making them ideal for noise-sensitive environments, thereby adding another layer of value for businesses striving to maintain a comfortable working atmosphere.

Environmental Benefits: Promote Sustainability with Backward Inclined Blowers

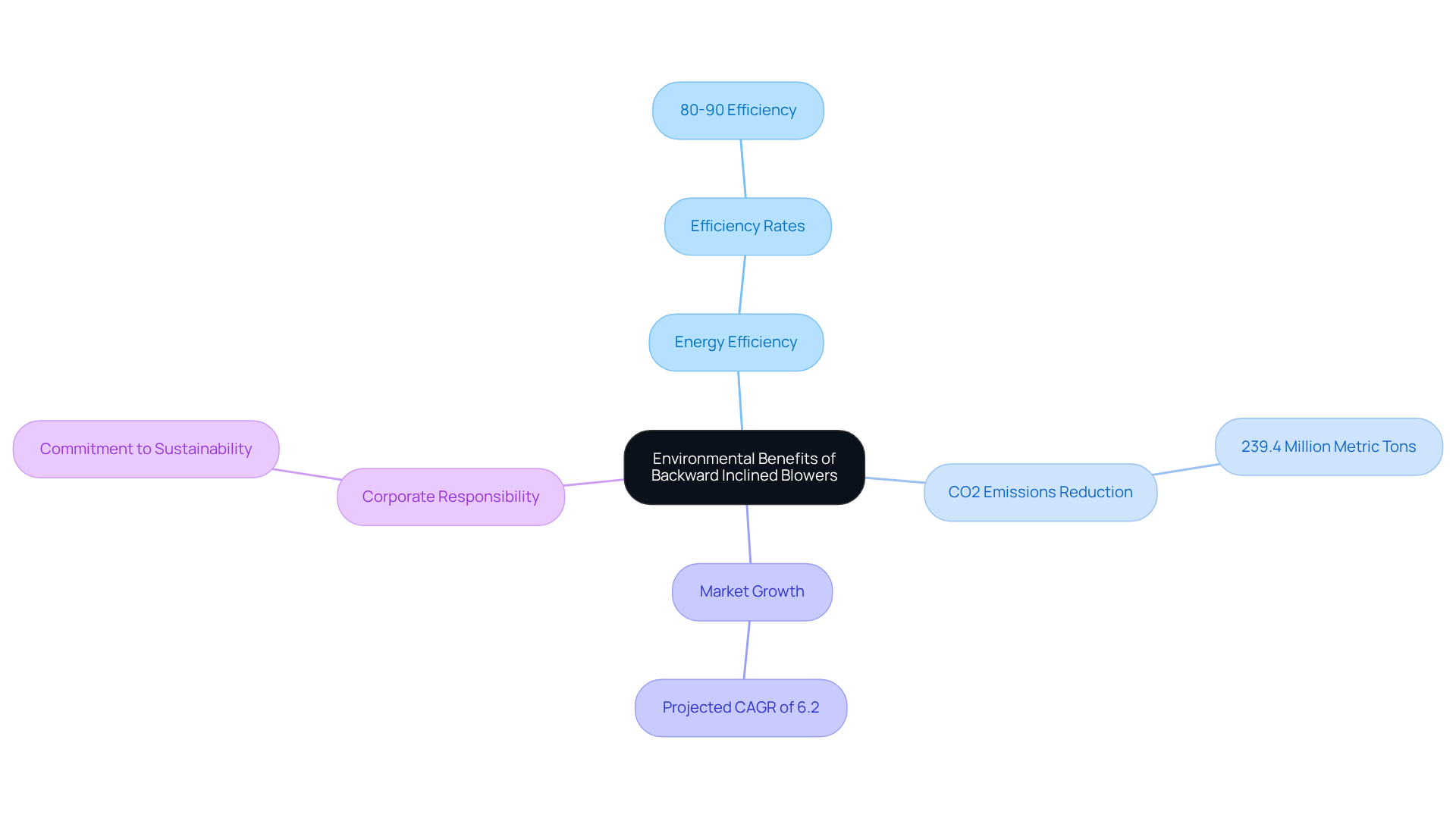

Backward-tilted fans play a crucial role in enhancing sustainability within the electronics temperature regulation sector by significantly reducing energy consumption and minimizing waste. These machines achieve remarkable efficiencies of 80-90%, which translates directly to lower greenhouse gas emissions and a diminished environmental footprint. By adopting slanted fans, businesses not only enhance their temperature regulation solutions but also align with broader sustainability initiatives, thereby reinforcing their commitment to corporate responsibility.

The Department of Energy estimates that the implementation of energy-efficient standards for general fans and blowers could result in cumulative emission reductions of 239.4 million metric tons of CO2, highlighting the considerable impact of these technologies. This trend aligns with the increasing demand for in the electronics industry, where energy-efficient solutions are becoming a priority.

Furthermore, the market for backward inclined blowers is projected to grow at a CAGR of 6.2% from 2026 to 2033, indicating a shift towards more sustainable cooling technologies. By investing in these advanced systems, organizations can contribute to a greener future while simultaneously reaping long-term operational cost savings.

Conclusion

Backward inclined blowers are transforming the landscape of electronics cooling, delivering a multitude of benefits tailored to the industry’s unique demands. Their innovative design not only improves energy efficiency but also guarantees reliable temperature regulation, establishing them as essential components in contemporary cooling systems. As engineers and companies pursue sustainable practices, these blowers emerge as a solution that harmonizes performance with environmental responsibility.

This article underscores several key advantages of backward inclined blowers, including:

- Reduced power consumption

- Minimal maintenance requirements

- Versatile applications across diverse sectors

Their compact design facilitates seamless integration into constrained spaces, while their noise-reducing capabilities promote a conducive working environment. Furthermore, the cost-effectiveness of these blowers, combined with their substantial environmental benefits, reinforces their pivotal role in advancing sustainable practices within the electronics industry.

As the demand for efficient and reliable cooling solutions escalates, adopting backward inclined blowers is not merely a prudent choice—it is a critical step toward achieving operational excellence and environmental stewardship. Organizations that prioritize these advanced cooling technologies will not only enhance their performance but also contribute to a greener future, ultimately positioning themselves as leaders in the pursuit of sustainability within the electronics sector.

Frequently Asked Questions

What are backward inclined blowers and their benefits?

Backward inclined blowers are advanced cooling devices that feature an aerodynamic blade design, which minimizes airflow resistance and significantly reduces power consumption compared to traditional fan systems. They enhance energy efficiency, leading to lower electricity bills and a reduced carbon footprint.

How do backward inclined blowers contribute to energy efficiency?

Their specialized blade configuration optimizes airflow, allowing for optimal performance with lower energy input. Innovations in their technology have achieved static efficiencies surpassing 80%, with some reaching as high as 82%. Facilities using these blowers have reported a 25% reduction in energy consumption.

What industries benefit from using backward inclined blowers?

Backward inclined blowers are particularly beneficial in the electronics industry for temperature control and heat dissipation. They are also suitable for various industrial applications due to their ability to withstand high temperatures, up to 1800°F.

What maintenance requirements do backward inclined blowers have?

These blowers are known for their minimal maintenance requirements, which reduces wear and tear, extends their lifespan, and decreases the frequency of repairs and replacements. This reliability helps maintain smoother operations and reduces equipment downtime.

What configurations are available for backward inclined blowers?

Backward inclined blowers come in various configurations, including flange mount and packaged units, allowing engineers to choose the ideal fan that meets their specific requirements.

How do backward inclined blowers impact operational efficiency?

Facilities employing backward inclined blowers experience enhanced operational efficiency due to their ability to manage polluted air with minimal maintenance. Companies have reported improvements in productivity and reduced maintenance costs as a result.