Overview

This article delineates ten significant benefits of employing DC centrifugal fans in engineering projects. It underscores their:

- Energy efficiency

- Compact design

- Low noise operation

- Versatility

- Reliability

- Ease of installation

- Advanced control options

- Durability

- Cost-effectiveness

Each benefit is meticulously detailed, illustrating how these fans enhance performance and efficiency across various applications. Consequently, they emerge as a valuable choice for engineers striving to optimize their projects.

Introduction

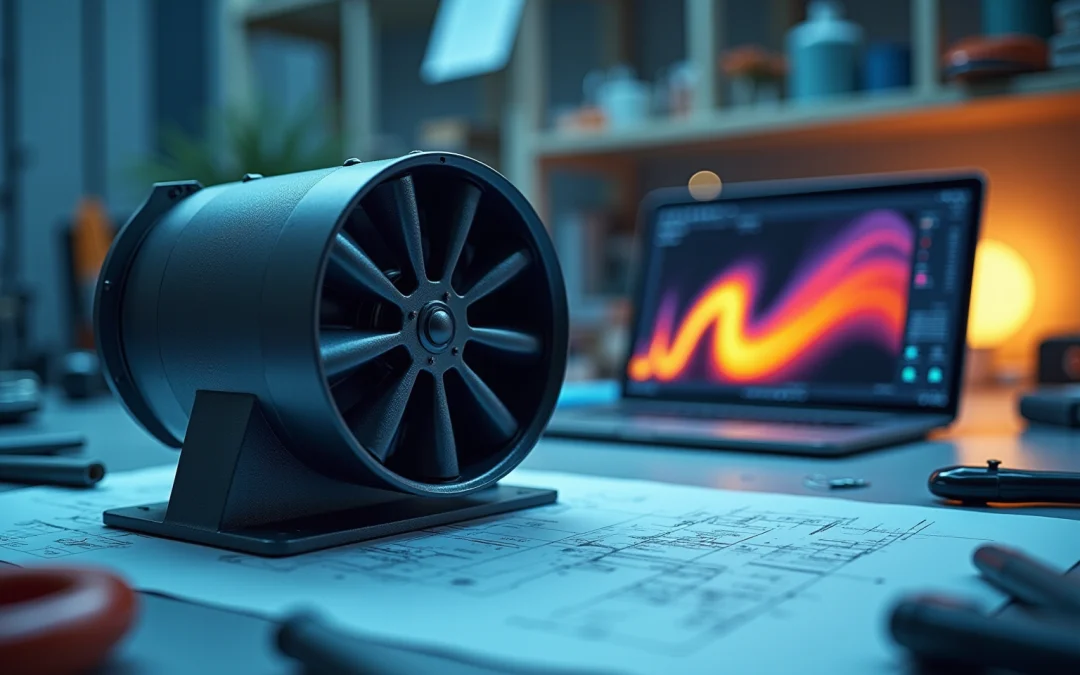

DC centrifugal fans are transforming engineering projects by delivering a powerful combination of efficiency, adaptability, and reliability. As industries increasingly focus on sustainable practices, these fans emerge as leaders due to their energy-saving capabilities and compact designs that optimize space utilization.

Yet, a critical question arises: how can engineers harness the unique advantages of DC centrifugal fans to enhance performance while addressing the complexities of contemporary engineering demands?

Gagner-Toomey Associates: Innovative Solutions for DC Centrifugal Fans

specializes in providing for essential components like in various . By partnering with a select group of exceptional manufacturers, the company guarantees that clients access cutting-edge products that significantly enhance performance and efficiency. Their deep expertise in , coupled with a robust focus on thermal and , empowers them to tailor offerings that meet specific client requirements. This positions Gagner-Toomey Associates as a trusted ally in the electronics industry, equipping engineers with the innovative solutions necessary for their success.

Energy Efficiency: Reduce Power Consumption with DC Centrifugal Fans

from Gagner-Toomey Associates exemplify high , resulting in significant reductions in . By leveraging alongside optimized airflow designs, the DC centrifugal fans effectively minimize energy waste, positioning themselves as an optimal choice for engineers dedicated to of their projects.

Offered in a diverse range of sizes from 15 to 225mm, these devices cater to various applications across industries such as electronics and automotive. This efficiency not only diminishes operational costs but also plays a crucial role in , aligning seamlessly with the increasing demand for environmentally responsible engineering solutions.

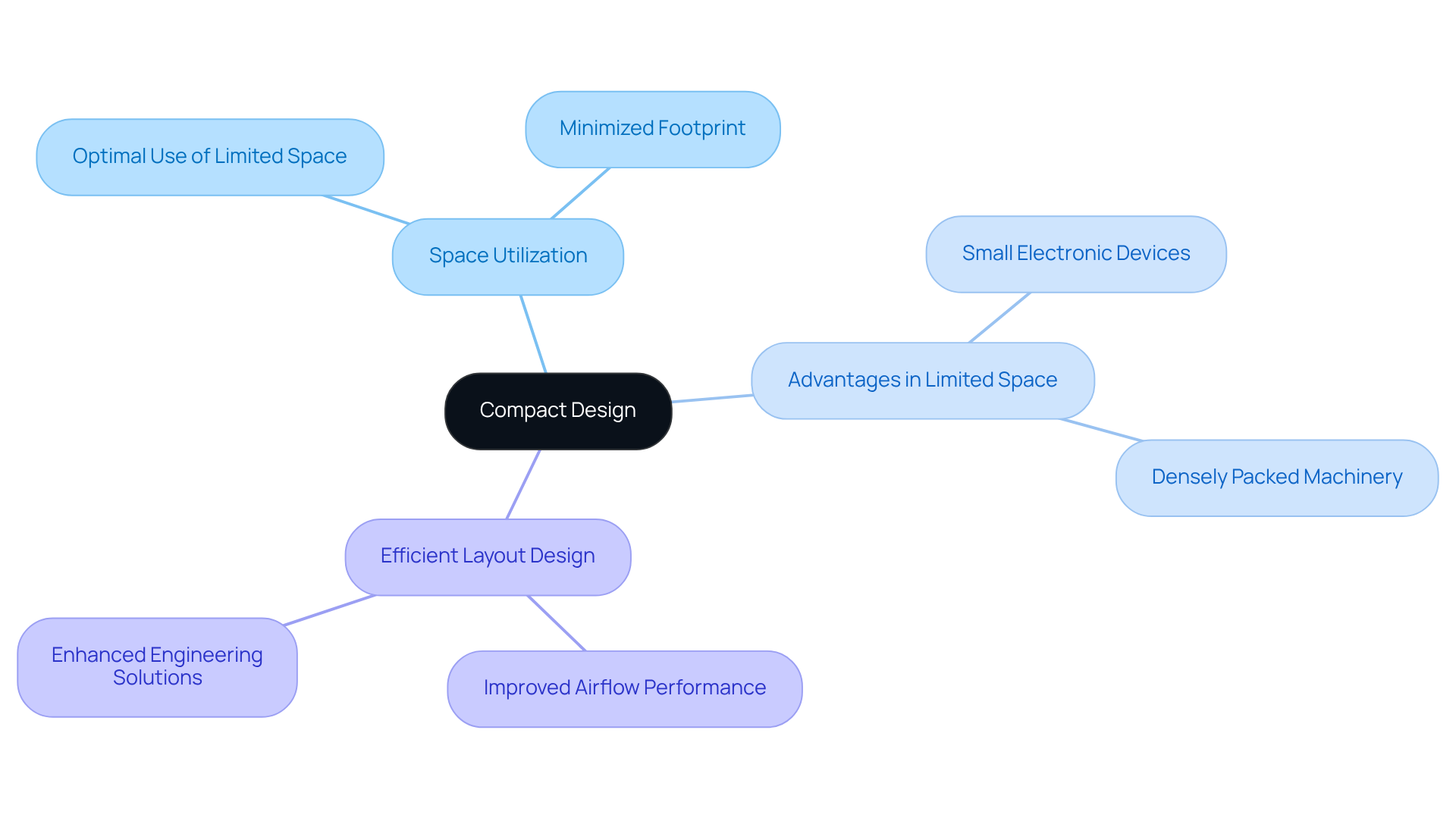

Compact Design: Maximize Space Utilization in Your Projects

A defining characteristic of DC rotary blowers is their , which facilitates in . This feature proves particularly advantageous in scenarios where , such as in small electronic devices or densely packed machinery. The of these devices empowers engineers to devise more without sacrificing .

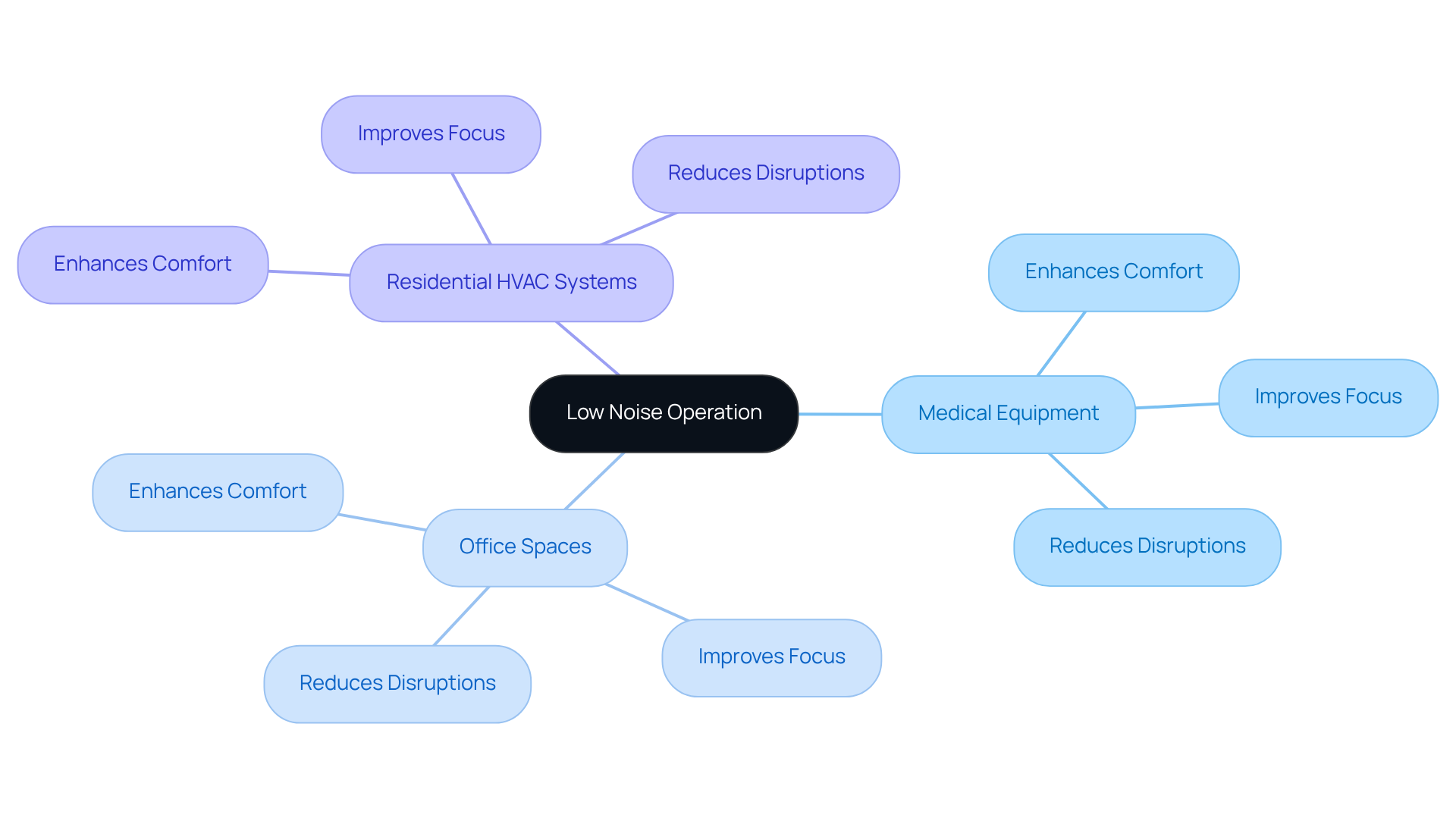

Low Noise Operation: Enhance Comfort in Sensitive Environments

are expertly engineered for , making them particularly suitable for where is essential. This feature is especially advantageous in applications such as:

- Medical equipment

- Office spaces

- Residential HVAC systems

By employing advanced design techniques and high-quality materials, these DC centrifugal fans deliver while significantly reducing the disruptive noise often associated with traditional models. Their enhances user comfort, particularly in settings where focus and tranquility are critical.

For instance, in , the of DC blower units are vital for maintaining a serene environment, allowing healthcare professionals to concentrate on patient care without auditory distractions. Furthermore, the ability of these devices to operate quietly makes them ideal for residential applications, ensuring that HVAC systems do not disturb the peace of home environments.

Additionally, DC blower units are designed to consume less electricity than older models, resulting in . In summary, the integration of low noise technology in DC centrifugal fans not only boosts operational efficiency but also significantly enhances user comfort in sensitive environments.

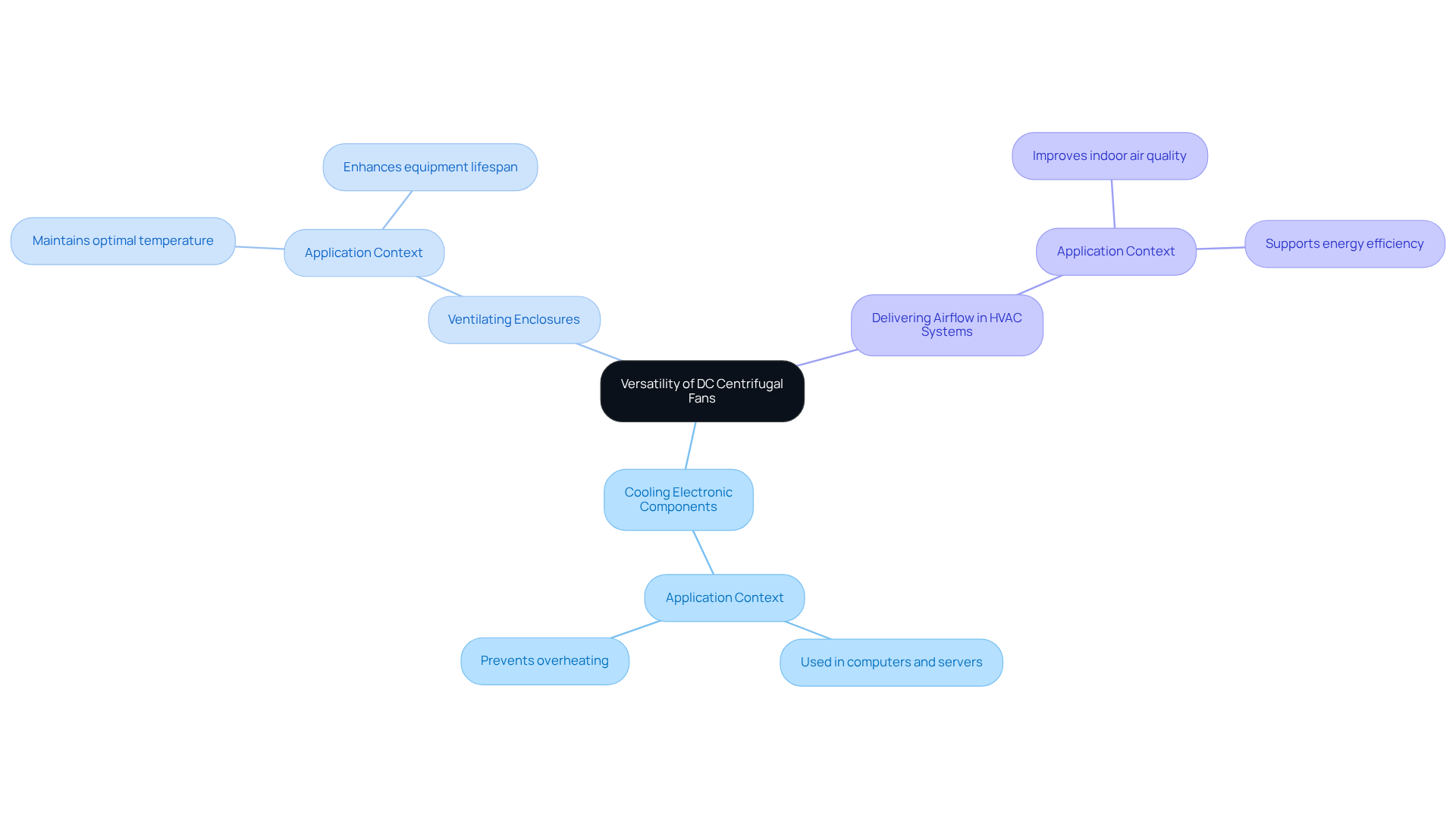

Versatility: Adapt DC Centrifugal Fans for Multiple Applications

demonstrate remarkable versatility, making them suitable for a wide array of applications across diverse industries. The DC centrifugal fan can be employed in:

- Delivering airflow in

This showcases its ability to adapt to specific performance requirements. This adaptability positions them as , facilitating innovative solutions tailored to meet unique challenges. By leveraging the capabilities of DC centrifugal blowers, engineers can confidently address complex scenarios, ensuring .

Reliability: Ensure Consistent Performance in Critical Systems

Dependability stands as a cornerstone in the selection of , and distinctly excel in this regard. Designed to withstand rigorous operating conditions, these units offer in critical systems where failure is simply not an option. Their robust construction, coupled with , guarantees without sacrificing efficiency or effectiveness. This reliability not only underscores their value but also positions them as a preferred choice for professionals seeking in demanding environments.

Ease of Installation: Simplify Integration into Your Systems

DC rotary blowers are designed with the simplicity of setup in mind, facilitating into various systems. Their standardized mounting options and significantly reduce the time and effort required for installation. This allows engineers to focus on other .

Particularly in fast-paced environments where time is crucial, this proves to be invaluable. By streamlining the setup process, DC rotary blowers not only enhance but also empower .

Advanced Control Options: Optimize Performance with DC Centrifugal Fans

DC rotary blowers are equipped with that empower engineers to tailored to specific project requirements. With features such as:

- Integrated feedback systems

and energy consumption are attainable. This exceptional level of control not only but also extends the lifespan of the devices by mitigating unnecessary wear and tear.

Durability: Achieve Long-Term Performance with DC Centrifugal Fans

Durability stands as a hallmark of the units from , crafted from specifically designed for extreme conditions. Their against the rigors of continuous use, making the DC centrifugal fan ideal for , automotive, and other industrial sectors where reliability is paramount.

With a comprehensive product range spanning from 15 to 225mm, these devices are and low noise, with IP protection available upon request. By investing in dependable ventilators, and significantly reduce the need for frequent replacements, thereby enhancing the effectiveness of their operations.

Cost-Effectiveness: Maximize Value with DC Centrifugal Fans

DC rotary blowers represent a significant opportunity for , offering value that transcends their initial acquisition cost. Their translates into reduced utility bills, while their inherent durability minimizes maintenance and replacement expenses over time. By selecting a , engineers can optimize their , achieving peak performance without surpassing budget constraints. This strategic choice not only but also aligns with fiscal responsibility, making it a for any engineering project.

Conclusion

DC centrifugal fans provide a wealth of advantages that significantly enhance engineering projects across diverse industries. Their energy efficiency, compact design, low noise operation, and versatility render them indispensable tools for engineers aiming to optimize performance while minimizing environmental impact. By integrating these innovative solutions, professionals can achieve exceptional results, ensuring their projects not only meet but surpass expectations.

The article highlights key benefits such as:

- Reliability

- Ease of installation

- Advanced control options

- Durability

These features collectively bolster the effectiveness and longevity of DC centrifugal fans, empowering engineers to confront complex challenges with confidence. Their adaptability to multiple applications further emphasizes their critical role in modern engineering, establishing them as essential components in systems ranging from electronics to HVAC.

Ultimately, the strategic utilization of DC centrifugal fans presents a significant opportunity for engineers to enhance operational efficiency while upholding fiscal responsibility. By prioritizing these advanced fan technologies, professionals can drive innovation and sustainability in their projects, securing long-term success in an increasingly competitive landscape. Embracing these solutions yields immediate benefits and positions engineering endeavors for future growth and resilience.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in providing innovative solutions for essential components like DC centrifugal fans in various engineering applications.

How does Gagner-Toomey Associates ensure product quality?

The company partners with a select group of exceptional manufacturers to guarantee access to cutting-edge products that enhance performance and efficiency.

What expertise does Gagner-Toomey Associates offer?

They have deep expertise in cooling technologies and a strong focus on thermal and power management solutions, enabling them to tailor offerings to meet specific client requirements.

What are the benefits of using DC centrifugal fans from Gagner-Toomey Associates?

These fans exemplify high energy efficiency, significantly reducing power consumption and minimizing energy waste, which helps enhance the sustainability of engineering projects.

What sizes are available for DC centrifugal fans?

DC centrifugal fans are offered in a diverse range of sizes from 15 to 225mm, catering to various applications across industries such as electronics and automotive.

How do DC centrifugal fans contribute to sustainability?

Their energy efficiency not only diminishes operational costs but also plays a crucial role in reducing the carbon footprint, aligning with the demand for environmentally responsible engineering solutions.

What is a key feature of DC rotary blowers?

A defining characteristic of DC rotary blowers is their compact design, which facilitates optimal space utilization in engineering projects.

In what scenarios is the compact design of DC rotary blowers particularly advantageous?

The compact design is particularly advantageous in scenarios with limited space, such as small electronic devices or densely packed machinery, allowing for more efficient layouts without sacrificing airflow performance.