Overview

The article “10 Benefits of Using Liquid Cold Plates in Electronics” presents a compelling overview of the advantages associated with liquid cold plates for thermal management in electronic systems. It emphasizes their superior heat dissipation capabilities, extensive customization options, and cost-effectiveness.

Collectively, these benefits significantly enhance the reliability and performance of high-density electronic applications. This addresses the increasing demand for efficient cooling solutions across various industries, making liquid cold plates an essential consideration for professionals seeking optimal thermal management strategies.

Introduction

In the rapidly evolving landscape of electronics, the demand for efficient cooling solutions has never been more critical. Gagner-Toomey Associates leads the charge with innovative liquid cold plates that promise to revolutionize thermal management across various industries. As the market for liquid cooling systems surges, reaching an impressive $152.53 billion in 2023, engineers are increasingly turning to these advanced technologies to address the challenges of heat dissipation in high-performance applications.

With a focus on customizability, reliability, and sustainability, liquid cold plates not only enhance performance but also contribute to cost savings and environmental goals. This article explores the transformative impact of liquid cooling technologies, highlighting their significance in optimizing the performance and longevity of electronic systems.

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics

Gagner-Toomey Associates leads , focusing on innovative temperature control solutions. The company’s emphasis on power management and thermal management showcases a diverse portfolio of manufacturers dedicated to solving complex engineering challenges. Their unwavering dedication to excellence ensures that engineers can leverage advanced technologies, including liquid cold plates, which are vital for effective thermal management in high-performance electronics. The significance of liquid temperature regulation systems is underscored by the market’s remarkable size, projected to reach around $152.53 billion in 2023. This figure illustrates the growing demand for sophisticated temperature management solutions that enhance data center efficiency. As the sector evolves, Gagner-Toomey Associates remains committed to providing tailored solutions that not only boost performance but also address the high costs associated with advanced temperature control technologies—a challenge particularly affecting small and medium-sized enterprises.

Recent case studies, such as the ‘Application Segment Analysis of New Electronic Temperature Regulation Technology Market,’ highlight successful implementations of liquid cold plate technologies across various application segments, including business computing and quantum research. These insights reveal market trends and challenges, enabling companies to strategize effectively in a dynamic environment. As the electronics sector continues to evolve, Gagner-Toomey Associates is poised to equip engineers with the latest advancements in temperature regulation solutions, ensuring they can introduce innovative concepts to the market.

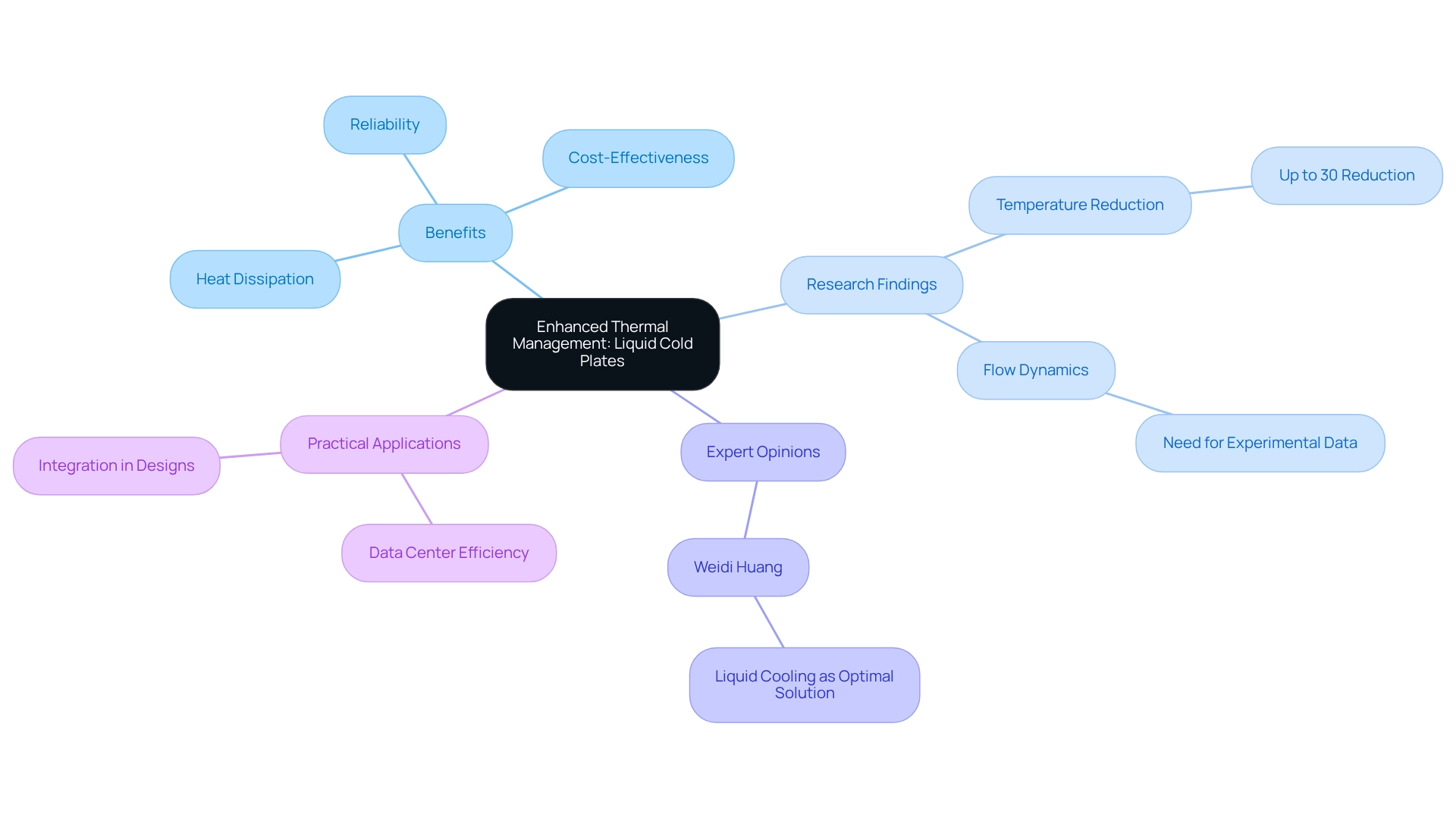

Enhanced Thermal Management: Efficient Heat Dissipation with Liquid Cold Plates

Liquid cold plates are engineered to deliver exceptional heat dispersion, significantly outperforming traditional air cooling methods. By utilizing as a fluid coolant, these surfaces efficiently absorb and transfer heat away from critical electronic components, which is essential in high-density applications where excessive heat can compromise performance and lead to failures. The superior thermal conductivity of extruded chill components not only enhances their efficiency in maintaining optimal operating temperatures but also reduces production costs, making them a cost-effective solution for engineers.

Research indicates that thermal management systems using a liquid cold plate can achieve average temperature reductions of up to 30% compared to air-based alternatives, thereby improving the reliability and longevity of electronic devices. A recent investigation into microchannel heat sinks, which are integral to liquid cold plate fluid refrigeration systems, highlights the need for further experimental data to optimize flow dynamics, crucial for maximizing thermal efficiency in data centers. This emphasizes the practical implications for engineers striving to enhance their temperature regulation technologies.

Moreover, expert opinions underscore the importance of liquid cold plate technology in fulfilling the energy efficiency demands of modern data centers. As Weidi Huang notes, “Liquid temperature control is the ideal answer for tackling data center temperature management challenges and energy efficiency requirements.” This consensus reinforces the recognition of the liquid cold plate as a vital component in high-performance environments. The benefits of fluid cooling surfaces, such as liquid cold plates, extend beyond mere temperature management; they play a pivotal role in enhancing overall system reliability and operational efficiency. In conclusion, engineers should consider the integration of liquid cold plate cooling components to enhance thermal control in their designs, ensuring improved performance and durability of electronic systems.

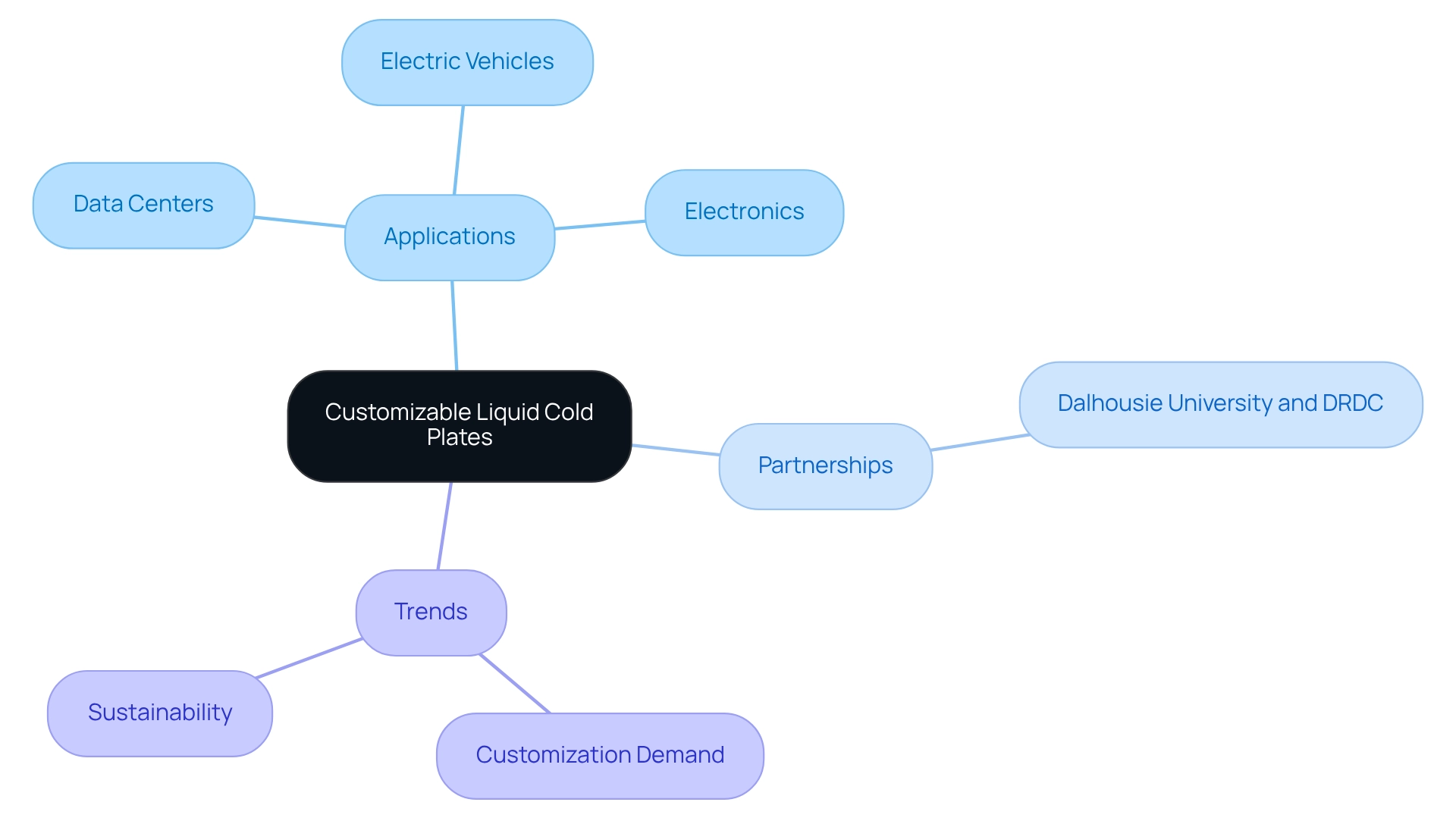

Design Flexibility: Customizable Liquid Cold Plates for Diverse Applications

One of the remarkable characteristics of fluid heat exchangers is their design adaptability. Producers can tailor these components to meet specific dimensions, fluid routes, and thermal specifications, rendering them suitable for a diverse array of applications—from data centers to electric vehicles. This flexibility empowers engineers to incorporate seamlessly into their designs, ensuring optimal temperature regulation aligned with the distinct requirements of each project.

Dalhousie University has partnered with Defence Research and Development Canada (DRDC) to address critical component supply issues for Canada’s aging submarine fleet, underscoring the importance of adaptable solutions across multiple sectors. As we approach 2025, the trend towards customizable fluid temperature management solutions, including liquid cold plate designs, continues to gain momentum, with engineers increasingly pursuing designs that can be integrated into their projects for superior temperature performance.

The versatility of liquid cold plates is evident in their extensive application across various industries. For instance, Compass Datacenters, recognized as one of Inc. Magazine’s 5000 fastest-growing firms, has effectively leveraged fluid refrigeration technologies to enhance project delivery speed while maintaining high-quality standards. Their commitment to sustainability and effective temperature regulation solutions illustrates the growing demand for innovative thermal management approaches.

Customization trends in fluid heat exchanger design are surging, with producers offering a range of options to meet specific application needs. This includes the capacity to modify fluid paths and optimize thermal performance based on unique project specifications. Experts emphasize that adjustable thermal devices, particularly liquid cold plates, not only enhance temperature management efficiency but also contribute to the overall functionality and reliability of electronic systems.

As the electronics sector evolves, the demand for adjustable thermal solutions, such as liquid cold plates, continues to rise, with applications spanning from high-density computing to electric vehicle energy management. The ability to customize liquid cold plates to various specifications ensures that engineers can achieve the necessary cooling efficiency, ultimately resulting in more effective and reliable electronic products.

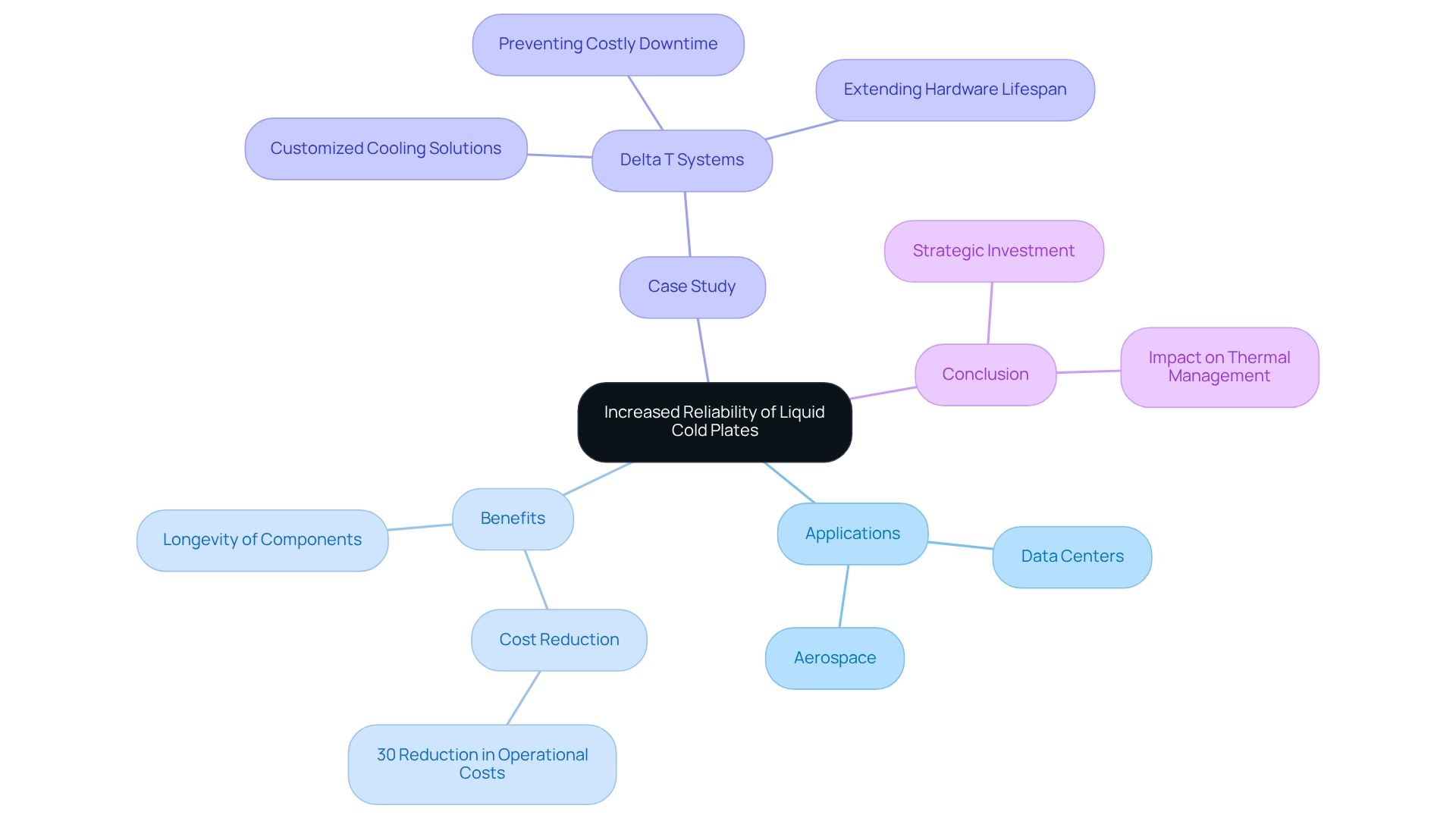

Increased Reliability: Dependable Performance of Liquid Cold Plates

Liquid cold plates are recognized for their exceptional reliability, particularly in critical environments such as data centers and aerospace applications. These liquid cold plates provide consistent thermal performance, effectively mitigating overheating and thermal fatigue in electronic components. This reliability is crucial; studies indicate that the implementation of fluid temperature regulation systems can reduce operational and maintenance costs by as much as 30%.

A case study on exemplifies this, demonstrating how their customized temperature control solutions have successfully averted costly downtime and prolonged hardware lifespan in data centers. Furthermore, the longevity of electronic components is significantly enhanced, as evidenced by these deployments.

In aerospace applications, a liquid cold plate for fluid temperature regulation has proven indispensable in preventing overheating, thereby ensuring optimal performance under demanding conditions. As Boyd noted, “Different kinds of CDUs satisfy various cooling requirements and setups,” underscoring the adaptability of fluid thermal interfaces across sectors.

In conclusion, the strategic application of thermal transfer devices represents a prudent investment for engineers aiming for long-term reliability and efficiency in their systems, particularly regarding the impact of effective thermal management on the longevity of electronic components.

Cost-Effectiveness: Economic Benefits of Implementing Liquid Cold Plates

Utilizing fluid temperature control systems offers substantial cost reductions in both operational and capital expenses. Their superior heat dissipation capabilities significantly minimize the need for , such as large air conditioning units, which can be expensive to install and maintain. By effectively preventing overheating, fluid cooling systems not only help avert costly equipment malfunctions but also extend the longevity of electronic components. This dual advantage of reduced energy expenses and lower maintenance costs positions cold plates as a financially advantageous choice for engineering projects.

Furthermore, as energy costs in Europe continue to rise, the shift towards energy-efficient solutions such as liquid cold plate technology becomes increasingly critical, underscoring the economic benefits of adopting these advanced technologies.

As noted by Motivair Corporation, “For data centers seeking to enhance their reliability and be prepared for future technological advancements, Motivair offers the comprehensive solutions needed to achieve these goals.” This statement highlights the importance of reliability in temperature control systems, further illustrated by the case study ‘Ensuring Reliability and Efficiency with Motivair’s Temperature Control Systems,’ which demonstrates how these solutions maintain optimal performance and sustainability in data centers.

Sustainability: Eco-Friendly Cooling Solutions with Liquid Cold Plates

Liquid cold plates are pivotal in advancing sustainability within the electronics industry, as they significantly reduce energy consumption compared to traditional temperature management methods. Their exceptional heat transfer capabilities facilitate optimal operating temperatures with considerably lower energy input. Additionally, many fluid cold plates employ environmentally friendly coolants, thereby minimizing their overall ecological footprint.

By implementing these innovative temperature regulation solutions, companies not only bolster their sustainability initiatives but also ensure high-performance temperature management, aligning with the growing demand for eco-friendly technologies in 2025 and beyond.

This transition towards fluid temperature management is substantiated by case studies, such as ‘,’ which demonstrate its effectiveness in meeting the temperature requirements of modern data centers, particularly as they adapt to the increasing demands of AI applications.

Chris Carriero, Chief Technology Officer, underscores that organizations face both challenges and opportunities with emerging technologies like cooling systems. The shift to liquid cold plate technology represents a strategic move towards more sustainable practices in the electronics sector.

Seamless Integration: Easy Adoption of Liquid Cold Plates in Existing Systems

Liquid cold plates are designed for seamless integration into existing electronic systems. Their modular design not only simplifies installation but often requires only minimal adjustments to current configurations. This streamlined adoption process is particularly advantageous for engineers seeking to enhance cooling efficiency through the use of without the burden of extensive redesigns.

By enabling rapid and effective improvements, fluid thermal interfaces empower organizations to quickly adapt to changing heat management demands. Moreover, the incorporation of these systems has been demonstrated to significantly boost operational efficiency, aligning with the increasing need for energy-efficient solutions within the electronics sector.

Performance Optimization: Maximizing Efficiency with Liquid Cold Plates

Liquid cold plates play a crucial role in enhancing the efficiency of electronic systems. By maintaining lower operating temperatures, they effectively prevent thermal throttling, enabling components to operate at their full potential. This optimization is vital in high-performance applications—such as gaming, data processing, and telecommunications—where every bit of efficiency matters.

Engineers can leverage the features of liquid cold plates within fluid cooling systems to push the boundaries of performance in their designs. Furthermore, Gagner-Toomey Associates provides innovative solenoid and rotary boost pump solutions that perfectly complement these systems.

With a wide array of AC and DC voltage inputs, adherence to automotive standards, and over 100 standard components available for shipment, these pumps ensure . This further enhances the efficiency of thermal management systems, including the use of liquid cold plates, making them indispensable in modern electronic applications.

Technological Advancements: Innovations in Liquid Cold Plate Design

Recent advancements in liquid cold plate technology have revolutionized thermal management, demonstrating remarkable improvements in performance and design flexibility. Innovations such as microchannel designs and the use of advanced materials have significantly enhanced heat transfer efficiency, enabling the development of more compact and lightweight temperature regulation solutions. These developments not only optimize cooling performance but also empower engineers to design smaller, more efficient electronic systems.

As aptly stated, “It’s easy to come up with new ideas; the hard part is letting go of what worked for you two years ago, but will soon be out of date.” This highlights the necessity for engineers to adapt to new technologies in thermal management.

Moreover, as demonstrated in the case study named ‘Maximizing Digital Transformation Investments,’ organizations that successfully adopt new technologies, such as liquid cold plates, are more likely to reach their strategic objectives.

As the sector continues to advance, fluid thermal surfaces are poised to spearhead innovative heat regulation solutions, showcasing the boundless possibilities for creativity in engineering.

Industry Impact: Transforming Electronics Cooling with Liquid Cold Plates

Liquid thermal surfaces are revolutionizing the electronics heat management sector by delivering effective, reliable, and customized solutions. Their extensive adoption across industries such as data centers, automotive, and aerospace highlights their capability in tackling thermal challenges. Notably, direct-to-chip temperature regulation has gained significant traction, currently commanding a 79.5% market share in fluid management solutions. This is particularly evident in data centers where high-heat components demand sophisticated temperature control methods.

is projected to surge from nearly $5 billion in 2024 to almost $15 billion within five years, reflecting a robust demand for innovative temperature regulation technologies. This growth is driven by the increasing need for high-performance electronics, which necessitate effective thermal management to ensure reliability and durability.

Recent advancements, such as microchannel heat exchange and two-phase direct-to-chip refrigeration, are enhancing the capabilities of thermal transfer units, making them indispensable in modern electronics. As regulatory pressures regarding environmental standards evolve, the industry is poised to experience further innovations in coolant technologies, positioning liquid cold plates at the forefront of electronics temperature management. Their versatility and performance improvements will continue to shape the future of temperature regulation technologies across diverse sectors.

Complementing these systems, Gagner-Toomey Associates offers cutting-edge solenoid and rotary boost pump solutions that enhance the performance of liquid temperature control applications. With a comprehensive range of AC and DC voltage inputs, adherence to IATF 16969 standards, and over 100 standard parts available for immediate shipment, these pumps guarantee precision and reliability in cooling systems. Features such as low noise operation and PWM control for precise pumping further emphasize their significance in high-performance electronics.

Conclusion

The evolution of liquid cold plates is fundamentally reshaping thermal management in electronics, delivering a multitude of benefits that significantly enhance performance, reliability, and sustainability. As this article highlights, these innovative cooling solutions are not merely essential for efficient heat dissipation; they also facilitate substantial cost savings and operational efficiency. With the market for liquid cooling systems projected for considerable growth, the demand for such advanced technologies is more critical than ever.

Liquid cold plates are distinguished by their customizable designs, allowing engineers to tailor solutions to meet specific application needs. This flexibility guarantees seamless integration across various sectors, from data centers to electric vehicles, thereby enhancing the overall performance of electronic systems. The reliability and extended lifespan of components cooled by these systems further underscore their value, particularly in high-stakes environments.

Additionally, the sustainability aspect of liquid cold plates warrants attention. By reducing energy consumption and utilizing eco-friendly coolants, these solutions align perfectly with the increasing emphasis on environmental responsibility within the electronics industry. As organizations continue to adapt to technological advancements, the strategic implementation of liquid cold plates will be pivotal in achieving both performance excellence and sustainability objectives.

In conclusion, liquid cold plates embody a transformative approach to cooling in the electronics sector. Their capability to optimize thermal management while addressing cost and sustainability challenges positions them as an essential component in the future of electronic design and engineering. Embracing these innovative solutions will empower engineers to redefine the boundaries of what is possible, ensuring the longevity and reliability of high-performance electronic systems.

Frequently Asked Questions

What is Gagner-Toomey Associates known for in the electronics sector?

Gagner-Toomey Associates leads the electronics sector by focusing on innovative temperature control solutions, emphasizing power management and thermal management through a diverse portfolio of manufacturers.

What are liquid cold plates, and why are they important?

Liquid cold plates are engineered surfaces that use liquid as a coolant to efficiently absorb and transfer heat away from critical electronic components, significantly outperforming traditional air cooling methods. They are essential for effective thermal management in high-density applications.

How do liquid cold plates compare to air-based cooling systems?

Thermal management systems using liquid cold plates can achieve average temperature reductions of up to 30% compared to air-based alternatives, improving the reliability and longevity of electronic devices.

What market trends are highlighted regarding temperature management solutions?

The liquid temperature regulation systems market is projected to reach around $152.53 billion in 2023, indicating a growing demand for sophisticated temperature management solutions that enhance data center efficiency.

How does Gagner-Toomey Associates support engineers in the evolving electronics sector?

Gagner-Toomey Associates provides tailored solutions that boost performance and address high costs associated with advanced temperature control technologies, particularly benefiting small and medium-sized enterprises.

What recent case studies have been conducted regarding liquid cold plate technologies?

Recent case studies highlight successful implementations of liquid cold plate technologies across various application segments, including business computing and quantum research, revealing market trends and challenges.

What role do customizable liquid cold plates play in various industries?

Customizable liquid cold plates can be tailored to meet specific dimensions, fluid routes, and thermal specifications, making them suitable for diverse applications, from data centers to electric vehicles.

What are the benefits of using fluid heat exchangers in electronic systems?

Fluid heat exchangers, such as liquid cold plates, enhance temperature management efficiency, contribute to overall system reliability, and allow for customization based on unique project specifications.

How are companies like Compass Datacenters utilizing fluid refrigeration technologies?

Compass Datacenters leverage fluid refrigeration technologies to enhance project delivery speed while maintaining high-quality standards, demonstrating the demand for innovative thermal management approaches.

What is the future outlook for liquid cold plates in the electronics sector?

The demand for adjustable thermal solutions like liquid cold plates continues to rise, with applications spanning high-density computing to electric vehicle energy management, ensuring engineers can achieve necessary cooling efficiency for reliable electronic products.