Overview

The article centers on essential automobile fan products that significantly enhance cooling performance. It highlights various components, including:

- Brushless blower motors

- Motor resistor kits

- Air door actuators

These products are crucial in improving efficiency, reducing energy consumption, and ensuring optimal vehicle temperature regulation. Such regulation is vital for maintaining engine performance and longevity, thus addressing a critical need in automotive maintenance.

Introduction

The automotive industry is experiencing a transformative shift as engineers and manufacturers strive to optimize vehicle performance through advanced cooling solutions. With the increasing complexity of modern vehicles, the significance of effective temperature regulation is paramount—it is essential for enhancing efficiency, prolonging engine life, and meeting stringent environmental standards.

However, amidst a plethora of options, how can automotive professionals pinpoint the critical fan products that deliver both reliability and innovation? This article explores ten indispensable automobile fan products designed to elevate cooling performance, ensuring vehicles not only meet but exceed contemporary demands.

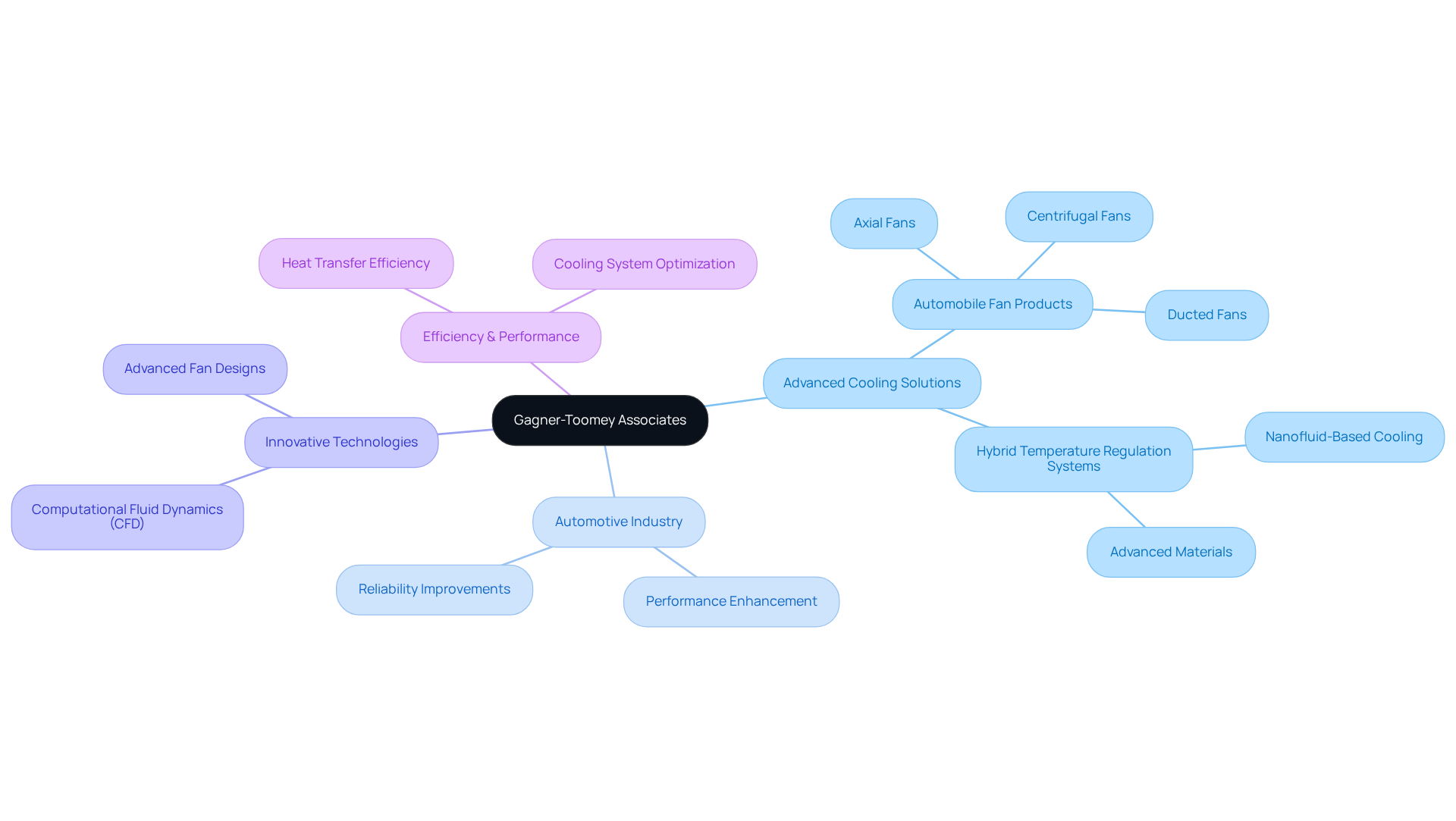

Gagner-Toomey Associates: Leading Provider of Advanced Cooling Solutions

Gagner-Toomey Associates stands as a leading provider of advanced tailored for the automotive industry. Collaborating with top producers, the firm delivers that meet the stringent demands of modern . Their focus on , including automobile fan products and hybrid temperature regulation systems, significantly enhances efficiency and performance—critical factors for maintaining optimal engine temperatures and prolonging .

Committed to excellence, Gagner-Toomey ensures engineers have access to the most effective solutions, facilitating the successful implementation of cutting-edge in vehicles. This dedication positions them as a pivotal player in the evolving landscape of , where ongoing advancements are essential to meet the needs of contemporary vehicle applications.

Four Seasons: High-Quality Automobile Cooling Components

Gagner-Toomey Associates stands out in the vehicle sector with its exceptional , including DC fans and . These are meticulously engineered to meet or exceed OEM standards, which is crucial for ensuring . By leveraging , , establishing its components as the .

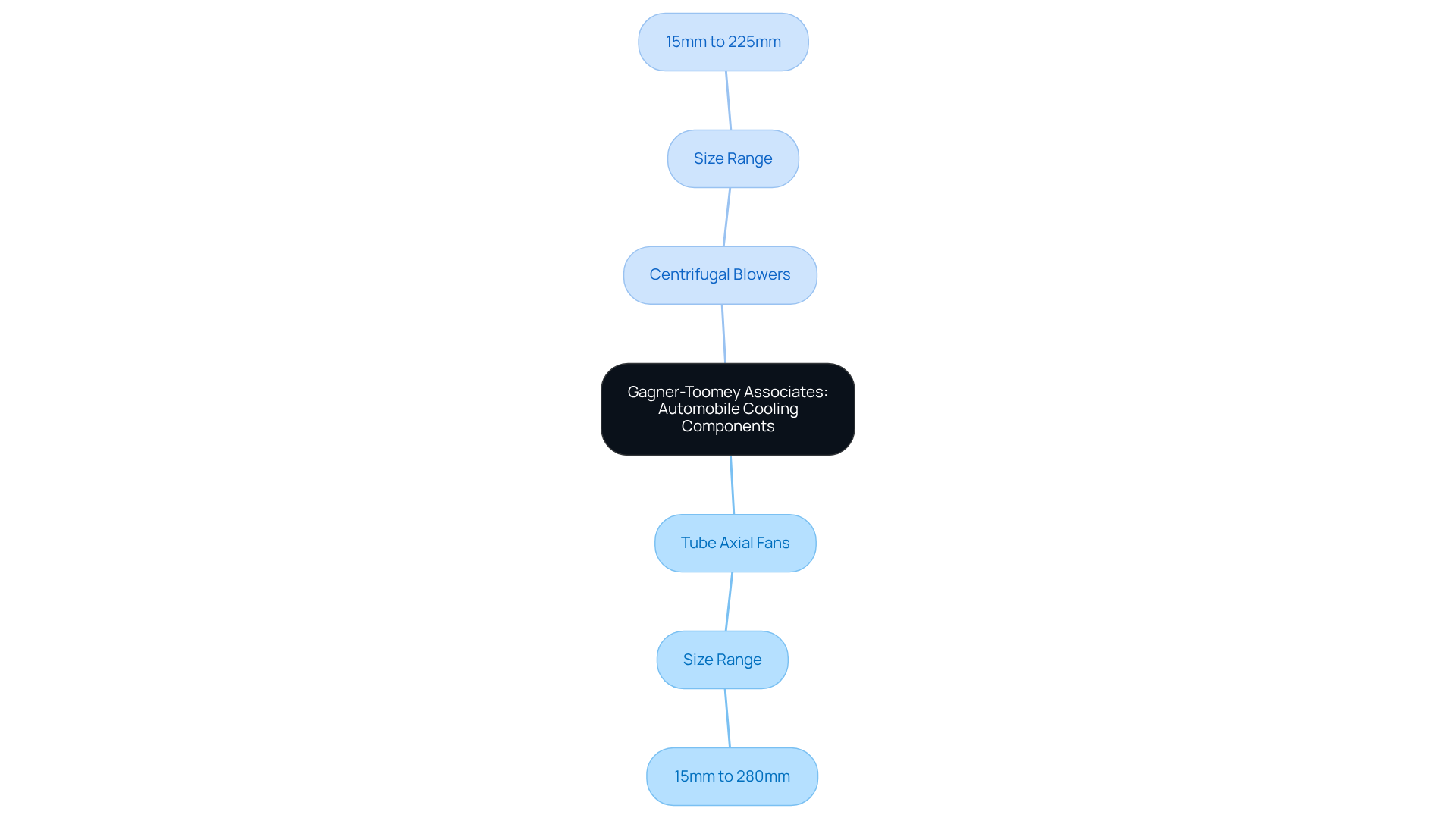

Their extensive portfolio features:

- Tube axial fans ranging from 15 to 280mm

- Centrifugal blowers from 15 to 225mm

This showcases the brand’s unwavering commitment to . This focus on elevated standards not only improves but also contributes to the durability of temperature regulation systems, solidifying Gagner-Toomey Associates’ position as a leader in automobile fan products within the vehicle temperature management sector. Their and product representation is evident, making them a trusted partner for automotive engineers.

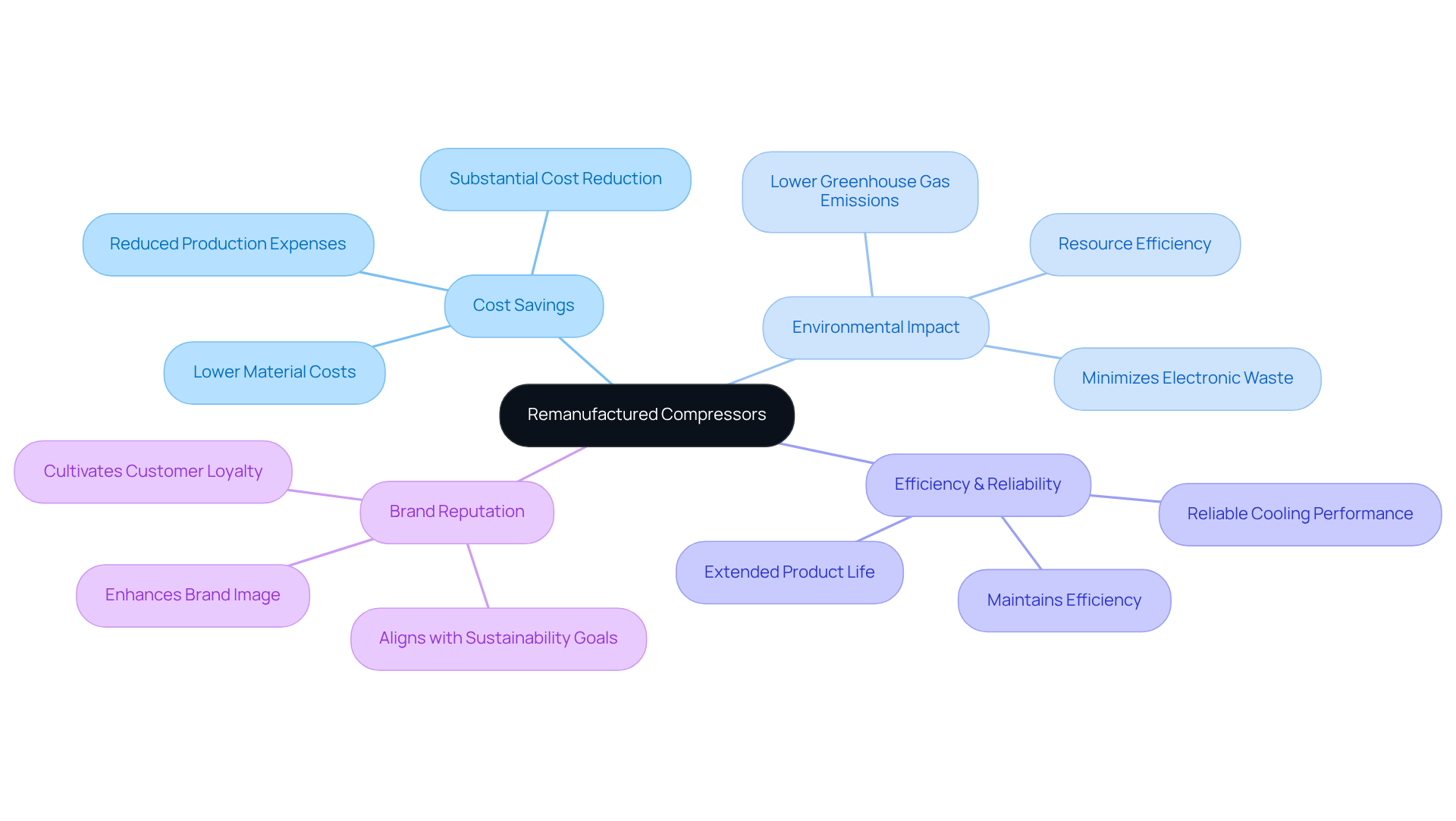

Remanufactured Compressors: Essential for Optimal Vehicle Cooling

Rebuilt compressors are crucial for achieving . These components undergo a meticulous restoration process that adheres to rigorous quality standards, positioning them as a cost-effective alternative to new units. Automotive engineers have reported , highlighting that not only provide but also lead to substantial —often being significantly less expensive than their new counterparts. For instance, engineers have observed that remanufactured compressors can reduce production expenses while maintaining the same level of efficiency and reliability.

Furthermore, the of utilizing remanufactured components is significant. By reusing existing materials, remanufacturing contributes to lowering greenhouse gas emissions and minimizing waste, addressing the critical issue of 55 million tonnes of electronic waste generated annually. Automotive engineers emphasize that the adoption of remanufactured parts aligns with the industry’s , enabling them to meet the expectations of environmentally conscious consumers. This commitment to sustainability not only but also cultivates customer loyalty, making remanufactured compressors an and repair.

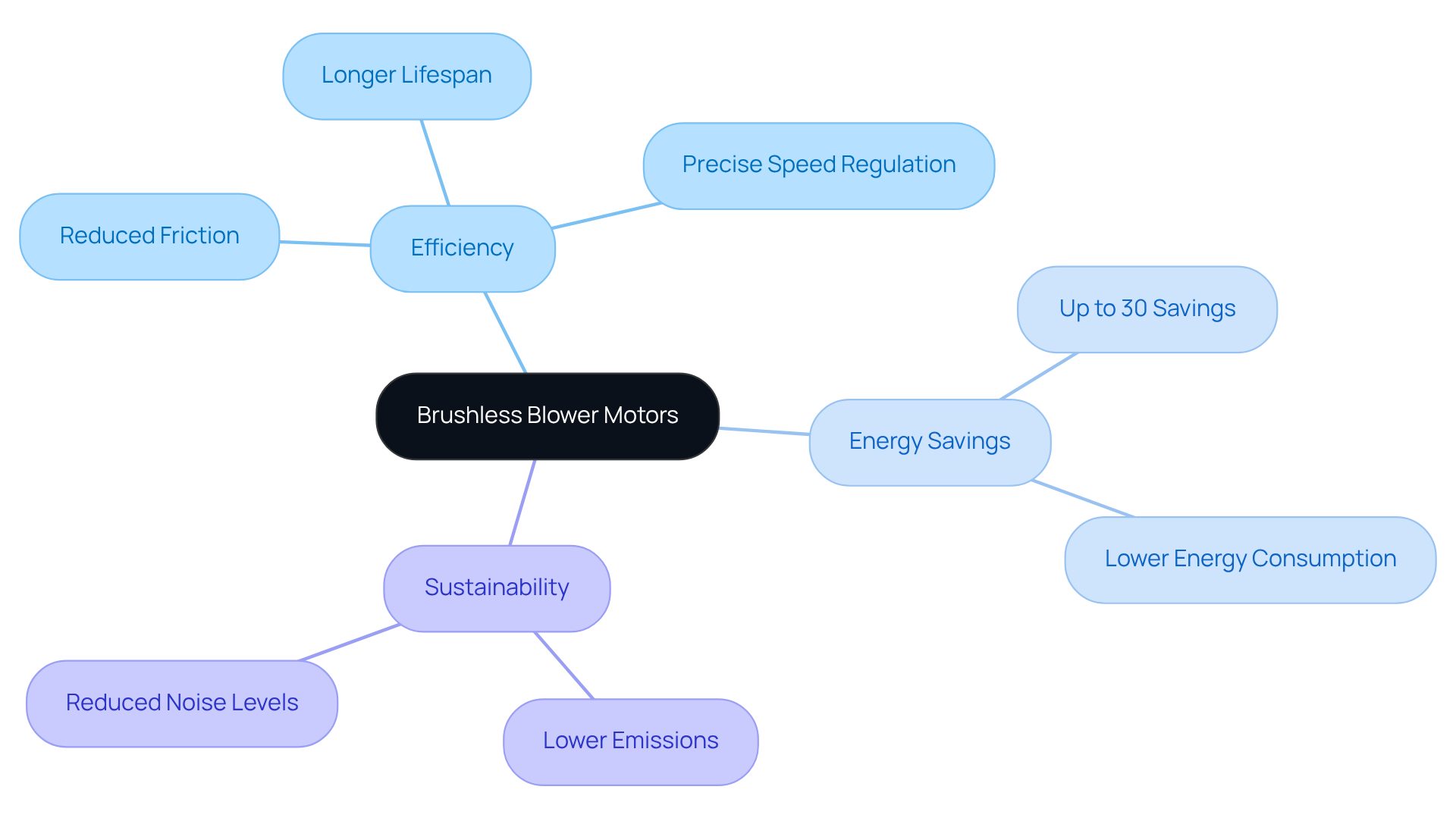

Brushless Blower Motors: Enhancing Cooling System Performance

Brushless blower engines are transforming vehicle temperature regulation through exceptional effectiveness and efficiency. In contrast to traditional motors, brushless designs significantly reduce friction and wear, leading to longer lifespans and lower energy consumption. These motors are engineered for precise speed regulation, which facilitates optimal airflow management and substantially enhances . Notably, brushless motors can achieve of up to 30% compared to their brushed counterparts.

Furthermore, are anticipated to experience a compound annual growth rate (CAGR) exceeding 7.5%, outpacing traditional brushed systems due to their efficiency and reduced . As the automotive industry increasingly emphasizes , the adoption of brushless technology in is projected to rise, with the market for these automobile fan products expected to reach $22.3 billion by 2025, following a market size of $18.9 billion in 2022.

This transition not only boosts performance but also aligns with , as brushless motors contribute to lower emissions and noise levels, thereby fostering the acceptance of . Industry experts, including Rick Wagner, Senior Product Manager at Continental, emphasize that integrating is crucial for enhancing capabilities, particularly in electric and hybrid vehicles where effective thermal management is essential.

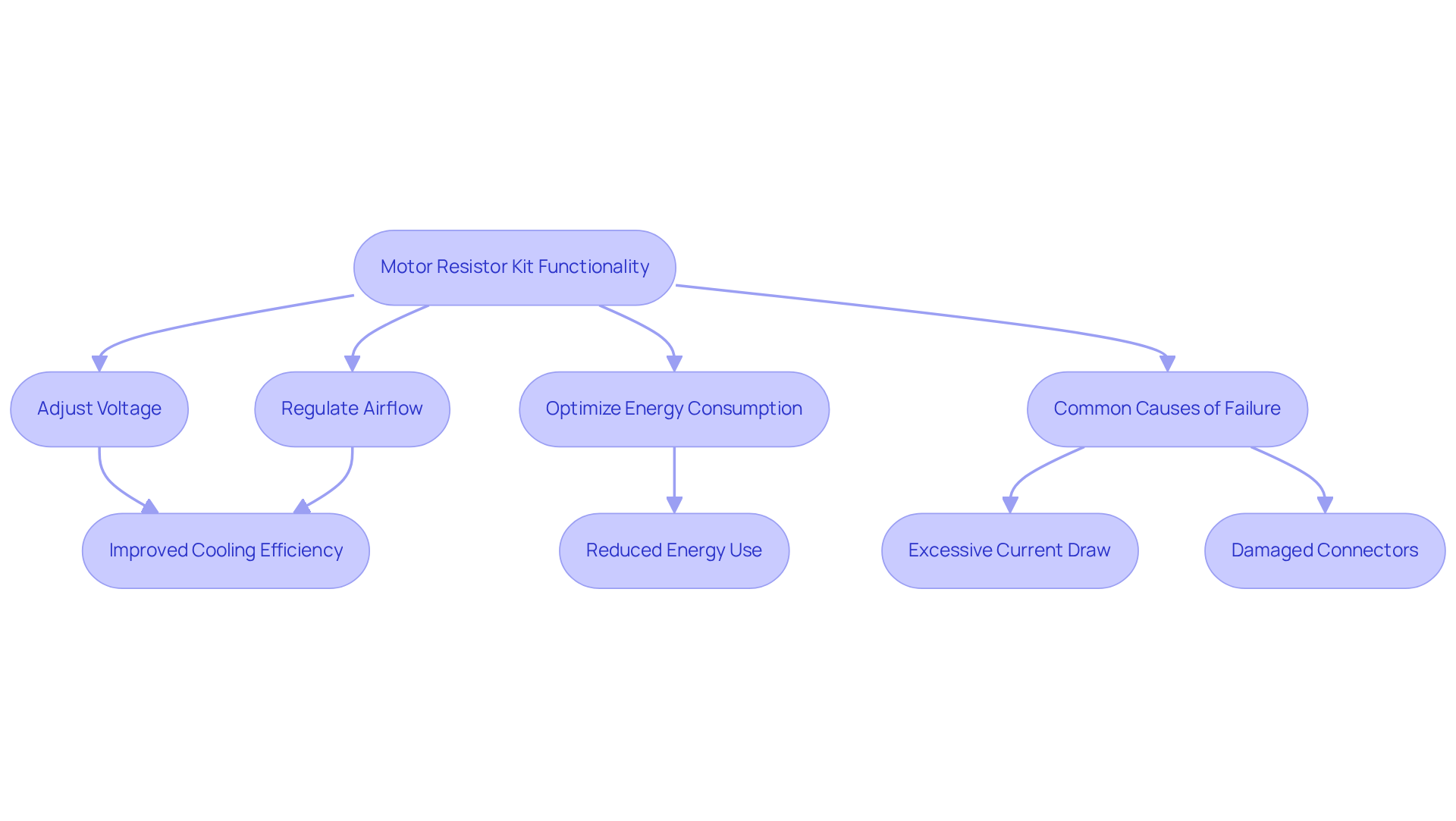

Motor Resistor Kits: Regulating Fan Speeds for Efficiency

are essential that help regulate fan speeds within automotive temperature control systems. By adjusting the voltage supplied to the fan motor, these kits facilitate precise modifications to airflow, responding effectively to varying temperature requirements. This capability not only but also significantly reduces , positioning motor resistor kits as a strategic choice for engineers aiming to optimize performance.

Statistics indicate that effective can lead to a reduction in energy consumption of up to 20%, underscoring the importance of these kits in modern vehicle design. Engineers have recognized that maintaining optimal fan speeds is crucial for preventing overheating, which can lead to costly repairs and diminished reliability. It is imperative to ensure that the remains below 80% of the fuse rating on high settings to avert potential failures.

Common causes of blower motor resistor failure include excessive current draw and damaged connectors due to heat, highlighting the necessity for . The integration of motor resistor kits thus represents a , especially for automobile fan products, ensuring that operate at peak efficiency while enhancing overall vehicle performance.

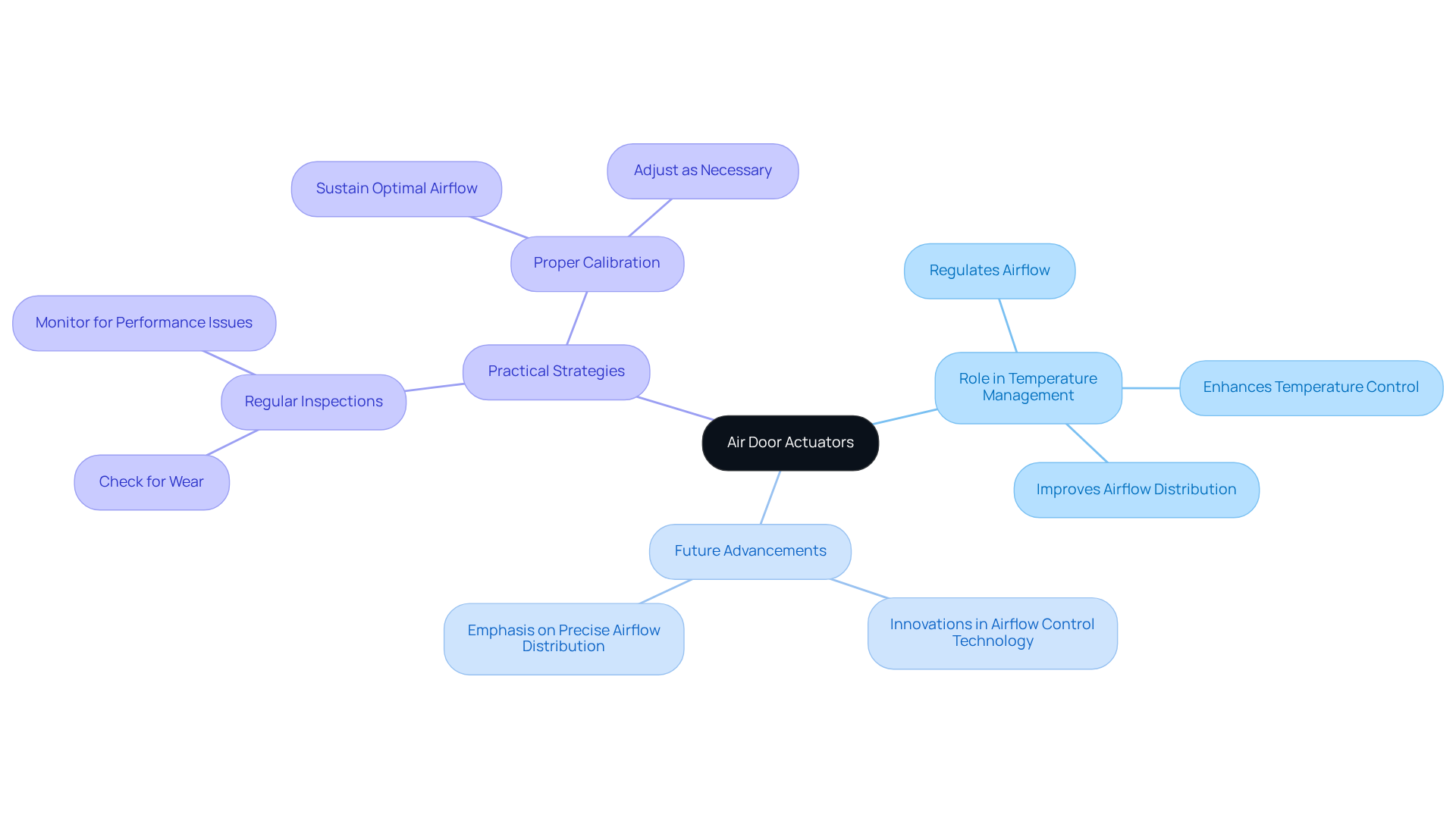

Air Door Actuators: Controlling Airflow for Effective Cooling

play a pivotal role in regulating airflow within vehicle . These sophisticated devices adjust the position of air doors to direct airflow to specific zones, thereby ensuring throughout the vehicle. By enhancing , air door actuators significantly improve overall temperature control, establishing themselves as a vital component in modern vehicle design.

Looking ahead to 2025, advancements in are expected to revolutionize transportation system temperature management. Engineers are emphasizing the critical importance of precise airflow distribution for optimizing efficiency and reliability.

For example, and is essential for prolonging the lifespan of an ; neglecting these aspects can result in expensive breakdowns and diminished range.

Drawing on insights from automotive engineers, it is imperative to monitor airflow patterns and adjust air door actuators as necessary to avert overheating and ensure that key components function within safe temperature limits.

Moreover, practical strategies for enhancing the efficiency of air door actuators include:

- Conducting regular inspections for wear

- Ensuring proper calibration to sustain optimal airflow

This proactive approach not only enhances but also contributes to the overall durability and effectiveness of the vehicle’s thermal management system.

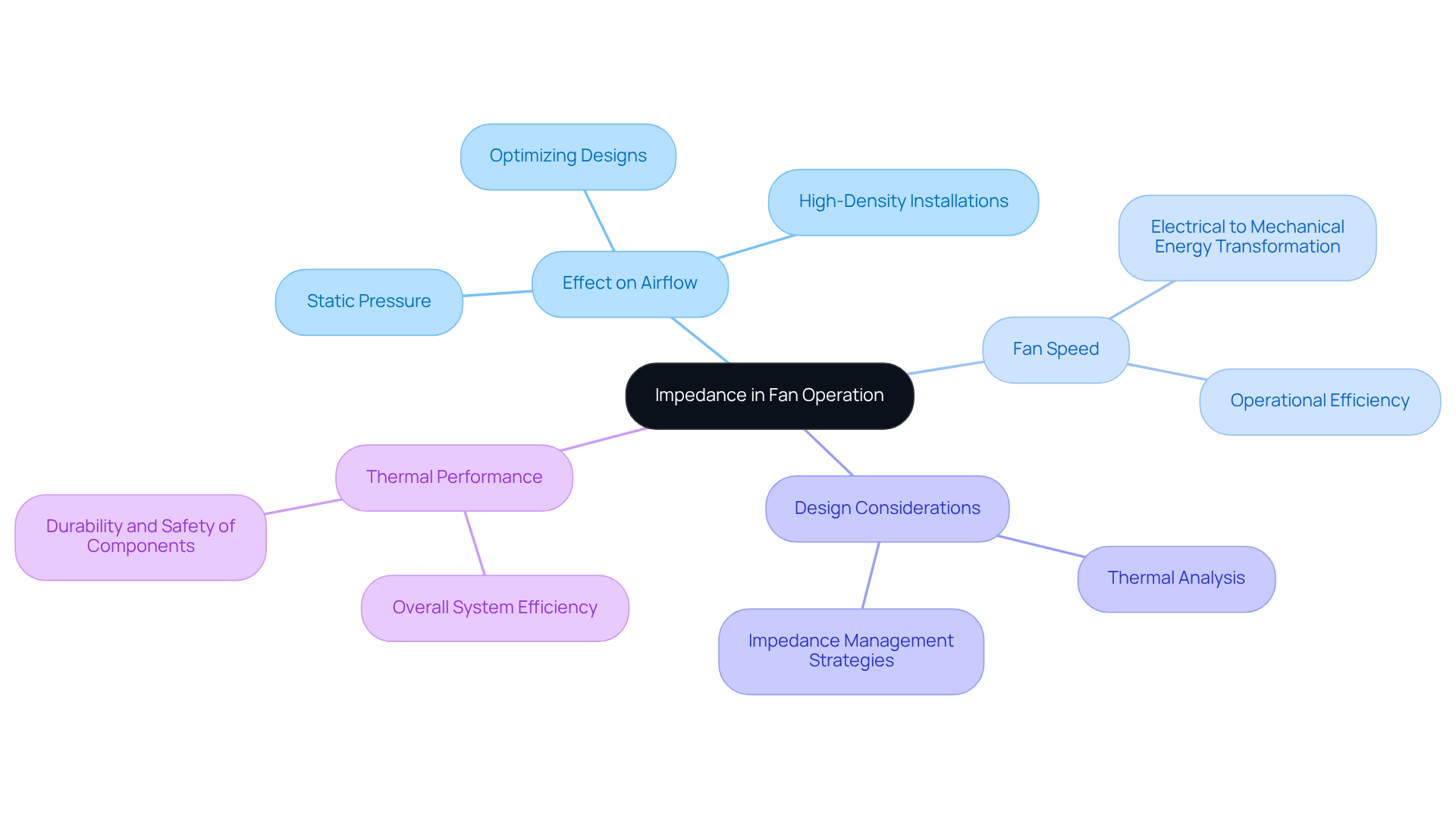

Understanding Impedance: Key to Efficient Fan Operation

Grasping impedance is essential for enhancing in automotive temperature regulation systems. Impedance, defined as the resistance to airflow, directly impacts the transformation of electrical energy into mechanical energy, thereby influencing fan speed and efficiency. By strategically addressing impedance during the design phase, engineers can significantly enhance , ensuring that fans operate within their optimal range. This optimization not only leads to but also contributes to in vehicles.

Real-world applications underscore the advantages of . For instance, case studies reveal that understanding the relationship between impedance and airflow is crucial for achieving desired temperature regulation outcomes, particularly in high-density installations where airflow is often restricted, resulting in increased static pressure. In such scenarios, engineers have noted that optimizing fan designs to account for impedance can yield substantial enhancements.

As Sam Pelonis states, “The first step in the is conducting a .” This emphasizes the importance of considering thermal dynamics alongside impedance. By focusing on these elements, that not only meet but exceed expectations, ultimately supporting the durability and safety of automotive components. Furthermore, it is critical to recognize that exhibit a negative correlation; as one increases, the other decreases, further highlighting the necessity for meticulous impedance management.

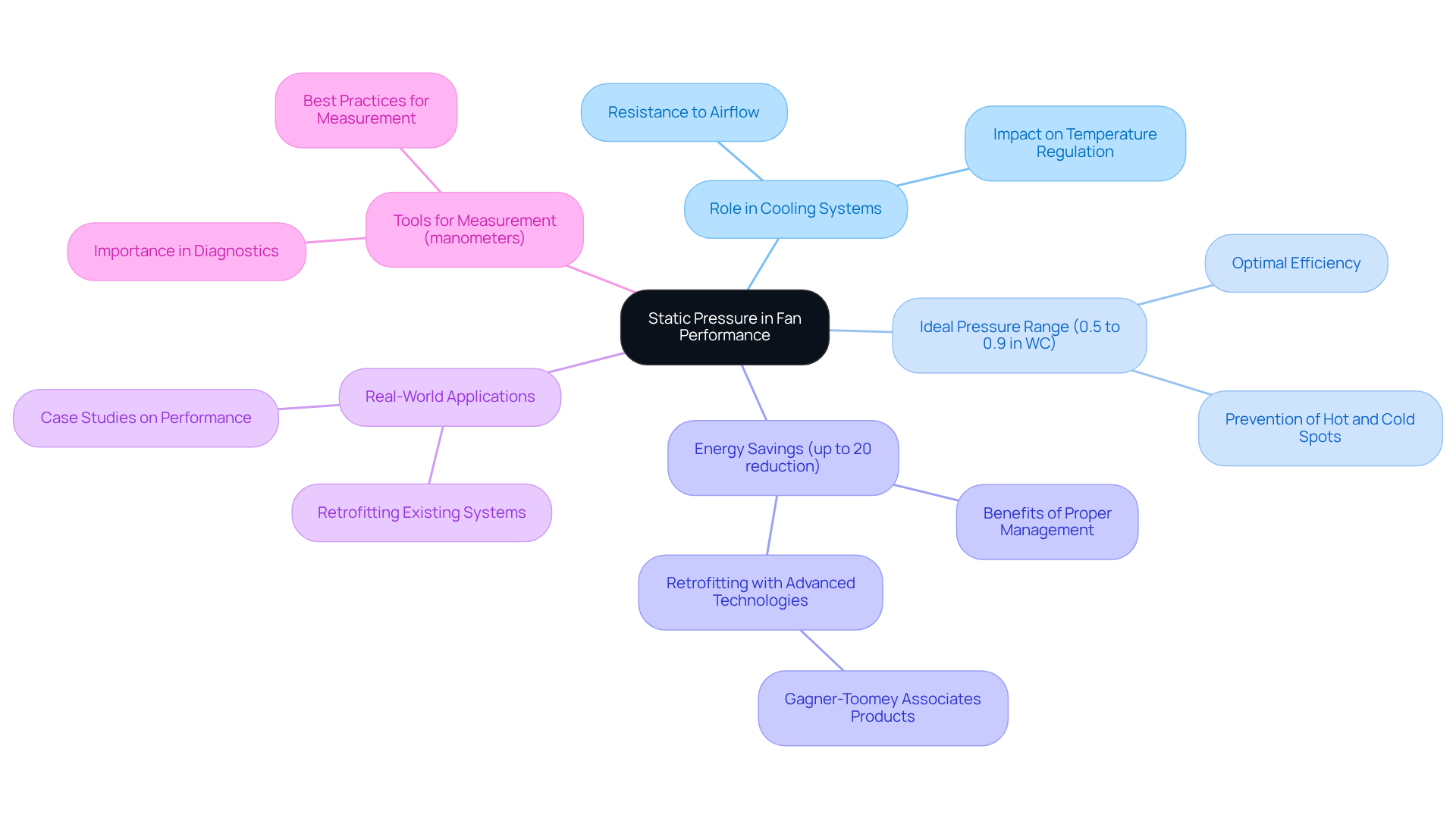

Static Pressure: Optimizing Fan Performance for Cooling

plays a pivotal role in within . It signifies the resistance that airflow encounters as it moves through the refrigeration device. By effectively managing static pressure, engineers can design cooling systems that maximize airflow while significantly reducing . This optimization is vital for improving performance, especially in 2025, when efficiency standards are becoming more demanding.

For instance, automotive engineers have found that maintaining static pressure within the ideal range of 0.5 to 0.9 inches of water column can lead to a , with systems operating at optimal efficiency consuming up to 20% less energy. Furthermore, can prevent common issues such as hot and cold spots within the vehicle, ensuring a consistent and comfortable environment for passengers.

Real-world applications demonstrate that retrofitting existing temperature regulation systems with from can yield , showcasing the tangible benefits of prioritizing static pressure in design and maintenance. Gagner-Toomey Associates, acknowledged as the globe’s biggest producer of standard and custom air-movers, provides an extensive product range of DC input tube axial fans from 15 to 280mm and centrifugal blowers from 15 to 225mm, enhanced for efficiency and low noise. Additionally, IP protection is available in most models upon request.

Ultimately, grasping and is crucial for attaining superior system efficiency and effectiveness in automobile fan products. Tools like manometers are essential for measuring static pressure, allowing engineers to diagnose issues and ensure efficient system operation. As Torben Lintrup Kirkholt states, ‘To assess how much energy is actually consumed to achieve the desired result, it is therefore always best to use the static efficiency.

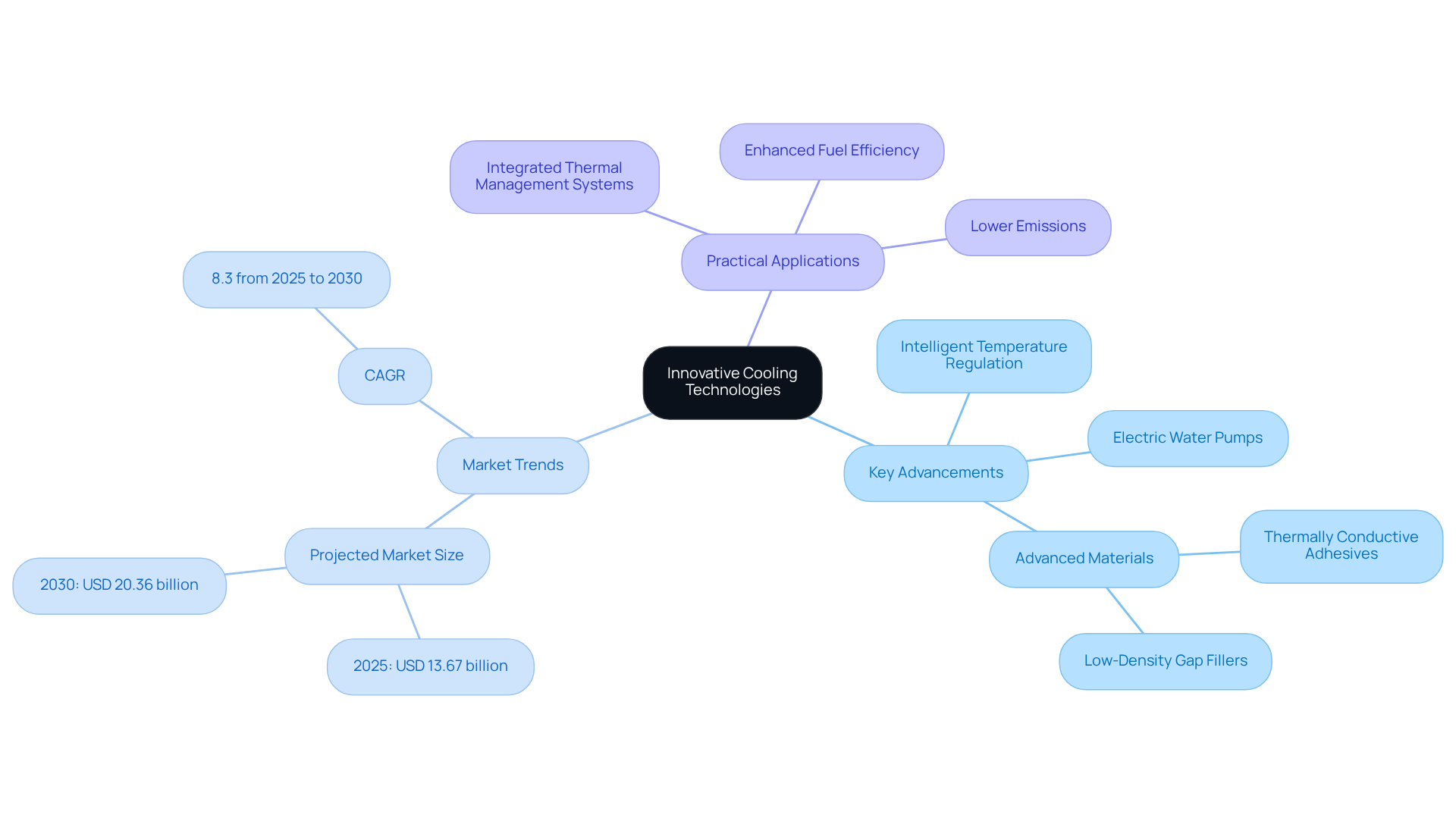

Innovative Cooling Technologies: Advancing Automotive Cooling Solutions

Innovative are revolutionizing the automotive industry, equipping engineers with cutting-edge tools to enhance vehicle performance. Key advancements include intelligent that dynamically adjust to varying conditions, significantly enhancing efficiency and responsiveness. The adoption of electric water pumps, for instance, allows for precise coolant flow control, optimizing thermal management based on real-time engine demands. Furthermore, the incorporation of and low-density gap fillers, improves thermal conductivity and durability in temperature regulation components.

Key elements of systems, such as radiators, thermostats, and , play a crucial role in maintaining optimal engine temperatures and preventing overheating. Market trends indicate a robust growth trajectory for , , with a compound annual growth rate (CAGR) of 8.3% from 2025. Notably, the market size for 2025 is estimated at USD 13.67 billion. This growth is driven by the rising demand for and strict emission regulations, especially in the Asia-Pacific region, which is anticipated to lead the market.

Practical uses of these advanced materials are apparent in the creation of integrated thermal management systems that enhance temperature regulation across various vehicle components. Such innovations not only boost effectiveness but also aid in lowering emissions and enhancing fuel efficiency, aligning with the automotive sector’s transition towards sustainability. As industry leaders stress the significance of these advancements, engineers must remain knowledgeable to apply the most efficient temperature control solutions in their designs.

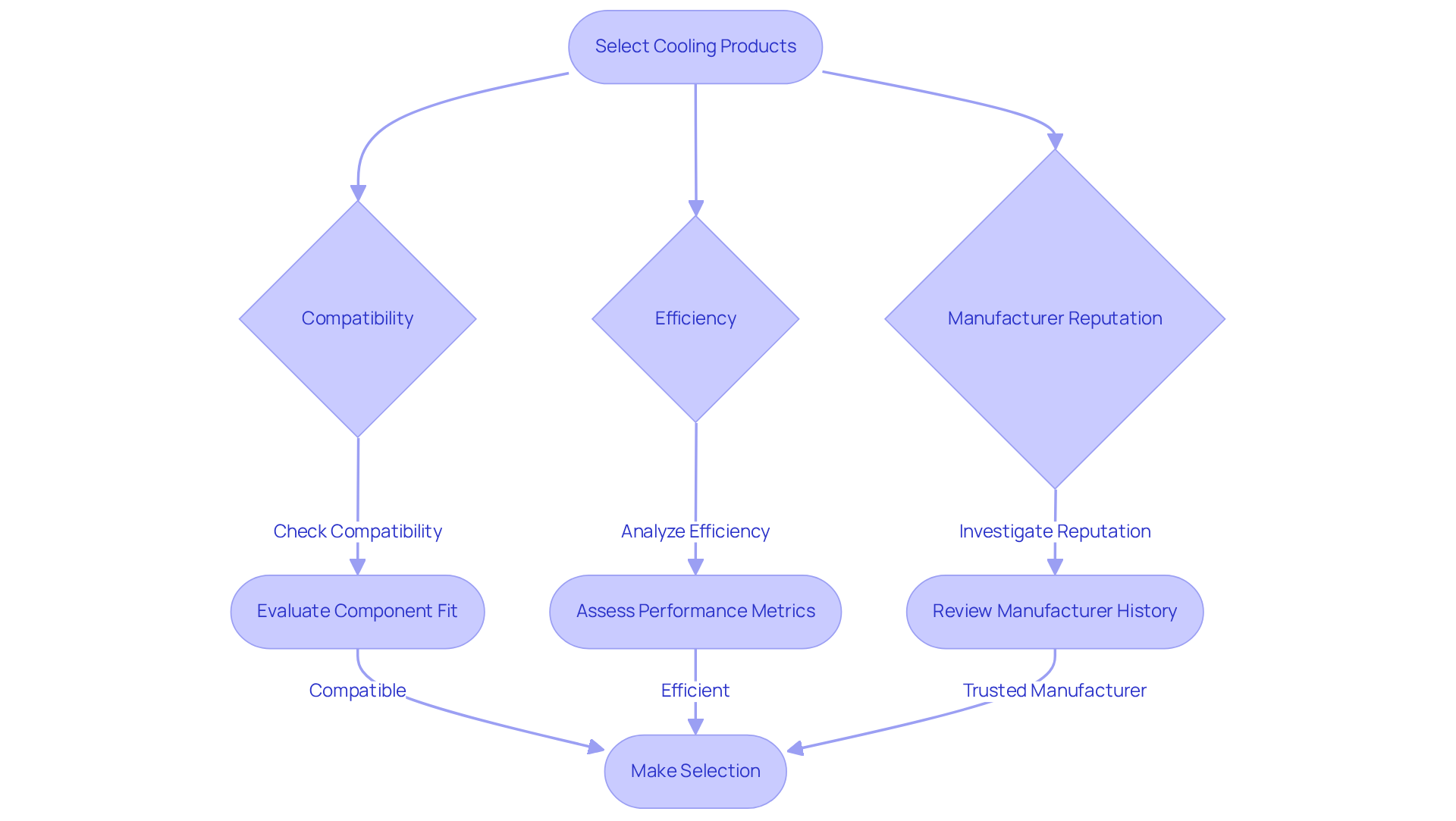

Selecting the Right Cooling Products: Ensuring Performance and Compliance

Selecting the right is essential for ensuring optimal functionality and compliance with industry standards. Engineers must consider critical factors such as compatibility, efficiency, and the reputation of manufacturers when selecting components.

Gagner-Toomey Associates, leveraging its extensive experience in the and unwavering , provides specialized solutions in that enhance the reliability and effectiveness of .

By prioritizing quality and , engineers can make significant contributions to , confident in the backing of a .

Conclusion

The pursuit of optimal cooling performance in vehicles is fundamentally tied to the integration of advanced automobile fan products and technologies. This article underscores the pivotal role that innovative solutions—such as those offered by Gagner-Toomey Associates and other industry leaders—play in enhancing vehicle efficiency and longevity. By leveraging state-of-the-art components, including brushless blower motors, remanufactured compressors, and motor resistor kits, automotive engineers can guarantee that temperature regulation systems function at peak performance.

Key insights from this discussion highlight the necessity of selecting high-quality cooling products that adhere to industry standards. Effective temperature management not only bolsters vehicle reliability but also aligns with sustainability objectives by minimizing waste and emissions. Moreover, a comprehensive understanding of concepts such as impedance and static pressure is crucial for engineers aiming to optimize fan performance and energy efficiency, thereby contributing to a more sustainable automotive industry.

As the automotive landscape evolves, the adoption of innovative cooling technologies becomes increasingly essential. Engineers and manufacturers are encouraged to remain informed and prioritize the implementation of advanced temperature regulation solutions. This approach ensures that vehicles not only fulfill performance expectations but also positively impact environmental sustainability. The future of automotive cooling rests on a steadfast commitment to excellence and innovation, paving the way for a more efficient and eco-friendly transportation sector.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in advanced temperature regulation solutions for the automotive industry, providing high-performance temperature control products that meet the demands of modern automobile fan products.

What types of products does Gagner-Toomey Associates offer?

They offer a range of temperature regulation components, including DC fans, centrifugal blowers, tube axial fans, and remanufactured compressors.

How do Gagner-Toomey’s products enhance vehicle performance?

Their innovative technologies improve efficiency and performance, which are critical for maintaining optimal engine temperatures and prolonging vehicle lifespan.

What are the specifications of the fans and blowers provided by Gagner-Toomey Associates?

Gagner-Toomey Associates offers tube axial fans ranging from 15 to 280mm and centrifugal blowers from 15 to 225mm.

What are the benefits of using remanufactured compressors?

Remanufactured compressors provide reliable cooling, are cost-effective alternatives to new units, and contribute to sustainability by reusing materials, thereby reducing greenhouse gas emissions and electronic waste.

How do remanufactured compressors impact production costs?

Automotive engineers have reported that remanufactured compressors can significantly reduce production expenses while maintaining the same level of efficiency and reliability as new compressors.

Why is sustainability important in the automotive industry?

The adoption of remanufactured parts aligns with the industry’s transition towards sustainability, addressing the environmental impact of electronic waste and meeting the expectations of environmentally conscious consumers.