Overview

The article titled “10 Essential Bearing Fan Insights for Electronics Engineers” presents critical insights that electronics engineers must consider when selecting and utilizing bearing fans in their designs. It underscores the necessity of comprehending the various fan bearing types, their performance characteristics, and the influence of innovative technologies in enhancing efficiency and reliability—elements that are vital for effective thermal management in electronic applications.

Introduction

In the rapidly evolving realm of electronics, effective cooling solutions have transitioned from a luxury to a necessity. As engineers confront the complexities of thermal management, innovative technologies and methodologies are emerging as essential tools in their arsenal.

- Cutting-edge fan designs

- Advanced materials

- IoT integration

are transforming the landscape of cooling solutions, promising enhanced performance and reliability. This article explores the latest advancements in fan technologies, examining their implications for electronics design and the critical considerations engineers must keep in mind to optimize system efficiency. By comprehending these innovations, professionals can adeptly navigate the challenges of modern thermal management and ensure their designs meet the demands of an increasingly complex industry.

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics Engineers

Gagner-Toomey Associates excels in delivering innovative temperature control solutions tailored for the electronics sector. With a collective experience exceeding 150 years, Gagner-Toomey partners with a diverse range of manufacturers to provide engineers with access to cutting-edge technologies that significantly improve thermal management.

Effective thermal management is essential, directly influencing the reliability and performance of electronic components. Recent trends reveal that 90% of companies are adopting hybrid models, highlighting the increasing demand for flexible temperature regulation solutions in dynamic work environments.

As Bernard Marr, a noted business author and consultant, states, “Adaptability is key to thriving in a rapidly changing landscape.” This perspective underscores the necessity for engineers to remain agile and receptive to emerging technologies and methodologies.

Moreover, Gagner-Toomey’s robust relationships with local distributors guarantee a steady supply of components, enhancing engineers’ access to innovative solutions. The case study illustrating the role of skepticism in engineering emphasizes the critical importance of thorough analysis and critical thinking in developing effective cooling solutions.

Gagner-Toomey’s unwavering commitment to excellence ensures that engineers can rely on high-quality products and services that meet stringent industry standards, ultimately fostering the development of reliable and efficient electronic systems.

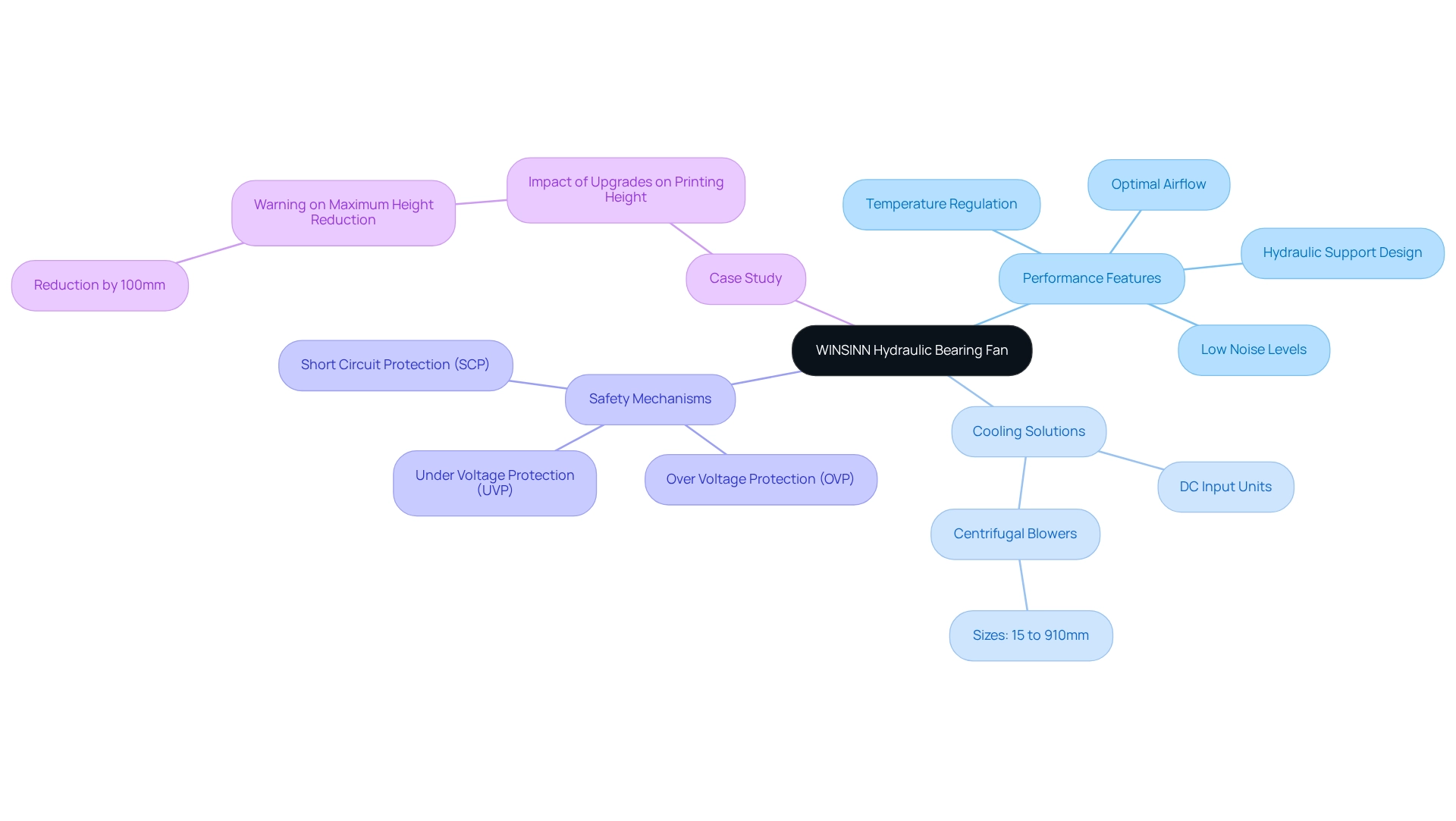

WINSINN Hydraulic Bearing Fan: Optimal Performance for 3D Printers

The WINSINN Hydraulic Fan is meticulously engineered for 3D printers, delivering exceptional performance through its cutting-edge support technology. Operating efficiently at high speeds, this fan guarantees optimal airflow while maintaining impressively low noise levels. The hydraulic support design minimizes friction, significantly extending the lifespan of the bearing fan and enhancing reliability, making it an exemplary choice for continuous operation in 3D printing environments.

By integrating this fan into their designs, engineers can achieve consistent temperature regulation, which is crucial for improving print quality and overall performance. Recent advancements in 3D printer fan technology have further solidified the WINSINN fan’s position as a market leader, demonstrating its effectiveness in real-world applications.

Performance statistics indicate that hydraulic support devices, featuring a bearing fan, surpass conventional designs, offering engineers a reliable solution for temperature regulation in 3D printing. Moreover, Gagner-Toomey Associates offers an extensive range of advanced cooling solutions, including:

- DC input units

- Centrifugal blowers

These products are optimized for performance and efficiency across diverse industrial applications. They are available in various sizes, ranging from 15 to 910mm, with IP protection options available upon request. Common power supply protection mechanisms, such as:

- Over Voltage Protection (OVP)

- Under Voltage Protection (UVP)

- Short Circuit Protection (SCP)

ensure the safety and reliability of the fan in various applications. Additionally, a case study titled ‘Impact of Upgrades on Printing Height’ serves as a cautionary note regarding potential limitations when integrating new technology, emphasizing the importance of considering all factors in 3D printer design.

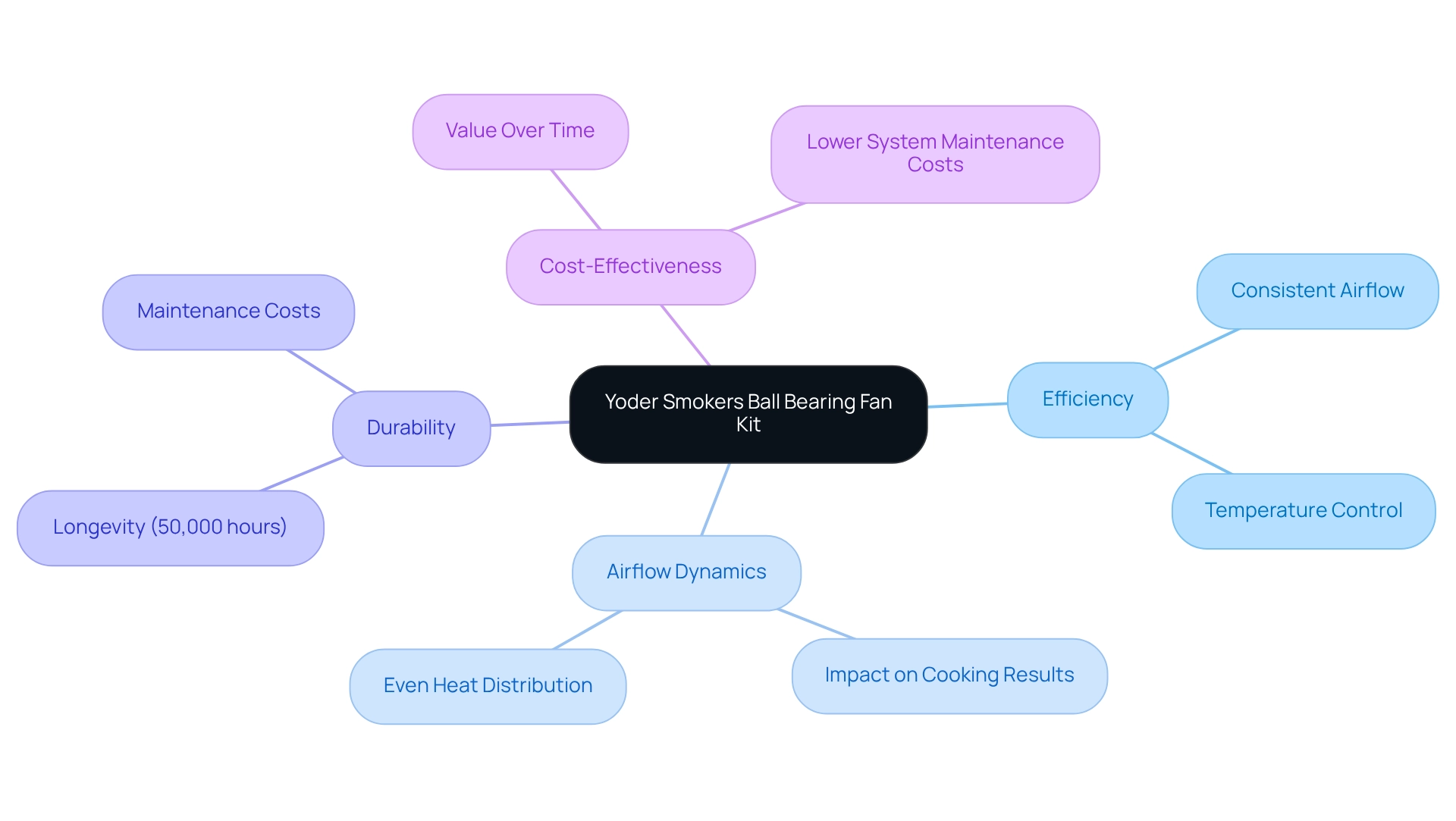

Yoder Smokers Ball Bearing Fan Kit: Enhancing Pellet Grill Efficiency

The Yoder Smokers bearing fan kit is expertly engineered to enhance the efficiency of pellet grills, ensuring consistent airflow and precise temperature control. This kit features high-quality balls that facilitate smooth operation and bolster durability, even under high-temperature conditions. By optimizing ignition and significantly curtailing startup times, the fan kit plays a vital role in elevating cooking performance and flavor retention.

Engineers specializing in outdoor cooking equipment can derive critical insights from this product’s innovative design and functionality, particularly regarding the direct impact of airflow dynamics on cooking results. Enhanced airflow not only boosts cooking efficiency but also guarantees even heat distribution, which is essential for achieving optimal outcomes.

Notably, ball support devices are recognized for their longevity, with lifespans reaching approximately 50,000 hours, establishing them as a reliable choice for improving equipment efficiency across various applications. Furthermore, these devices provide increased value over time due to lower maintenance costs, making them an economical selection for engineers.

In contrast to sleeve fans, which typically have shorter lifespans and are more susceptible to environmental influences, bearing fans excel in both efficiency and durability. As Ryan Smoot, an Applications Engineer, articulates, ‘With an extensive knowledge of Same Sky’s products, I provide customers with a wide range of technical and application support capabilities in the field.’ This expertise highlights the critical importance of choosing the appropriate fan technology to ensure optimal performance in cooking equipment.

Understanding Fan Bearing Types: Essential Knowledge for Electronics Engineers

A thorough understanding of bearing fan support types is essential for electronics engineers, as it directly impacts performance and reliability across various applications. The main categories of supports consist of sleeve types, ball types, and fluid dynamic types, each characterized by unique attributes.

Sleeve Supports: Recognized for their cost-efficiency and quieter performance, sleeve supports are frequently preferred in scenarios where noise reduction is crucial. However, it is important to note that they typically have a shorter lifespan compared to other types, which may render them less suitable for high-demand environments.

Ball Components: These elements excel in durability and performance, particularly in high-speed applications. Their design allows for greater load capacity and efficiency, making them a preferred choice for engineers seeking reliability in challenging conditions. Statistics indicate that dual ball fan systems are versatile and suitable for all types of fan mountings, thereby enhancing their applicability across various projects.

Fluid Dynamic Supports: Offering superior noise reduction and longevity, fluid dynamic supports are engineered for high-performance scenarios. While they come at a higher cost, their extended operational life and reduced friction make them an attractive option for advanced cooling solutions.

Recent advancements in fan support technologies, such as the omniCOOL™ solution introduced by Same Sky, showcase innovative alternatives to conventional designs. This system utilizes magnetic rotor-balancing and enhanced bearing technologies to minimize friction and noise while extending the fan’s operational life, effectively bridging the gap between conventional and advanced bearing solutions.

As Annie Chan, Account Manager of CCHV and EAGLE enthusiast, states, “The purpose of this article is to share knowledge related to DC devices for optimizing your thermal solutions.” When selecting a bearing fan for electronic applications, engineers must weigh these factors carefully. The typical lifespan of sleeve supports is significantly less than that of ball supports, which can greatly affect long-term performance and maintenance expenses. Practical instances demonstrate the efficiency of each support type in temperature regulation, highlighting the significance of making informed decisions based on specific project needs. Gagner-Toomey Associates is committed to excellence in customer service and product representation, ensuring that engineers have the support they need in their decision-making process.

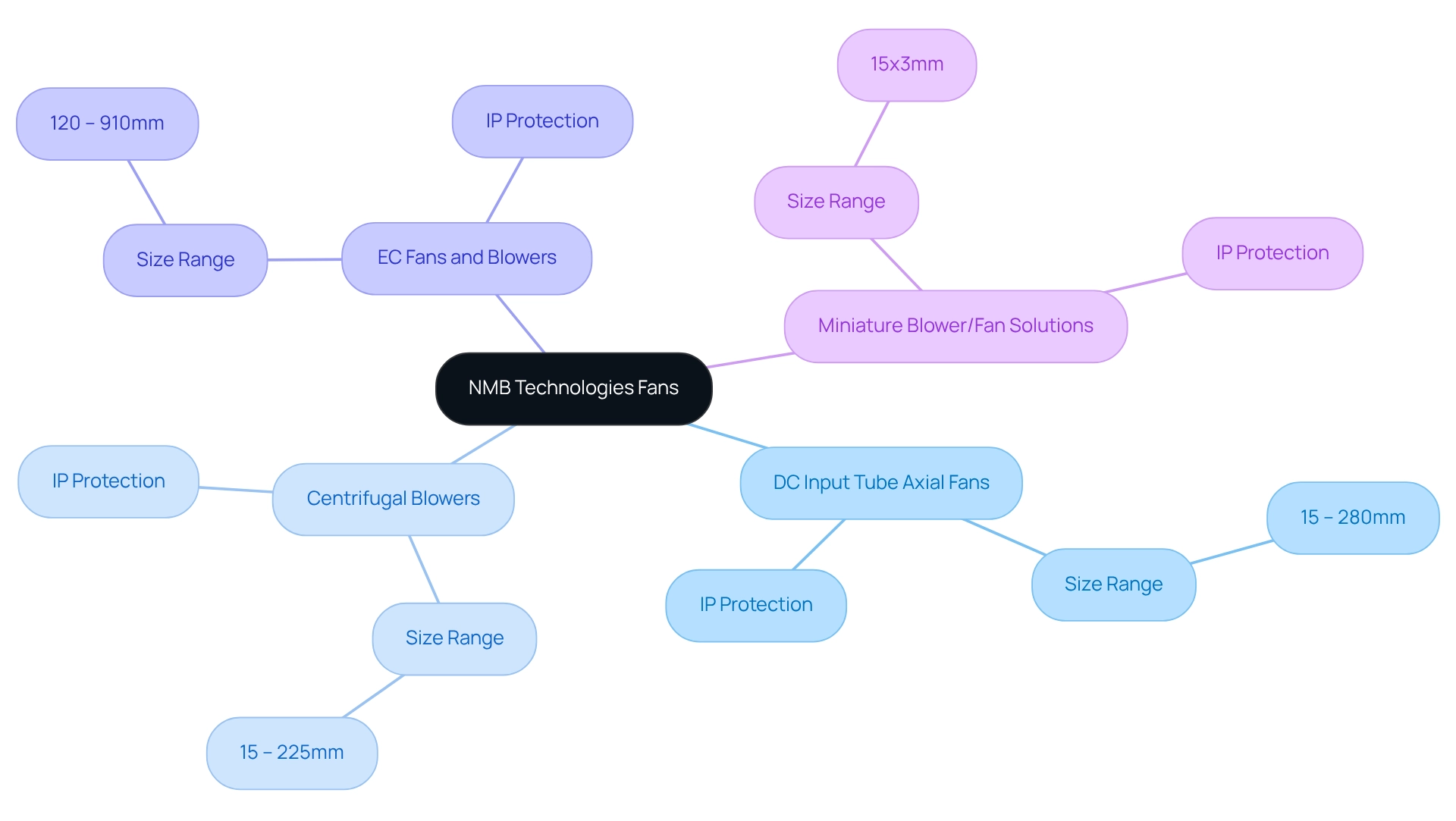

NMB Technologies 04020VA-12Q-CA-00: Reliable Fans for Harsh Environments

NMB Technologies 04020VA-12Q-CA-00: Reliable Fans for Harsh Environments

The NMB Technologies 04020VA-12Q-CA-00 fan is meticulously engineered for dependable performance in harsh environments, boasting an impressive IP rating that safeguards against dust and moisture. This feature renders it particularly suitable for applications where exposure to challenging conditions is inevitable. Its robust ball bearing fan design not only enhances longevity but also ensures consistent airflow, making it a top choice for engineers dedicated to maintaining system integrity under demanding circumstances.

Gagner-Toomey Associates, a prominent producer of tailored and standard thermal management solutions, offers an extensive selection of DC input ventilators and centrifugal blowers optimized for performance and efficiency, ideal for electronic and automotive applications. Key features include:

- DC Input Tube Axial Fans: Available in sizes from 15 – 280mm.

- Centrifugal Blowers: Ranging from 15 – 225mm.

- EC Fans and Blowers: Sizes from 120-910mm.

- Miniature Blower/Fan Solutions: Starting from 15x3mm for consumer applications.

- IP Protection: Available in most models upon request.

As noted by Justin Annarino, owner of Key’s Custom Automotive, “The air movement is so powerful, and everyone who comes in the shop asks about them. They’re absolutely amazing supporters and keep us cool every day.” This real-world endorsement underscores the fan’s reliability and effectiveness. The fan’s capability to endure environmental stresses while delivering optimal temperature regulation emphasizes the critical significance of selecting components that adhere to strict reliability standards. Furthermore, the effectiveness of IP ratings in protecting electronic components cannot be overstated, particularly in settings where durability is paramount. A recent case study on step-stress accelerated life testing illustrates the importance of rigorous testing protocols to ensure fan reliability in harsh environments, reinforcing the necessity for engineers to prioritize IP ratings in their component selection.

Fan Maintenance Essentials: Ensuring Longevity and Performance

To maximize the longevity and performance of cooling fans, regular maintenance is crucial. This maintenance encompasses not only the cleaning of dust and debris from the bearing fan blades and housings but also the inspection for signs of wear and the lubrication of bearings as necessary. Engineers must develop a maintenance schedule tailored to the specific operating environment and usage frequency.

Research indicates that regular maintenance can significantly decrease the likelihood of unforeseen failures, which can disrupt operations. For instance, a case study titled ‘The Science Behind PC Cooling’ explores the complexities of radiator fan technology, emphasizing the interplay between CFM, SP, and impedance in achieving optimal cooling. This underscores the importance of understanding airflow dynamics and performing regular fan maintenance to enhance efficiency.

Additionally, statistics reveal that regular fan maintenance can reduce failure rates by as much as 30%, highlighting its critical role. As Kaylyn Rudy articulates, ‘Regular maintenance is key to ensuring that systems operate smoothly and efficiently.’ By adhering to these best practices, engineers can ensure optimal fan performance and extend the lifespan of their cooling solutions.

It is also vital to recognize that a 12-inch fan may not perform the same as another 12-inch fan from a different manufacturer, making it essential to understand the specific characteristics of the fans being maintained.

Selecting the Right Fan: Key Considerations for Electronics Applications

Selecting the appropriate fan for electronics applications necessitates a thorough evaluation of several critical factors. Engineers must assess airflow requirements, noting that a decrease in fan speed by approximately 800 RPM can lead to a 10.7% reduction in airflow, which directly impacts performance. Additionally, noise levels are paramount; excessive noise can detrimentally affect user experience and reliability. Size constraints must also be considered to guarantee compatibility with the overall design.

It is vital to align the fan’s specifications with the cooling needs of the system to achieve optimal performance. Engineers should scrutinize the bearing fan type, as this significantly influences longevity and efficiency. Furthermore, power consumption is a pivotal consideration; fans equipped with PWM (Pulse Width Modulation) capabilities provide enhanced control over speed and energy usage, making them the preferred choice for numerous applications.

Environmental factors, such as temperature and humidity, can also impact fan performance and should be integrated into the selection process. Moreover, the adoption of advanced technologies in temperature control is essential for enhancing the efficiency and reliability of refrigeration units. By implementing these technologies, engineers can bolster the performance and durability of electronic components, ensuring they meet both current and future demands.

Gagner-Toomey Associates serves a crucial function in connecting engineers with a robust distribution network, guaranteeing a consistent supply of components from industry leaders like CONEC and Delta. This extensive network of local distributors facilitates effective fan selection, enabling engineers to ensure their cooling solutions are not only efficient but also reliable and adaptable to future requirements.

Cooling Fans in Power Management: Enhancing System Efficiency

Bearing fans are essential components in power management systems, effectively dissipating heat generated by electronic devices. Proper thermal management is critical for maintaining system efficiency and preventing overheating, which can result in performance degradation or even failure. Insufficient temperature control can significantly increase the frequency of overheating incidents, leading to costly equipment failures and damage. Moreover, effective temperature regulation can reduce maintenance costs by minimizing the likelihood of equipment breakdowns and associated harm. Therefore, engineers must carefully evaluate the positioning and specifications of ventilation devices to ensure they provide adequate airflow while optimizing energy consumption. By incorporating high-efficiency units, not only can the overall functionality of power management solutions be enhanced, but the durability of components is also supported. For instance, in energy storage systems (ESS), the bearing fan plays a pivotal role in regulating temperatures, thereby extending battery lifespan and ensuring the secure operation of power electronics. Efficient thermal control in these frameworks has been shown to prolong component longevity and maintain reliability across various applications.

As the industry evolves in 2025, the importance of thermal management strategies continues to grow, with experts emphasizing the need for innovative temperature regulation solutions. In line with our commitment to reducing environmental impact, as a global manufacturer with an extensive product reach, we are dedicated to fostering a low-carbon society by developing and offering products aligned with this overarching goal. By adopting advanced cooling technologies, engineers can markedly enhance efficiency and reliability, aligning with broader environmental objectives while reducing the carbon footprint of electronic devices. Furthermore, engineers in search of customized solutions are encouraged to contact SANYO DENKI for quotes and technical support, thereby further enhancing their design capabilities.

Advancements in Fan Technology: Implications for Electronics Design

Recent advancements in blower technology, particularly the emergence of electronically commutated (EC) units and intelligent air circulation solutions, are transforming electronics design. EC units are engineered for enhanced energy efficiency, often achieving reductions in motor noise by as much as 20 dB at critical frequencies, thereby improving user experience and overall performance. These devices seamlessly integrate with management frameworks, facilitating dynamic performance adjustments based on real-time data. Intelligent devices elevate this further by automatically modulating their speed in response to temperature fluctuations, ensuring optimal cooling and energy savings.

As engineers develop structures, the integration of these innovations is crucial for enhancing performance, minimizing energy consumption, and bolstering overall reliability. The increasing consumer awareness of energy-efficient solutions is shaping market trends, with many consumers opting for higher-quality, efficient models despite their initial costs, as they recognize the long-term savings these investments offer.

A case study on consumer perceptions of cooling devices’ efficiency indicates that many consumers may not fully appreciate the value of energy-efficient models, prompting manufacturers to prioritize lower initial costs over long-term savings. This shift underscores the importance of incorporating advanced fan technologies into modern electronic frameworks.

Furthermore, the exploration of solar-powered window fans as an energy-efficient alternative reflects the broader trend towards sustainable solutions in fan technology. As Mark Walker aptly noted, “Literal interpretation of DEI is tiresome. Here’s the deal:…” emphasizing the necessity for innovative approaches in design and efficiency.

Future Innovations in Fan Technologies: What Electronics Engineers Should Anticipate

As the electronics industry advances, engineers must prepare for significant innovations in bearing fan technologies. A primary focus is the integration of Internet of Things (IoT) capabilities, facilitating remote monitoring and control of fan units, which enhances operational efficiency and responsiveness. Data from the ventilation, heating, air-conditioning, and commercial refrigeration equipment market report suggests that the uptake of IoT in refrigeration solutions is anticipated to increase significantly, with a projected growth rate of 25% each year over the next five years, as numerous firms invest in intelligent technologies to enhance performance and energy management.

Furthermore, progress in materials is poised to transform fan design, resulting in products that are not only more durable but also lighter, thus enhancing overall efficiency. These innovations are particularly crucial for high-density applications, where effective thermal management is essential.

Real-world examples demonstrate the effect of IoT integration in temperature control solutions. For instance, recent developments in smart fan systems allow for real-time data collection and analysis, enabling engineers to optimize performance and predict maintenance needs. Moreover, industry trends indicate an increasing focus on sustainability, with companies investigating clean technologies to improve their temperature control solutions. A significant instance is the recent purchase of Cofimco by PX3 Partners, which seeks to promote innovation in large fan systems and position the company for expansion in sustainable technologies.

Looking ahead, engineers should anticipate a wave of innovations in fan technologies, particularly in bearing fan designs that enhance energy efficiency, improve noise reduction, and incorporate advanced control algorithms. As Mark Zuckerberg noted, “Whenever I hear people saying AI is going to hurt people in the future I think, yeah, technology can generally always be used for good and bad and you need to be careful about how you build it.” This perspective underscores the importance of thoughtful integration of technology in cooling solutions. These advancements will not only address current thermal management challenges but also pave the way for future applications in the rapidly evolving electronics landscape.

Conclusion

Innovative cooling solutions have emerged as a cornerstone of modern electronics design, with advancements in fan technologies paving the way. Gagner-Toomey Associates exemplifies a commitment to providing cutting-edge products that enhance thermal management, equipping engineers with the necessary tools to address the complexities of today’s electronic systems. From hydraulic bearing fans optimized for 3D printing to ball bearing fan kits that enhance pellet grill efficiency, the diverse options available facilitate tailored solutions that meet specific operational demands.

Understanding the nuances of different fan bearing types is essential for engineers, as these choices directly influence performance and reliability. The insights presented in this article underscore the significance of selecting the appropriate fan technology based on project requirements, environmental conditions, and efficiency objectives. Regular maintenance practices further extend the lifespan and effectiveness of cooling fans, highlighting the necessity for engineers to integrate these considerations into their designs.

As the industry progresses, the integration of IoT capabilities and advancements in materials will shape the future of fan technologies. Engineers must remain attuned to these trends to enhance system efficiency and sustainability. By embracing innovative cooling solutions, professionals can ensure that their electronic designs not only satisfy current demands but also anticipate future challenges. The unwavering commitment to excellence in thermal management will ultimately drive the reliability and performance of electronic systems within an increasingly complex landscape.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in delivering innovative temperature control solutions tailored for the electronics sector.

How much experience does Gagner-Toomey Associates have in the industry?

Gagner-Toomey Associates has a collective experience exceeding 150 years.

Why is effective thermal management important in electronics?

Effective thermal management is essential as it directly influences the reliability and performance of electronic components.

What recent trend is affecting the demand for temperature regulation solutions?

Recent trends show that 90% of companies are adopting hybrid models, increasing the demand for flexible temperature regulation solutions in dynamic work environments.

What does Bernard Marr emphasize regarding adaptability in engineering?

Bernard Marr emphasizes that “Adaptability is key to thriving in a rapidly changing landscape,” highlighting the necessity for engineers to remain agile and receptive to emerging technologies and methodologies.

How does Gagner-Toomey ensure access to innovative solutions for engineers?

Gagner-Toomey maintains robust relationships with local distributors, guaranteeing a steady supply of components that enhance engineers’ access to innovative solutions.

What is the significance of skepticism in engineering according to the case study mentioned?

The case study emphasizes the critical importance of thorough analysis and critical thinking in developing effective cooling solutions.

What types of products does Gagner-Toomey offer for cooling solutions?

Gagner-Toomey offers an extensive range of advanced cooling solutions, including DC input units and centrifugal blowers.

What power supply protection mechanisms are available for Gagner-Toomey fans?

Common power supply protection mechanisms include Over Voltage Protection (OVP), Under Voltage Protection (UVP), and Short Circuit Protection (SCP).

What is the WINSINN Hydraulic Fan designed for, and what are its key features?

The WINSINN Hydraulic Fan is designed for 3D printers and features exceptional performance with optimal airflow, low noise levels, and a hydraulic support design that extends the lifespan of the bearing fan.

How does the WINSINN fan contribute to 3D printing performance?

By integrating the WINSINN fan into designs, engineers can achieve consistent temperature regulation, which is crucial for improving print quality and overall performance.

What is the lifespan of the ball support devices in the Yoder Smokers bearing fan kit?

The ball support devices in the Yoder Smokers bearing fan kit have a lifespan of approximately 50,000 hours.

How does the Yoder Smokers bearing fan kit enhance cooking performance?

The fan kit ensures consistent airflow and precise temperature control, optimizing ignition and reducing startup times, which elevates cooking performance and flavor retention.

What advantages do bearing fans have over sleeve fans?

Bearing fans excel in efficiency and durability, with longer lifespans and less susceptibility to environmental influences compared to sleeve fans.