Overview

The article examines the diverse types, applications, innovations, and control techniques of advanced DC motors, underscoring their critical importance for electronics engineers. It articulates the necessity of comprehending the characteristics of these motors and the integration of modern technologies such as IoT and AI to enhance performance and efficiency. This focus addresses the escalating demand across various industries, particularly in automation and electric vehicles, making it imperative for professionals in the field to stay informed and adapt to these advancements.

Introduction

In the dynamic landscape of modern engineering, DC motors serve as a cornerstone of innovation, powering a wide array of applications across diverse industries. They are pivotal in the automotive sector, driving electric vehicle functionalities, and in industrial automation, where they significantly enhance productivity on assembly lines. The versatility of DC motors is undeniably remarkable.

However, engineers often face daunting challenges when navigating the complexities of motor types, control techniques, and integration issues. As advancements in technology usher in a new era of smart motors, equipped with IoT and AI capabilities, a solid understanding of the fundamentals and recent innovations becomes essential.

This article delves into the critical aspects of DC motors, exploring their types, applications, advanced control strategies, and the transformative impact of emerging technologies. The aim is to equip engineers with the knowledge necessary to optimize performance and efficiency in their projects.

Fundamentals of DC Motors: Types and Mechanisms

DC machines are classified into several types based on their design and functional traits, each providing distinct benefits tailored for various applications:

- Brushed DC Machines: These devices utilize brushes to deliver current to the rotor, making them straightforward and cost-effective. However, they necessitate regular maintenance due to brush wear, which can impact performance over time.

- Brushless DC Devices: By eliminating brushes and employing electronic controllers, brushless DC devices achieve greater efficiency and an extended lifespan. This design reduces maintenance needs and enhances reliability, making them increasingly popular in modern applications. Notably, India accounted for over 14% of the Asia Pacific brushless DC engine market, driven by automation, electric vehicle adoption, and governmental initiatives for electric mobility.

- Permanent Magnet DC Machines: These devices employ permanent magnets to generate the magnetic field, resulting in high torque at low speeds. Their efficiency and compact design render them ideal for applications requiring precise control and performance.

- Series and Shunt Wound Machines: Series machines are designed for high starting torque, making them suitable for applications such as electric vehicles and cranes. In contrast, shunt devices excel in providing superior speed regulation, which is essential in applications that require consistent speed under varying loads.

Understanding these advanced DC motor types is crucial for engineers, as it enables them to select the most appropriate option for specific applications, ensuring optimal performance and efficiency. The market for advanced DC motors is robust, with the global electric DC drive sector valued at approximately USD 13 billion in 2021 and projected to reach around USD 25 billion by 2030. This growth is fueled by technological advancements and increasing demand across various sectors, including automation, electric mobility, and the utilization of advanced DC motors.

For instance, the United States maintains a leading position in the North American DC engine market, representing approximately 89% of the share in 2024, primarily due to a strong manufacturing sector and the pursuit of energy-efficient solutions. As Brian Moore, VP of NICCA USA, Inc., noted, ‘The quality of research they have conducted for us has been excellent,’ underscoring the importance of comprehensive research in understanding DC machinery technology. As industries continue to evolve, the significance of selecting the appropriate type of DC device becomes increasingly essential for achieving desired operational outcomes.

Applications of DC Motors Across Industries

Advanced DC motors are pivotal in a multitude of applications across various sectors, underscoring their adaptability and importance in modern technology. In the automotive industry, these motors are indispensable for functionalities such as electric windows, windshield wipers, and seat adjustments. The emergence of electric vehicles (EVs) equipped with advanced DC motors has significantly heightened their relevance, with global EV sales soaring to 14% of all new cars sold in 2022.

This remarkable surge can be largely attributed to the integration of advanced DC motors, particularly Brushless DC (BLDC) devices, which deliver enhanced efficiency and performance, thereby improving production capabilities among automotive manufacturers. Furthermore, policy initiatives in major economies have bolstered this growth, creating a favorable environment for EV adoption.

In the realm of industrial automation, advanced DC motors are critical for driving conveyor belts, robotic arms, and assembly lines, facilitating streamlined operations and heightened productivity. The market for advanced DC motor devices in this domain is projected to expand significantly, propelled by advancements in automation technologies and the increasing demand for efficient machinery. Notably, leading companies such as ABB Ltd., Siemens AG, and Nidec Corporation are heavily investing in research and development to innovate and refine technologies for engines.

High-speed engines, particularly advanced DC motors operating between 2001-10,000 RPM, are especially crucial in applications demanding rapid performance, further emphasizing the advancements in DC technology.

The consumer electronics sector also relies on advanced DC motors, which are commonly found in devices such as hair dryers, vacuum cleaners, and toys, where precision and reliability are essential. In medical equipment, advanced DC motors are utilized in pumps and surgical instruments, ensuring accurate and regulated functions vital for patient safety.

In the aerospace industry, advanced DC motors are employed in actuators and control surfaces, contributing to the precision and reliability required in aircraft systems. The versatility of advanced DC motors across these diverse applications highlights their essential role in driving innovation in product design and functionality, rendering them indispensable in today’s technological landscape.

As the industry evolves, expert insights underscore the ongoing significance of advanced DC motors in enhancing performance and efficiency across sectors, reinforcing their status as a fundamental component of contemporary engineering solutions. As Brian Moore, VP of NICCA USA, Inc., remarked, “The quality of research they have conducted for us has been excellent,” reflecting the high standards and advancements in DC machinery technology.

Advanced Control Techniques for Enhanced Motor Performance

Sophisticated management methods for direct current machines have notably progressed, offering engineers robust instruments to improve performance and efficiency. Key methodologies include:

- Pulse Width Modulation (PWM): This method adjusts the duration of voltage pulses to regulate the energy supplied to the engine. By adjusting the duty cycle, PWM enables precise speed control and enhanced energy efficiency, establishing it as a cornerstone of contemporary drive control systems. Recent advancements in PWM techniques have led to smoother operation and reduced acoustic noise, which are critical in applications requiring high precision.

- Field-Oriented Control (FOC): FOC is a sophisticated method that optimizes the torque and efficiency of brushless DC machines by aligning the device’s magnetic field with the rotor’s position. This technique not only enhances performance but also improves dynamic response, allowing motors to maintain a constant speed of 3000 RPM even under varying load conditions. The stability of FOC under changes in resistance (Rs) has been well-documented, showcasing its reliability in demanding applications.

- Sensorless Control: This innovative approach estimates rotor position using advanced algorithms, eliminating the need for physical sensors. By minimizing complexity and expense, sensorless management frameworks can attain performance benchmarks similar to conventional approaches, while also improving reliability and decreasing maintenance requirements.

- Adaptive Management: This technique involves real-time adjustments to governing parameters based on performance feedback. By persistently observing behavior, adaptive regulation improves responsiveness and enables optimal performance across various operational conditions. As noted by J.W. Zhang, “To tackle the unsatisfactory dynamic response of the PI controller due to operation point shift during charging with wide-range speed shift, a robust management strategy that includes an extended state observer and takes into account speed variations in the DC-link voltage regulator is essential.”

These advanced control techniques not only enhance the efficiency of advanced DC motors but also enable engineers to create frameworks that can adapt to dynamic environments. The integration of these methods is supported by a growing body of evidence, including case studies that demonstrate the effectiveness of PWM and FOC in real-world applications. For instance, the Predictive Current Control (PCC) strategy has shown promising results, achieving a torque ripple of 1.0 Nm and a total harmonic distortion (THD) of 3.4%.

However, it remains sensitive to variations in system parameters, which poses challenges in its implementation.

As the industry keeps adopting these advanced techniques, the advantages of PWM and FOC in machinery regulation are becoming more acknowledged, with statistics showing a notable increase in their application across various sectors. This trend highlights the significance of remaining updated on the latest developments in movement regulation technology, particularly as issues like optimizing tiny fc inference for MCU timing continue.

Recent Innovations in DC Motor Technology

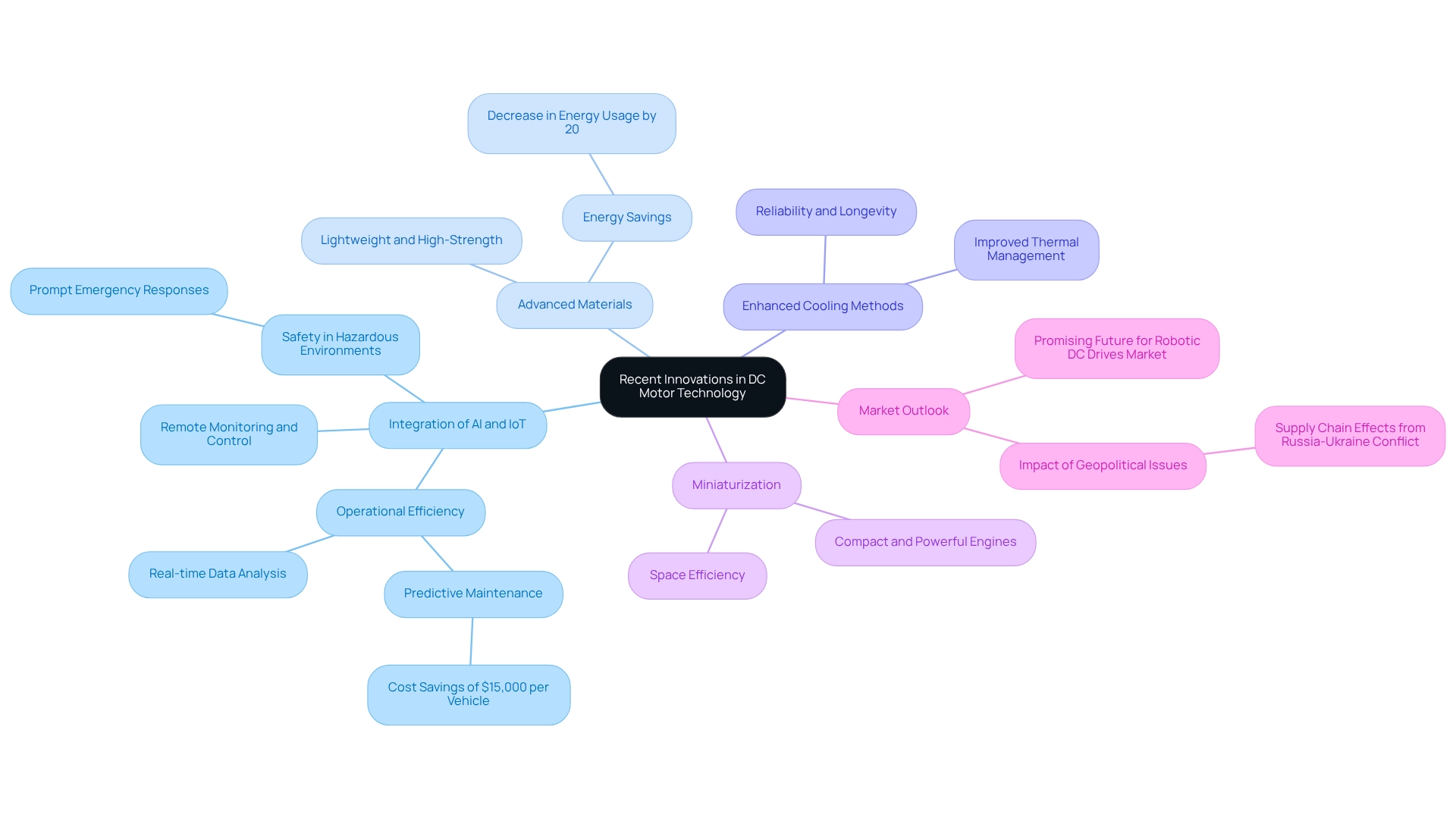

Recent innovations in advanced DC motor technology are reshaping the capabilities and applications of these essential components. Key advancements include:

- Integration of AI and IoT: The emergence of intelligent devices, equipped with advanced sensors and connectivity features, facilitates remote monitoring and control. This integration significantly enhances operational efficiency, allowing for real-time data analysis and predictive maintenance, which can lead to substantial cost savings. For instance, Shell’s LubeAnalyst software has demonstrated the potential to reduce maintenance costs by nearly $15,000 per vehicle annually, showcasing the financial benefits of such technologies. Furthermore, the integration of AI and IoT is crucial for ensuring safety in hazardous environments, as highlighted in a case study where remote monitoring capabilities enabled prompt emergency responses to potential risks, securing both company data and employee safety.

- Advanced Materials: The adoption of lightweight yet high-strength materials is revolutionizing vehicle design. These materials not only enhance performance but also aid in energy savings, making machines more efficient. Recent studies suggest that using advanced materials can result in a decrease in energy usage by up to 20%, an essential aspect in today’s energy-aware environment.

- Enhanced Cooling Methods: Innovations in thermal management are vital for boosting the reliability and longevity of advanced DC motor devices, especially when operating under heavy loads. Improved cooling systems guarantee that engines function within ideal temperature limits, thus avoiding overheating and prolonging their operational lifespan.

- Miniaturization: Progress in design and production techniques has facilitated the development of more compact, powerful engines. This miniaturization is especially advantageous for compact uses, where space is limited, enabling engineers to incorporate powerful drive solutions into a range of devices and systems.

- Market Outlook: The future perspective for the Robotic DC Drives Market is encouraging, fueled by technological innovations and rising automation throughout sectors. As pointed out by Rajeev Chandrasekhar, Minister of State for Electronics and Information Technology in India, the current geopolitical issues, like the Russia-Ukraine conflict, have affected supply chains across various sectors, including the semiconductor field, which is essential for driving technology.

These innovations are not only changing the landscape of applications for advanced DC motors but also enabling engineers to create more efficient, versatile, and dependable systems that fulfill the requirements of contemporary technology.

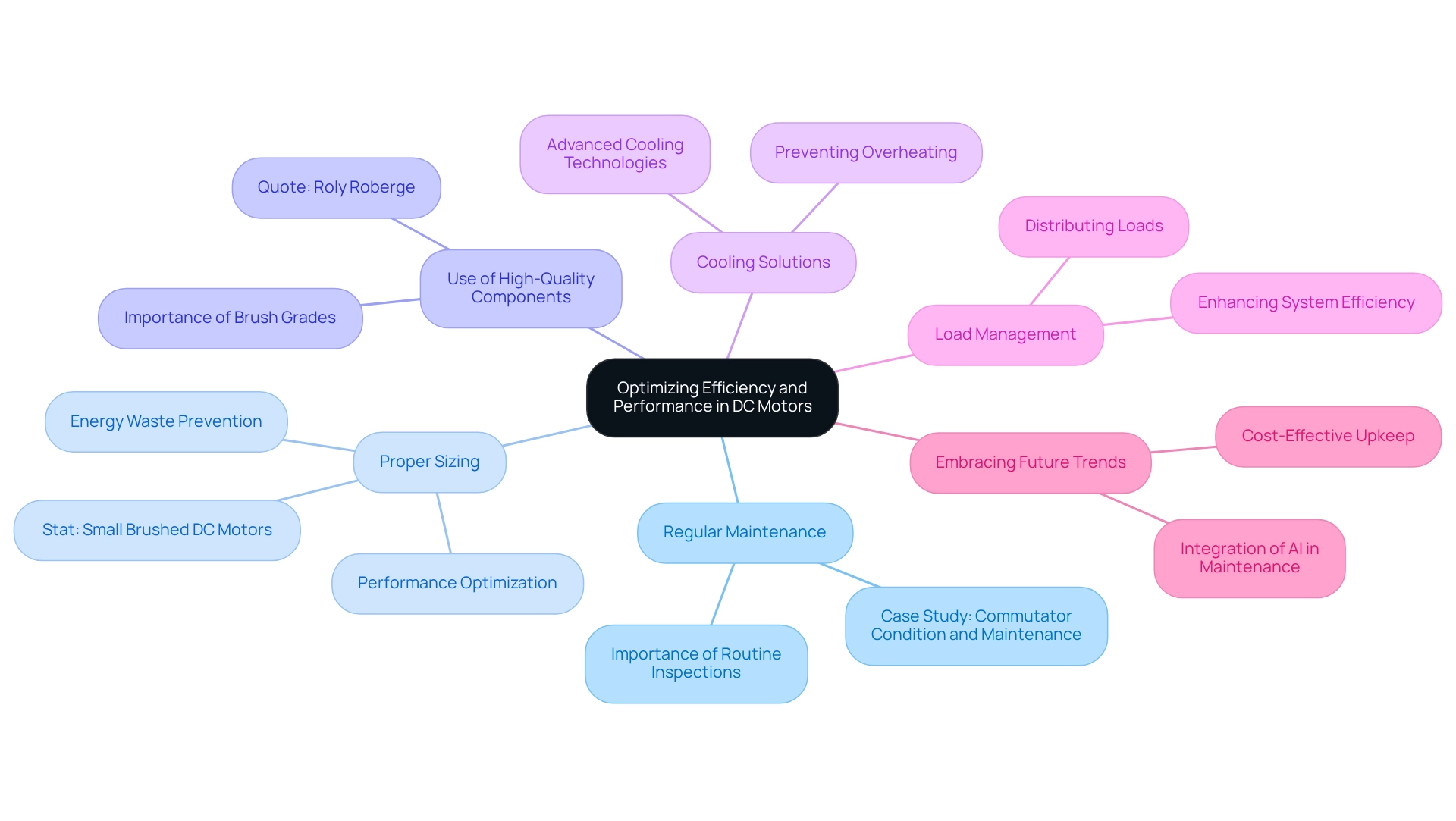

Optimizing Efficiency and Performance in DC Motors

To enhance the efficiency and performance of DC motors, engineers must implement the following strategies:

- Regular Maintenance: Conducting routine inspections and maintenance is crucial for preventing wear and tear. Consistent observation of commutator conditions, for example, can prevent catastrophic failures and prolong the lifespan of units, ultimately ensuring efficient operation and lowering replacement expenses. Insights from the case study titled “Commutator Condition and Maintenance” highlight the significance of maintaining an acceptable brush film to avoid destructive conditions that can lead to severe damage.

- Proper Sizing: Selecting the appropriate engine size for specific applications is essential. Proper sizing not only prevents energy waste but also optimizes performance. Data indicates that small brushed DC devices, typically featuring three poles, can significantly enhance operational efficiency when correctly sized for their intended use.

- Use of High-Quality Components: Investing in high-quality materials and components is vital for enhancing reliability and efficiency. The selection of appropriate brush grades is particularly important; as Roly Roberge, a design and application engineer manager, states, “Selecting the appropriate brush grade helps to avoid commutator damage, arcing, and destructive sparking.” This underscores the necessity for careful consideration in component selection to maintain optimal performance of the machinery.

- Cooling Solutions: Implementing effective cooling methods is necessary to prevent overheating, which can severely affect the lifespan of the machinery. Advanced cooling technologies can be integrated to ensure that engines operate within safe temperature ranges, thereby prolonging their operational life.

- Load Management: Distributing loads among several machines can enhance overall system efficiency. By strategically managing loads, engineers can improve the performance of each device while minimizing energy consumption.

- Embracing Future Trends: As the industry evolves, the integration of AI in maintenance strategies is becoming increasingly significant. AI can enable cost-efficient and proactive upkeep, ensuring that DC machines function at optimal efficiency.

By adopting these strategies, engineers can significantly enhance the performance and durability of DC devices in various applications, ensuring they meet the demands of modern electronics.

Challenges in DC Motor Integration and Solutions

Integrating DC motors into existing systems presents several common challenges that engineers must navigate:

- Compatibility Issues: Achieving compatibility between DC drives and existing systems can be intricate. Engineers can address this by adopting standardized interfaces and protocols, which facilitate smoother integration and reduce the likelihood of operational conflicts. Recent statistics indicate that compatibility issues are a significant barrier, with a notable percentage of integration failures attributed to mismatched components. Additionally, it has been observed that Georgia and Delaware were the slowest in finding optimal values for DC drive control, underscoring the importance of addressing compatibility in the integration process.

- Thermal Management: Thermal management is essential, as overheating poses a significant threat to the reliability and longevity of advanced DC motors. Implementing robust thermal management solutions, such as advanced cooling technologies and real-time monitoring, is crucial. Real-world instances illustrate that efficient thermal management can greatly improve motor performance and avert early failure, guaranteeing that setups function within optimal temperature ranges.

- Managing Complexity: The intricacy of contemporary management frameworks can complicate the integration process. To alleviate this, engineers are encouraged to simplify control algorithms and utilize modular components, which can streamline implementation and improve responsiveness. This approach not only reduces the learning curve but also enhances overall system efficiency. As noted by Kashif Saleem from the Faculty of Engineering and Computing at Liwa College, while the MGO demonstrates significant advantages in terms of fast convergence and robustness, certain limitations remain that engineers must consider.

- Power Supply Variability: Fluctuations in power supply can negatively impact performance, resulting in erratic operation. Utilizing voltage regulators and filters can stabilize power delivery, ensuring that DC devices receive a consistent voltage supply. This is especially vital in contexts where accuracy is paramount.

By proactively tackling these challenges, engineers can significantly improve the reliability and performance of systems using advanced DC motors, paving the way for innovative applications in the electronics sector. A relevant case study titled “Difference Between Traditional BLDC/Gearbox Combination and ElectroCraft LRPX” illustrates how integrated designs can improve performance and address compatibility challenges, showcasing the potential for superior designs that combine efficiency with compactness.

The Role of IoT and AI in Modern DC Motor Control

The integration of IoT and AI in DC control is catalyzing significant advancements, delivering a suite of benefits that enhance operational efficiency and reliability:

- Remote Monitoring: IoT-enabled devices empower real-time observation, facilitating predictive maintenance that minimizes downtime and extends equipment lifespan. This capability is essential in industries where operational continuity is critical. For instance, the Internet of Medical Things (IoMT) illustrates how remote monitoring can enhance patient care through real-time information, ultimately saving lives.

- Data Analytics: By leveraging AI algorithms, engineers can evaluate performance data to optimize machinery operations. These algorithms not only improve efficiency but also forecast potential failures, allowing for proactive measures that avert costly disruptions. Digital twin technology, which enables precise simulations of physical objects using real-world data, plays a pivotal role in this process, enhancing the accuracy of predictive maintenance strategies.

- Enhanced Control: Intelligent algorithms dynamically adjust engine parameters based on real-time operational conditions. This adaptability enhances efficiency and responsiveness, ensuring that engines perform optimally under varying loads and conditions.

- Scalability: IoT networks inherently possess scalability, allowing for the seamless integration of multiple engines into a unified management framework. This scalability is vital for extensive applications, where effectively managing numerous engines significantly impacts overall system performance.

These advancements are revolutionizing engine management, empowering engineers to design more efficient and reliable systems that meet the demands of modern applications. As Bernard Marr noted, the value of the IoT healthcare market is projected to reach approximately $150 billion this year, underscoring the broader implications of IoT advancements across diverse sectors, including vehicle control. As the industry continues to evolve, the role of IoT and AI in enhancing the performance of advanced DC motors will only grow, paving the way for smarter, more interconnected solutions.

Key Takeaways: Mastering Advanced DC Motors

To effectively master advanced DC motors, engineers should concentrate on several key areas:

- Understanding Fundamental Types and Mechanisms: A solid grasp of the various types of DC motors—such as brushed and brushless—is essential. Brushless devices, while providing longer lifespans and greater efficiency, generally necessitate more intricate controllers and incur higher initial expenses. As Isa Ali Ibrahim observes, ‘Direct current (DC) machines are frequently utilized due to their low cost, great dependability, and availability in various sizes and forms, which makes them user-friendly and versatile.’

- Recognizing Diverse Applications: DC devices are utilized across a multitude of industries, from automotive to robotics, due to their adaptability and reliability. Their capacity to offer accurate regulation makes advanced DC motors suitable for applications that demand variable speed and torque. A recent study examines various servos and contrasts their traits, underscoring the benefits of DC types over AC types, which further highlights their adaptability in different uses.

Implementing advanced regulation methods, such as PID controllers, in advanced DC motor systems has been demonstrated to greatly improve engine performance. Research indicates that these frameworks enhance response speed and accuracy, which is essential for applications requiring high precision. For example, a case study named ‘Simulation of Servo Actuator Control Frameworks’ illustrates that PID controller frameworks greatly enhance response speed and precision, highlighting the efficiency of control frameworks in improving servo actuator performance. The simulation of the servo mechanism system was conducted using MATLAB, providing a practical example of how these advanced techniques can be applied in real-world scenarios.

- Staying Updated on Innovations: The area of vehicle technology is rapidly evolving. Engineers should stay updated on the latest advancements, including developments in IoT and AI, which are paving the way for smarter control solutions.

- Optimizing Efficiency: Regular maintenance and careful design selections can significantly improve the effectiveness of DC machines. Understanding the impact of these factors is vital for maximizing performance and longevity.

- Addressing Integration Challenges: Engineers must be ready to confront integration difficulties that emerge when incorporating DC drives into more extensive frameworks. Efficient solutions frequently require a comprehensive grasp of both the machine’s capabilities and the network’s requirements.

- Leveraging IoT and AI: The integration of IoT and AI technologies into vehicle control systems is a key trend in 2025. These technologies enable real-time monitoring and adjustments, leading to improved operational efficiency and predictive maintenance.

By focusing on these critical areas, engineers can fully leverage the capabilities of the advanced DC motor, ensuring successful outcomes in their engineering projects.

Conclusion

DC motors stand as a cornerstone of modern engineering, their diverse types and applications playing a vital role across various industries. A comprehensive understanding of the different motor types—such as brushed, brushless, and permanent magnet DC motors—equips engineers with the necessary knowledge to select the most suitable options for specific applications. This selection process is crucial, particularly in light of the growing demand for efficiency and performance in sectors like automotive and industrial automation.

Advanced control techniques, including Pulse Width Modulation and Field-Oriented Control, have significantly enhanced the capabilities of DC motors. These techniques allow for precise performance adjustments that meet the stringent demands of contemporary applications. The integration of IoT and AI into motor control systems is revolutionizing operational efficiency, enabling real-time monitoring and predictive maintenance that can drastically reduce downtime and costs.

As the industry evolves, addressing the challenges of integrating DC motors into existing systems is paramount. Compatibility issues, thermal management, and control complexity present significant hurdles. However, by staying informed about innovations and implementing effective strategies, engineers can navigate these challenges, ensuring that DC motors are utilized to their fullest potential.

Ultimately, mastering the intricacies of DC motors not only enhances performance and efficiency but also drives innovation across multiple sectors. As technology advances, the role of DC motors will continue to expand, reinforcing their importance in the landscape of modern engineering solutions. The future is promising for DC motor technology; embracing these developments will pave the way for smarter, more efficient systems that meet the demands of an increasingly automated world.

Frequently Asked Questions

What are the main types of DC machines?

The main types of DC machines include Brushed DC Machines, Brushless DC Devices, Permanent Magnet DC Machines, and Series and Shunt Wound Machines. Each type has unique design and functional traits suited for different applications.

What are Brushed DC Machines and their characteristics?

Brushed DC Machines utilize brushes to deliver current to the rotor, making them straightforward and cost-effective. However, they require regular maintenance due to brush wear, which can affect performance over time.

How do Brushless DC Devices differ from Brushed DC Machines?

Brushless DC Devices eliminate brushes and use electronic controllers, leading to greater efficiency and a longer lifespan. This design reduces maintenance needs and enhances reliability, making them popular in modern applications.

What advantages do Permanent Magnet DC Machines offer?

Permanent Magnet DC Machines use permanent magnets to generate the magnetic field, providing high torque at low speeds. Their efficiency and compact design make them ideal for applications that require precise control and performance.

What are the differences between Series and Shunt Wound Machines?

Series Wound Machines are designed for high starting torque, suitable for applications like electric vehicles and cranes. Shunt Wound Machines excel in providing superior speed regulation, essential for maintaining consistent speed under varying loads.

Why is understanding advanced DC motor types important for engineers?

Understanding advanced DC motor types helps engineers select the most appropriate option for specific applications, ensuring optimal performance and efficiency.

What is the market outlook for advanced DC motors?

The global electric DC drive sector was valued at approximately USD 13 billion in 2021 and is projected to reach around USD 25 billion by 2030, driven by technological advancements and increasing demand across various sectors.

Which country leads the North American DC engine market and why?

The United States leads the North American DC engine market, representing about 89% of the share in 2024, primarily due to a strong manufacturing sector and the pursuit of energy-efficient solutions.

In what applications are advanced DC motors used in the automotive industry?

Advanced DC motors are used in automotive applications such as electric windows, windshield wipers, and seat adjustments. They are particularly important in electric vehicles, which saw global sales reach 14% of all new cars sold in 2022.

How do advanced DC motors contribute to industrial automation?

Advanced DC motors drive conveyor belts, robotic arms, and assembly lines, facilitating streamlined operations and increased productivity in industrial automation.

What role do advanced DC motors play in consumer electronics?

Advanced DC motors are commonly found in consumer electronics such as hair dryers, vacuum cleaners, and toys, where precision and reliability are essential.

How are advanced DC motors utilized in the aerospace industry?

In the aerospace industry, advanced DC motors are employed in actuators and control surfaces, contributing to the precision and reliability required in aircraft systems.