Overview

This article presents a comprehensive overview of the D350 model, emphasizing its essential features that are pivotal for electronics engineers. The D350 distinguishes itself with advanced capabilities in power management, thermal solutions, and integration. These attributes significantly enhance performance and efficiency in electronic designs. Notably, its impressive power output, high efficiency ratings, and seamless compatibility with existing systems underscore its value. For engineers seeking to elevate their electronic designs, the D350 model emerges as a compelling choice.

Introduction

In the dynamic realm of electronics engineering, Gagner-Toomey Associates stands out as a leader of innovation with its D350 solutions. Specifically crafted for engineers, the D350 integrates a wide range of advanced technologies designed to boost performance and efficiency across numerous applications. This includes:

- Sophisticated cooling systems

- Power management solutions

- Robust RF capabilities

- Adherence to regulatory standards

All tailored to satisfy the stringent requirements of contemporary electronic systems. As engineers face the challenges of incorporating these solutions into existing infrastructures, Gagner-Toomey’s unwavering dedication to exceptional customer service and consultative support empowers them to effectively navigate these complexities. This article explores the multifaceted features of the D350, illustrating how it not only meets industry standards but also revolutionizes the design and development processes within the field of electronics engineering.

Gagner-Toomey Associates: Leading Provider of D350 Solutions for Electronics Engineers

Gagner-Toomey Associates stands out as a premier provider of solutions specifically designed for electronics professionals, including D350. By leveraging a diverse portfolio of top-tier manufacturers, the company delivers cutting-edge technologies in cooling, power management, RF, and interconnect solutions that significantly enhance performance and efficiency across a range of applications.

With an unwavering commitment to exceptional customer service embedded in its corporate culture, Gagner-Toomey ensures that technical staff receive comprehensive support, thereby facilitating the effective implementation of these advanced solutions.

This consultative approach, powered by a highly experienced and motivated team, empowers engineers to achieve their project goals with confidence. Gagner-Toomey Associates is resolutely dedicated to assisting clients in bringing world-changing ideas to market.

Its commitment to fostering strong relationships with a diverse customer base positions the company as a trusted partner. This dedication is reflected in its growing market share within the electronics solutions sector, underscoring a robust reputation among peers and clients alike.

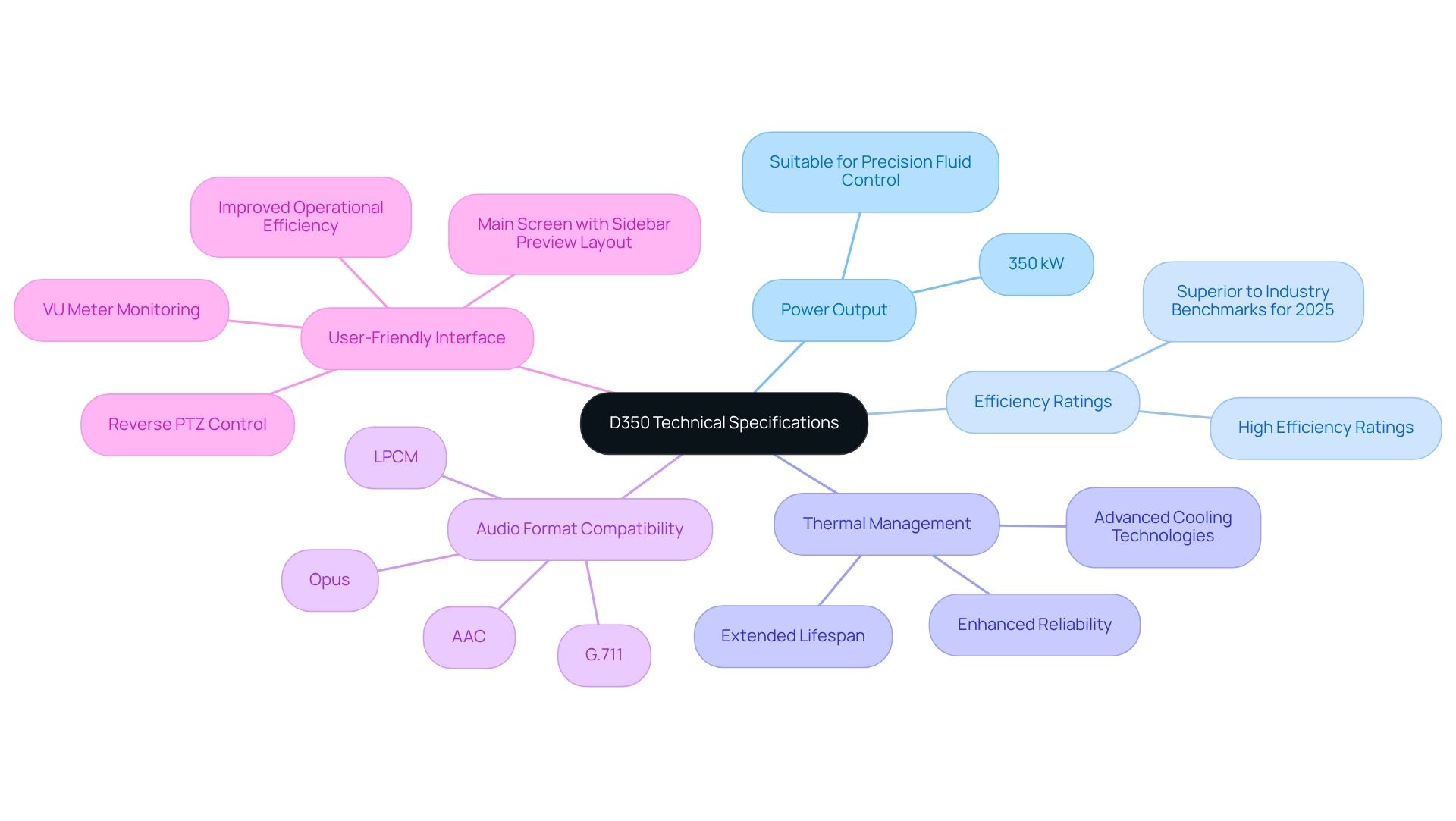

D350 Technical Specifications: Key Features and Performance Metrics

The model is meticulously engineered with an extensive array of technical specifications tailored to meet the rigorous demands of contemporary electronics applications. Key features include:

- Power Output: The D350 is capable of delivering up to 350 kW, providing a robust energy supply suitable for a diverse range of applications, including those necessitating precision fluid control with solenoid and rotary boost pumps.

- Efficiency Ratings: Boasting high efficiency ratings, this model minimizes energy loss, significantly enhancing overall system performance and sustainability. Compared to industry benchmarks for 2025, the model’s efficiency is markedly superior, positioning it as a competitive option for engineers focused on innovative power management solutions.

- Thermal Management: Equipped with advanced cooling technologies, this model ensures optimal operating temperatures, thereby enhancing reliability and extending the unit’s lifespan. This feature is particularly critical in contexts utilizing Gagner-Toomey’s innovative air-movers and thermal management solutions.

- Audio Format Compatibility: The device accommodates various audio formats, including AAC, G.711, Opus, and LPCM, rendering it versatile for audio applications.

These performance metrics are crucial for engineers striving to refine their designs and comply with industry standards. Notably, the device’s user-friendly interface, featuring a main screen with a sidebar preview layout, facilitates seamless monitoring of audio and camera controls. This design, as illustrated in the case study titled “User-Friendly Interface,” enhances operational efficiency by enabling users to effortlessly preview multiple video streams and switch between them. Furthermore, the interface supports VU meter monitoring and reverse PTZ control, underscoring its significance in electronics applications. As of 2025, the D350 model continues to set benchmarks in power output and efficiency, reinforcing its position as a leader in the industry.

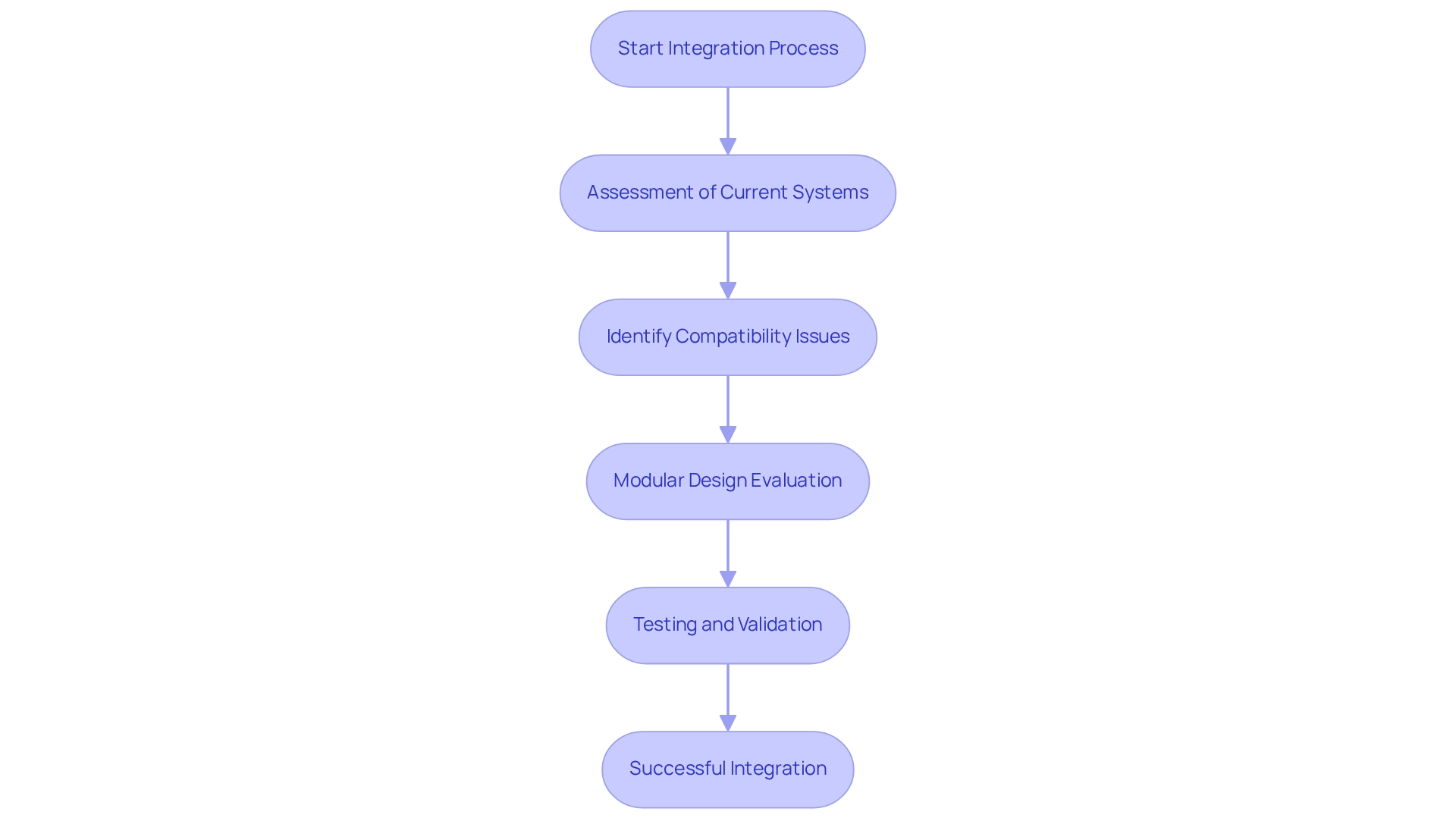

D350 Integration: Ensuring Compatibility with Existing Systems

Incorporating this model into current frameworks necessitates a comprehensive understanding of compatibility factors. Key strategies for successful integration include:

- Assessment of Current Systems: Engineers must conduct a thorough evaluation of their existing infrastructure to identify potential integration points. This critical step is essential for recognizing any compatibility issues that may emerge during the integration process.

- Modular Design: The model boasts a modular design that simplifies integration with various components. As industry expert S.K. notes, ‘The modular approach not only reduces installation complexity but also enhances flexibility, enabling designers to adapt the system to meet specific project requirements. Rigorous testing and validation are vital to ensure that the D350 operates seamlessly within the existing framework. By validating performance and compatibility, specialists can minimize disruptions and guarantee reliable operation.

Statistics indicate that integration difficulties for new electronic setups are projected to rise in 2025, with 34% of projects facing significant obstacles. By adhering to these strategies, engineers can effectively integrate the D350 model into their projects, overcoming integration challenges and leveraging its advanced features to enhance performance. Case studies have demonstrated the successful incorporation of the model with current electronic frameworks, showcasing the practical application of these strategies.

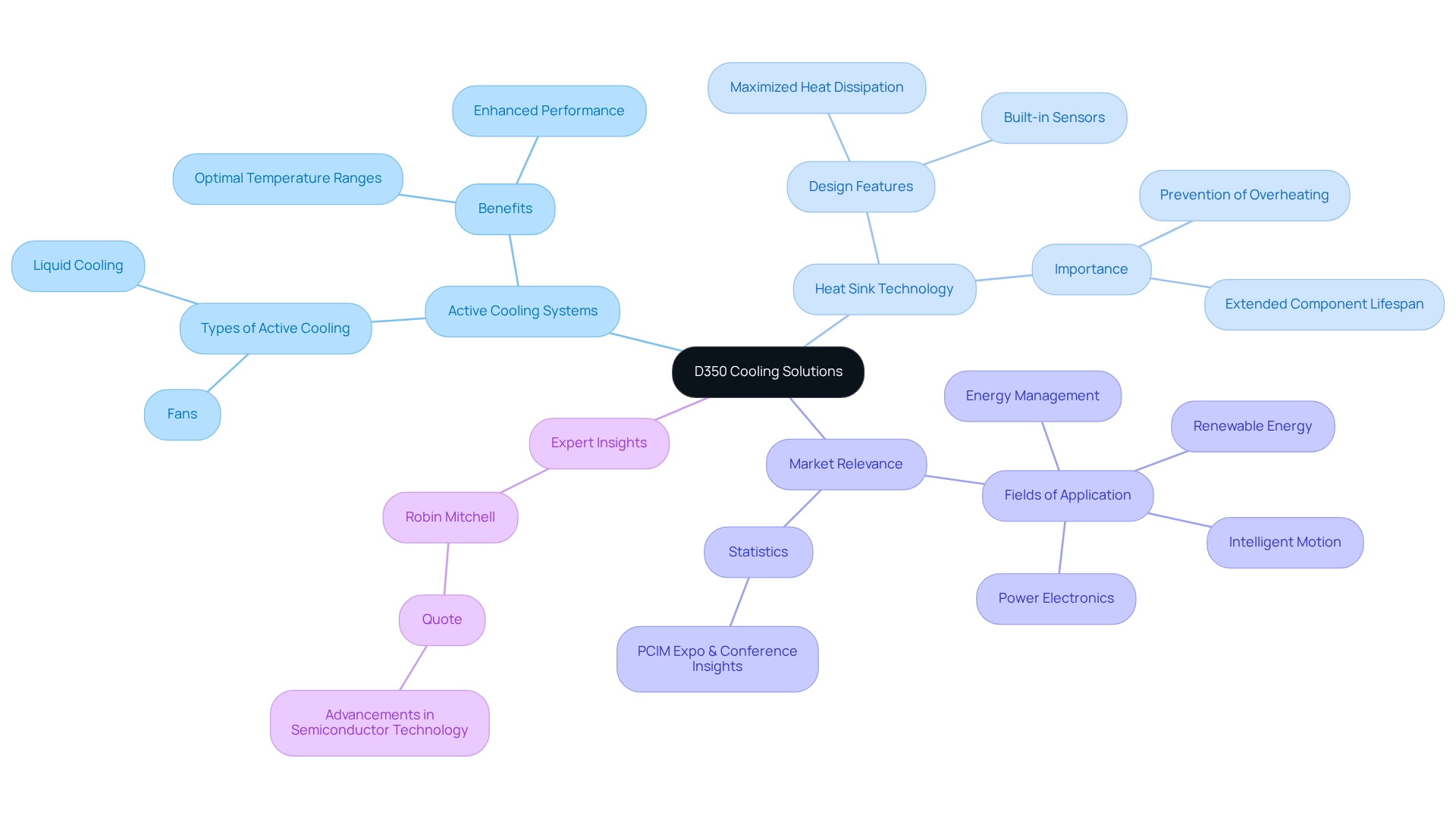

D350 Cooling Solutions: Optimizing Thermal Management in Electronics

The model is engineered with advanced cooling solutions that significantly enhance thermal management in electronic systems. Key features include:

- Active Cooling Systems: The model employs sophisticated active cooling mechanisms, including fans and liquid cooling, to effectively dissipate heat. This ensures that components operate within optimal temperature ranges, which is vital for maintaining performance and reliability.

- Heat Sink Technology: Integrated heat sinks are meticulously designed to maximize heat dissipation, thereby extending the lifespan of electronic components. This technology is critical in preventing overheating, which can lead to component failure, especially with the D350, which is equipped with built-in sensors that provide real-time temperature data, enabling engineers to proactively manage thermal conditions. This feature is essential for enhancing performance and preventing thermal-related issues.

In 2025, statistics from the PCIM Expo & Conference indicate that effective cooling solutions are paramount in the fields of Power Electronics, Intelligent Motion, Renewable Energy, and Energy Management. These advancements can significantly improve the reliability of electronic systems. Recent research has unveiled further magnetic characteristics of current produced by the quantum Hall effect, potentially reshaping our understanding of magnetism and its applications in technology, thereby underscoring the importance of innovative cooling solutions. As thermal management becomes increasingly vital in electronic design, this cutting-edge cooling technology positions itself as a market leader. Recent advancements in cooling technologies, featuring specialized plating materials and deposition parameters, further enhance the device’s capabilities, enabling tailored cooling solutions that meet specific requirements. Expert insights, such as those from Robin Mitchell, an Electronic Engineer, emphasize that advancements in semiconductor technology, particularly through the development of thermal transistors, represent a significant milestone in the evolution of electronic devices. Case studies illustrate the device’s effectiveness across diverse electronic applications, showcasing its contribution to enhancing thermal management practices. Overall, these features are indispensable for engineers focused on improving the reliability and performance of their electronic designs.

D350 Power Management: Enhancing Energy Efficiency in Electronics

This model is meticulously engineered with advanced power management capabilities that significantly enhance energy efficiency in electronic devices. The key attributes include:

- Dynamic Load Management: This feature automatically adjusts power distribution based on real-time demand, ensuring optimal energy utilization. Recent advancements in dynamic load management have demonstrated a notable reduction in energy consumption, aligning with the industry’s drive for smarter energy solutions by 2025. As Nick Pappas noted, “Utilities and carbon removal: A gigaton scale opportunity,” underscoring the essential role of energy efficiency in contemporary designs.

- Low Standby Power Usage: This model minimizes energy consumption during idle periods, crucial for enhancing overall performance. This aspect is particularly pertinent, as energy efficiency statistics reveal that reducing standby power can yield significant savings in energy costs. According to a Deloitte survey of 60 US executives and senior leaders conducted in September 2024, the integration of digital tools is vital for adapting to evolving market demands within the power and utilities sector.

- Integration with Renewable Energy Sources: The device seamlessly interfaces with solar and wind energy systems, fostering sustainable practices and facilitating the transition to greener energy solutions. This aligns with insights from a recent case study that highlights the importance of integrating digital tools and bolstering energy efficiency across both traditional and renewable energy sectors.

These features position this model as an exemplary choice for engineers dedicated to developing energy-efficient designs, reflecting the growing emphasis on sustainability and efficiency within the electronics sector. Furthermore, as the upcoming publication of fossil fuel receipts on March 25, 2025, will illustrate, the shift towards more sustainable energy options is becoming increasingly critical—an objective that the organization actively supports.

D350 Timing Technologies: Ensuring Precision in Electronic Systems

The D350 features cutting-edge timing technologies that ensure accuracy in electronic devices. Key components include:

- High-Precision Oscillators: Delivering precise timing signals, these oscillators are crucial for synchronization in complex electronic setups. Their importance is underscored in applications where timing accuracy is essential.

- Real-Time Clock (RTC): The RTC provides exact timekeeping, vital for applications requiring precise timing, such as data logging and event scheduling. Recent advancements have enabled contemporary RTCs to achieve accuracy levels within a few parts per million.

- Synchronization Protocols: This model supports a variety of synchronization protocols, facilitating seamless integration with other timing-dependent systems and enhancing overall system performance.

These technologies are indispensable for engineers striving for exceptional precision in their designs. For instance, the DL350 Assistant software streamlines data management, allowing users to back up files and control the device remotely, thereby enhancing user convenience and operational efficiency. Furthermore, the device’s capabilities are exemplified by the statistic that the 701934 External Probe Power Supply can power up to four probes, showcasing its efficiency in power management related to timing technologies. Case studies illustrate the device’s effectiveness in applications demanding stringent timing standards, including the D350, demonstrating its ability to meet the challenges of modern electronic engineering. Additionally, the device supports various software tools for data analysis, including LabVIEW Driver and MATLAB WDF Access Toolbox, highlighting its versatility and compatibility with contemporary engineering tools.

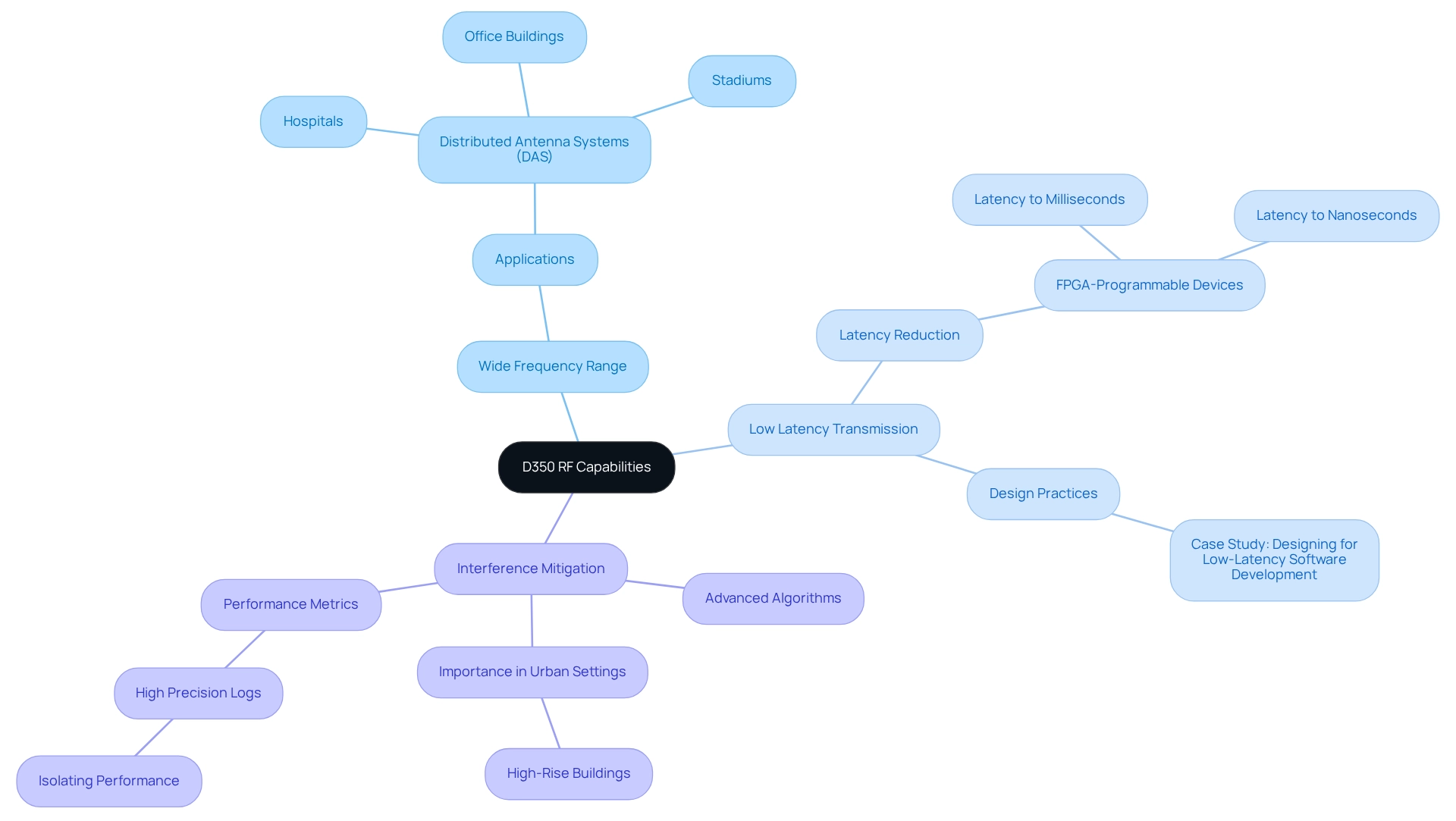

D350 RF Capabilities: Advancing Wireless Communication Solutions

The model is designed with advanced RF features that significantly enhance wireless communication solutions. Its key features include:

- Wide Frequency Range: The D350 supports a broad spectrum of frequencies, making it suitable for various applications across different sectors, including Distributed Antenna Systems (DAS), commonly found in office buildings, hospitals, and stadiums.

- Low Latency Transmission: This model ensures rapid data transfer, essential for real-time communication systems. Recent advancements in FPGA-programmable devices have demonstrated that latency can be minimized to milliseconds or even nanoseconds, underscoring the device’s competitive advantage in low-latency environments. Insights from the case study “Designing for Low-Latency Software Development” reveal that specific design practices are crucial for achieving these low-latency outcomes.

- Interference Mitigation: Equipped with advanced algorithms, this device effectively reduces interference, thereby enhancing signal quality and reliability. This capability is particularly critical in urban and high-rise settings where maintaining interference-free networks poses a challenge. As noted by Pedro Pinto, the use of high precision logs is essential for isolating performance metrics, further emphasizing the importance of precise measurements in achieving low-latency performance.

These features establish this device as an essential instrument for engineers committed to creating cutting-edge wireless solutions, particularly concerning the latest trends in RF technologies and the increasing demand for low-latency transmission in electronics. Furthermore, data on RF capabilities for 2025 suggest a notable advancement in wireless communication, reinforcing the model’s role in addressing future requirements.

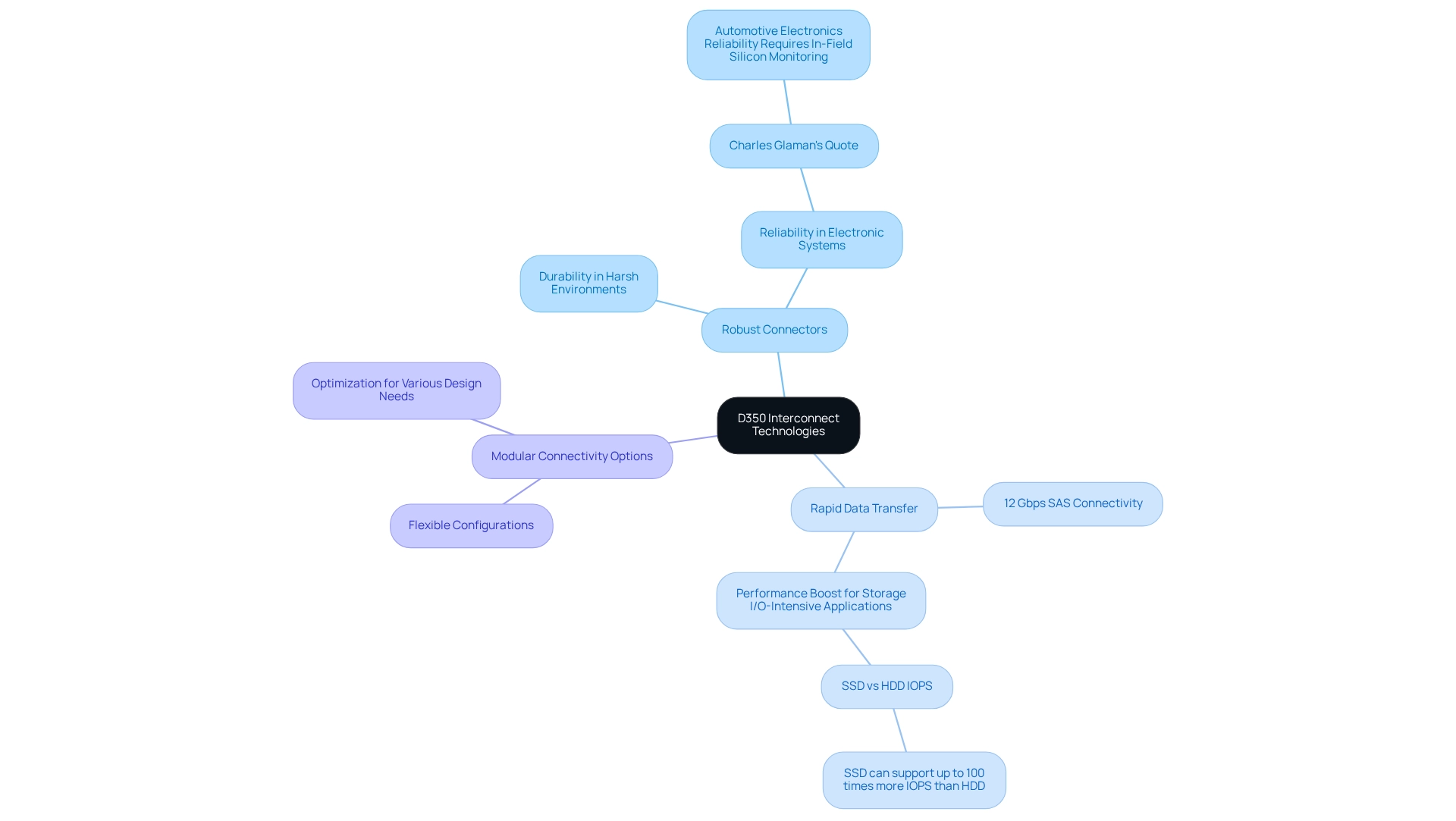

D350 Interconnect Technologies: Ensuring Reliable Connections

The D350 features state-of-the-art interconnect technologies that guarantee dependable connections in electronic setups, a crucial aspect supported by Gagner-Toomey Associates through its extensive network of local distributors. Key features include:

- Robust Connectors: Engineered to endure harsh environments, these connectors deliver exceptional durability and reliability, which are crucial for maintaining system integrity in challenging conditions. As noted by Charles Glaman, “Automotive Electronics Reliability Requires In-Field Silicon Monitoring,” emphasizing the critical nature of reliability in electronic systems.

- Rapid Data Transfer: The device supports fast connections, essential for contemporary applications. With advancements such as 12 Gbps SAS internal storage connectivity, the D350 significantly enhances performance for storage I/O-intensive applications by doubling the data transfer rate compared to previous models. Notably, SSDs can support up to 100 times more I/O operations per second than typical HDDs, underscoring the importance of robust connectors in achieving such performance.

- Modular Connectivity Options: This feature allows for flexible configurations, accommodating various design needs and enabling professionals to optimize their systems effectively.

These attributes are essential for professionals aiming to achieve high performance in their electronic designs, particularly as the demand for efficient data movement continues to grow. Gagner-Toomey Associates’ strategic partnerships with leading manufacturers like CONEC and Delta further enhance the reliability of interconnect technologies, ensuring that engineers have access to the best components available. The introduction of new OIF electrical standards will facilitate interoperability, providing additional avenues for faster and more efficient data transfer. In 2025, the reliability of interconnect technologies remains essential, with statistics indicating that robust connectors play a crucial role in ensuring optimal performance across diverse applications. Additionally, system management solutions aim to improve performance and reduce expenses, thereby enhancing the value of interconnect technologies.

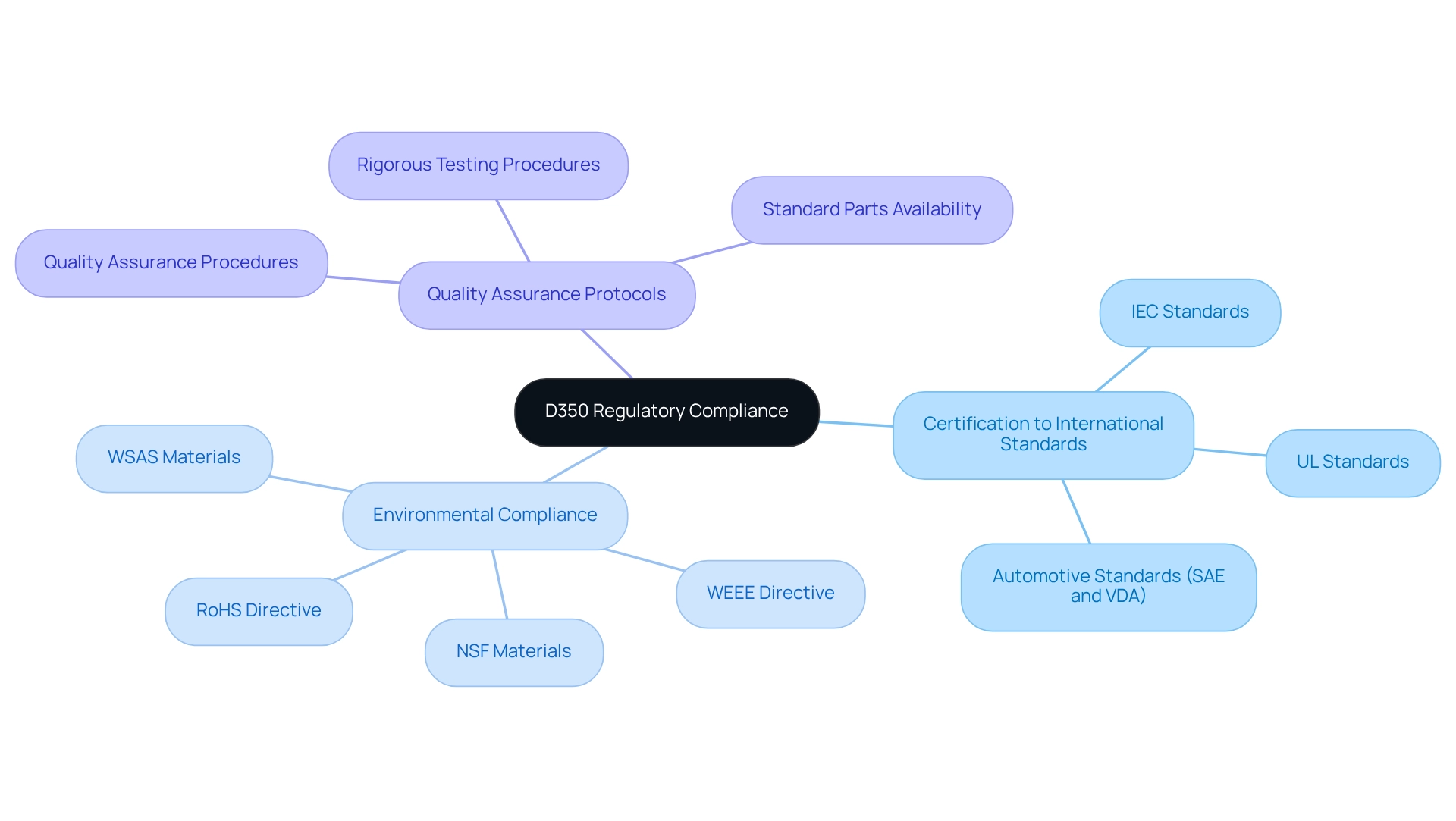

D350 Regulatory Compliance: Meeting Industry Standards and Requirements

The model is meticulously designed to meet stringent regulatory standards, ensuring both safety and dependability in electronic applications. Its key compliance features include:

- Certification to International Standards: This device adheres to IEC, UL, and other pertinent standards, facilitating global acceptance and integration into various markets. Moreover, Gagner-Toomey Associates’ products comply with Automotive Standards SAE and VDA, thereby enhancing their applicability across diverse sectors.

- Environmental Compliance: It meets RoHS and WEEE directives, underscoring a commitment to environmentally responsible practices in electronics manufacturing. This commitment is further reflected in the application of NSF and WSAS materials in Gagner-Toomey’s cutting-edge solenoid and rotary boost pumps, which emphasize low noise operation and efficiency.

- Quality Assurance Protocols: The application of rigorous testing and quality assurance procedures guarantees the dependability of the model, making it a reliable option for professionals. With over 100 standard parts in stock ready to ship, Gagner-Toomey Associates ensures prompt service and support for engineers’ needs.

These compliance features are critical for engineers when selecting components for their designs, particularly in light of the increasing emphasis on safety and environmental responsibility within the electronics industry. The model’s specifications, including its compatibility with various solenoid and rotary boost pumps, further enhance its value in engineering applications.

D350 Impact on Electronics Engineering: Transforming Design and Development

The D-series model is revolutionizing electronics engineering by introducing features that significantly enhance design and development processes. Its modularity and integration capabilities streamline design workflows, allowing engineers to focus on innovation rather than becoming overwhelmed by complexity. This simplification is essential in a time when efficiency is crucial.

Furthermore, the device optimizes power management and thermal solutions, resulting in substantial improvements in performance metrics. Engineers utilizing this model can achieve higher performance levels, which is vital as the demand for more advanced and efficient electronic solutions continues to grow. Gagner-Toomey Associates plays a critical role in this landscape by connecting engineers with a reliable network of local distributors, ensuring that essential components are readily available to support the advanced features of the system.

As Jim Beneke, Vice President of Tria Americas, observed, “The successful players in this market will be those who can effectively leverage these trends to create more intelligent, efficient, and secure electronic systems that meet the growing demands of our increasingly connected and power-hungry world.”

Moreover, the device is instrumental in facilitating sophisticated applications across various industries, including IoT, automotive, and telecommunications. By enabling the development of these innovative applications, this device drives significant progress within the industry. As we advance towards 2025, with deep AI integration along with a focus on sustainability and security shaping the electronic components market, the D350 emerges as an essential tool for engineers looking to push the boundaries of electronic design.

Conclusion

The D350 solutions from Gagner-Toomey Associates mark a significant advancement in electronics engineering, equipping engineers with sophisticated technologies that enhance performance and efficiency across diverse applications. These solutions encompass:

- Advanced cooling systems

- Robust power management features

- Cutting-edge RF capabilities

- Regulatory compliance

All meticulously designed to address the intricate demands of contemporary electronic systems.

As engineers confront the complexities of integrating these solutions into existing infrastructures, the D350 distinguishes itself not only through its impressive technical specifications but also via its user-friendly interface and consultative support. This holistic approach empowers engineers to realize their project objectives while adhering to industry standards, ultimately fostering innovation within the field.

In a rapidly changing landscape where sustainability and efficiency are critical, the D350 plays a pivotal role in revolutionizing design and development processes. By streamlining workflows and optimizing performance metrics, it enables engineers to concentrate on crafting intelligent and efficient electronic systems capable of meeting the escalating demands of our interconnected world. As the industry progresses, Gagner-Toomey Associates remains steadfast in its commitment to providing engineers with the essential tools and resources for success, reinforcing the D350’s status as an indispensable asset in electronics engineering.

Frequently Asked Questions

What solutions does Gagner-Toomey Associates provide for electronics professionals?

Gagner-Toomey Associates offers solutions specifically designed for electronics professionals, including advanced technologies in cooling, power management, RF, and interconnect solutions that enhance performance and efficiency across various applications.

How does Gagner-Toomey Associates support its clients?

The company is dedicated to exceptional customer service and provides comprehensive support to technical staff, facilitating the effective implementation of advanced solutions. Their consultative approach empowers engineers to achieve their project goals confidently.

What is the D350 model, and what are its key features?

The D350 model is engineered with specifications tailored for contemporary electronics applications, featuring a power output of up to 350 kW, high efficiency ratings that minimize energy loss, advanced thermal management technologies, and compatibility with various audio formats.

How does the D350 model enhance system performance?

The D350 model boasts high efficiency ratings that significantly enhance overall system performance and sustainability, making it a competitive option for innovative power management solutions.

What role does thermal management play in the D350 model?

The advanced cooling technologies in the D350 model ensure optimal operating temperatures, enhancing reliability and extending the unit’s lifespan, which is particularly important in applications using Gagner-Toomey’s air-movers and thermal management solutions.

What are the strategies for integrating the D350 model into existing frameworks?

Key strategies include assessing current systems to identify integration points, utilizing the model’s modular design to reduce installation complexity, and conducting rigorous testing and validation to ensure seamless operation within the existing framework.

What challenges are anticipated for integrating new electronic setups by 2025?

Statistics indicate that integration difficulties for new electronic setups are projected to rise, with 34% of projects facing significant obstacles due to compatibility issues.

How does the user-friendly interface of the D350 model contribute to its functionality?

The D350 features a user-friendly interface that allows for seamless monitoring of audio and camera controls, supporting VU meter monitoring and reverse PTZ control, which enhances operational efficiency in electronics applications.