Overview

Revolutions per second (RPS) serves as a critical measurement in electronics, denoting the number of complete rotations an object executes around an axis within one second. This metric directly influences the efficiency and performance of electric machines and systems. Understanding RPS is paramount for engineers seeking to optimize designs and ensure effective thermal management. This principle is exemplified in various applications, including:

- Electric motors

- Cooling fans

- Robotics

where precise speed regulation is essential for functionality and reliability. By focusing on RPS, engineers can enhance system performance and reliability, thereby driving innovation in their respective fields.

Introduction

In the realm of electronics, Revolutions Per Second (RPS) stands as a pivotal metric that quantifies the rotational frequency of devices, influencing everything from electric motors to cooling systems. Understanding RPS transcends mere academic interest; it is essential for engineers who aim to optimize performance, efficiency, and thermal management in their designs.

As technology continues to advance, the necessity of accurately measuring and applying RPS across various applications—from high-performance motors in electric vehicles to precision cooling solutions in industrial machinery—becomes increasingly evident.

This article explores the significance of RPS, the methodologies for its calculation, and its practical applications, illuminating how this fundamental concept propels innovation and sustainability within the electronics industry.

Define Revolutions Per Second and Its Importance in Electronics

Revolutions per second (RPS) stands as a pivotal metric for measuring rotational frequency, encapsulating the total number of complete rotations an object performs around a fixed axis each second. This specific measurement is particularly vital in electronic applications, especially within electric machines, where RPS directly influences efficiency metrics such as speed, power consumption, and thermal management. For instance, in advanced pump technologies like solenoid and rotary boost pumps, utilized in precise applications such as espresso machines, the measurement of revolutions per second is critical for ensuring optimal functionality. These pumps, equipped with DC brushless drives and PWM for control precision, demonstrate how increased revolutions per second can lead to enhanced performance, necessitating careful thermal management to prevent overheating.

Understanding revolutions per second is essential for engineers aiming to optimize designs and ensure that electronic components function within their specified limits. Recent advancements in measuring revolutions per second have improved precision, facilitating better evaluations and enhancements in engine performance. Importantly, the relationship between revolutions per second and electric machine performance is key; while an increase in revolutions per second can boost functionality, it may also introduce challenges in thermal management.

In practical applications, the measurement of revolutions per second (RPS) plays a vital role across various fields, from automotive to industrial equipment, where precise regulation of machine speed is imperative. Insights from experts, such as Miloje M. Kostic, highlight the importance of power levels, indicating that lower associated power levels (around 10 kW) and upper power exceeding 100 kW are crucial for understanding performance dynamics. As the industry progresses, the relevance of revolutions per second in electronics continues to expand, emphasizing the necessity for engineers to remain informed about its implications for design and operational efficiency, particularly in light of innovative solutions provided by Gagner-Toomey Associates.

Calculate RPS: Key Formulas and Methods

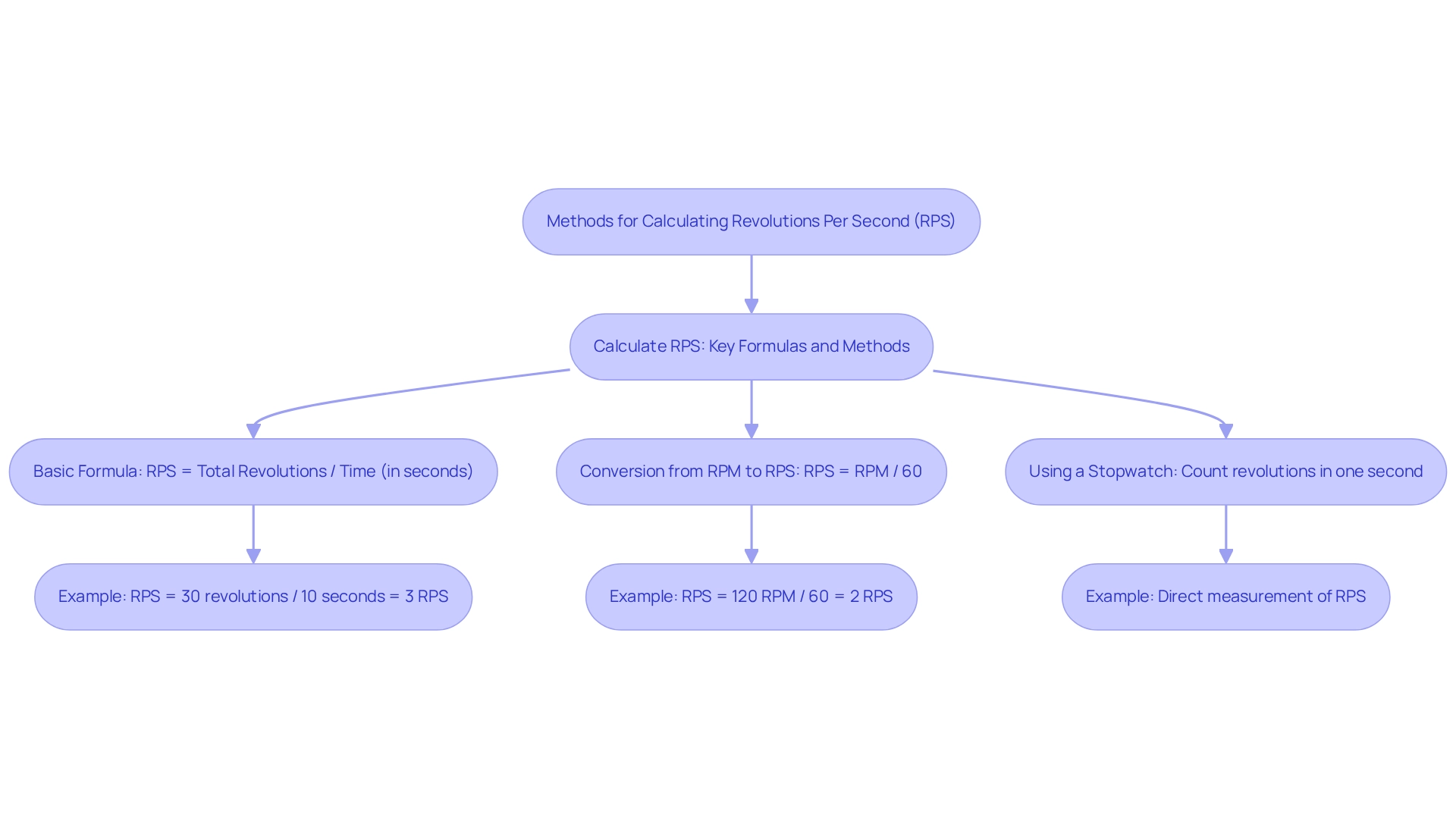

To calculate Revolutions Per Second (RPS), the following formulas are utilized:

-

The basic formula for revolutions per second (RPS) is RPS = Total Revolutions / Time (in seconds). For example, if a wheel completes 30 revolutions in 10 seconds, the calculation would be: RPS = 30 revolutions / 10 seconds = 3 RPS.

-

Conversion from RPM to RPS: To convert speed from Revolutions Per Minute (RPM) to RPS, use the formula: RPS = RPM / 60. For instance, if a motor operates at 120 RPM, the conversion would be: RPS = 120 RPM / 60 = 2 RPS.

-

Using a Stopwatch: For direct measurement of RPS, employ a stopwatch to count the number of revolutions in one second. This practical approach is especially beneficial for evaluating engines or fans in laboratory environments.

These calculation methods are essential for engineers to ensure systems function efficiently and adhere to design specifications. Understanding revolutions per second is crucial, particularly as the average revolutions per second values for electric devices in the industry generally range from 1 to 10 revolutions per second, depending on the application. As Richard Hamming noted, “We must turn out people who can play responsible major roles in our changing society,” highlighting the importance of mastering these calculations in the context of engineering responsibilities. Furthermore, keeping up with digital transformation is vital for maintaining relevance in engineering jobs. By mastering these techniques, engineers can enhance their problem-solving capabilities in various electronic applications, ensuring safety and efficiency in their designs.

Apply RPS in Electronic Systems: Real-World Examples

Revolutions per second (RPS) are integral to the functionality of numerous electronic systems. The significance of RPS is evident in a variety of real-world applications, which illustrate its critical importance:

- Electric Motors: RPS is crucial for establishing the speed of machines. For instance, a machine designed to operate at 3000 RPM runs at 50 revolutions per second. This understanding enables engineers to create machines that meet specific speed and torque criteria, thereby enhancing efficiency across diverse applications. Notably, assessments of electric motorcycle motors reveal that various motor types exhibit differing levels of effectiveness, influenced by their revolutions per second.

- Cooling Fans: In cooling systems, such as those found in computers and industrial machinery, the RPS of fans directly impacts airflow and cooling performance. A fan operating at 2000 RPM translates to approximately 33.33 revolutions per second, which is vital for maintaining optimal temperatures in electronic components, thus improving reliability and efficiency. The importance of RPS in cooling systems is underscored by the fact that higher RPS can lead to enhanced airflow, essential for effective thermal management in electronics.

- Gyroscopes: In navigation systems, gyroscopes utilize RPS to measure angular velocity. For example, a gyroscope spinning at 60 revolutions per second provides critical data for stabilizing aircraft and spacecraft, ensuring precise orientation and control, which are paramount for safety and operational effectiveness.

- Robotics: RPS is also pivotal in robotic systems, where it governs the speed of wheels and joints. A robotic arm that rotates at 10 revolutions per second can perform tasks with high accuracy, significantly influencing the effectiveness of automated processes and enhancing productivity in manufacturing environments. As highlighted by ABB Ltd.’s launch of the OmniCoreTM platform, advancements in robotics increasingly focus on enhancing productivity and sustainability, with RPS playing a vital role.

These instances underscore the essential role of revolutions per second in diverse electronic applications, emphasizing the necessity for engineers to accurately understand and compute revolutions per second to optimize system functionality. Furthermore, the impact of revolutions per second on cooling fan performance is substantial; research indicates that higher revolutions per second can result in improved airflow, which is crucial for effective thermal management in electronics. As technology advances, the relevance of revolutions per second in enhancing system efficiency and performance continues to grow, making it a fundamental concept for engineers in the electronics industry. Additionally, considering that North American greenhouse gas emissions totaled 6,340 million metric tons in 2021, the push for energy-efficient designs in electric motors and cooling systems becomes increasingly significant in the context of sustainability.

Conclusion

RPS transcends mere numerical value; it embodies a fundamental concept that profoundly influences the design and functionality of electronic systems across diverse industries. Its critical role in optimizing performance metrics, such as speed and efficiency, is evident in applications that span electric motors, cooling systems, and robotics. By mastering the understanding and accurate calculation of RPS, engineers can significantly enhance the operational capabilities of devices while effectively addressing pressing challenges like thermal management and energy consumption.

The methodologies for calculating RPS, whether through basic formulas or practical measurement techniques, empower engineers with the essential tools for precise performance assessments. As technology continues to evolve, the mastery of these calculations becomes increasingly vital to ensure that electronic components operate within their optimal parameters. Moreover, the real-world applications of RPS illustrate its pervasive influence on system efficiency and reliability, underscoring the necessity for engineers to remain informed about advancements in measurement techniques and industry standards.

As the electronics industry advances towards innovation and sustainability, the significance of RPS will only intensify. Embracing this metric not only facilitates enhanced design and operational efficiency but also aligns with broader environmental objectives by promoting energy-efficient solutions. In this context, understanding RPS is not merely an academic exercise; it is a crucial element of engineering practice that propels progress and supports the development of sustainable technologies.

Frequently Asked Questions

What does revolutions per second (RPS) measure?

Revolutions per second (RPS) measures the total number of complete rotations an object performs around a fixed axis each second.

Why is RPS important in electronic applications?

RPS is vital in electronic applications, particularly within electric machines, as it directly influences efficiency metrics such as speed, power consumption, and thermal management.

How does RPS affect advanced pump technologies?

In advanced pump technologies like solenoid and rotary boost pumps, RPS is critical for ensuring optimal functionality, particularly in precise applications like espresso machines.

What role does thermal management play concerning RPS?

Increased revolutions per second can enhance performance but may also introduce challenges in thermal management, necessitating careful monitoring to prevent overheating.

How do engineers use RPS in design optimization?

Engineers use RPS to optimize designs and ensure that electronic components function within their specified limits, particularly in terms of performance and efficiency.

What advancements have been made in measuring RPS?

Recent advancements in measuring RPS have improved precision, facilitating better evaluations and enhancements in engine performance.

In what fields is RPS measurement particularly vital?

RPS measurement is vital across various fields, including automotive and industrial equipment, where precise regulation of machine speed is imperative.

What insights do experts provide regarding power levels and RPS?

Experts highlight the importance of understanding performance dynamics at lower associated power levels (around 10 kW) and upper power exceeding 100 kW in relation to RPS.

How is the relevance of RPS evolving in electronics?

As the industry progresses, the relevance of RPS in electronics continues to expand, emphasizing the necessity for engineers to stay informed about its implications for design and operational efficiency.