Overview

The article titled “10 Essential DC Blowers for Electronics Engineers in 2025” identifies key DC blower models that are crucial for electronics engineers in the upcoming year. It emphasizes the importance of diverse and innovative blower solutions, highlighting their efficiency, low noise, and adaptability to various applications. These attributes are essential for meeting the demands of modern electronic systems and improving overall performance. By understanding the landscape of available technologies, engineers can make informed decisions that enhance their projects and drive innovation in the field.

Introduction

In the ever-evolving landscape of technology, the significance of efficient airflow management is paramount. From the intricate cooling systems in electronics to the powerful blowers utilized in landscaping, advancements in blower technology are fundamentally reshaping industries. This article explores the innovative solutions provided by leading companies such as Gagner-Toomey Associates and Eltech Solutions, focusing on their high-performance DC blowers and the implications of their designs across various applications. Moreover, it underscores the increasing importance of sustainability, safety, and efficiency in blower operations, offering insights into best practices and emerging trends. Whether you are an engineer aiming to optimize designs or a consumer seeking eco-friendly alternatives, grasping the nuances of blower technology is essential in today’s market.

Gagner-Toomey Associates: Innovative Solutions for DC Blower Applications

Gagner-Toomey Associates stands at the forefront of innovative solutions for applications, focusing on critical areas such as cooling, , and . As the world’s largest producer of both standard and custom air movers, Gagner-Toomey delivers and low noise, meticulously designed to meet the demanding standards of the electronics sector.

The company offers an extensive range of DC blowers, which includes:

- DC input tube axial fans spanning from 15 to 280mm

- Centrifugal units ranging from 15 to 225mm

This ensures that professionals have access to a diverse selection of tailored for various applications, including automotive and telecommunications, while current market trends indicate a growing demand for diverse DC blowers, as existing options remain limited compared to conventional AC fans, potentially diminishing consumer interest.

A recent report underscores the necessity for manufacturers to expand the selection of DC blowers to align with consumer preferences. In response, , ensuring that engineers have access to the , including features such as IP protection available upon request. This commitment not only addresses but also positions Gagner-Toomey as a leader in fostering the development of innovative cooling solutions that are essential for modern electronics.

Eltech Solutions DC Blower: High Efficiency and Low Noise Performance

Eltech Solutions are distinguished by their exceptional efficiency and remarkably low noise levels, making them particularly suitable for . Utilizing advanced , these devices significantly reduce friction and energy loss, leading to quieter operation and . Industry statistics indicate that the incorporation of Maglev technology can yield compared to conventional air movement systems. This innovative design not only enhances system performance but also fosters a more comfortable acoustic environment for users.

In conjunction with these sophisticated fans, Gagner-Toomey Associates offers , meticulously tailored for precision applications within the electronics sector. These pumps boast a pressure rating of up to 16 Bar, DC brushless motors, and EMI suppression circuits, ensuring . The integration of these , including DC blowers, complements the cooling solutions provided by Gagner-Toomey Associates, addressing the increasing demand for .

As experiences significant growth, driven by rising demand across various applications, engineers can confidently employ these advanced fans and pumps to optimize their systems while tackling the challenges of noise sensitivity in electronic environments.

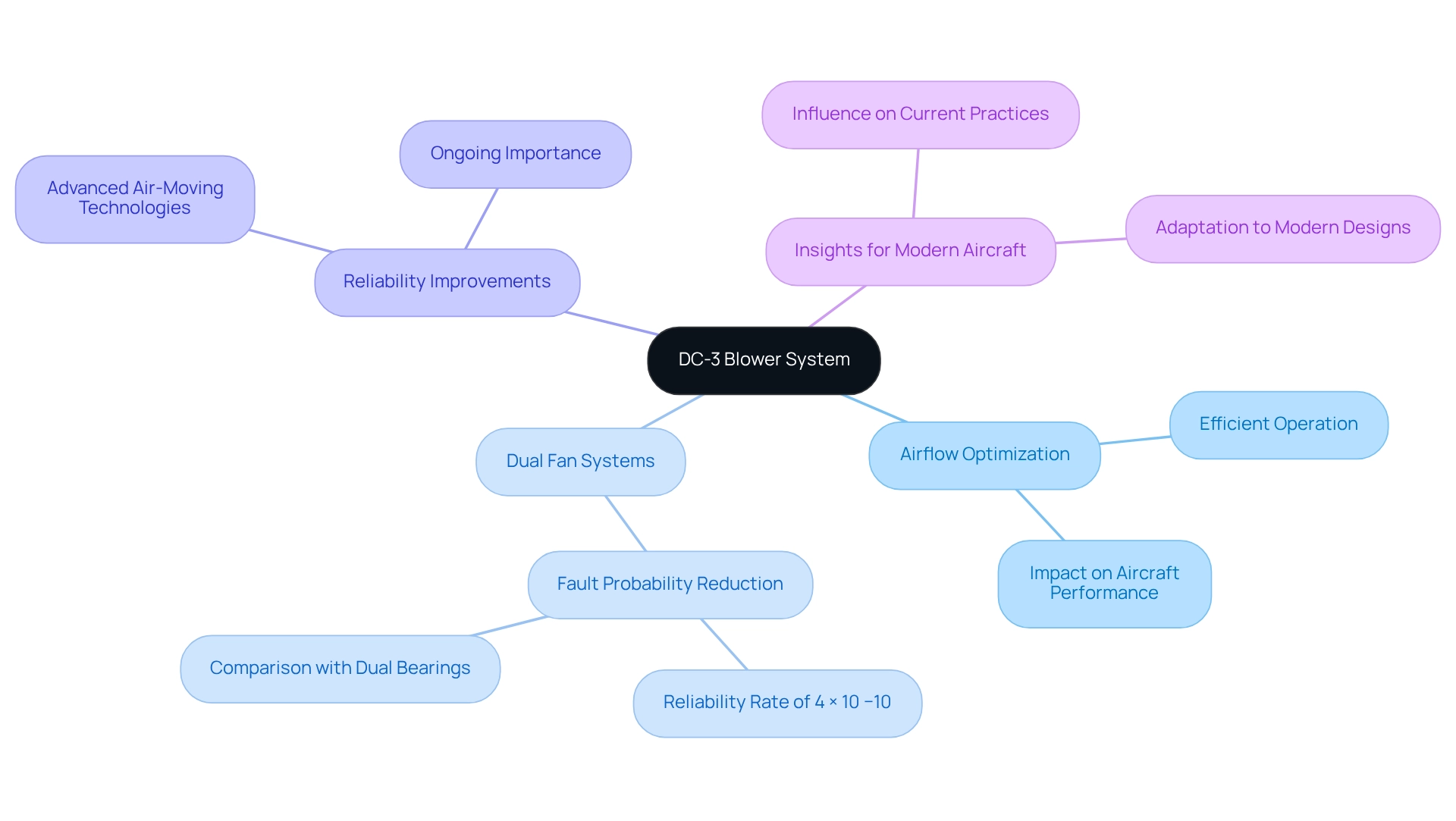

DC-3 Blower System: Utilizing Blowers for Enhanced Aircraft Performance

The DC-3 exemplifies how such devices can significantly enhance . By optimizing airflow and cooling across various systems, these devices facilitate efficient operation at diverse altitudes and speeds. Aerospace engineers can glean essential insights from the DC-3’s ventilation system, insights that can be adapted to to boost efficiency and reliability. Notably, the integration of has been demonstrated to dramatically reduce fault probabilities, achieving an impressive reliability rate of 4 × 10 −10, as highlighted by Louis C. Chow. This underscores the critical role of in contemporary aviation. Furthermore, the continue to inform current practices, stressing the ongoing importance of in enhancing aircraft operational capabilities. As Richard Bach astutely observed, the is a quest for excellence through mastery and comprehension of the aircraft—a principle that resonates with advancements in ventilation technology.

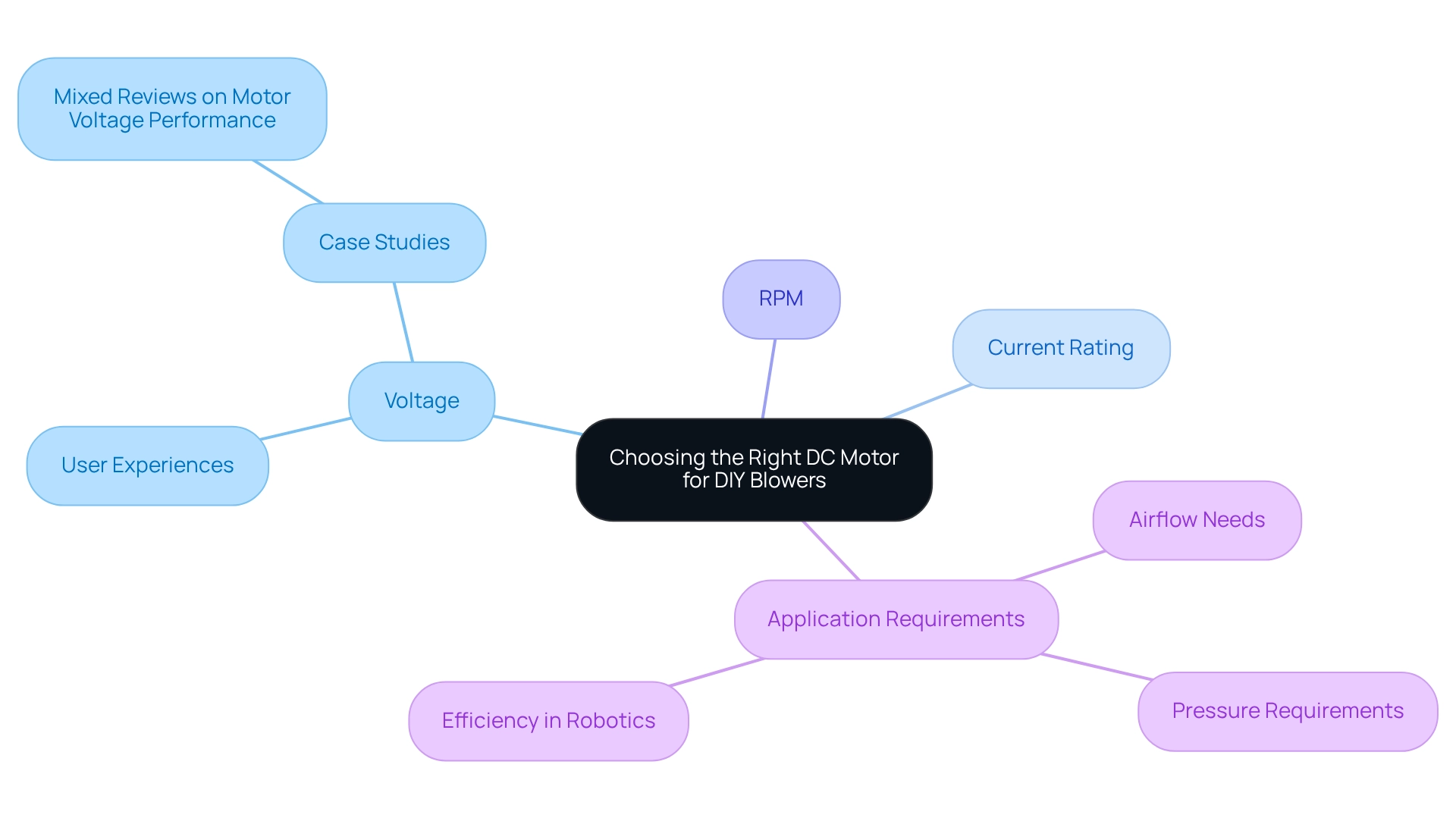

DIY Centrifugal Blower: Choosing the Right DC Motor for Custom Projects

Selecting the appropriate is essential for the success of any . Engineers must evaluate several key factors, including voltage, current rating, and RPM, to ensure the motor corresponds with their fan design. Furthermore, comprehending the —such as airflow and pressure—is crucial for making a well-informed decision. For instance, DC gear motors are particularly efficient in robotics and automation, delivering , which can significantly enhance fan performance.

In the evaluation of motor options, professionals should also take into account the varied experiences shared by users regarding . A recent case study revealed of a replacement motor, with some users encountering failures shortly after installation. This inconsistency underscores the importance of before finalizing a motor choice, as it can directly influence the reliability of the ventilation system. Resources such as provide invaluable insights into for DIY ventilation projects in 2025, assisting professionals in navigating the complexities of selecting the right motor. By leveraging expert advice and staying informed about current trends in DIY centrifugal fan projects, engineers can ensure their designs fulfill both performance and reliability standards.

Electric Leaf Blowers: Balancing Performance and Environmental Impact

Electric leaf devices represent a pivotal transformation in landscaping technology, delivering robust performance while significantly reducing . Unlike their gas-powered counterparts, operate with zero emissions, establishing themselves as a more . Recent advancements in have focused on enhancing efficiency and performance, ensuring these tools not only meet but exceed industry standards.

According to CLCA members, many clients find it challenging to afford or are reluctant to incur the without vacuum devices, underscoring the industry’s reliance on these tools. Furthermore, the U.S. EPA has implemented emission standards for , highlighting the urgent need for cleaner options such as electric devices.

The current market share of electric fans in landscaping technology has seen a marked increase, reflecting a rising preference for , with specific statistics indicating a substantial rise in adoption rates. Sustainability experts assert that electric models contribute to reduced noise pollution, with safe exposure levels ranging from 60 to 75 dB, rendering them suitable for residential areas.

As the industry progresses, are anticipated to further diminish their environmental footprint, reinforcing their role in fostering cleaner landscaping practices. Additionally, the CLCA advocates for educational campaigns to promote the safe and responsible use of , encompassing equipment inspections and adherence to local regulations, which aligns with the broader emphasis on sustainability.

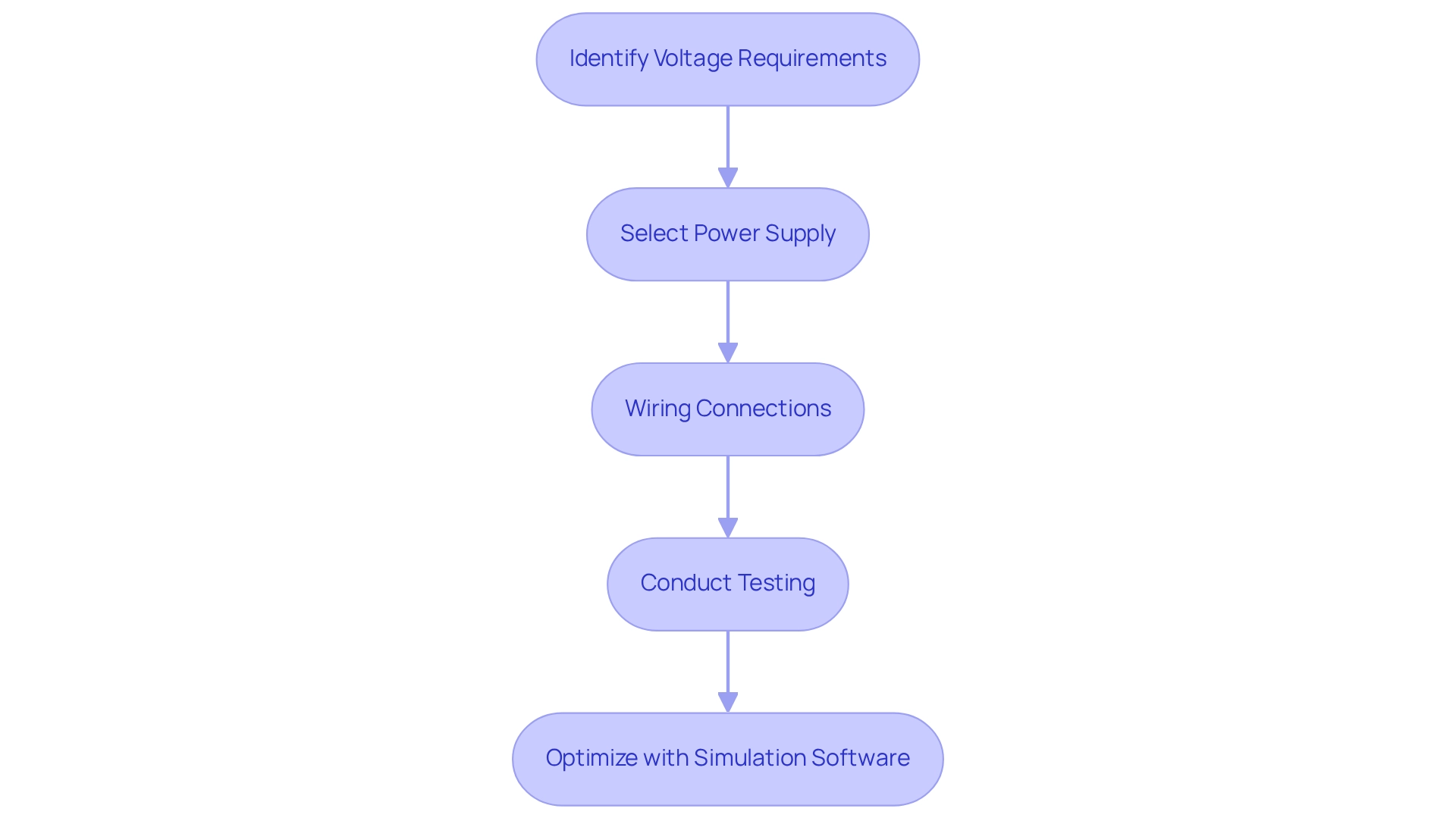

AC Conversion for DC Blower Fans: Step-by-Step Guide

Transforming AC power sources for use with units can be a straightforward process when approached methodically. Begin by identifying the voltage requirements: determine the specific voltage needed for your DC fan, which typically ranges from 12V to 48V, depending on the application. Next, select a suitable ; choose one that efficiently converts , ensuring it meets the necessary . These power supplies are capable of delivering for various electronic devices, which is crucial for .

The third step involves : connect the power supply to the fan, paying close attention to correct polarity to avoid damage. Utilize high-quality wiring to minimize resistance and ensure stable performance. As noted by industry experts, following can significantly enhance the reliability of your setup.

Fourth, conduct thorough testing before full operation to confirm functionality and safety. Monitor for any fluctuations in voltage that could affect performance. Integrating smoothing capacitors can assist in diminishing ripple voltage, providing a more stable output. By adhering to these steps, professionals can guarantee a safe and effective conversion, facilitating the successful application of DC blowers in various uses. This approach not only improves productivity but also conforms to current best practices in wiring and power management. Additionally, utilizing , can aid in optimizing power supply designs, ensuring safety and compliance throughout the process.

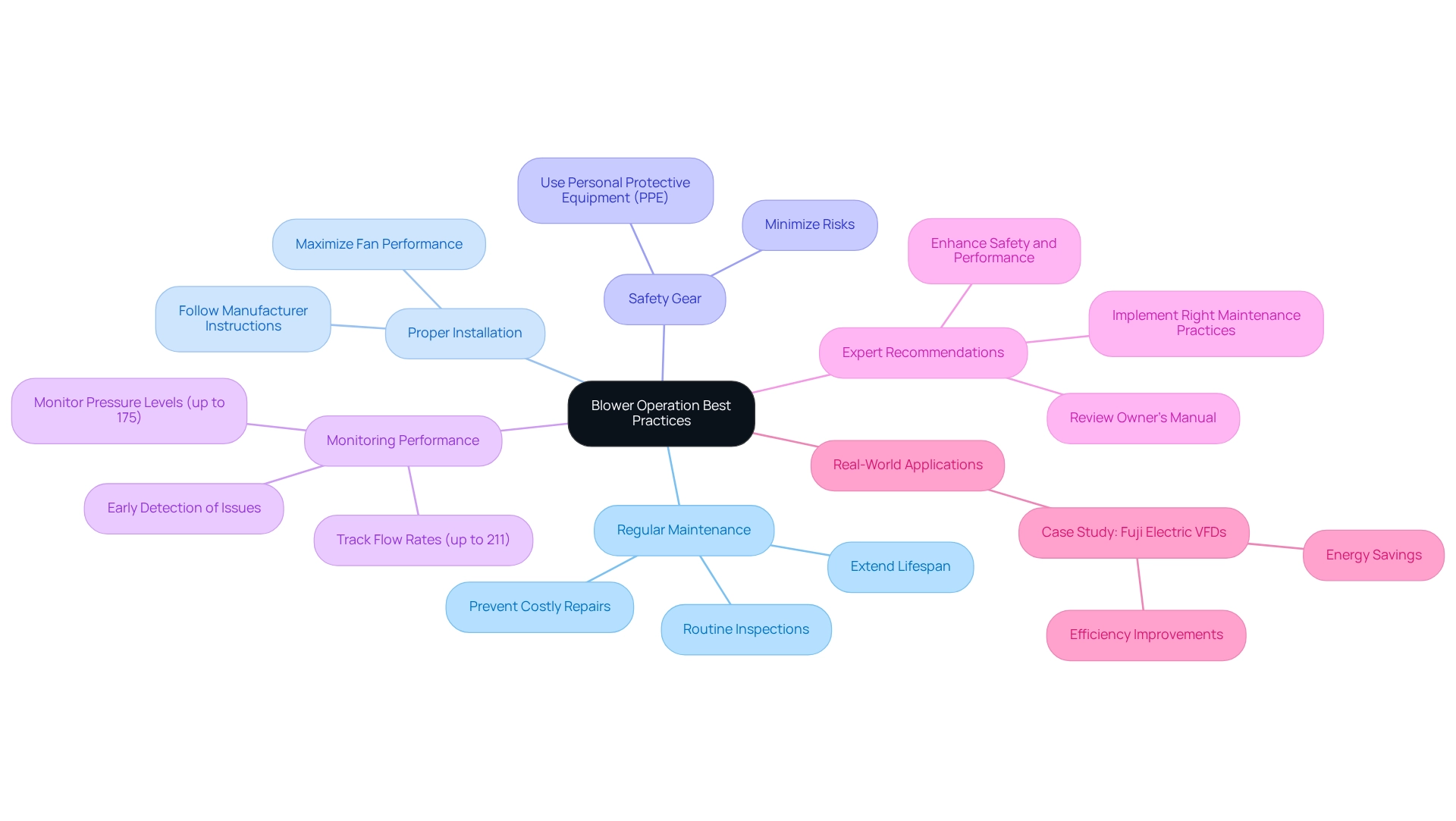

Blower Operation Best Practices: Ensuring Safety and Efficiency

To ensure safety and efficiency in dc blowers operation, engineers must adhere to and reliability.

- : Routine inspections and upkeep are crucial for extending the lifespan and . Regular maintenance of dc blowers not only prevents costly repairs and downtime but also ensures their optimal operation.

- : Following manufacturer instructions during setup is essential for maximizing fan performance and safety. Correct installation of dc blowers is fundamental to achieving the best operational outcomes.

- : Utilizing suitable personal protective equipment (PPE) is imperative when operating air-moving devices. This practice minimizes risks and fosters a safe working environment by utilizing dc blowers.

- Monitoring Performance: Continuously , including flow rates (up to 211) and pressure levels (up to 175), allows for early detection of potential issues. This vigilance is vital for preserving the integrity and performance of dc blowers in the system.

- Expert Recommendations: Industry leaders stress the importance of . Kris Kiser, President and CEO, emphasizes, “You want to have the right fuel on hand and review your owner’s manual now so you can use your equipment safely.” Routine inspections not only enhance safety but also elevate the overall performance of dc blowers within ventilation systems.

- : Case studies, such as the implementation of Fuji Electric VFDs in industrial refrigeration, illustrate how can lead to and energy savings.

By adopting these methods, engineers can greatly enhance the durability and dependability of their ventilation systems, ensuring they function safely and efficiently across diverse applications.

Battery Recycling for Electric Blowers: A Sustainable Approach

Battery recycling plays a crucial role in enhancing sustainability in the use of electric devices. Engineers must consider several key aspects:

- Recycling Programs: Engaging in is essential for ensuring responsible disposal of batteries, which can otherwise contribute to environmental hazards.

- : Effective recycling processes can recover valuable materials, significantly reducing the demand for new resources. For instance, recent projects, such as Revex Technologies Inc., aim to produce , which is vital for manufacturing and supports the supply chain for . This initiative exemplifies how recycling can yield critical materials necessary for various applications, including dc blowers.

- : Proper recycling practices not only minimize pollution but also conserve energy, aligning with global sustainability goals. Statistics indicate that recycling efforts can lead to significant decreases in waste and energy use, creating a compelling argument for professionals to support these initiatives. Additionally, the University of Akron has been awarded $2,000,000 to recycle plastics and polymers from end-of-life EV battery packs, showcasing the economic benefits of recycling initiatives.

- Collaborative Efforts: As Weikang Li, a postdoctoral researcher, emphasizes, “Teamwork is absolutely important. Therefore, with the Department of Energy’s full support, we are confident of accomplishing the proposed target and aim to achieve higher goals.” This highlights the .

By actively participating in and promoting material recovery, engineers can significantly contribute to a more , ensuring that the technologies they develop and utilize are environmentally responsible while supporting a robust supply chain for .

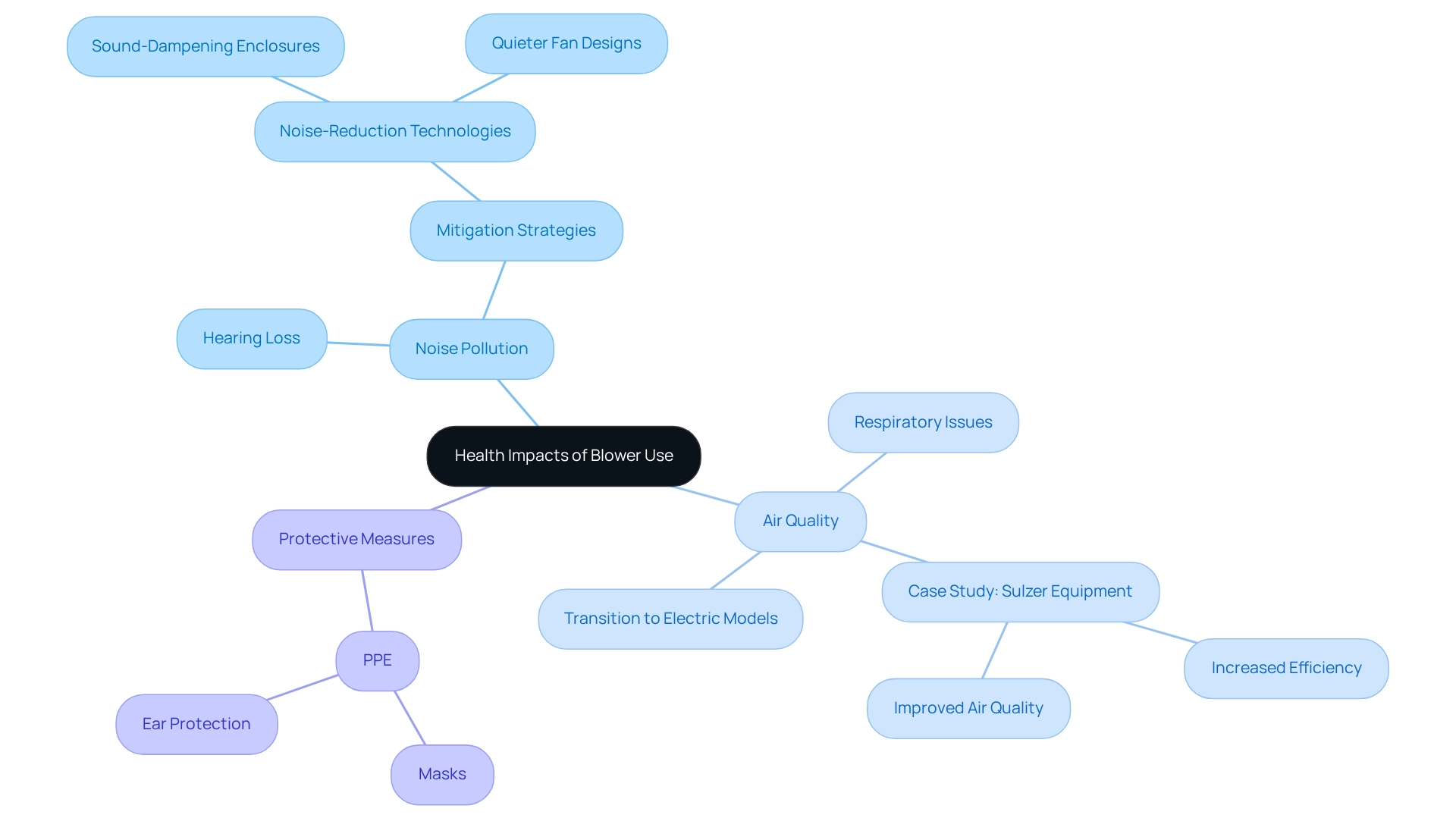

Health Impacts of Blower Use: Understanding Risks and Mitigation

The operation of fans, particularly gas-powered types, presents significant health hazards linked to and emissions. Engineers must consider the following critical factors:

- Noise Pollution: Continuous exposure to elevated noise levels can lead to irreversible hearing loss. By implementing , such as sound-dampening enclosures and quieter fan designs, this risk can be significantly mitigated. Real-world applications of these technologies have demonstrated a marked decrease in noise levels, thereby .

- : Emissions from gas-powered equipment are recognized as contributors to respiratory issues. Current data indicates that gas fan emissions correlate with . Transitioning to electric models can drastically reduce harmful emissions, thereby and minimizing health risks associated with respiratory issues. A relevant case study involving Sulzer Equipment illustrated how but also contributed to improved air quality in the workplace.

- Protective Measures: The use of is essential when operating air movers. Engineers should advocate for the use of masks to filter out harmful particles and ear protection to safeguard against noise-induced hearing loss. As Harold Wimmer, President & CEO of , stated, “Today’s rule to help clean up pollution from heavy-duty trucks is a public health victory, especially for the 72 million Americans living in close proximity to heavy trucking corridors.” This underscores the importance of addressing pollution from all sources, including fans.

By proactively addressing these health impacts, professionals can enhance safety and comfort in the workplace, ultimately fostering a healthier environment for all users.

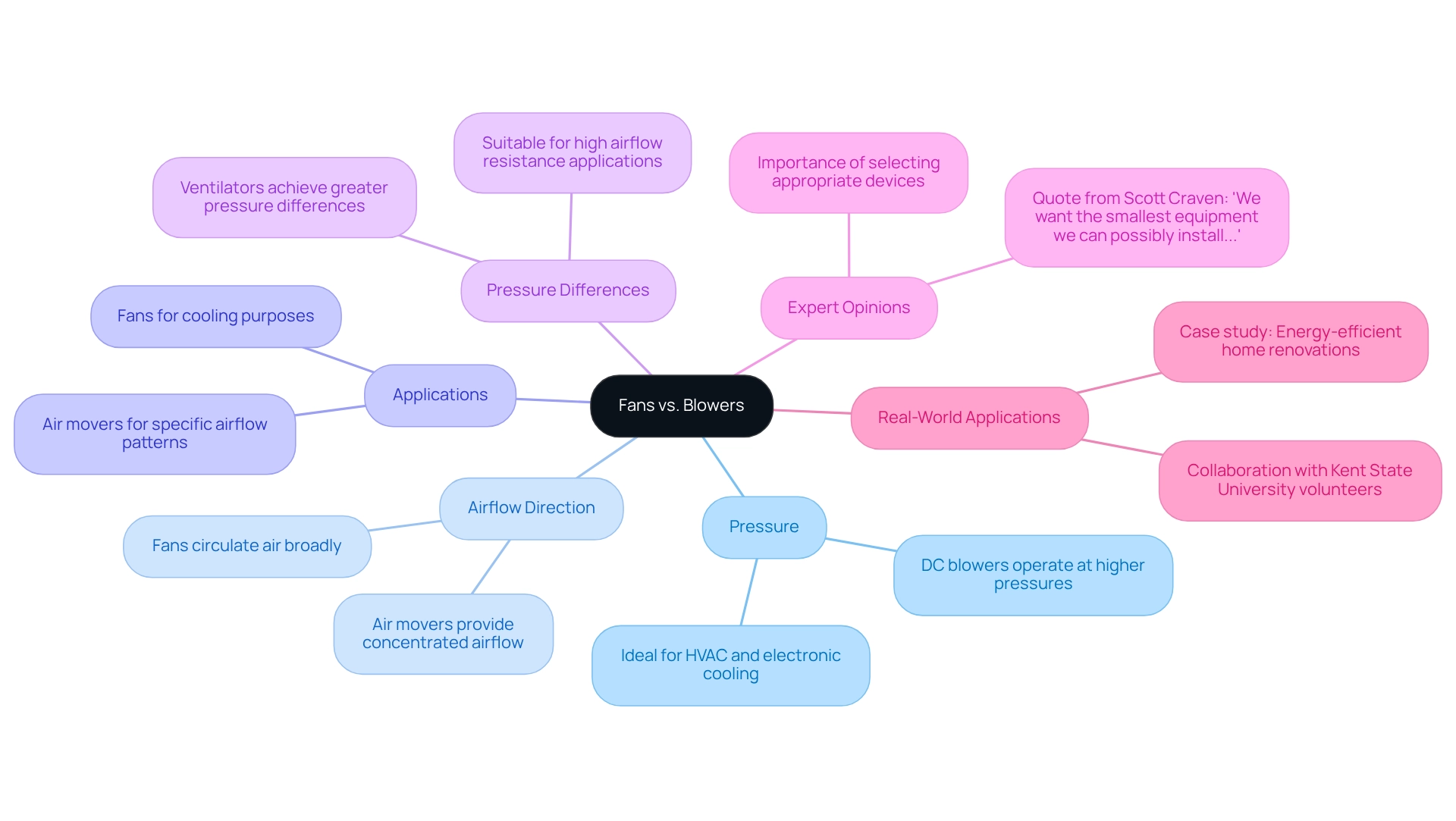

Fans vs. Blowers: Key Differences Every Engineer Should Know

Understanding the distinctions between fans and is crucial for engineers in 2025. The key differences are as follows:

- Pressure: are engineered to operate at significantly higher pressures than fans, making them ideal for applications that require directed airflow, such as and .

- Airflow Direction: While fans circulate air over a broad area, air movers provide a concentrated stream of air, allowing for precise control across various applications. This directional capability enhances efficiency in systems where targeted airflow is essential.

- Applications: Fans are typically utilized for , whereas air movers are employed in scenarios that necessitate specific airflow patterns. For instance, in electronic cooling, fans effectively manage heat dissipation by directing airflow precisely where it is needed.

- : Current data indicates that ventilators can achieve pressure differences several times greater than those of fans, making them more suitable for applications that demand significant airflow resistance. Notably, the cycle of for fans was conducted over a span of 7 weeks, underscoring their reliability under pressure.

- Expert Opinions: HVAC engineers stress the importance of selecting the appropriate device for each task. As Scott Craven, Construction Manager for , remarked, “We want the smallest equipment we can possibly install, while still ensuring the house can stay at 70 on a 5 degree day.” This highlights the necessity for efficiency and proper sizing in ventilation applications.

- Real-World Applications: Case studies illustrate the advantages of air movers over fans in various engineering contexts. For example, in a recent project focused on , fans were preferred for their ability to maintain comfortable indoor temperatures even on extremely cold days, demonstrating their effectiveness in practical scenarios. This project also showcased the collaboration of volunteers from Kent State University and local organizations, emphasizing the spirit of teamwork and community with the use of DC blowers.

By recognizing these distinctions, that enhance the performance and efficacy of their designs. Furthermore, the team plans to share results and insights from the project on the Energy Smart Blog and JLC Online as the work progresses, offering additional context on blower efficiency and applications.

Conclusion

Efficient airflow management is increasingly crucial across various industries, underscored by the innovative solutions offered by companies like Gagner-Toomey Associates and Eltech Solutions. Their advancements in DC blower technology prioritize high performance, low noise, and energy efficiency, setting new standards in diverse fields from electronics to landscaping. With a growing emphasis on sustainability and health, the transition towards electric blowers and responsible battery recycling not only benefits the environment but also enhances user safety and comfort.

The exploration of various applications—such as the DC-3 blower system in aviation, DIY centrifugal blowers, and electric leaf blowers—demonstrates the versatility of blower technology. A nuanced understanding of the differences between fans and blowers empowers engineers to make informed decisions that optimize performance in their designs. Furthermore, implementing best practices in blower operation is essential to ensure safety and efficiency, thereby mitigating the health risks associated with noise and emissions.

As the industry evolves, the integration of advanced technologies and sustainable practices will play a pivotal role in shaping the future of blower applications. By prioritizing these innovations, both engineers and consumers can contribute to a more efficient, eco-friendly, and healthier environment. Embracing these trends is vital for anyone aiming to stay ahead in the rapidly changing landscape of technology and engineering.

Frequently Asked Questions

What types of DC blowers does Gagner-Toomey Associates offer?

Gagner-Toomey Associates offers a wide range of DC blowers including DC input tube axial fans ranging from 15 to 280mm and centrifugal units ranging from 15 to 225mm.

What industries can benefit from Gagner-Toomey’s DC blower solutions?

Gagner-Toomey’s DC blowers are suitable for various applications, including automotive and telecommunications.

What recent market trend is affecting the demand for DC blowers?

There is a growing demand for diverse DC blowers as existing options are limited compared to conventional AC fans, which may diminish consumer interest.

How is Gagner-Toomey responding to the demand for DC blowers?

Gagner-Toomey is focused on enhancing product variety and ensuring engineers have access to the latest advancements in fan technology, including features such as IP protection.

What technology do Eltech Solutions DC blowers utilize to improve performance?

Eltech Solutions DC blowers utilize advanced Maglev technology, which reduces friction and energy loss, leading to quieter operation and decreased power consumption.

What are the benefits of using Maglev technology in DC blowers?

The incorporation of Maglev technology can yield energy savings of up to 30% compared to conventional air movement systems, enhancing system performance and creating a more comfortable acoustic environment.

What additional solutions does Gagner-Toomey Associates provide along with DC blowers?

Gagner-Toomey Associates offers cutting-edge solenoid and rotary boost pump solutions, which are tailored for precision applications within the electronics sector.

What is the pressure rating of the pumps offered by Gagner-Toomey Associates?

The pumps offered by Gagner-Toomey Associates boast a pressure rating of up to 16 Bar.

How do advanced air-moving technologies impact aircraft performance?

Advanced air-moving technologies, such as those exemplified by the DC-3 ventilation system, enhance aircraft performance by optimizing airflow and cooling, facilitating efficient operation at diverse altitudes and speeds.

What reliability rate has been achieved through the integration of dual fan systems in aircraft?

The integration of dual fan systems has achieved an impressive reliability rate of 4 × 10 −10, significantly reducing fault probabilities.