Introduction

The demand for efficient cooling solutions in electronics is surging, fueled by the necessity for high-performance devices that can reliably function under increasing thermal loads. Among the innovative options available, 48V DC fans are emerging as a pivotal advancement for engineers, delivering substantial energy savings alongside enhanced performance. Yet, with a multitude of features to consider, what essential attributes render these fans indispensable in contemporary electronic applications? This article delves into ten critical features of 48V DC fans that not only optimize thermal management but also align with sustainability objectives, empowering engineers to make informed decisions in their designs.

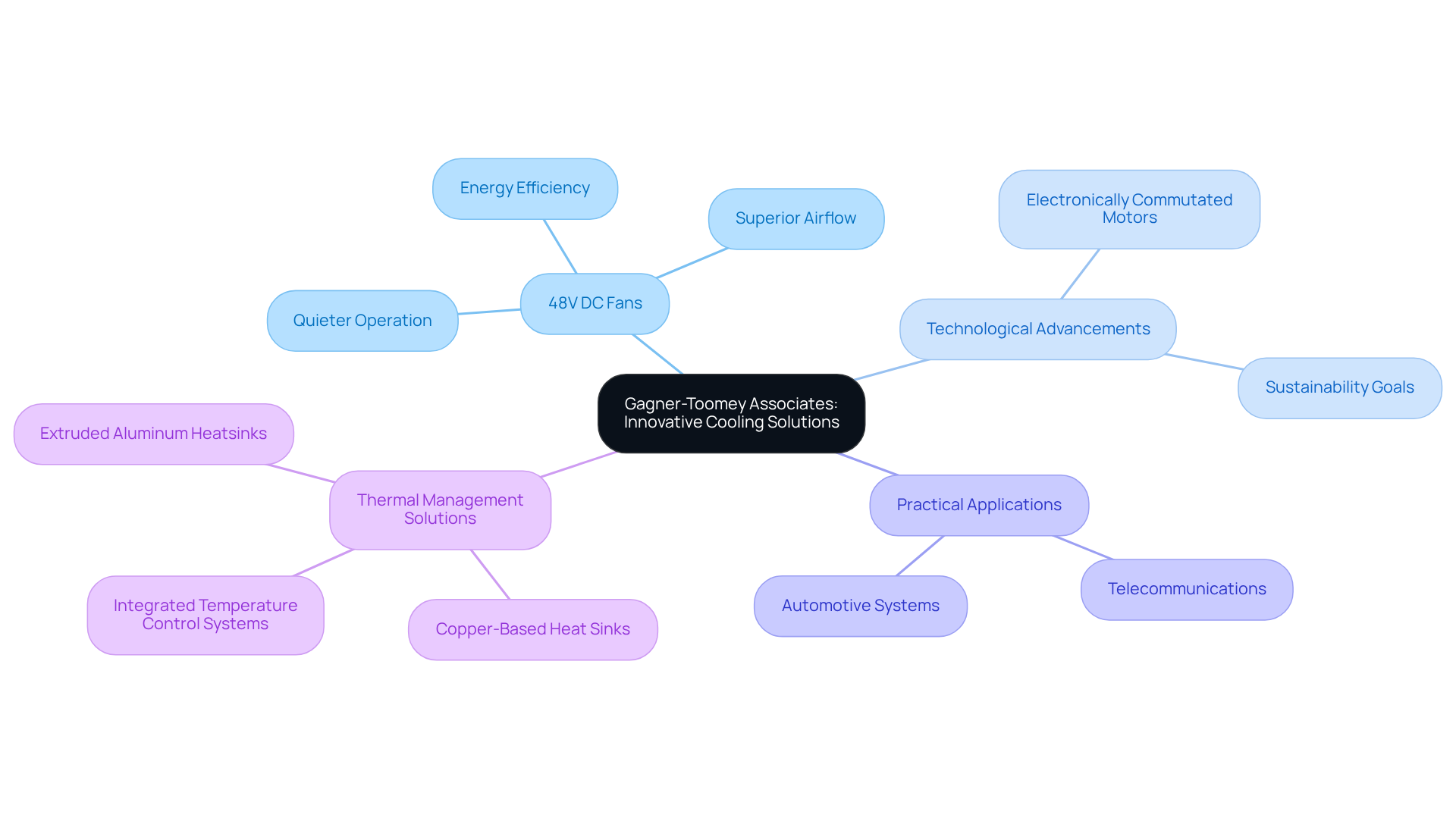

Gagner-Toomey Associates: Innovative Cooling Solutions for 48V DC Fans

Gagner-Toomey Associates stands at the forefront of innovative cooling solutions tailored specifically for the electronics sector, particularly emphasizing the 48V DC fan. These devices are increasingly recognized for their remarkable energy efficiency, consuming up to 70% less power than traditional AC units while providing superior airflow and quieter operation. This efficiency is vital as engineers work to meet the escalating demands for high-performance electronics, including smartphones and data centers.

Recent advancements in technology for the 48V DC fan showcase the integration of electronically commutated motors (ECMs), which significantly enhance operational efficiency and minimize electromagnetic interference. These features not only boost performance but also align with sustainability goals, making them ideal for modern electronic applications. Furthermore, many models can be equipped with IP protection upon request, ensuring reliability across diverse environments.

The practical applications of the 48V DC fan span various sectors, including telecommunications and automotive systems, where effective thermal management is crucial for device longevity and reliability. Gagner-Toomey Associates also provides a comprehensive range of thermal management solutions, including:

- Extruded aluminum heatsinks

- Copper-based heat sinks

- Integrated temperature control systems

As the market for cooling solutions continues to grow, Gagner-Toomey Associates is committed to ensuring that clients benefit from cutting-edge technologies and expert insights, reinforcing their dedication to excellence in the electronics industry.

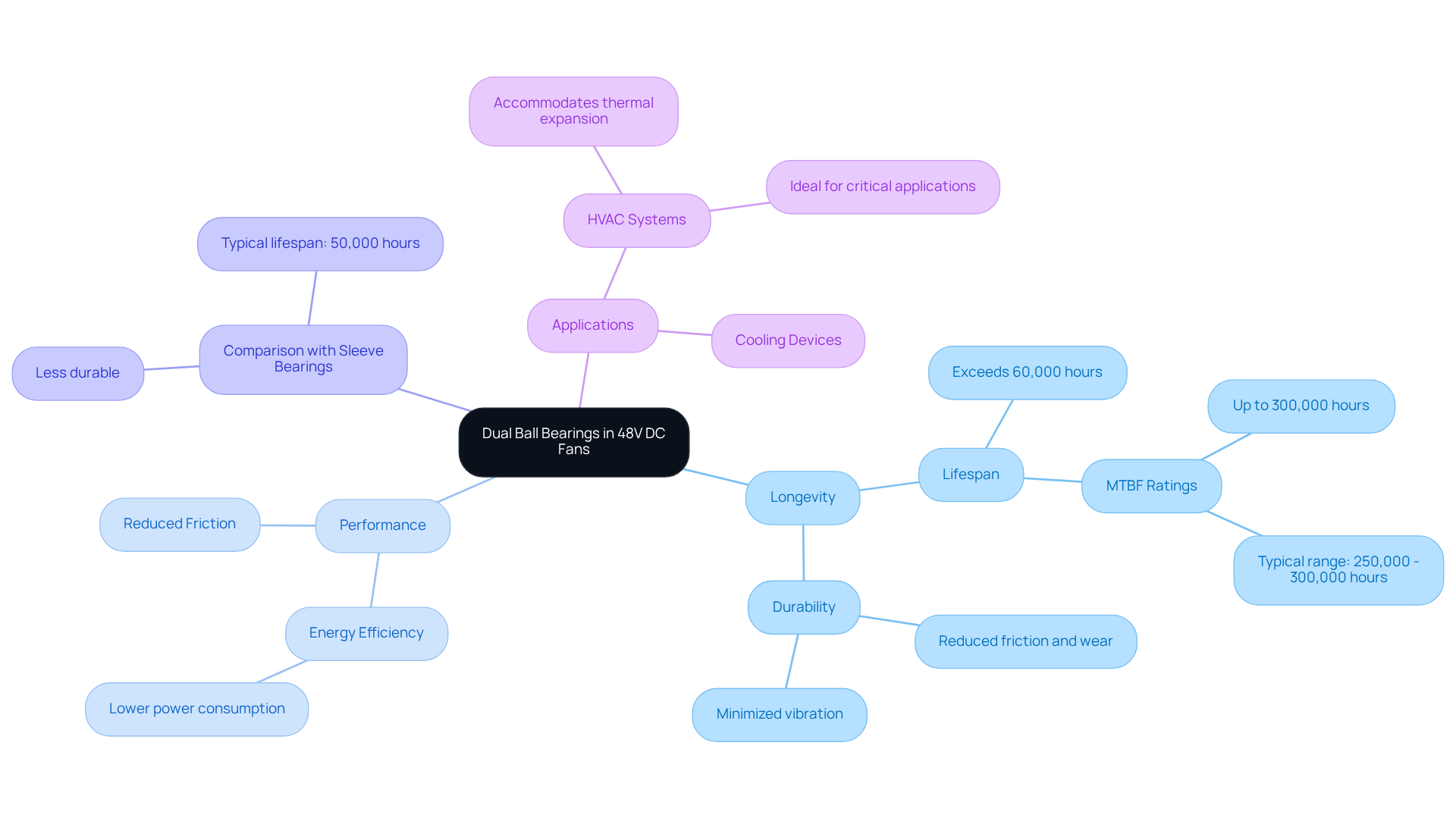

Dual Ball Bearings: Ensuring Longevity and Performance in 48V DC Fans

Dual ball bearings play a pivotal role in extending the lifespan and efficiency of the 48V DC fan used in cooling devices. Unlike sleeve bearings, which tend to be less durable, dual ball bearings significantly reduce friction and wear. This allows devices to operate smoothly for extended periods. Typically, this design results in lifespans that exceed 60,000 hours under normal operating conditions, with some manufacturers, such as Orion Fans, reporting MTBF ratings of up to 300,000 hours. Such durability ensures consistent performance across varying load conditions, making these devices ideal for critical applications where reliability is paramount.

For instance, in HVAC systems, devices equipped with dual ball bearings excel by accommodating thermal expansion and structural shifts. This capability minimizes vibration and early wear, further enhancing their longevity. The benefits of dual ball bearings extend beyond mere durability; they also improve energy efficiency by reducing friction, which subsequently lowers power consumption.

As engineers seek dependable solutions for their thermal management needs, the choice of dual ball bearings in the 48V DC fan units emerges as a crucial factor in achieving optimal performance. By prioritizing this component, professionals can ensure that their systems operate reliably and efficiently, meeting the demands of modern applications.

High Static Pressure: A Key Feature for Effective Cooling in 48V DC Fans

High static pressure is crucial for the efficiency of the 48v dc fan, particularly in situations where airflow is obstructed by components or enclosures. Fans engineered with high static pressure capabilities excel at pushing air through narrow spaces, ensuring optimal temperature regulation even in demanding environments. This feature is especially beneficial in data centers and telecommunications, where maintaining ideal temperatures is essential for the performance and longevity of equipment.

For instance, static pressure devices can generate force ratings around 3.0 inH2O, demonstrating their ability to overcome resistance from filters and heatsinks. Moreover, static pressure units maintain CPU temperatures approximately 3 degrees Celsius lower than ventilation units in radiator configurations, underscoring their effectiveness in temperature management.

As the demand for reliable cooling solutions continues to rise, the significance of high static pressure in electronics cooling will only increase. Market trends indicate a shift towards advanced cooling solutions, making it imperative for engineers to prioritize this feature when selecting blowers for their applications. Balancing airflow requirements with resistance factors is essential to ensure optimal performance.

Energy Efficiency: Reducing Costs with 48V DC Fans

Energy efficiency stands out as a key feature of 48v dc fans used in ventilation devices. These devices consume significantly less power than their AC counterparts, often achieving energy savings of up to 70%. This remarkable reduction in energy consumption not only lowers operational costs but also contributes to a smaller carbon footprint, positioning them as an environmentally friendly choice for cooling solutions. Engineers are encouraged to leverage this efficiency to enhance the sustainability of their designs.

Noise Levels: Ensuring Quiet Operation in 48V DC Fans

Noise levels play a pivotal role in the design of 48V DC fans, particularly in medical devices, office environments, and residential settings. The challenge lies in achieving low sound output without compromising performance. Contemporary 48V DC fans leverage advanced motor technologies and optimized blade designs to achieve remarkably low sound levels, often averaging around 25 to 30 decibels, which is quieter than a whisper. This focus on quiet operation is essential for fostering a serene atmosphere, especially in medical facilities where noise can disrupt patient care and recovery.

In office spaces, reduced fan noise significantly enhances productivity by minimizing distractions. As we look toward 2025, advancements in fan technology continue to evolve, introducing features such as Intelligent Motion Controls and aerodynamic blade designs that further lower noise levels while ensuring effective temperature regulation. The ability to operate quietly not only elevates user experience but also safeguards sensitive electronic components from the detrimental effects of noise, thereby enhancing overall device performance.

In summary, the integration of these technologies not only addresses the critical issue of noise but also positions the 48V DC fan as a superior choice for environments where tranquility and efficiency are paramount.

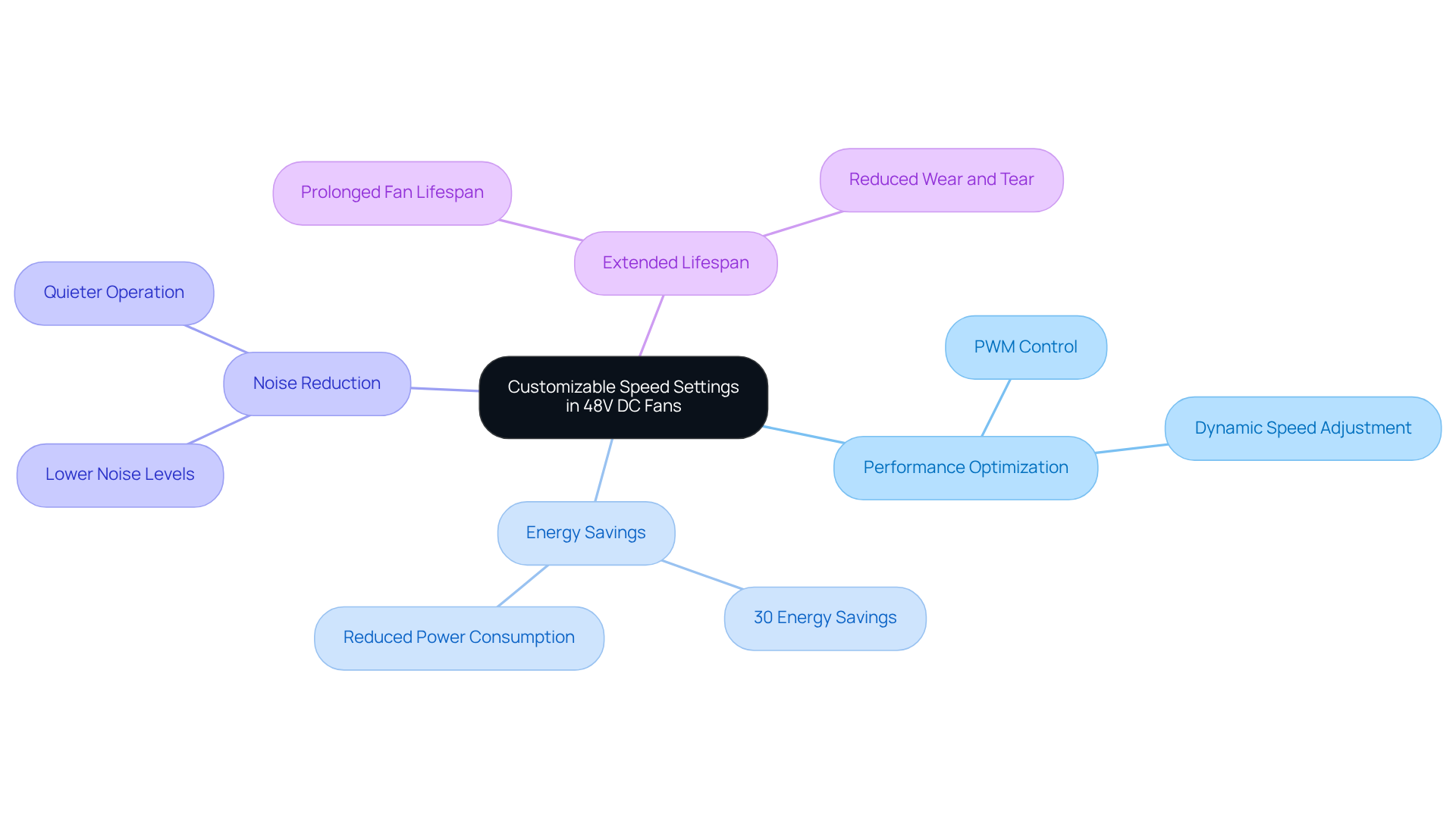

Customizable Speed Settings: Tailoring Performance in 48V DC Fans

Adjustable speed options present a significant advantage of the 48V DC fan units, allowing engineers to optimize performance according to specific temperature control requirements. Many proponents of this technology leverage PWM (Pulse Width Modulation) control, which facilitates precise speed adjustments based on real-time temperature or system demands. This adaptability not only boosts cooling efficiency but also results in substantial energy savings. For instance, systems employing PWM technology can achieve energy savings of up to 30% compared to traditional DC devices, particularly during periods of low demand, as noted by the University of Toronto.

Moreover, PWM control allows these devices to operate at lower speeds while maintaining effective airflow, which can reduce noise levels by as much as 30%. This makes them ideal for environments where sound sensitivity is crucial. As Annie Chan articulates, “With PWM, since the fan adjusts its speed based on need, it can reduce unnecessary wear, prolonging the fan’s lifespan and ensuring that it runs quieter for longer.”

The integration of PWM in 48V DC fan devices exemplifies how tailored performance can meet the evolving demands of modern electronic applications, ensuring optimal thermal regulation and extending the longevity of components.

Compact Design: Maximizing Space Efficiency with 48V DC Fans

The compact design of the 48V DC fan units from Gagner-Toomey Associates addresses a critical challenge in contemporary electronic systems regarding space efficiency. These meticulously engineered devices deliver high performance while occupying minimal space, making them ideal for applications in telecommunications, data centers, and consumer electronics. Their compact dimensions allow for adaptable integration into confined areas, ensuring efficient temperature control without compromising the overall system design.

For instance, Gagner-Toomey’s 48V DC fan units seamlessly integrate into compact devices, enhancing thermal management and supporting the ongoing trend toward miniaturization in electronics. This adaptability not only optimizes airflow but also extends the lifespan of electronic components by preventing overheating. As the demand for space-efficient solutions continues to rise, the role of the 48V DC fan in achieving effective temperature regulation becomes increasingly vital.

Moreover, the Electronic Compact Fan Market is projected to experience significant growth, driven by the escalating need for compact, high-performance cooling solutions. Gagner-Toomey’s devices are designed with energy efficiency and reliability in mind, making them indispensable in modern applications. The incorporation of technologies such as Pulse Width Modulation (PWM) enhances energy efficiency and reduces noise levels, further solidifying the advantages of the 48V DC fan in today’s electronic landscape.

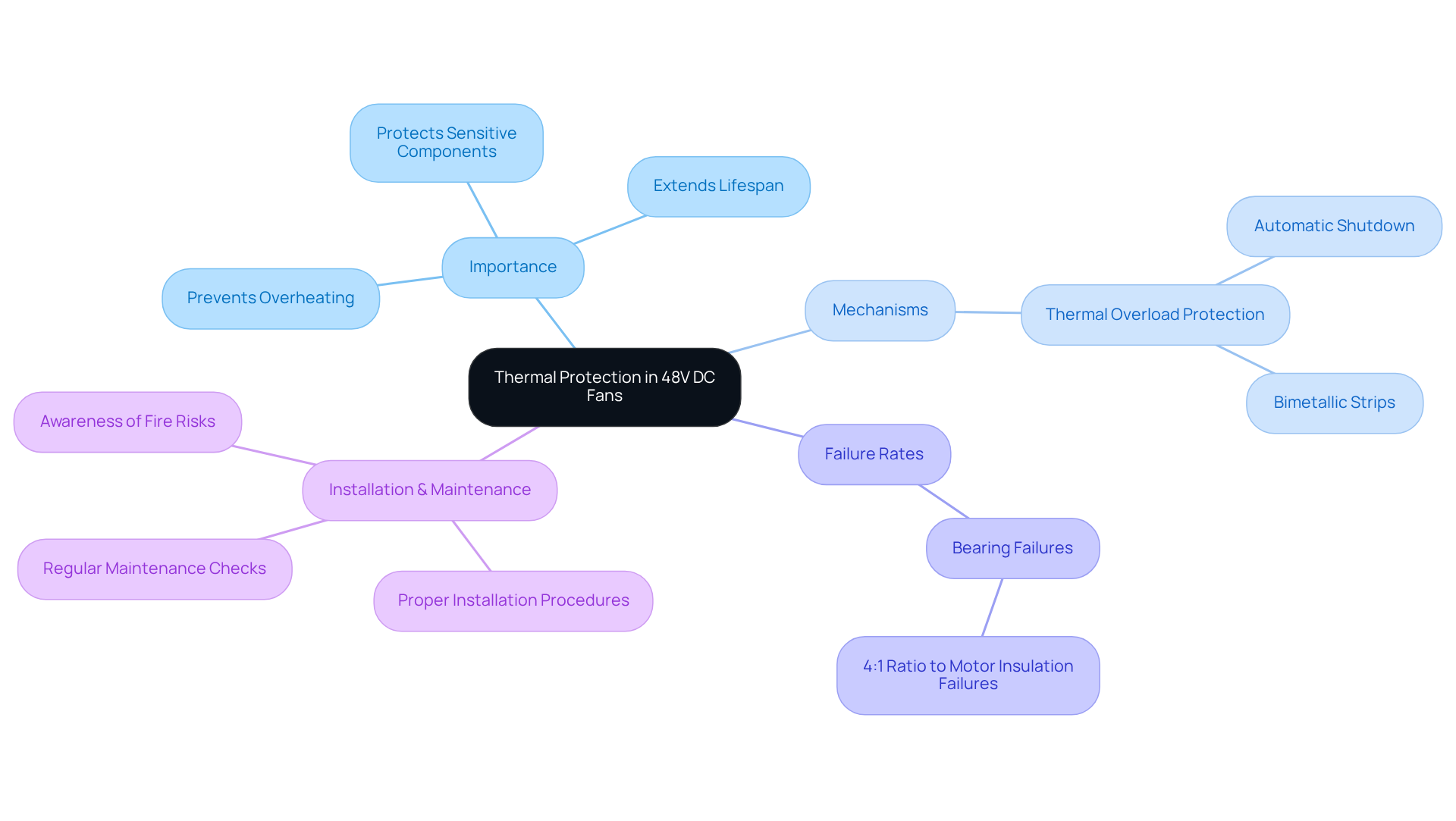

Thermal Protection: Enhancing Reliability in 48V DC Fans

Thermal protection characteristics are essential in 48V DC fans, providing crucial safeguards against overheating and ensuring reliable performance in challenging environments. Many manufacturers integrate thermal overload protection, which automatically shuts down the device when temperatures exceed safe thresholds. This mechanism not only extends the lifespan of the fan but also protects sensitive electronic components from heat-related damage.

In fact, fans lacking thermal protection face significantly higher failure rates, with bearing failures occurring at a ratio of 4:1 compared to motor insulation failures. By incorporating thermal overload protection, engineers can significantly enhance the reliability of their cooling solutions, making it a critical consideration in the design of robust electronic systems.

Moreover, proper installation and maintenance procedures are vital to mitigate fan-related fire risks, underscoring the importance of these protective features across various applications. As we approach 2025, the significance of these protective features continues to escalate, particularly in scenarios where consistent performance is paramount.

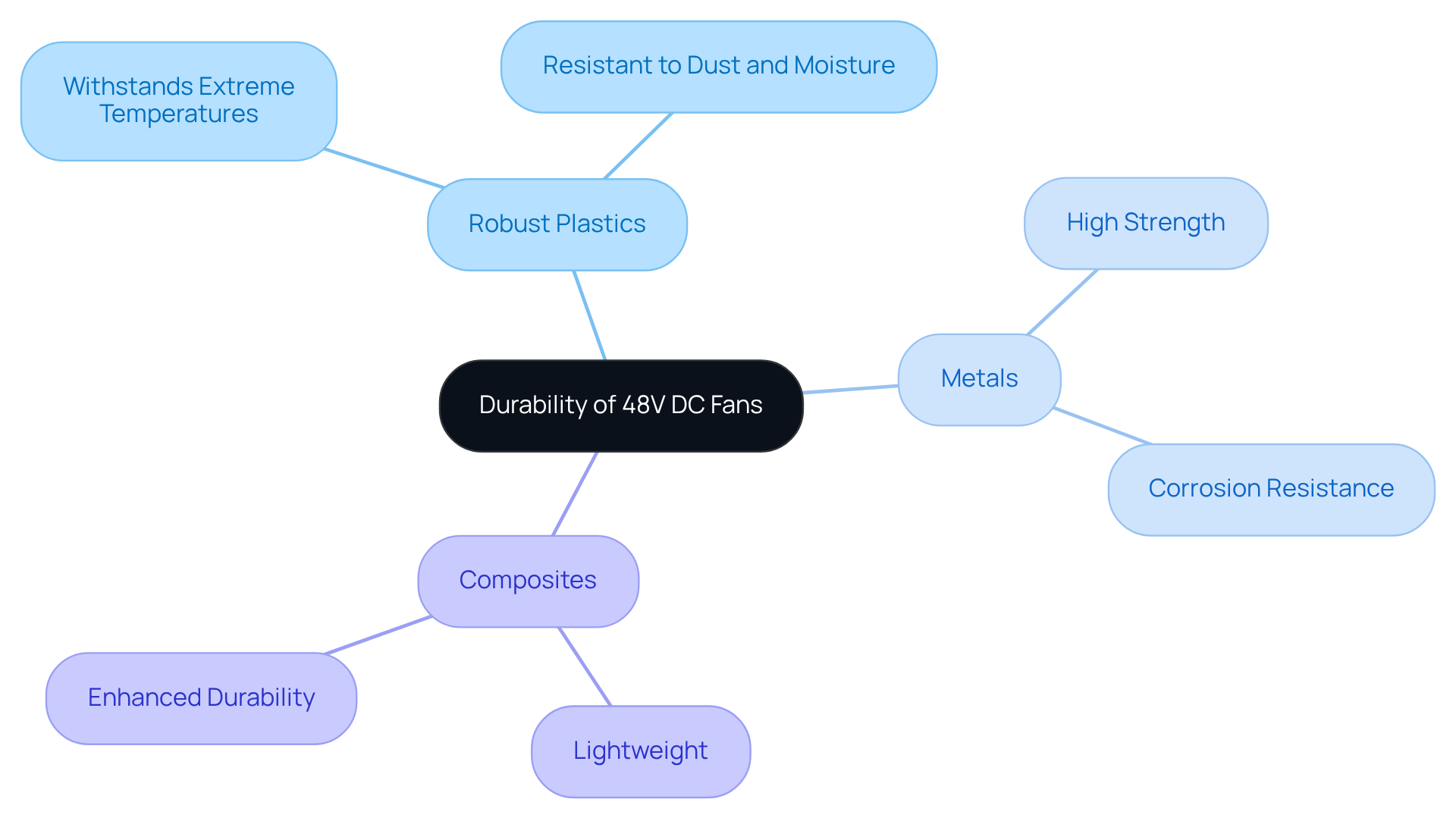

Robust Construction Materials: Ensuring Durability in 48V DC Fans

The durability of Gagner-Toomey Associates’ 48v dc fan units stands as a testament to the high-quality materials used in their construction. By utilizing robust plastics, metals, and composites, these devices are engineered to withstand harsh operating conditions, including extreme temperatures and exposure to dust or moisture. This meticulous construction guarantees that Gagner-Toomey’s devices, such as the 48v dc fan, operate reliably over extended periods, making them ideal for industrial applications where performance and longevity are paramount.

As the world’s largest manufacturer of standard and custom air-movers, Gagner-Toomey Associates offers a comprehensive range of cooling solutions tailored to meet diverse needs. Their commitment to quality and innovation not only addresses the challenges faced by industries today but also positions them as leaders in the market.

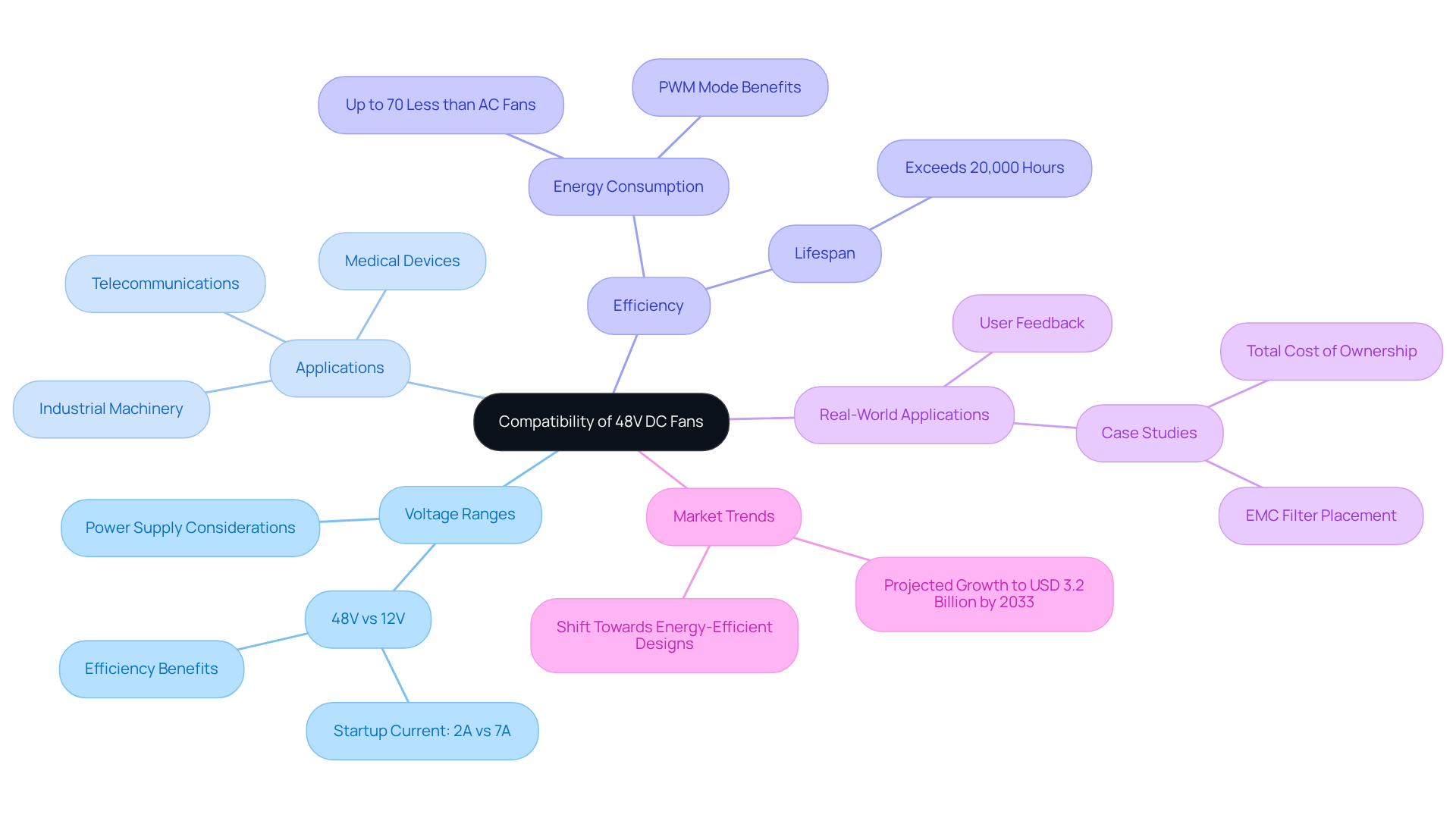

Compatibility: Ensuring Seamless Integration of 48V DC Fans with Electronic Systems

When selecting a 48V DC fan for electronic systems, compatibility is paramount. These devices operate across various voltage ranges, making them suitable for diverse applications, including telecommunications and industrial machinery. By ensuring compatibility with existing systems, engineers can deploy effective cooling solutions without extensive modifications. This not only streamlines the design process but also enhances overall system performance.

Significantly, 48V DC fans exhibit lower startup currents of 2A compared to 7A for their 12V counterparts. This efficiency simplifies their integration into high-performance systems. Real-world applications demonstrate the seamless incorporation of 48V DC fans in industrial environments, where maintaining optimal thermal conditions is crucial for preventing material aging and ensuring the longevity of electronic devices.

As the market for DC cooling fans is projected to reach USD 3.2 billion by 2033, the emphasis on compatibility and integration will continue to shape the landscape of electronic cooling solutions in 2025 and beyond. Engineers and decision-makers must prioritize these factors to stay ahead in a rapidly evolving industry.

Conclusion

The exploration of 48V DC fans highlights their essential role in boosting the efficiency and reliability of contemporary electronic systems. These fans are more than just energy savers; they represent a sophisticated blend of technology and design tailored to meet the demanding needs of various applications, from telecommunications to automotive systems. Their energy efficiency, quiet operation, and robust construction make them indispensable tools for electronics engineers focused on optimal thermal management.

Key features such as dual ball bearings, high static pressure capabilities, and customizable speed settings significantly enhance their performance. The integration of thermal protection and the use of durable materials ensure that these fans can endure challenging environments while maintaining functionality. As the market for cooling solutions continues to grow, the importance of selecting the right fan technology becomes increasingly clear.

In conclusion, the significance of 48V DC fans transcends mere cooling; they are a vital component in the quest for sustainability and innovation in electronics. Engineers are urged to harness these advanced features to improve the performance and longevity of their systems. Embracing these technologies not only leads to enhanced efficiency but also positions engineers at the forefront of the evolving landscape of electronic cooling solutions.

Frequently Asked Questions

What are the benefits of 48V DC fans compared to traditional AC units?

48V DC fans are recognized for their remarkable energy efficiency, consuming up to 70% less power than traditional AC units while providing superior airflow and quieter operation.

What advancements have been made in 48V DC fan technology?

Recent advancements include the integration of electronically commutated motors (ECMs), which enhance operational efficiency and minimize electromagnetic interference, aligning with sustainability goals.

In which sectors are 48V DC fans commonly used?

48V DC fans are used in various sectors, including telecommunications and automotive systems, where effective thermal management is crucial for device longevity and reliability.

What thermal management solutions does Gagner-Toomey Associates offer?

Gagner-Toomey Associates offers a range of thermal management solutions, including extruded aluminum heatsinks, copper-based heat sinks, and integrated temperature control systems.

How do dual ball bearings improve the performance of 48V DC fans?

Dual ball bearings extend the lifespan and efficiency of 48V DC fans by significantly reducing friction and wear, allowing for smoother operation and lifespans that can exceed 60,000 hours under normal conditions.

What is the expected lifespan of fans with dual ball bearings?

Fans equipped with dual ball bearings typically have lifespans exceeding 60,000 hours, with some manufacturers reporting MTBF ratings of up to 300,000 hours.

Why are high static pressure capabilities important in 48V DC fans?

High static pressure is crucial for pushing air through narrow spaces and overcoming resistance from components, ensuring optimal temperature regulation in environments like data centers and telecommunications.

How do high static pressure fans perform in temperature management?

Static pressure fans can maintain CPU temperatures approximately 3 degrees Celsius lower than ventilation units in radiator configurations, enhancing their effectiveness in temperature management.

What trends are influencing the market for cooling solutions?

There is a growing demand for reliable cooling solutions, leading to a shift towards advanced cooling technologies that prioritize features like high static pressure for optimal performance.