Overview

This article delivers critical insights into the applications of fan blowers within electronics engineering, emphasizing their vital roles in cooling, ventilation, and energy efficiency. It discusses various types of fans, essential maintenance practices, and the latest technological advancements, underscoring the necessity of selecting the appropriate fan blower to optimize performance and adhere to the industry’s evolving regulatory standards.

Introduction

In the ever-evolving realm of electronics engineering, the significance of fan blowers is paramount. These devices play a crucial role in ensuring optimal cooling and airflow management, which are essential for the reliability and longevity of electronic components. As the demand for efficient thermal management solutions escalates, Gagner-Toomey Associates emerges as a leader, offering innovative solutions that address the unique challenges within the electronics sector.

By delving into the intricacies of fan blower technology—from operating principles to energy efficiency and regulatory compliance—engineers can refine their designs and adeptly navigate the complexities of modern applications.

This article explores the various types of fan blowers, their applications, and the essential considerations for achieving optimal performance, thereby equipping engineers with the knowledge necessary to excel in this dynamic field.

Gagner-Toomey Associates: Innovative Solutions for Fan Blower Applications

Gagner-Toomey Associates stands out as a leader in delivering innovative solutions specifically for fan blower systems tailored for the electronics sector. Through collaboration with a diverse range of manufacturers, the company empowers engineers with cutting-edge technologies that significantly enhance cooling and power management capabilities. This unwavering commitment to excellence guarantees that clients receive customized solutions to address complex challenges in electronics design and manufacturing, thereby facilitating the creation of high-performance products.

As the demand for efficient thermal management solutions escalates, particularly within compact electronic devices, Gagner-Toomey remains at the forefront of market trends. The integration of advanced technologies effectively addresses the evolving needs of the industry. Their consultative approach, supported by a highly experienced team, ensures that engineers are equipped with the necessary support to navigate the complexities of modern electronics.

Fan blowers, for instance, play a crucial role in preventing overheating in compact electronic devices such as laptops and tablets. Manufacturers like Pelonis Technologies, Inc. produce engineered micro fans that effectively cool internal components. Their expertise in fan blower applications is evident in successful executions that enhance performance and reliability, establishing them as a trusted collaborator for engineers.

Furthermore, Gagner-Toomey Associates connects engineers with local distribution partners, guaranteeing a stable supply of components when and where they are needed. This expansive network enhances the overall efficiency of the electronics supply chain, facilitating timely and effective solutions.

Scott Craven, Construction Manager for Habitat for Humanity of Portage County, underscores the significance of effective thermal management, stating, “We’re using central ductwork with a standard split heat pump and providing excellent filtration, dehumidification, and central fresh air distribution.” This highlights the vital role that innovative fan blowers play in ensuring optimal functionality in electronics. Additionally, with continuous advancements in the sector, including a project commitment set for August 28, Gagner-Toomey Associates exemplifies a proactive strategy towards market trends, reinforcing their position as leaders in the fan blower industry.

Understanding the Operating Principles of Fan Blowers

Fan devices operate on the foundational principles of fluid dynamics, harnessing mechanical energy to effectively move air or gas. Central to this operation is the impeller, which accelerates the air, generating a pressure differential that drives airflow. Mastery of these principles is essential for engineers, as it directly influences the design and choice of blowers customized for particular uses, thereby enhancing performance and efficiency.

Recent research highlights the significance of understanding flow characteristics in the design of cross-flow fans (CFFs), which have been patented since 1893. This long history underscores the ongoing innovations and applications of CFFs, such as their integration in vehicle engines and combined cleaning systems, showcasing their versatility. For instance, studies utilizing computational fluid dynamics (CFD) are currently exploring the performance of CFFs in combined cleaning shoes, providing insights into airflow dynamics that can lead to improved designs. As mentioned by Funaki et al., “A significant outcome” of this research is the improved understanding of airflow dynamics that can guide better fan designs.

Engineers stress that a thorough understanding of fan blower mechanics is crucial for optimizing mechanical energy utilization in these systems. By utilizing fluid dynamics principles, they can enhance the designs of fan blowers to satisfy the requirements of contemporary electronics uses, ensuring that these devices function at optimal efficiency while tackling the intricacies of airflow management.

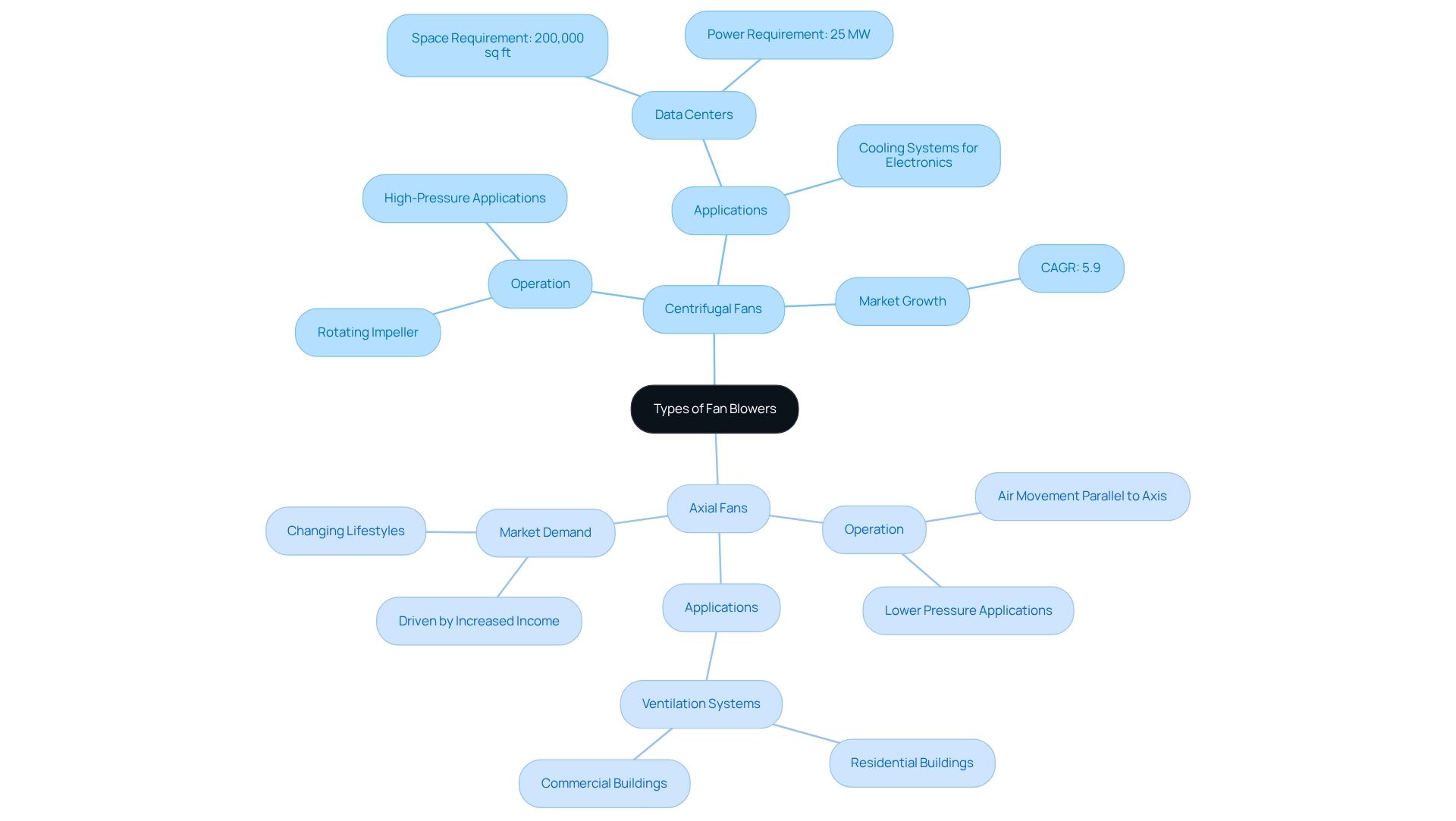

Exploring Different Types of Fan Blowers: Centrifugal and Axial

Fans are primarily classified into two categories: centrifugal and axial. Centrifugal fans operate by employing a rotating impeller that draws air in and expels it at a right angle, making them particularly effective for high-pressure applications. They are frequently utilized in environments that demand significant pressure increases, such as data centers, where each facility typically requires around 200,000 square feet and 25 MW of power to be established, thereby necessitating robust airflow management.

Conversely, axial fans promote air movement parallel to the fan’s axis, achieving high airflow rates at lower pressures. This design proves advantageous in scenarios where space is constrained and high volume is prioritized over pressure, such as in ventilation systems for residential and commercial buildings. The increasing personal income and evolving lifestyles are driving the demand for household fans and ventilation systems, further underscoring the relevance of axial fans in these contexts.

Understanding the distinctions between these two types of fans is crucial for engineers when selecting the appropriate equipment for specific project requirements. For instance, the industrial sector of the ventilation and air movement market is projected to grow at a CAGR of 5.9%, reflecting the rising demand for efficient airflow solutions across various applications, including domestic uses.

Practical applications illustrate these differences: centrifugal fans are commonly employed in cooling systems for electronics, whereas axial fans are favored in general ventilation. A notable case study is the transformation of CG Power and Industrial Solutions, which has enhanced its operational capabilities to better meet the evolving demands in the fans and air-moving equipment sector. This transformation highlights the importance of selecting the correct type of fan, as it can significantly improve market responsiveness and operational efficiency.

Choosing the Right Fan Blower for Optimal Performance

Selecting the appropriate fan blower necessitates a thorough evaluation of several critical factors, such as airflow requirements, pressure ratings, and energy efficiency. Recognizing the specific application—whether for cooling electronic components or ventilating spaces—is essential in identifying the optimal fan blower type and size. Performance curves and manufacturer specifications are invaluable resources that guide engineers in making informed decisions aligned with their project objectives. Additionally, assessing the efficiency of the fan blower significantly impacts overall system effectiveness, underscoring the importance of considering both the operational environment and intended use. By prioritizing these factors, engineers can ensure optimal performance and reliability in their systems.

Gagner-Toomey Associates, a global leader in power conversion products, offers a comprehensive range of solutions, including standard, modified, and custom power supplies tailored for medical, industrial, and server applications. These power supplies are designed to meet the specific needs of diverse applications, ensuring compatibility and performance. As highlighted in recent discussions at APEC 2025, advancements in technologies such as SiC products play a pivotal role in enhancing power efficiency, which is directly relevant to fan systems. Moreover, Maurizio Di Paolo Emilio emphasized the importance of selecting efficient components in electronic applications, reinforcing the necessity for engineers to thoughtfully consider these factors.

Applications of Fan Blowers in Electronics Engineering

Fan blowers are indispensable in electronics engineering, fulfilling a variety of applications such as:

- Cooling computer processors

- Ensuring proper ventilation in enclosures

- Facilitating air circulation in manufacturing processes

By maintaining optimal operating temperatures, these devices prevent overheating and significantly enhance the reliability of electronic components. Effective airflow management is crucial, as it directly influences the performance and longevity of electronic systems.

Recent statistics indicate that the global ventilation and exhaust industry is poised for expansion, with a compound annual growth rate (CAGR) of 5.7% projected from 2023 to 2031. This growth reflects the increasing demand for effective cooling solutions, including fan blowers, across various sectors, such as electronics. The establishment of new data centers is expected to substantially elevate the need for fan blowers in the commercial sector, particularly as these facilities require advanced cooling systems to manage the heat generated by high-density computing.

Market segmentation by technology, deployment, power source, and distribution channel further illustrates the diverse applications of fans within the electronics industry. Expert opinions underscore that airflow management is vital for the optimal performance of electronic components. Engineers consistently emphasize that inadequate cooling can lead to diminished efficiency and premature failure of devices. Real-world examples highlight the effectiveness of fans in manufacturing processes, where they are employed to maintain consistent temperatures and enhance product quality.

In 2025, innovative cooling solutions utilizing fan blowers are anticipated to emerge, further enhancing their role in electronics cooling tasks. Case studies, such as those presented at APEC 2025, showcase advancements in technologies like silicon carbide (SiC), which markedly improve power efficiency and thermal management in electronic systems. As Peter Friedrichs from Infineon Technologies remarked, “Our wide portfolio of SiC products demonstrates the critical role of advanced materials in enhancing cooling solutions for electronic applications.”

In summary, fan blower devices are essential for ensuring optimal functionality and reliability in the rapidly evolving field of electronics engineering.

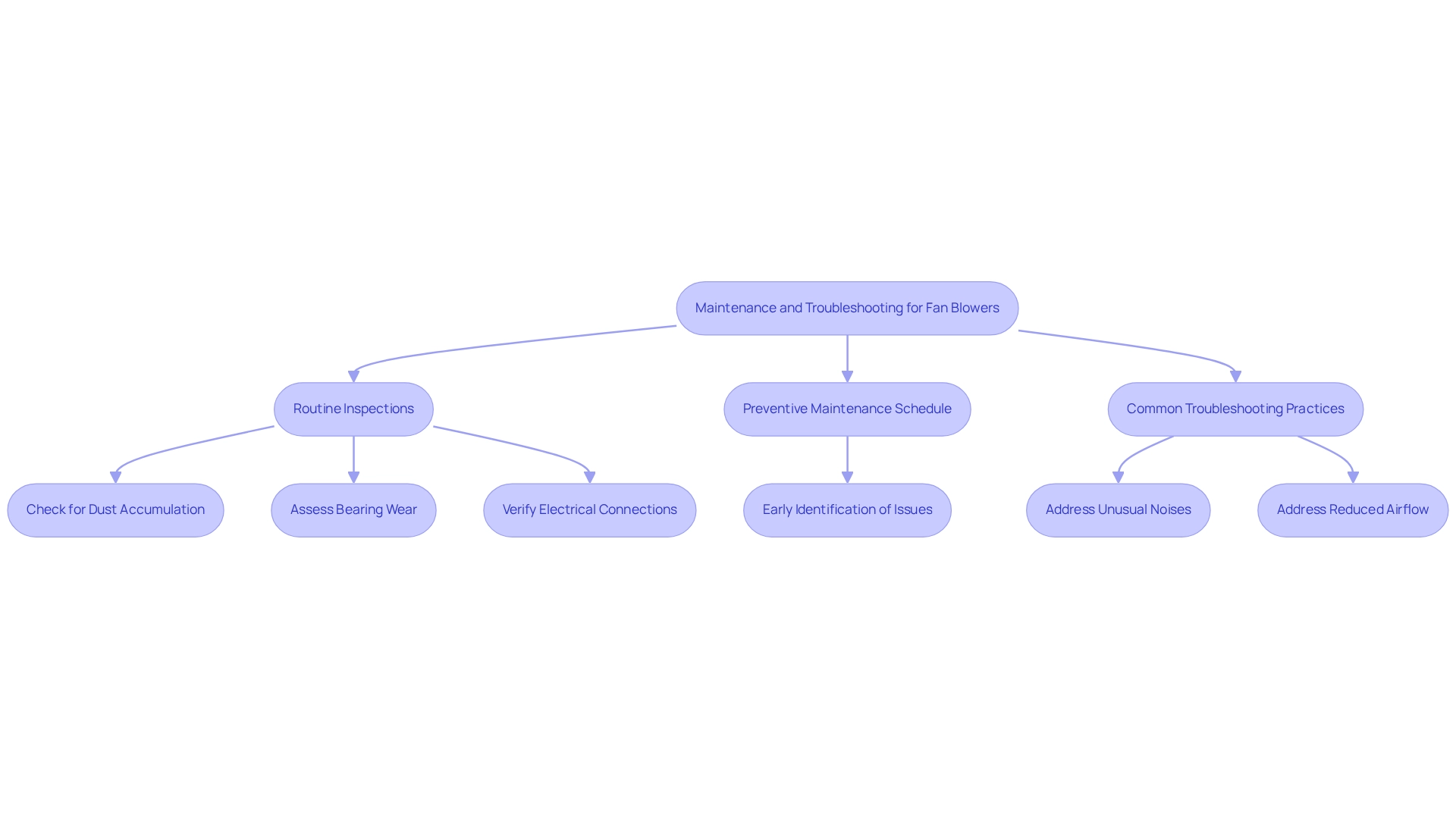

Maintenance and Troubleshooting Tips for Fan Blowers

To ensure peak operation and prolong the durability of the fan blower, regular upkeep is crucial. Engineers must conduct routine inspections to check for dust accumulation, assess bearing wear, and verify that all electrical connections are secure. Establishing a preventive maintenance schedule is vital; it facilitates the early identification of potential issues, thereby preventing costly system failures.

A recent project underscored the importance of these practices, showcasing how systematic maintenance led to a significant reduction in operational disruptions. Notably, effective maintenance practices can yield substantial benefits, with a predicted annual energy savings of $226 following renovations.

Common troubleshooting practices include addressing unusual noises and reduced airflow, frequent indicators of underlying problems. As one client, Kevan, remarked, compared to some previous projects he had undertaken, this project was ‘a breath of fresh air.’

By adhering to these professional maintenance recommendations, engineers can enhance the reliability and efficiency of air-moving systems, such as the fan blower, ultimately leading to improved results in electronic applications. This method not only establishes a benchmark for future home performance initiatives but also emphasizes the essential role of maintenance in achieving high standards in the performance of the fan blower.

Energy Efficiency Considerations in Fan Blower Design

Energy efficiency stands as a pivotal element in the design of fan blowers, particularly as the industry transitions towards more sustainable practices. Engineers must prioritize fan blowers that are equipped with electronically commutated (EC) motors, known for their significant energy savings. Although specific statistics on energy savings were not derived from the provided external information, it is widely acknowledged that EC motors can achieve substantial reductions in energy consumption when compared to traditional AC motors.

Innovations in the fan blower design for 2025 are centered on optimizing inlet and outlet configurations to reduce turbulence, thus enhancing airflow efficiency. Furthermore, the integration of high flow rate pumps and non-slam check valves within ventilation systems exemplifies the industry’s commitment to improved energy management and efficiency in contemporary applications. These components are essential for ensuring that systems operate effectively, particularly in heavy cargo handling scenarios, as evidenced by recent projects.

Moreover, the significance of energy-efficient designs extends beyond mere operational costs; they also enhance indoor air quality. For example, Daikin systems are recognized for their superior air filtration capabilities, which contribute to improved indoor environments by eliminating allergens and irritants.

To further enrich this discussion, engineers are urged to consider practical measures such as conducting simulations akin to those employed in the FSAPDS ammunition study, which aimed at optimizing outcomes through comprehensive analysis. By embracing these energy-efficient designs and practices, engineers not only mitigate operational costs but also play a vital role in advancing sustainability initiatives within the electronics sector.

Regulatory Compliance for Fan Blowers in Electronics

Engineers face the challenge of navigating a complex landscape of regulatory compliance requirements for fans, which can vary significantly by region and application. The Department of Energy (DOE) and the American National Standards Institute (ANSI) set forth essential operational and efficiency standards that govern the design and functioning of these systems. Compliance with these regulations is crucial, not only for product approval and successful market entry but also for ensuring safety and environmental sustainability.

In 2025, the DOE and ANSI standards for fan performance will underscore the necessity of energy efficiency and operational effectiveness. Compliance with these standards is under increasing scrutiny, as the DOE’s analysis reveals the burdens linked to proposed test procedures. For example, the Air Movement and Control Association (AMCA) advises referencing Section 6.3 of AMCA 214-21 for bare shaft fans paired with regulated motors, highlighting the significance of precise compliance measures.

Real-world examples demonstrate the successful integration of these standards in fan blower design, illustrating how manufacturers have adapted to meet DOE and ANSI requirements. As industry expert Mike Wolf, PE, the 2023-2024 president of AMCA International, notes, “Fortunately, federal grants are available to help offset the cost,” emphasizing the financial support accessible for compliance efforts. The importance of these standards cannot be overstated; they not only facilitate market access but also enhance product reliability and performance.

Moreover, recent discussions within the industry, including concerns raised by Trane regarding potential redesigns of embedded fans, underscore the ongoing challenges in balancing compliance with cost-effectiveness. These redesign challenges significantly influence engineers’ decision-making processes, as they must evaluate the costs of compliance against the benefits of adhering to regulatory standards. As the regulatory landscape evolves, engineers must remain vigilant and informed to ensure their designs not only meet current standards but also anticipate future regulatory changes. Additionally, the DOE’s examination of the final rule’s implications under Executive Order 13132 concerning federalism indicates that the rule would not exert a substantial direct effect on state governments, a crucial consideration for engineers navigating compliance.

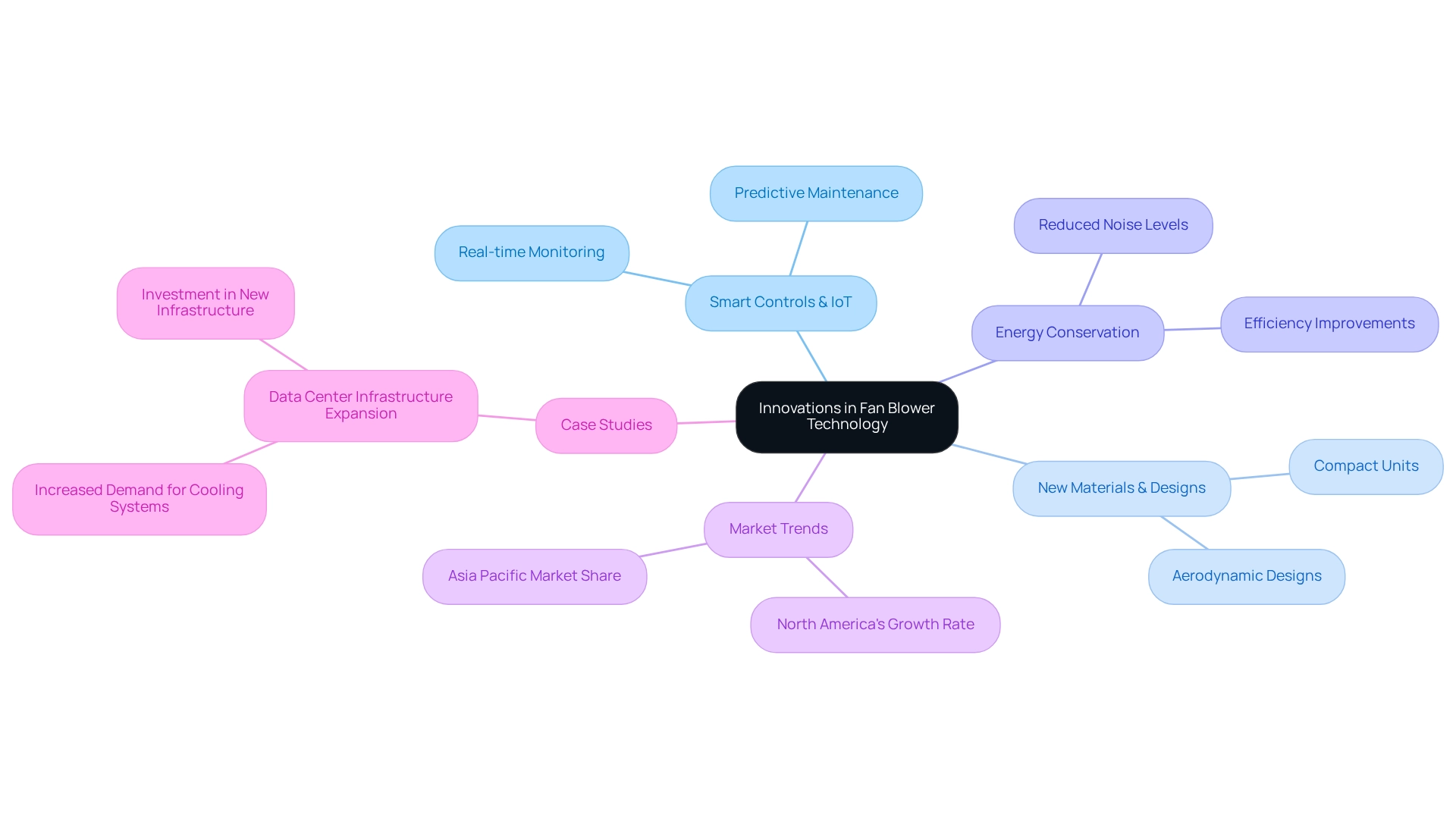

Recent Innovations in Fan Blower Technology

Recent innovations in fan blower technology have significantly transformed the landscape of cooling solutions. The integration of smart controls and IoT capabilities enables real-time monitoring and adjustments based on environmental conditions, enhancing operational efficiency. These advancements facilitate predictive maintenance, thereby minimizing downtime and optimizing performance. Furthermore, the development of new materials and aerodynamic designs has resulted in more compact and efficient units, which are essential for contemporary electronic applications.

These innovations not only enhance performance but also contribute to energy conservation and reduced noise levels, making them increasingly suitable for sensitive environments such as data centers. The rapid growth of data centers in North America, driven by the demand for advanced cooling systems, underscores the critical importance of these technologies. As funding for new infrastructure continues, the market for air movers is projected to grow substantially, particularly in commercial sectors. Notably, North America is expected to experience the highest growth rate in the global fans and ventilators market, while the Asia Pacific region is anticipated to maintain the largest market share throughout the forecast period. A significant case study titled ‘Data Center Infrastructure Expansion’ highlights how the swift expansion of data centers is generating a substantial demand for fan blowers, which are essential for cooling systems. Overall, the convergence of intelligent technology and innovative design is establishing a new benchmark for fan systems in the electronics sector, especially as companies like CG Power and Industrial Solutions Limited undergo changes that could influence market trends.

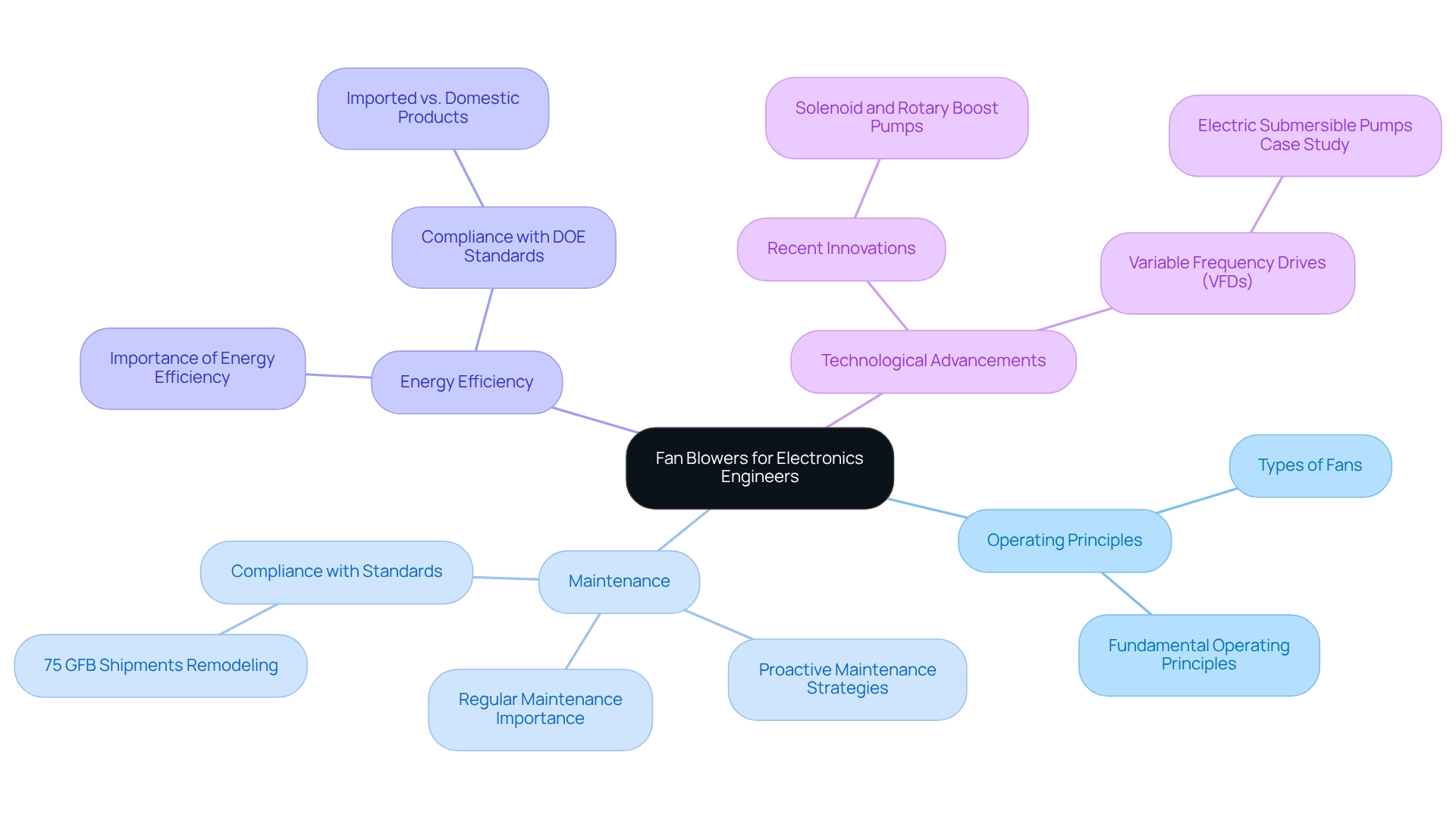

Key Takeaways for Electronics Engineers on Fan Blowers

Electronics engineers must grasp the fundamental operating principles and various types of fans to make informed choices tailored to their specific applications. Regular maintenance is imperative, as it directly influences the lifespan and performance of ventilation systems. Notably, models accounting for 75 percent of all GFB shipments will necessitate remodeling within the next five years to comply with standards, highlighting the urgency for proactive maintenance strategies.

Energy efficiency emerges as another vital consideration; it not only enhances performance but also guarantees compliance with evolving regulations. The Department of Energy’s recent proposal to amend energy conservation standards underscores the importance of selecting energy-efficient fans, particularly as domestic products face stricter guidelines compared to their imported counterparts. As noted by AHRI, imported HVAC products equipped with built-in fan blowers are exempt from these energy conservation standards, emphasizing the necessity for engineers to focus on compliance when selecting fan blower systems.

Staying informed about recent advancements in fan blower technology empowers engineers to leverage cutting-edge solutions that enhance the reliability and efficiency of electronic systems. For instance, Gagner-Toomey Associates provides innovative solenoid and rotary boost pumps that function across a broad spectrum of AC and DC voltages, featuring low noise operation and compliance with automotive standards such as SAE and VDA. The facility is certified under quality management IATF 16969, ensuring high production standards.

The integration of variable frequency drives (VFDs) in applications like Electric Submersible Pumps has shown considerable improvements in operational efficiency and reduced electrical power costs. This case study exemplifies the tangible benefits of adopting advanced blower technologies, reinforcing the significance of energy efficiency and maintenance. By prioritizing these elements, engineers can ensure their designs are not only compliant but also optimized for both performance and sustainability.

Conclusion

Understanding the intricacies of fan blower technology is essential for electronics engineers who strive for optimal cooling and airflow management in their designs. By exploring the operating principles, types, and applications of fan blowers, engineers can make informed decisions that enhance the reliability and efficiency of electronic systems. Insights into centrifugal and axial blowers, alongside the critical importance of regular maintenance and energy efficiency, underscore the multifaceted considerations necessary for achieving high performance.

As the electronics industry continues to evolve, the demand for innovative solutions—such as those provided by Gagner-Toomey Associates—highlights the importance of collaboration and advanced technology integration. Staying abreast of regulatory compliance and recent technological innovations, including smart controls and IoT capabilities, empowers engineers to navigate the complexities of modern applications effectively.

Ultimately, prioritizing energy efficiency, rigorous maintenance, and informed selection of fan blowers not only enhances system performance but also aligns with the industry’s shift towards sustainability. By embracing these principles, engineers can contribute to the longevity and reliability of electronic components, ensuring that their designs meet the challenges of today and the future.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in delivering innovative solutions for fan blower systems tailored specifically for the electronics sector.

How does Gagner-Toomey Associates support engineers in the electronics industry?

The company collaborates with various manufacturers to provide engineers with cutting-edge technologies that enhance cooling and power management capabilities, ensuring customized solutions for complex challenges in electronics design and manufacturing.

Why is effective thermal management important in compact electronic devices?

Effective thermal management is crucial in compact electronic devices, such as laptops and tablets, to prevent overheating and ensure optimal performance.

Who are some of the manufacturers Gagner-Toomey Associates works with?

Gagner-Toomey Associates works with manufacturers like Pelonis Technologies, Inc., which produces engineered micro fans for cooling internal components.

How does Gagner-Toomey Associates enhance the electronics supply chain?

The company connects engineers with local distribution partners to ensure a stable supply of components, thereby improving the efficiency of the electronics supply chain.

What role do fan blowers play in the functionality of electronics?

Fan blowers play a vital role in ensuring optimal functionality in electronics by preventing overheating and supporting effective thermal management.

What are the two main types of fans and how do they differ?

The two main types of fans are centrifugal and axial. Centrifugal fans draw air in and expel it at a right angle, making them effective for high-pressure applications, while axial fans move air parallel to the fan’s axis, achieving high airflow rates at lower pressures.

In what applications are centrifugal fans commonly used?

Centrifugal fans are commonly used in cooling systems for electronics and in environments that require significant pressure increases, such as data centers.

What advantages do axial fans offer?

Axial fans are advantageous in scenarios where space is limited and high volume airflow is prioritized over pressure, such as in residential and commercial ventilation systems.

What is the projected growth rate for the industrial sector of the ventilation and air movement market?

The industrial sector of the ventilation and air movement market is projected to grow at a CAGR of 5.9%, reflecting the increasing demand for efficient airflow solutions across various applications.