Overview

This article presents essential insights for engineers concerning fan efficiency curves, which are vital for optimizing thermal management in electronic systems. Understanding these curves empowers engineers to select fans that maximize airflow while minimizing energy consumption. This not only enhances system performance but also contributes to sustainability within the electronics industry.

Introduction

Understanding the intricacies of fan efficiency curves is paramount for engineers aiming to optimize thermal management in electronic systems. As the demand for energy-efficient solutions in data centers and high-performance computing environments surges, the ability to interpret and apply these curves presents significant advantages. However, with the complexities of airflow, static pressure, and power consumption at play, how can engineers ensure they are making the most informed decisions? This article delves into ten essential insights surrounding fan efficiency curves, equipping professionals with the knowledge needed to enhance performance, reduce energy costs, and navigate the evolving landscape of electronic cooling solutions.

Gagner-Toomey Associates: Pioneering Solutions for Fan Efficiency in Electronics

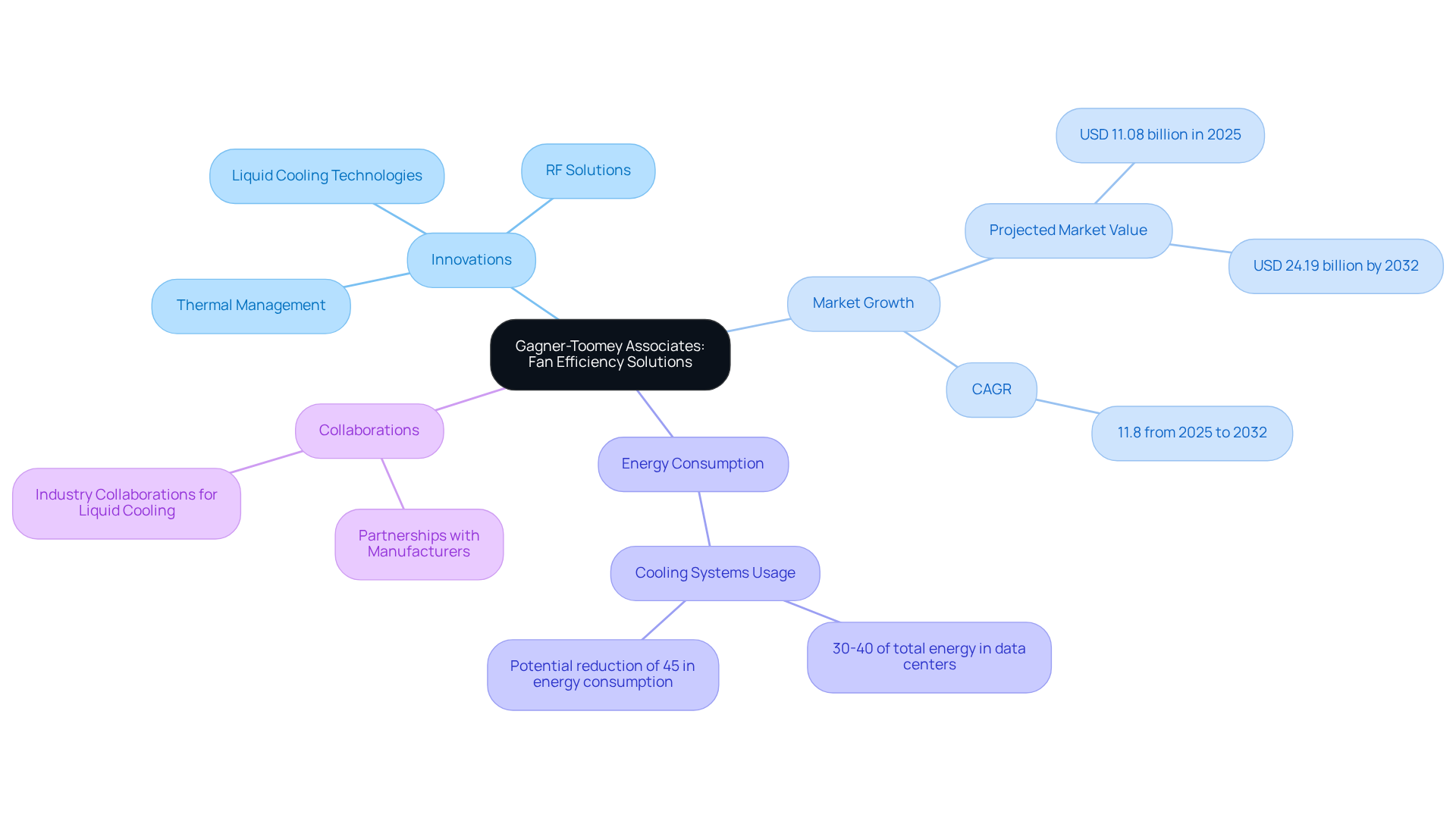

Gagner-Toomey Associates stands at the forefront of advancing fan efficiency curves within the electronics sector, specializing in thermal, power, RF, interconnect, and electromechanical solutions. By collaborating with a diverse array of outstanding manufacturers, the company plays a pivotal role in developing innovative temperature control solutions that enhance both performance and energy efficiency.

Recent advancements in refrigeration technologies reveal that effective temperature control strategies can reduce overall energy consumption by up to 45%, particularly noteworthy as these systems account for 30-40% of total energy usage in typical data centers. This highlights the critical importance of these innovations in contemporary electronic systems.

As the demand for high-performance computing escalates, especially in data centers, Gagner-Toomey Associates ensures that engineers have access to state-of-the-art resources and expert sales support to tackle intricate thermal management challenges. This commitment to excellence not only facilitates the adoption of advanced temperature control technologies but also fosters the industry’s shift towards sustainable practices, as illustrated by fan efficiency curves.

The global data center temperature regulation market is projected to grow from USD 11.08 billion in 2025 to USD 24.19 billion by 2032, achieving USD 26.5 billion in 2025, with a CAGR of 11.8%. This growth underscores the increasing reliance on effective temperature regulation solutions to accommodate the rising thermal loads linked to advanced electronics.

As SK Telecom highlights, the development of tailored liquid cooling technologies for data centers is crucial for addressing these challenges, exemplifying the collaborative efforts within the industry.

Understanding Fan Curves: The Basics of Performance Metrics

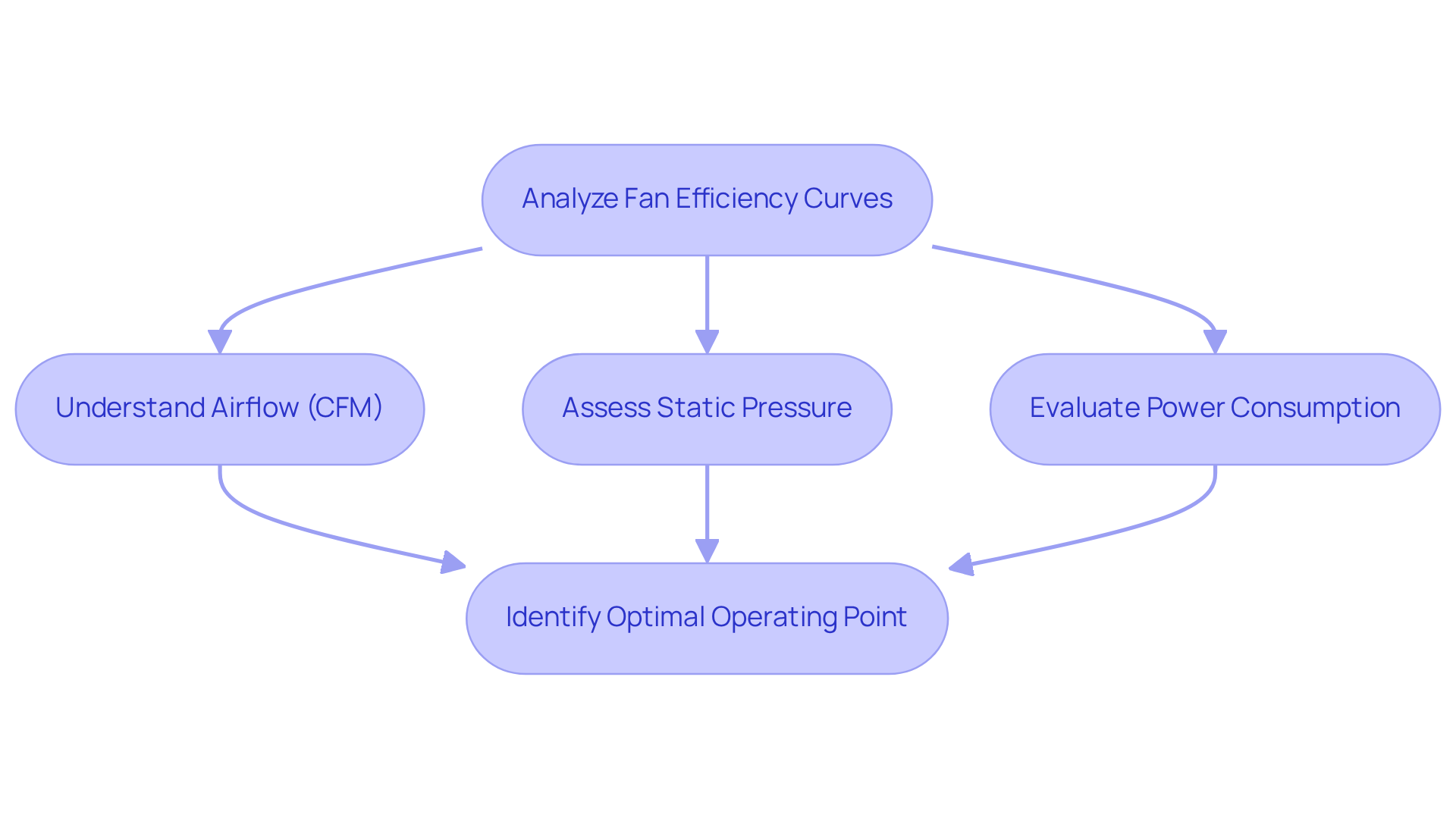

Fan efficiency curves are essential graphical tools that illustrate the intricate relationship between airflow (measured in cubic feet per minute, or CFM), static pressure, and power consumption for specific fans. For engineers, understanding fan efficiency curves is vital, as these curves reveal how a fan operates under varying conditions.

By meticulously analyzing fan efficiency curves, engineers can identify the optimal operating point for their applications, which is crucial for achieving efficient thermal management in electronic systems. This comprehension not only enhances efficiency but also contributes to energy conservation, reducing operational expenses and extending equipment lifespan.

Notably, actual airflow for most forced air ventilation applications is typically about half of the fan’s maximum airflow, underscoring the importance of selecting the appropriate operating point. Case studies, such as ‘Variable Speed Fan and Variable Setup,’ illustrate that engineers who effectively utilize fan efficiency curves can significantly enhance energy management and overall system efficiency, making these insights indispensable in the design and implementation of cooling solutions.

Furthermore, it is crucial to recognize that the common belief regarding a 1.5 in. WC static pressure setpoint as optimal can lead to inefficiencies, highlighting the necessity for a comprehensive understanding of static pressure in assessing fan efficiency.

As Mike Turner wisely noted, ‘It is best to choose a fan that will provide an operating point leaning toward the high flow, low pressure end of the efficiency curve to maintain propeller effectiveness and to prevent propeller stall.

Static Pressure: Key to Evaluating Fan Performance

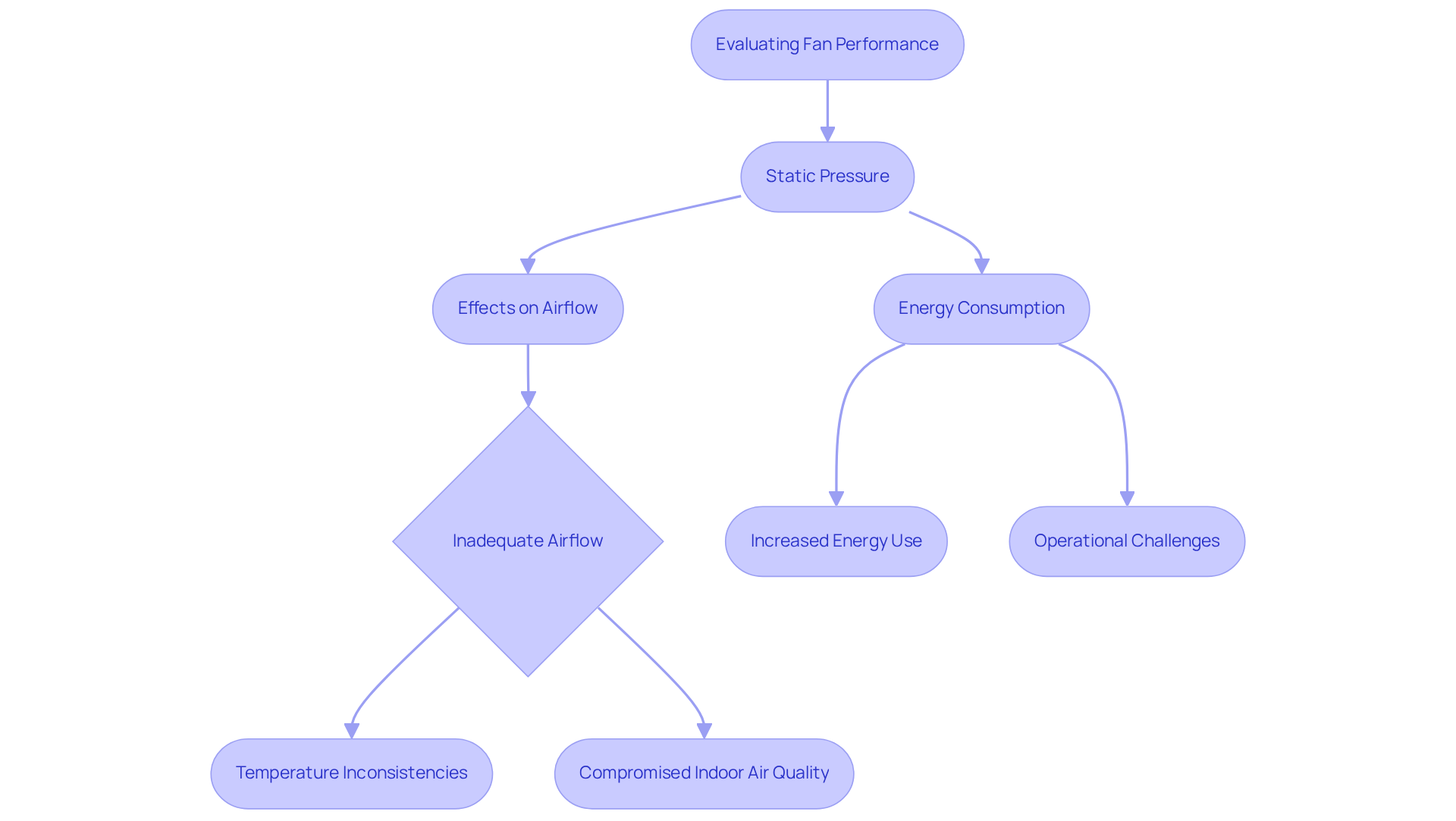

Static pressure signifies the resistance a fan must surmount to facilitate air movement through a network, establishing it as a critical metric for assessing fan functionality. This parameter directly impacts both airflow and efficiency; elevated static pressure frequently results in increased energy consumption and possible operational challenges. Engineers are tasked with meticulously evaluating the static pressure requirements of their systems when selecting blowers. Insufficient static pressure may lead to inadequate airflow, culminating in temperature inconsistencies and compromised indoor air quality.

For example, a 12-inch fan typically achieves approximately 1,654 CFM at 0.05 inH O static pressure, yet this capacity can diminish considerably as static pressure escalates. Gagner-Toomey Associates offers an extensive range of DC input Tube Axial units and Centrifugal Blowers, optimized for performance and efficiency, specifically designed to tackle static pressure challenges across various applications.

Grasping the static pressure curve is vital for engineers, as it facilitates informed choices regarding fan efficiency curves and overall system design. By analyzing fan operation metrics, such as the ventilation efficiency rate (VER)—which for a 12-inch fan at 0.05 inH O is 8.73 cfm/W—engineers can ensure that the selected fans from Gagner-Toomey align with specific application requirements while maximizing energy efficiency.

To realize reliable and efficient temperature regulation solutions, engineers should evaluate static pressure in conjunction with airflow metrics and consider Gagner-Toomey’s innovative air-movers tailored for diverse applications. This approach will aid in securing optimal performance and energy efficiency in refrigeration units.

Air Volume (CFM): Maximizing Efficiency in Fan Design

Air volume, measured in Cubic Feet per Minute (CFM), serves as a critical metric that quantifies the volume of air a fan can move in one minute. Maximizing CFM is essential for effective cooling in electronic systems, as it directly influences the fan’s capability to dissipate heat. For instance, a control cabinet generating 400 Watts of heat necessitates a blower or a set of blowers capable of delivering at least 64 CFM to maintain optimal temperatures. Engineers must meticulously evaluate the CFM requirements tailored to their applications when selecting fans, ensuring that the chosen model can provide adequate airflow to avert overheating. Furthermore, it is imperative to keep the maximum internal temperature below 110°F (43°C) and the maximum ambient temperature at or below 90°F (32°C) to safeguard the longevity of electronic components.

Understanding the interplay between CFM, static pressure, and fan efficiency curves is crucial for achieving the desired outcomes. As airflow increases, static pressure may also rise, which can influence the fan efficiency curves. Engineers should factor in this dynamic during the design process, as optimizing both CFM and static pressure can enhance the fan efficiency curves related to temperature regulation. For example, devices designed with blade pitch and diameter tailored to specific airflow requirements can significantly boost performance, ensuring that electronic components remain within safe operating temperatures.

Data suggests that for rooms ranging from 200 to 300 square feet, a recommended CFM range of 3,000 to 4,000 is optimal, while larger spaces exceeding 450 square feet may require between 5,000 to 9,000 CFM. Additionally, for rooms sized between 300 to 450 square feet, the recommended CFM falls between 4,000 to 6,000. This correlation between airflow and temperature regulation underscores the importance of selecting fans that not only meet CFM requirements but also align with the overall configuration of the setup. By prioritizing air volume in fan design, engineers can enhance reliability and extend the lifespan of critical electronic components.

As Eric Fitz observes, the requisite amount of air is contingent upon the heating or cooling load of the room, making it vital for engineers to calculate airflow based on these parameters. Moreover, sealing openings for fans and filters is essential to uphold IP/NEMA ratings, ensuring that the setup remains reliable and protected from dust and moisture. By applying these insights, engineers can bolster fan efficiency curves and contribute to the durability of their electronic systems.

Fan Speed: Optimizing Performance for Different Applications

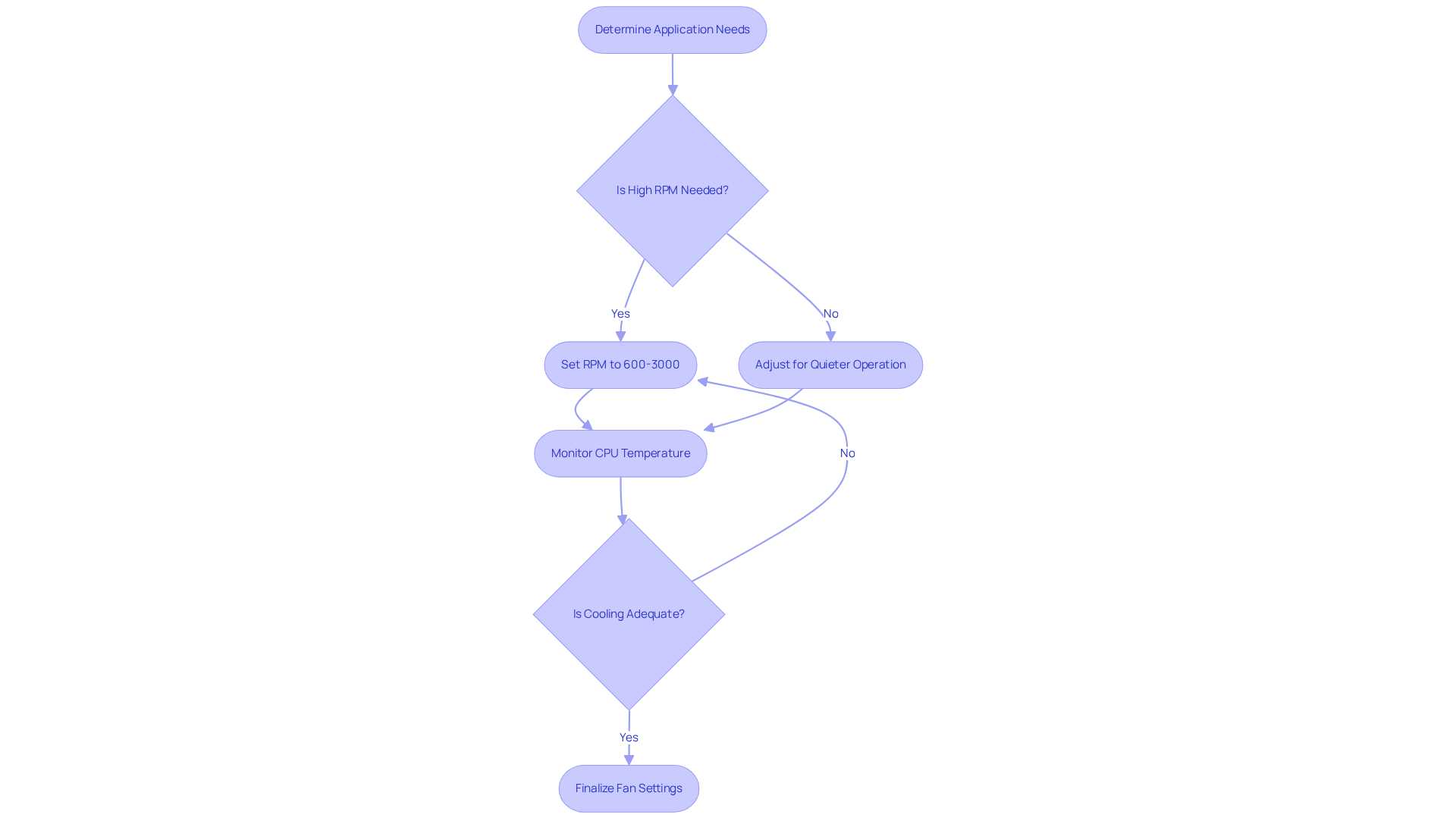

Fan speed, quantified in revolutions per minute (RPM), plays a pivotal role in defining a fan’s operational characteristics. By meticulously adjusting the fan speed, engineers can optimize airflow and static pressure to meet specific application demands.

For example, high-performance electronics often necessitate elevated speeds to ensure adequate temperature management, while lower speeds can facilitate quieter operation, thereby reducing noise pollution in sensitive environments. According to Intel, optimal fan performance generally ranges from 600 to 3000 RPM, with larger fans effectively functioning at reduced speeds while still maintaining airflow.

Adjusting the fan speed not only affects cooling efficiency but also influences power consumption and noise levels. Rakesh Sharma highlights that insufficient fan speed can lead to CPU overheating, resulting in throttling or potential damage; conversely, excessive speeds may cause increased noise and higher power usage.

Therefore, understanding and fine-tuning fan speed, alongside fan curves, is essential for achieving optimal performance in electronic devices. It is crucial to monitor CPU temperature using software tools to make informed adjustments to fan speed, ensuring a harmonious balance between cooling efficiency and noise levels, which is vital for preserving system integrity and longevity.

Choosing the Right Fan: Applying Fan Curve Data Effectively

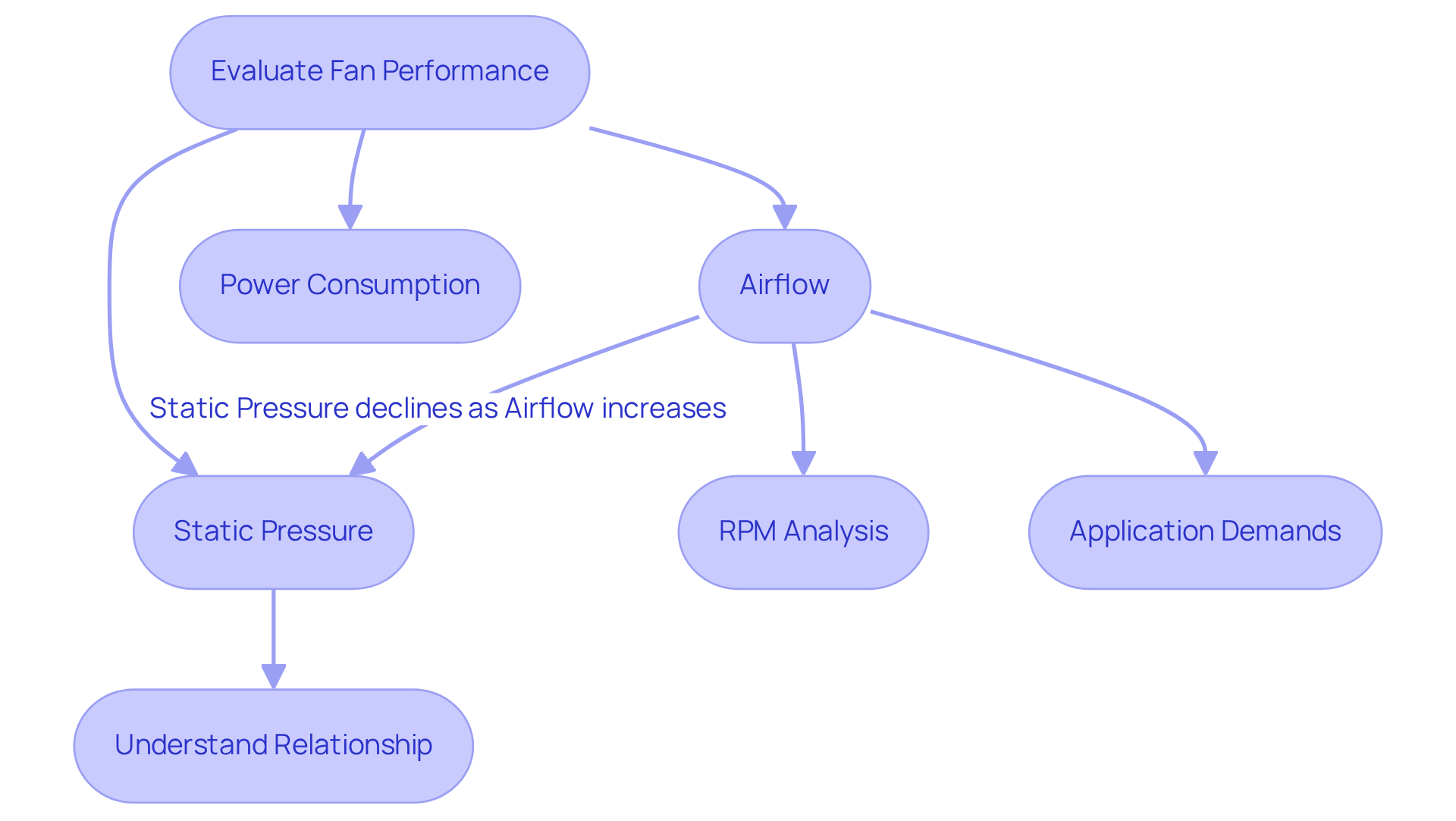

Selecting the appropriate fan requires a thorough examination of fan efficiency curves to ensure that the fan’s attributes align with the specific demands of the application. Engineers must prioritize critical factors such as:

- Airflow

- Static pressure

- Power consumption

It is important to understand that static pressure generally declines as airflow increases, which is essential for grasping fan performance. By analyzing fan efficiency curves at various RPMs, engineers can identify the most suitable fan for their configurations, ensuring optimal performance across different conditions. This analytical approach is vital for achieving effective thermal management, enhancing overall efficiency, and addressing the unique temperature control requirements of diverse applications.

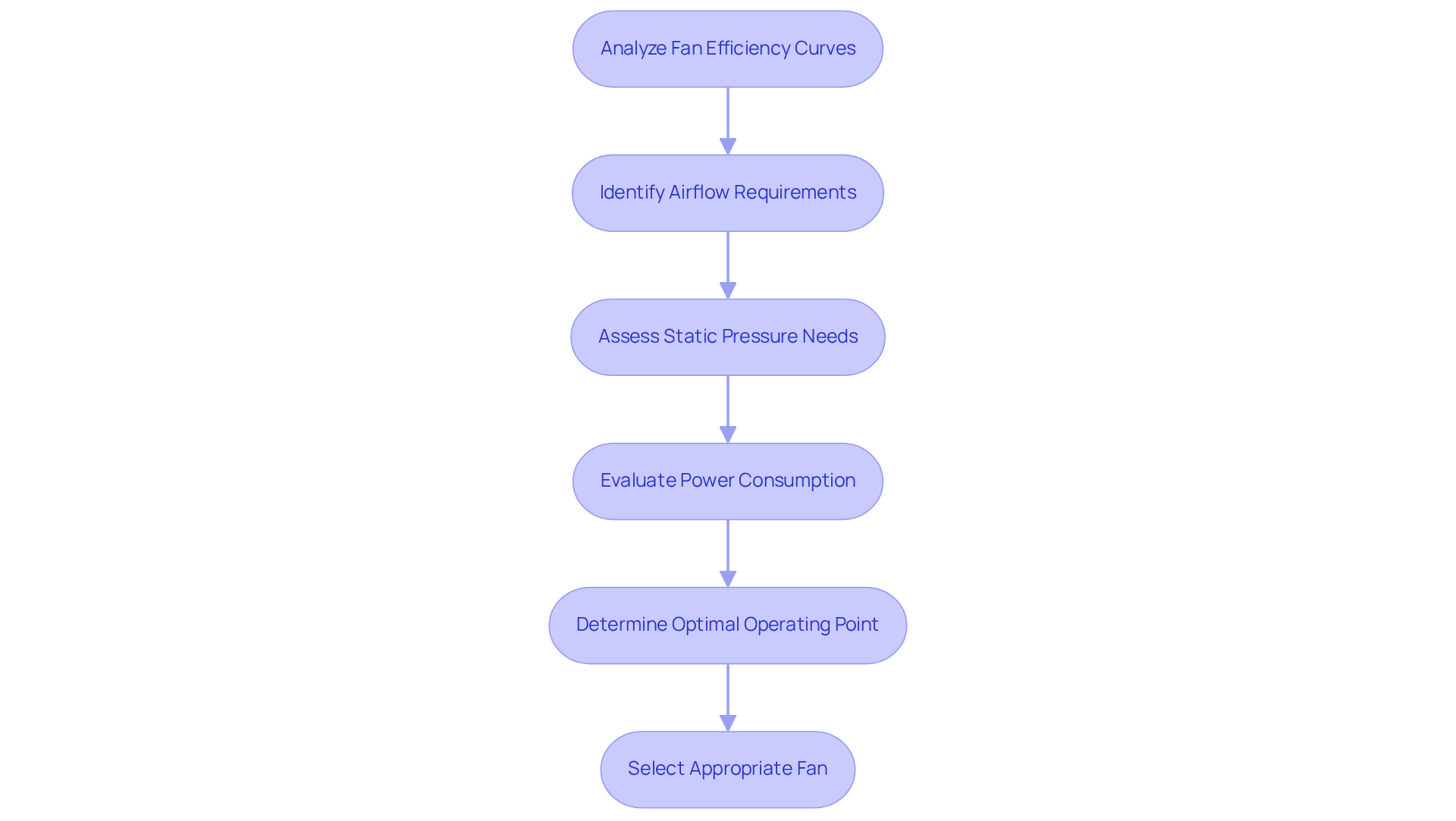

Analyzing Fan Curves: Matching Performance with Application Needs

Analyzing fan efficiency curves is essential for understanding the intricate relationship between airflow, static pressure, and power consumption. This examination ensures that the selected fan aligns perfectly with the specific needs of the application. Engineers must identify the optimal operating point on the fan efficiency curves, ensuring that the fan can effectively deliver the necessary airflow while simultaneously minimizing energy consumption. Such analysis is not merely beneficial; it is crucial for circumventing potential issues like inadequate cooling or excessive energy expenditure. Ultimately, this leads to the development of more efficient system designs, reinforcing the importance of meticulous analysis of fan efficiency curves.

Types of Fan Curves: Understanding Variations Across Designs

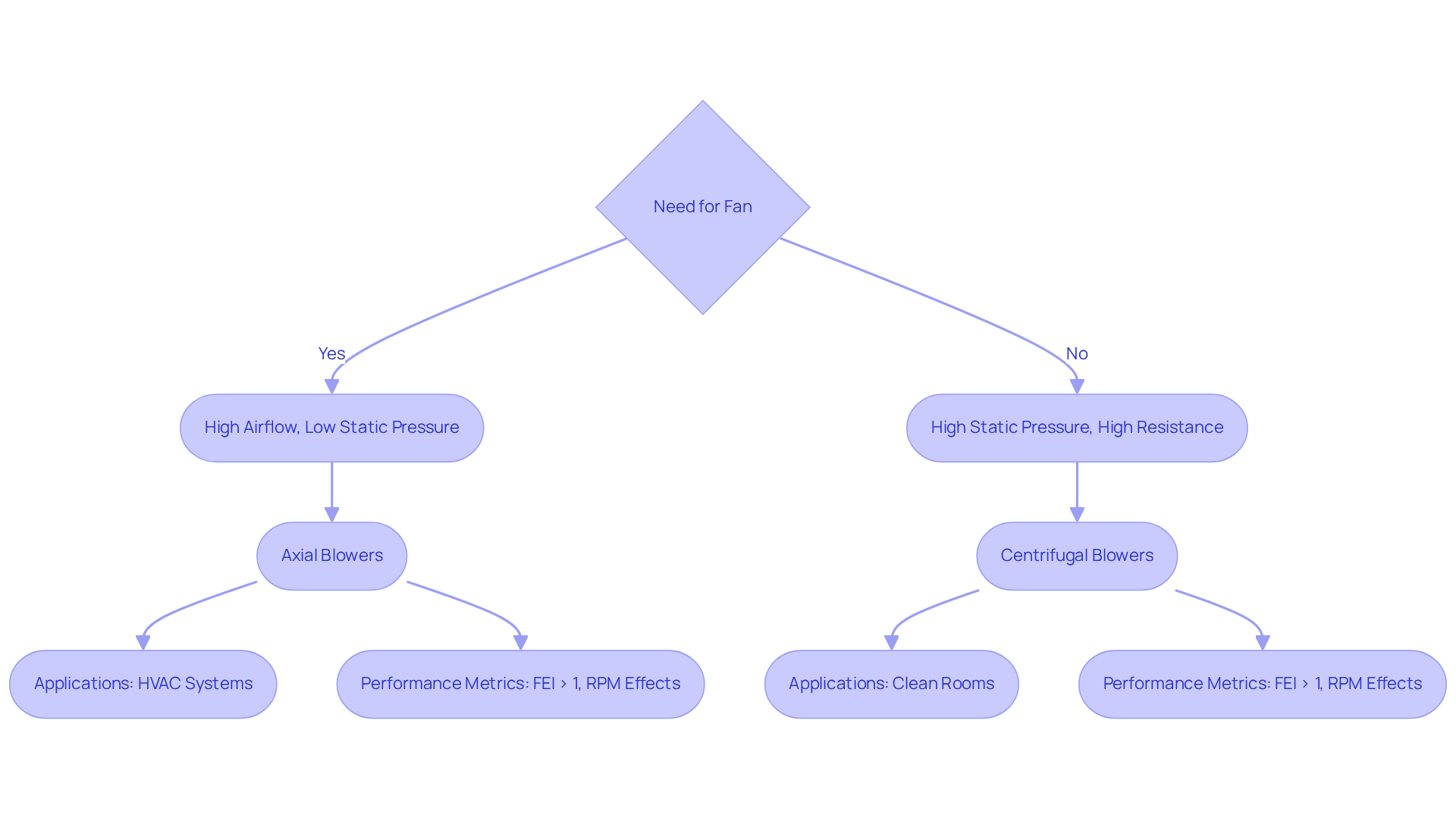

Blower curves serve as essential instruments for engineers, illustrating the performance traits of various blower designs, particularly axial and centrifugal types. Each fan curve unveils unique relationships between airflow and static pressure, which are critical for selecting the appropriate fan for specific applications. Axial blowers typically demonstrate greater airflow at reduced static pressures, making them ideal for scenarios that require high volume but lower resistance. Conversely, centrifugal blowers excel in generating higher static pressures, suitable for environments with significant airflow resistance, such as ducted systems.

Understanding these distinctions empowers engineers to optimize cooling solutions effectively. For instance, in HVAC systems, axial blowers are frequently employed for general ventilation, while centrifugal blowers are preferred for applications necessitating precise airflow regulation, such as in clean rooms or industrial processes.

Data indicates that fans with an FEI (Fan Energy Index) exceeding 1 are more efficient than baseline models, underscoring the importance of selecting the right fan type to enhance energy efficiency. An FEI greater than 1 is generally the minimum criterion for fan selection, highlighting the necessity for engineers to prioritize efficiency in their decisions. Moreover, a 10% reduction in RPM results in a 10% decrease in airflow (CFM), a crucial consideration when evaluating fan efficiency.

By mastering the intricacies of fan efficiency curves, including stall regions and their efficiency characteristics, engineers can make informed decisions that not only improve performance but also reduce operational costs and energy consumption. The system line plays a pivotal role in determining the fan’s operating point, further assisting engineers in optimizing their designs.

Practical Tips for Engineers: Making Informed Decisions on Fan Efficiency

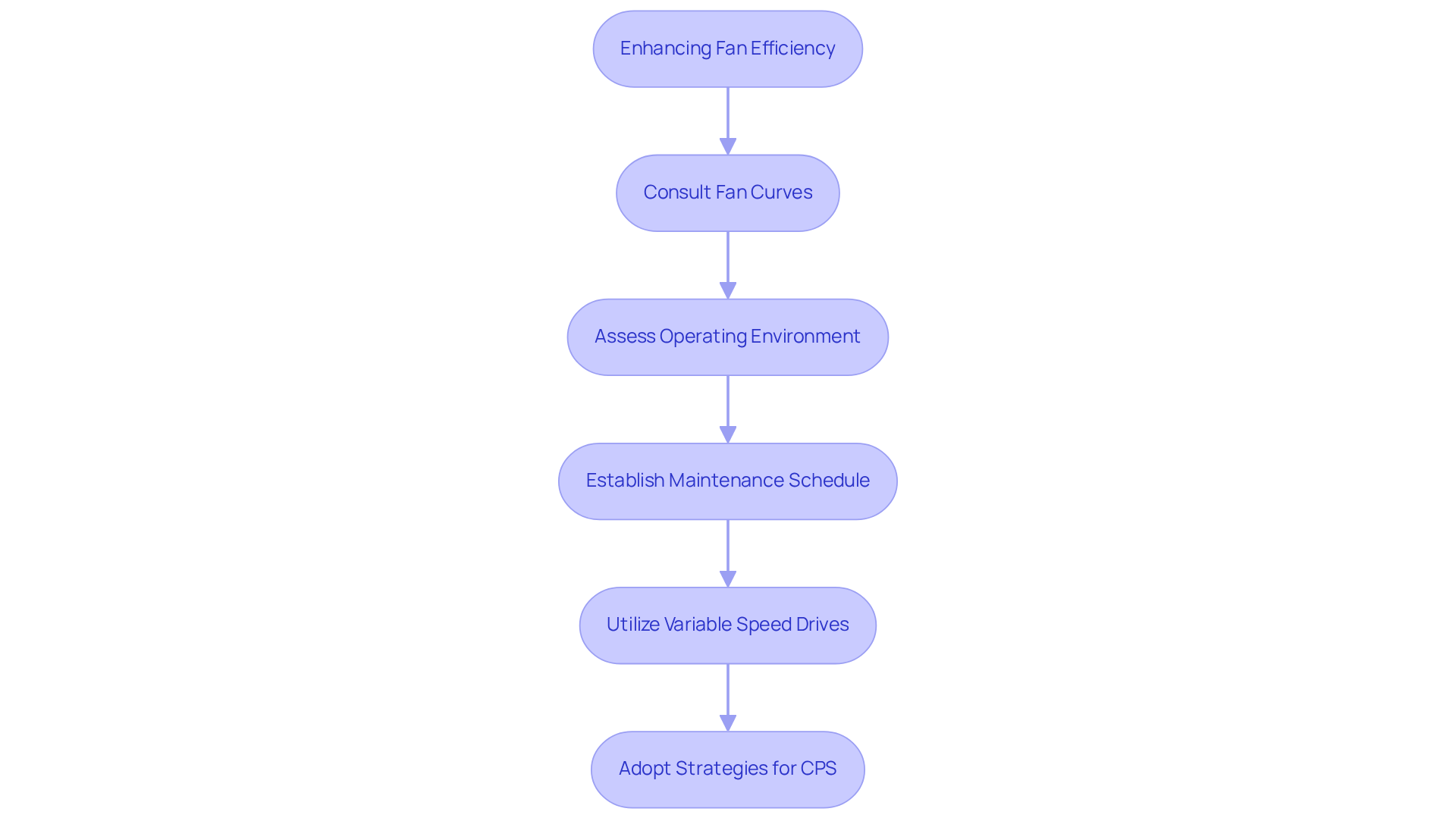

Engineers can significantly enhance fan efficiency curves by implementing the following practical strategies:

- Always consult fan curves during selection to ensure alignment with the specific airflow and pressure requirements of the application. As Deaton states, “Our design supports extreme, high-density computing blades consuming up to 6,000 watts per blade,” underscoring the critical necessity for effective temperature management in high-power environments.

- Assess the operating environment and identify any potential obstructions that could impede airflow.

- Establish a regular maintenance schedule to prevent dust accumulation, which can hinder performance; regular maintenance is essential for optimal fan operation.

- Utilize variable speed drives to dynamically adjust fan speed based on real-time temperature requirements, thereby improving energy efficiency.

By adopting these strategies, engineers can markedly enhance the efficiency of their refrigeration setups, particularly within Cyber Physical Systems (CPS), which facilitate real-time adjustments and monitoring.

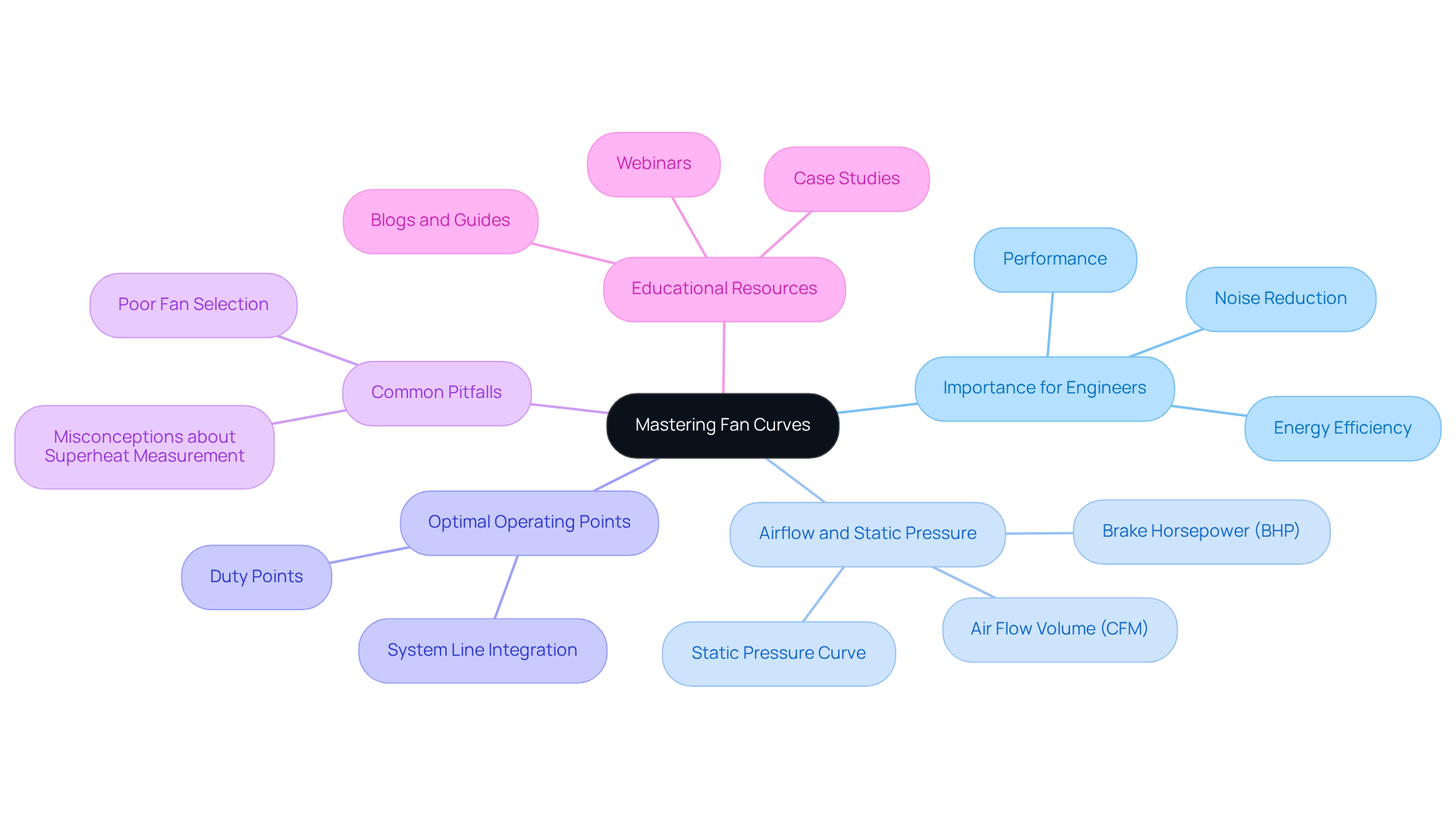

Mastering Fan Curves: Essential Knowledge for Every Engineer

Mastering fan efficiency curves is crucial for engineers involved in designing and implementing temperature regulation solutions. A comprehensive understanding of how to read and interpret fan efficiency curves empowers engineers to make informed decisions that significantly enhance both performance and energy efficiency.

For instance, grasping the relationship between airflow, static pressure, and fan speed enables engineers to pinpoint the ideal operating point, thus ensuring that temperature control solutions are both effective and sustainable. As noted by Gagner-Toomey Associates, mastering fan profiles and understanding fan efficiency curves allows engineers to identify the optimal operating point for a cooling setup, guaranteeing effective fan performance without unnecessary noise.

This expertise not only facilitates the selection of suitable fans but also alleviates common pitfalls associated with poor fan selection, which can result in inefficiencies and increased operational costs. Additionally, there are prevalent misconceptions regarding superheat measurement on TXV systems, which can also be relevant to the analysis of fan efficiency curves, underscoring the necessity for precise understanding in engineering practices.

Furthermore, familiarity with fan PWM controllers is vital for efficient fan management. Statistics indicate that a considerable percentage of engineers lack confidence in their understanding of fan effectiveness metrics, highlighting the importance of ongoing education in this domain.

By incorporating fan efficiency curves into their design processes, engineers contribute to technological advancement in the electronics industry, promoting innovation and sustainability in their projects. To enhance their designs, engineers should proactively seek resources and training on fan performance metrics.

Conclusion

Mastering fan efficiency curves is crucial for engineers aiming to optimize thermal management solutions in electronics. A comprehensive understanding of these curves facilitates informed decisions that enhance both performance and energy efficiency, ultimately fostering more sustainable engineering practices.

This article has delved into key insights regarding fan efficiency curves, highlighting the importance of:

- Static pressure

- Airflow (CFM)

- Fan speed

in achieving optimal performance. By analyzing these metrics, engineers are empowered to select the appropriate fan for specific applications, ensuring effective cooling and energy conservation. Furthermore, practical strategies for enhancing fan efficiency have been underscored, particularly the significance of:

- Regular maintenance

- Implementation of variable speed drives

As the demand for efficient temperature regulation solutions escalates, engineers are urged to harness their expertise in fan efficiency curves to spearhead innovation within the electronics industry. By embracing best practices and remaining abreast of advancements in fan technology, professionals can contribute to improved system designs that not only fulfill performance requirements but also advance sustainability in engineering projects.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates specializes in advancing fan efficiency curves within the electronics sector, focusing on thermal, power, RF, interconnect, and electromechanical solutions to develop innovative temperature control strategies.

How can effective temperature control strategies impact energy consumption?

Effective temperature control strategies can reduce overall energy consumption by up to 45%, particularly in refrigeration systems, which account for 30-40% of total energy usage in typical data centers.

What is the projected growth of the global data center temperature regulation market?

The global data center temperature regulation market is projected to grow from USD 11.08 billion in 2025 to USD 24.19 billion by 2032, with a compound annual growth rate (CAGR) of 11.8%.

Why are fan efficiency curves important for engineers?

Fan efficiency curves are essential as they illustrate the relationship between airflow, static pressure, and power consumption for specific fans, helping engineers identify the optimal operating point for efficient thermal management.

What is the common misconception regarding static pressure setpoints?

A common misconception is that a 1.5 in. WC static pressure setpoint is optimal, which can lead to inefficiencies; understanding static pressure is crucial for assessing fan efficiency.

What role does static pressure play in fan performance evaluation?

Static pressure indicates the resistance a fan must overcome to move air, impacting airflow and efficiency. Elevated static pressure can lead to increased energy consumption and operational challenges.

How does Gagner-Toomey Associates address static pressure challenges?

Gagner-Toomey Associates offers a range of DC input Tube Axial units and Centrifugal Blowers optimized for performance and efficiency, specifically designed to tackle static pressure challenges across various applications.

What is the ventilation efficiency rate (VER) for a 12-inch fan at 0.05 inH O static pressure?

The ventilation efficiency rate (VER) for a 12-inch fan at 0.05 inH O static pressure is 8.73 cfm/W.

What should engineers consider when selecting fans for their systems?

Engineers should evaluate static pressure alongside airflow metrics and consider Gagner-Toomey’s innovative air-movers to ensure optimal performance and energy efficiency in refrigeration units.