Overview

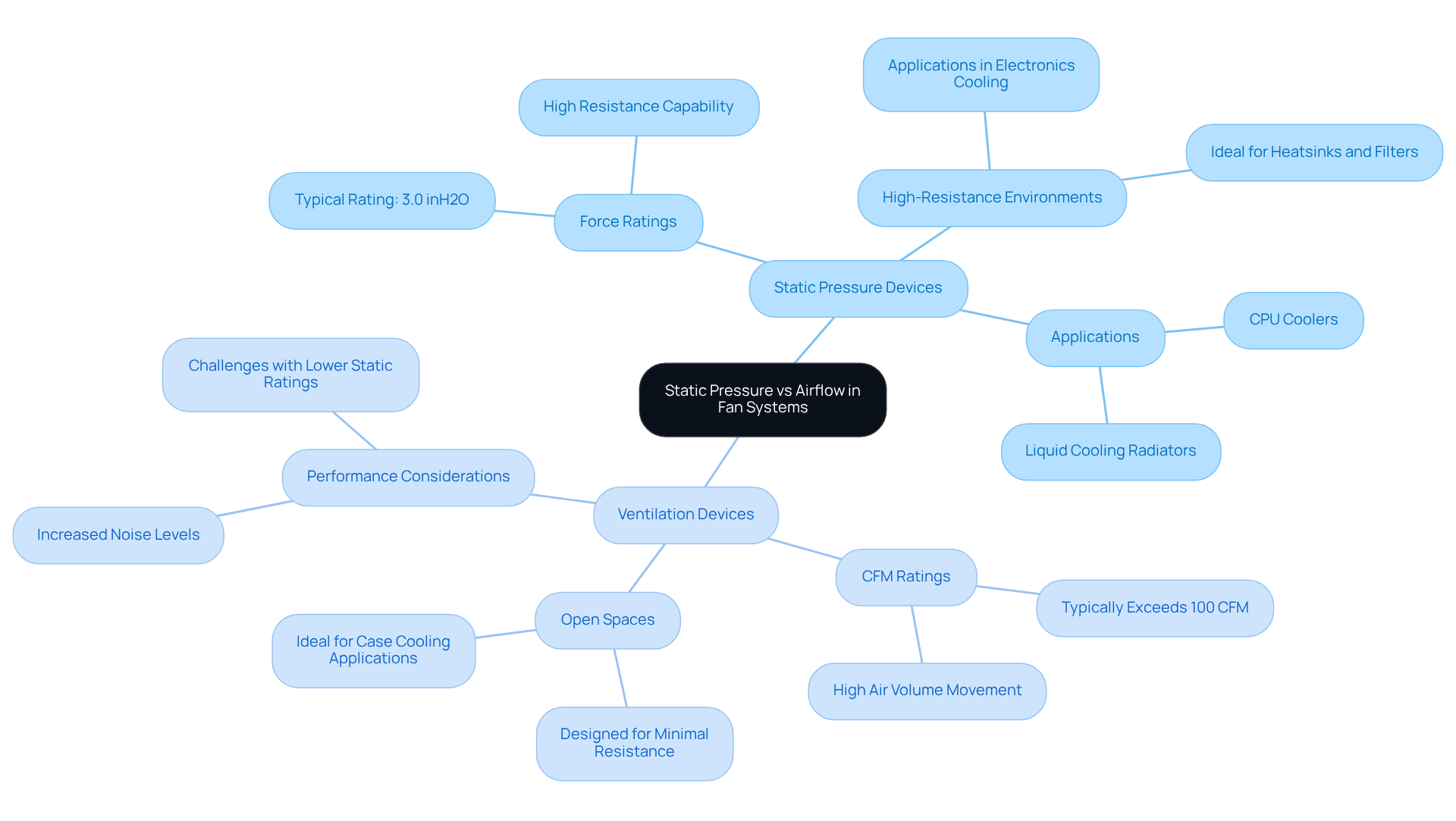

The article presents essential insights into static pressure and airflow within fan systems, emphasizing their unique roles and implications for engineering design. It establishes that static pressure fans are crucial for overcoming resistance in high-resistance environments, while airflow fans are specifically optimized for moving large volumes of air in open spaces. This distinction guides engineers in selecting the appropriate fan type tailored to specific application needs.

Introduction

Understanding the intricate balance between static pressure and airflow is crucial for engineers navigating the complexities of fan systems. As the demand for efficient cooling solutions escalates across various industries, the ability to optimize fan performance can lead to significant energy savings and enhanced equipment longevity. However, misconceptions abound regarding the roles of static pressure and airflow, often complicating the decision-making process.

How can engineers effectively leverage these insights to design systems that not only meet performance criteria but also address the unique challenges posed by modern electronic applications?

Gagner-Toomey Associates: Expert Solutions for Fan System Performance

stands at the forefront of delivering within the electronics industry. By partnering with a diverse array of manufacturers, including those in Telecom, Automotive, IoT, and Medical sectors, the company empowers that substantially enhance . Their tailored solutions effectively tackle , solidifying their reputation as a .

With a , Gagner-Toomey Associates possesses a , fostering enduring relationships with clients. This unwavering commitment to innovation and excellence positions them prominently in the , ensuring that engineers can confidently meet the challenges presented by modern electronic applications.

Define Static Pressure in Fan Systems

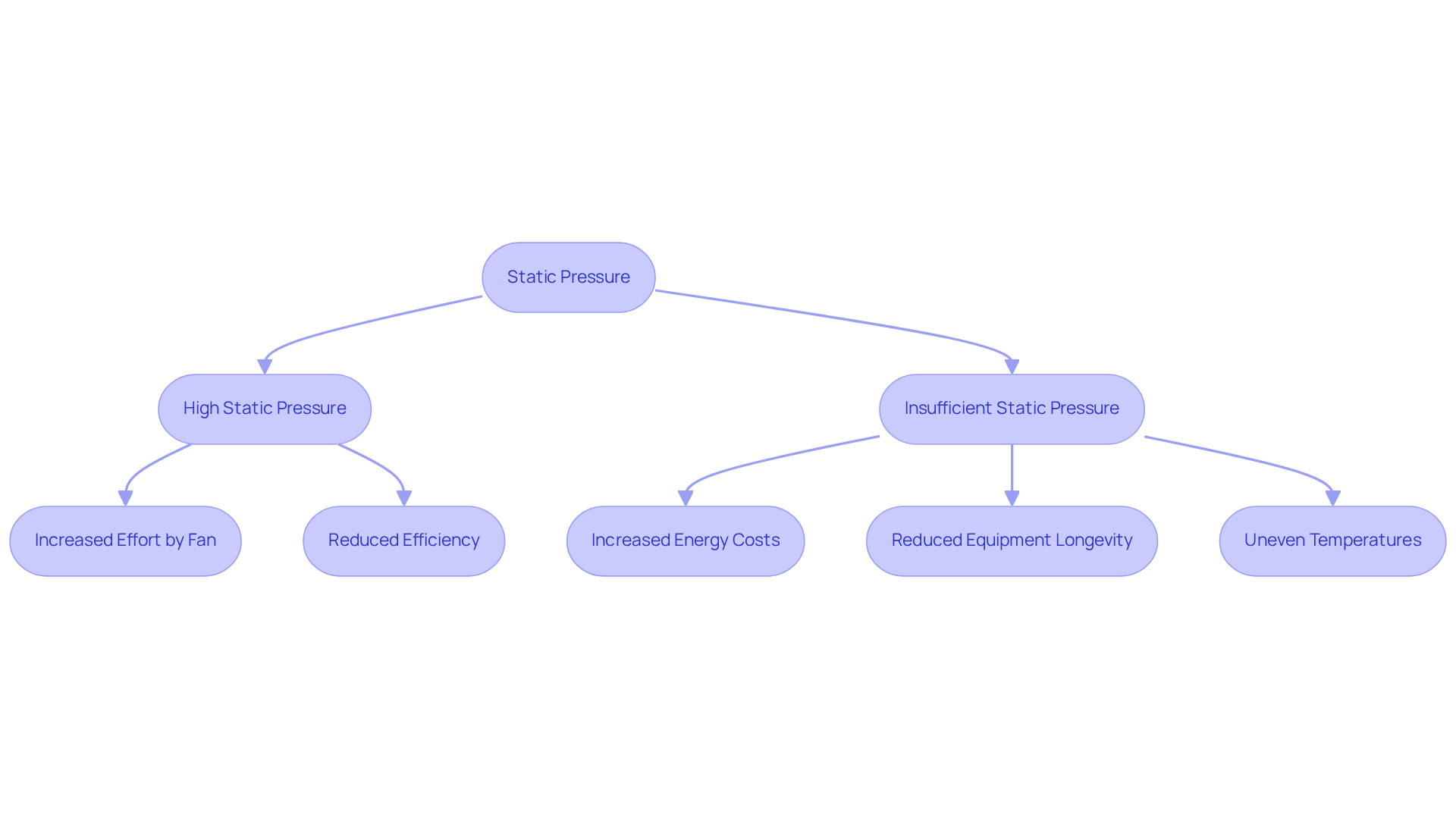

signifies the resistance encountered by air as it traverses ducts and other components. Measured in inches of water gauge (in. wg), inches of water column (in. wc.), or pascals (Pa), it represents the force exerted by the air in all directions within the system. A high indicates that the fan must exert greater effort to push air through, which can adversely affect and performance.

Understanding the concept of is essential for engineers when selecting fans for specific applications, especially in environments with significant . Insufficient static force can lead to increased due to excessive wear and tear.

Moreover, issues related to static airflow can result in uneven temperatures and elevated noise levels in . Therefore, are critical strategies to sustain optimal static force and operational effectiveness.

Define Airflow in Fan Systems

in fan setups is defined as the volume of air that a fan can move within a specific time frame, typically measured in cubic feet per minute (CFM). This metric is crucial for determining how effectively a fan can . Unlike fixed resistance, which gauges opposition, the movement of air quantifies the actual flow.

Engineers must consider the relationship between when designing systems to ensure that the selected fan meets the necessary performance criteria. In the electronics sector, are especially vital, as they directly and equipment reliability.

For instance, frequently require that can reach up to 17,000 m³/h, underscoring the necessity for accurate calculations. can lead to , significantly enhancing operational efficiency. Engaging with industry specialists can further refine ventilation calculations, ensuring optimal performance in cooling applications.

As one engineer remarked, ‘You can always include baseboards for extra warmth, but that seems incorrect after putting in all this effort,’ emphasizing the importance of achieving proper ventilation from the outset. Furthermore, is essential to confirm that cooling units are functioning correctly and not emitting harmful gases or vapors.

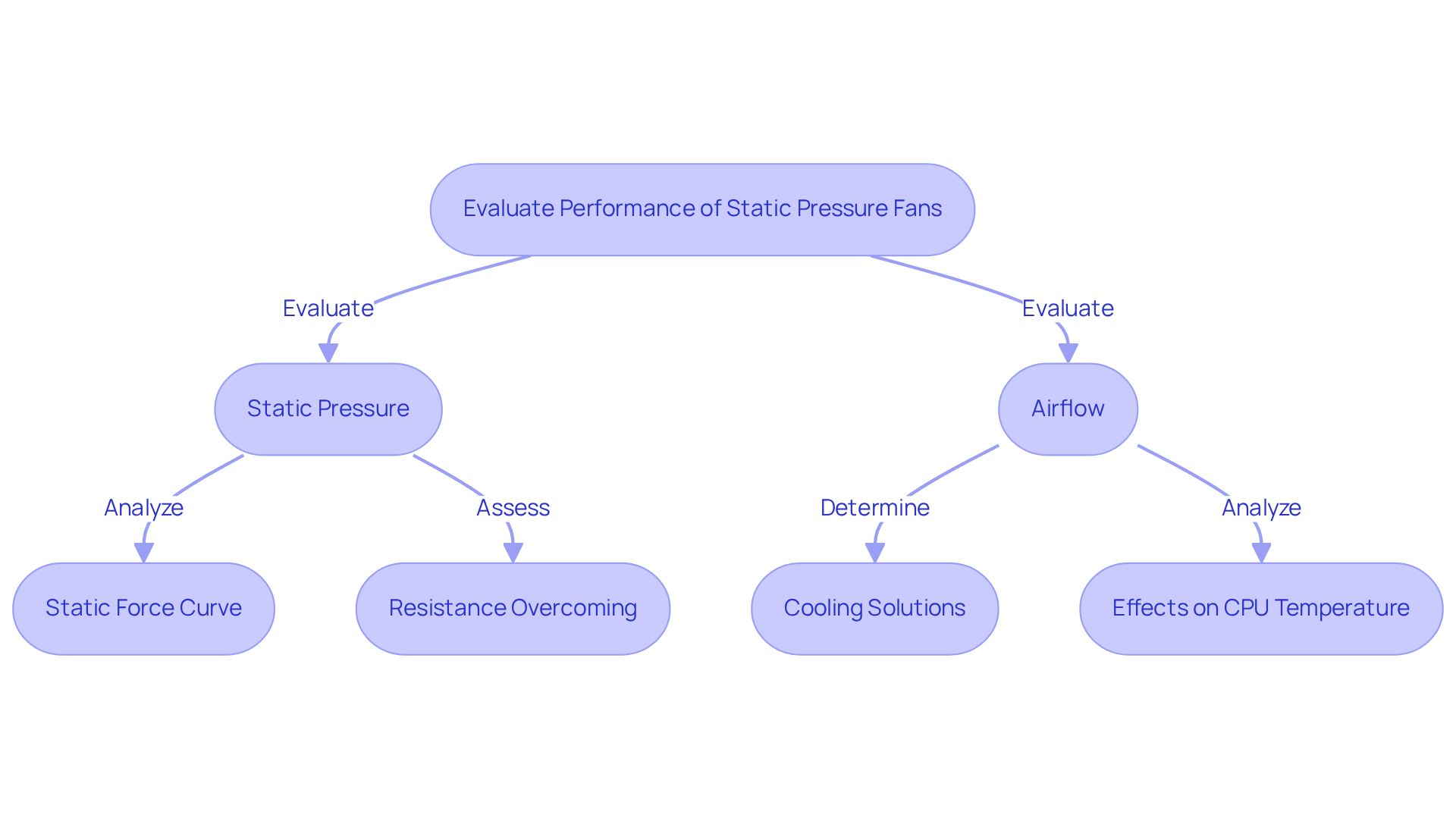

Evaluate Performance of Static Pressure Fans

where air movement is limited, such as ducted systems or during air transfer through filters and radiators. Their performance is primarily evaluated based on their ability to generate substantial while ensuring sufficient air movement. Key performance indicators include the fan’s static force curve, which demonstrates how force varies with different flow rates. to ascertain that the selected fan can effectively surmount the resistance encountered in their specific applications.

In high-resistance scenarios, can maintain than their circulation counterparts in radiator configurations, underscoring their efficacy. Furthermore, these devices prove particularly beneficial in setups featuring filters or heatsinks, where airflow is often impeded. Understanding the is essential for engineers, as it directly influences the selection of appropriate fan configurations for .

Assess Performance of Airflow Fans

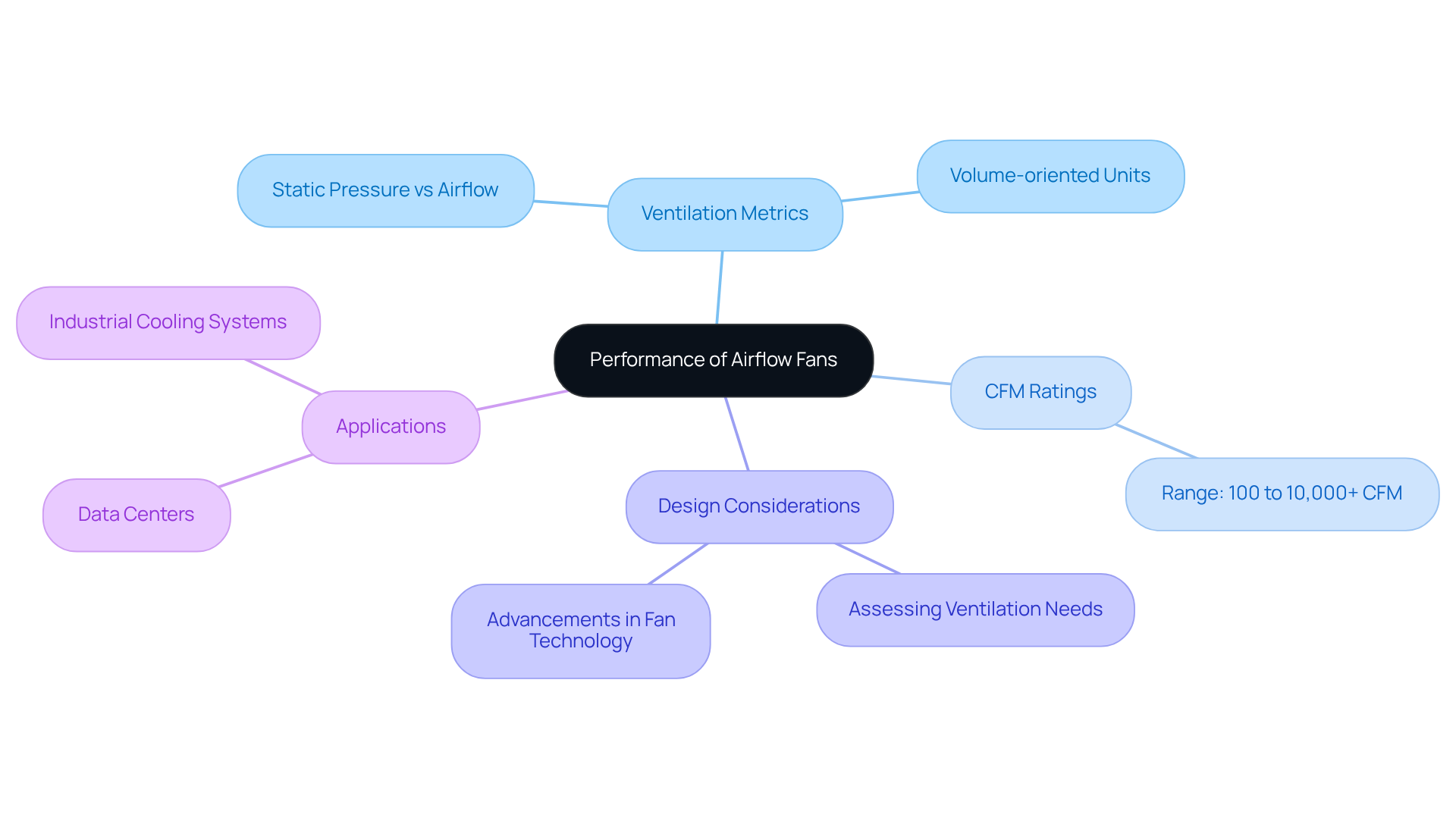

play a crucial role in applications that require the rapid transfer of significant air volumes, particularly in open environments and cooling systems with minimal resistance. Their effectiveness is primarily evaluated through , especially (CFM), which reflects their capacity to sustain consistent circulation under varying conditions.

For instance, standard CFM ratings for ventilation devices in electronic applications can range from 100 to over 10,000 CFM, depending on the specific requirements of the system. In contrast to , which excel in high-resistance environments, volume-oriented units are designed to prioritize capacity over pressure, making them less effective in such conditions.

Therefore, the of their systems when selecting these devices to ensure optimal performance. Recent advancements in fan technology have resulted in , further bolstering their efficacy across diverse applications.

, such as in data centers and industrial cooling systems, demonstrate their capability to maintain performance while adapting to fluctuating environmental conditions. To accurately assess in fan systems, engineers should consider not only the CFM ratings but also the relationship of static pressure vs airflow and the unique requirements of the application.

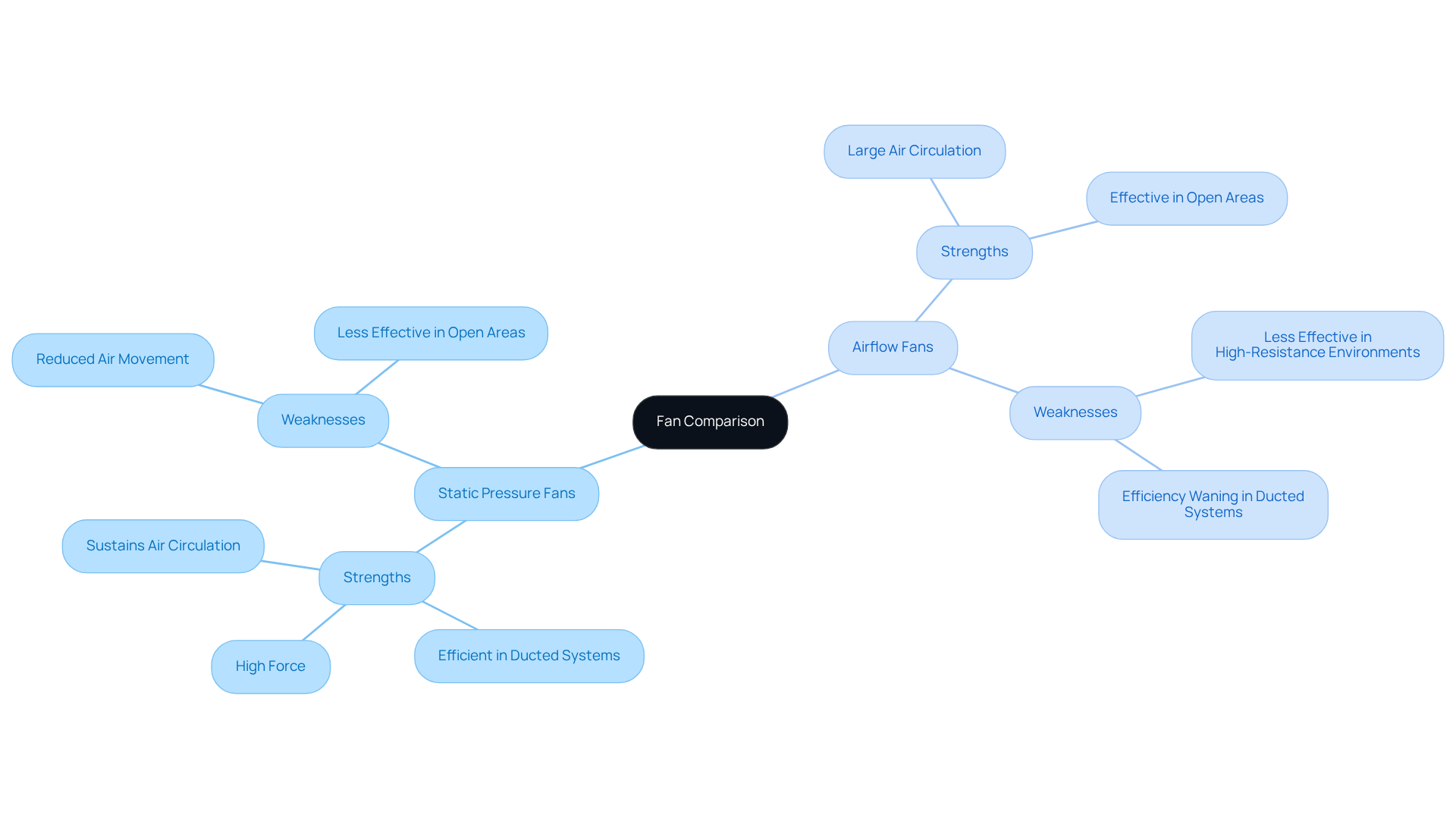

Compare Strengths and Weaknesses of Static Pressure vs Airflow Fans

are specifically engineered for applications necessitating high force to overcome resistance, rendering them particularly efficient in ducted systems and environments equipped with filters. Their primary advantage lies in their ability to sustain , even against significant resistance; however, this often leads to diminished air movement compared to circulation devices.

For example, (RTO) can achieve of up to 97%, demonstrating the effectiveness of static airflow devices in . In contrast, excel in scenarios requiring extensive air circulation, particularly in open areas with minimal obstruction. While they are adept at moving large volumes of air, their efficiency wanes in high-resistance environments, where prove more effective.

As Anguil states, “RTO offers lower capital and operating costs at process exhaust flows of 5,000 SCFM or larger,” underscoring the critical nature of for specific operational demands. For engineers, understanding these strengths and weaknesses is vital for choosing the most suitable fan type tailored to distinct operational needs.

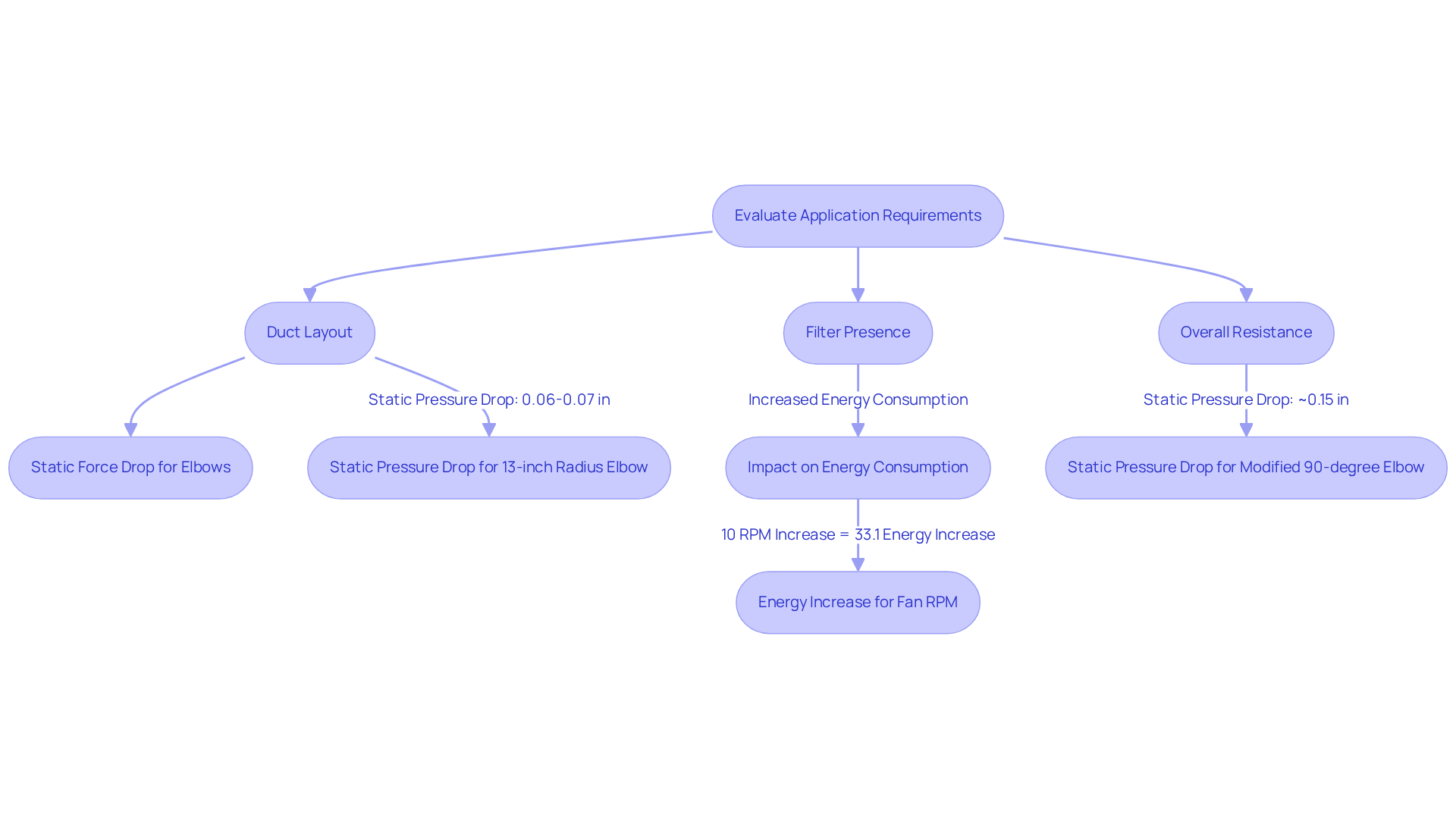

Implications of Static Pressure vs Airflow on System Design

The connection between is paramount in design, significantly influencing performance and . Engineers must meticulously evaluate the specific requirements of their applications, taking into account factors such as .

For instance, the for a 13-inch radius elbow is approximately .06-.07 inches, while a modified 90-degree elbow can result in a drop nearing .15 inches. An optimally designed setup achieves a harmonious balance between sufficient airflow and requisite static pressure vs airflow, which is critical for efficient operation.

Neglecting these factors can lead to diminished performance, heightened energy consumption, and potential failures within the system. Notably, increasing a fan’s RPM by 10% necessitates a 33.1% rise in energy, underscoring the importance of .

Therefore, during the design phase are vital to ensure that systems operate efficiently and sustainably. , particularly the significance of selecting fans tailored to specific applications, to enhance both performance and reliability in their projects.

As Charlie Vollhaber, Executive Vice President & Officer, articulates, ‘We believe in equipping our team members with the right tools and resources to succeed.’ This mindset is crucial for achieving .

Debunk Common Misconceptions About Static Pressure and Airflow

Misinterpretations related to and the movement of air can significantly obstruct . A prevalent misconception is that heightened ventilation directly correlates with improved performance. This viewpoint overlooks the essential function of , especially in high-resistance settings where the movement of air may be restricted. For instance, in applications with complex ductwork or filters, vs airflow is essential, as relying solely on airflow metrics can lead to inefficiencies and suboptimal performance. According to industry experts, “If you purchase a heating or cooling system that is too large for your home, it will essentially short-cycle, which is frequently turning on and off,” underscoring the importance of .

Another is that static pressure devices are ineffective at moving air. Contrary to this notion, these fans are specifically designed to excel in overcoming resistance, which is crucial in understanding static pressure vs airflow when circulation is hindered. For instance, in , utilizing the appropriate fan type can significantly and operational efficiency. A case study illustrates that numerous homeowners wrongly assume that shutting vents in unoccupied rooms will lower heating and cooling expenses; however, this disrupts the balanced circulation intended in contemporary HVAC setups, resulting in heightened strain on the equipment.

Statistics reveal that misconceptions about fan performance can lead to design choices that result in increased . For example, large setups can short-cycle, leading to inconsistent temperatures and increased humidity levels. Engineers must be informed about these misconceptions to ensure that fan systems are designed by considering static pressure vs airflow, ultimately maximizing performance and efficiency. By addressing these common misconceptions, engineers can that enhance the reliability and effectiveness of their designs.

![]()

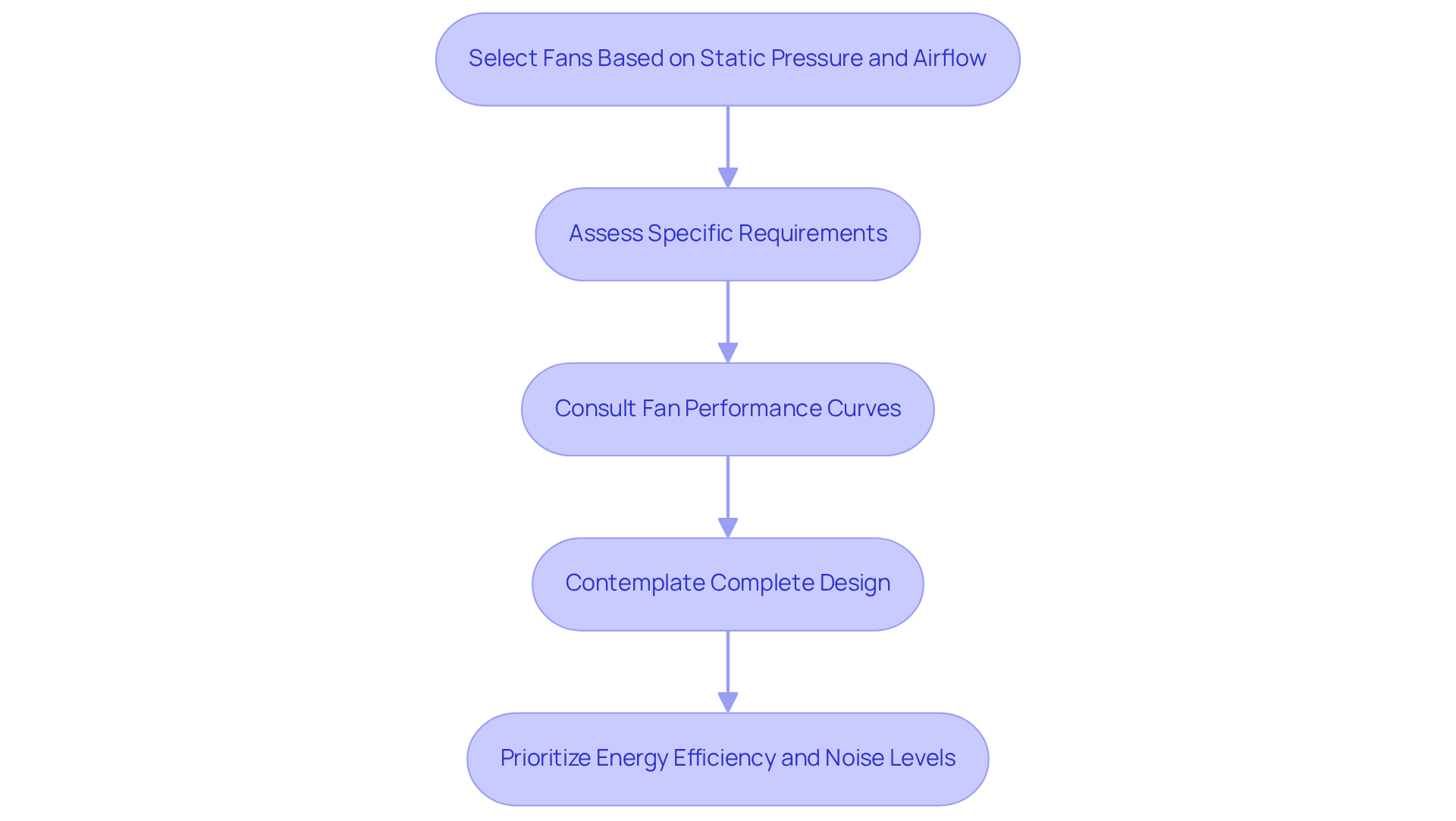

Best Practices for Selecting Fans Based on Static Pressure and Airflow

When selecting blowers based on and air movement, to several .

- It is essential to assess the , including the expected static pressure vs airflow and resistance levels. This initial evaluation sets the foundation for .

- Consulting is crucial to understand how different fans will operate under varying conditions, allowing for an informed selection process.

- Engineers should contemplate the complete design of the setup, including duct arrangements and potential obstacles that could .

- Prioritizing and noise levels is vital, as these elements significantly influence both performance and user satisfaction.

By following these , engineers can effectively meet the demands of their applications.

Key Takeaways on Static Pressure vs Airflow in Fan Systems

In conclusion, understanding the distinctions between is crucial for engineers working with fan systems. , typically generating force ratings around 3.0 inH2O, are ideally suited for , effectively moving air through barriers such as heatsinks and filters. In contrast, , designed to maximize with minimal resistance, often achieving impressive CFM ratings exceeding 100.

Engineers must evaluate the specific requirements of their applications, including the relationship of static pressure vs airflow and resistance factors, when selecting blowers. By dispelling common myths and adhering to —such as assessing coverage area and recognizing the challenges faced by ventilation systems with lower static ratings (approximately 1.0 inH2O)—engineers can optimize their designs for enhanced performance and efficiency.

As one industry leader aptly stated, are akin to ‘the powerlifters of the PC cooling world,’ underscoring their ability to push air through dense components. This understanding is essential for successful engineering projects that depend on .

Conclusion

Understanding the intricate dynamics between static pressure and airflow is essential for engineers tasked with optimizing fan systems. This knowledge empowers professionals to select the right fans tailored to specific application requirements, ensuring that both cooling efficiency and operational performance are maximized in diverse environments.

Throughout the article, key insights were shared on the definitions, evaluations, and implications of static pressure and airflow in fan systems. Static pressure devices are highlighted for their strength in overcoming resistance, making them ideal for high-resistance applications. In contrast, airflow fans excel in open environments where volume is paramount. The significance of careful assessment and planning during the design phase was emphasized, alongside the necessity to debunk common misconceptions that can hinder effective system performance.

Ultimately, engineers are encouraged to adopt best practices when selecting fans, which include:

- Evaluating the unique demands of their applications

- Consulting performance metrics

By fostering a deeper understanding of static pressure and airflow, engineers can enhance the reliability and efficiency of their designs, paving the way for successful outcomes in engineering projects. Embracing this knowledge not only leads to superior fan system performance but also contributes to significant energy savings and sustainability in engineering practices.

Frequently Asked Questions

What services does Gagner-Toomey Associates provide?

Gagner-Toomey Associates delivers specialized solutions for fan operation performance in the electronics industry, partnering with manufacturers in sectors such as Telecom, Automotive, IoT, and Medical to enhance cooling and power management capabilities.

How experienced is the sales staff at Gagner-Toomey Associates?

The sales staff at Gagner-Toomey Associates averages over 20 years of experience, providing a profound understanding of industry needs and fostering enduring client relationships.

What is static pressure in fan systems?

Static pressure in fan systems refers to the resistance encountered by air as it moves through ducts and components, measured in inches of water gauge (in. wg), inches of water column (in. wc.), or pascals (Pa).

Why is understanding static pressure important for engineers?

Understanding static pressure is crucial for engineers when selecting fans, as insufficient static force can lead to increased energy costs, reduced equipment longevity, uneven temperatures, and elevated noise levels in HVAC units.

What is airflow in fan systems?

Airflow in fan systems is the volume of air that a fan can move within a specific time frame, typically measured in cubic feet per minute (CFM), and is critical for determining a fan’s effectiveness in cooling or ventilating a space.

How do static pressure and airflow relate to each other?

Engineers must consider the relationship between static pressure and airflow to ensure that the selected fan meets performance criteria, as they directly influence cooling effectiveness and equipment reliability.

What are the potential energy savings from effective ventilation management?

Effective ventilation management can lead to energy savings of up to 20%, significantly enhancing operational efficiency in cooling applications.

Why is regular LEV testing important?

Regular LEV (Local Exhaust Ventilation) testing is essential to confirm that cooling units are functioning correctly and not emitting harmful gases or vapors.