Introduction

The realm of industrial fan engineering is undergoing a significant transformation, propelled by cutting-edge technologies and a growing demand for energy-efficient solutions. As smart systems and advanced design tools emerge, professionals in this sector find themselves with exceptional opportunities to boost both performance and sustainability. Yet, amidst this evolution, a critical question arises: how can engineers effectively harness these vital tools to address the intricate demands of contemporary applications? This article explores ten essential tools that are revolutionizing industrial fan engineering, providing engineers with the insights needed to navigate this dynamic landscape and excel in their projects.

Gagner-Toomey Associates: Innovative Solutions for Fan Design

Gagner-Toomey Associates stands at the forefront of innovative industrial fan engineering solutions specifically tailored for the electronics sector. By partnering with a diverse range of manufacturers, the company equips professionals with access to cutting-edge technologies in cooling, power management, and interconnect solutions. This unwavering commitment to excellence empowers professionals in industrial fan engineering to develop efficient fan systems that not only meet but also surpass the demanding requirements of modern applications.

Recent advancements in motor efficiency and energy consumption are significantly enhancing product longevity. Moreover, the integration of smart technologies is transforming the user experience, making it more intuitive and responsive. As the market for sophisticated cooling solutions continues to grow, Gagner-Toomey Associates remains an essential partner in driving innovation within industrial fan engineering.

The company serves a wide array of sectors, including Telecom, IoT, Automotive, and Medical, ensuring that its solutions are relevant and impactful across various applications. With Gagner-Toomey Associates, professionals can confidently navigate the complexities of modern cooling demands.

Computational Fluid Dynamics (CFD): Optimize Fan Performance

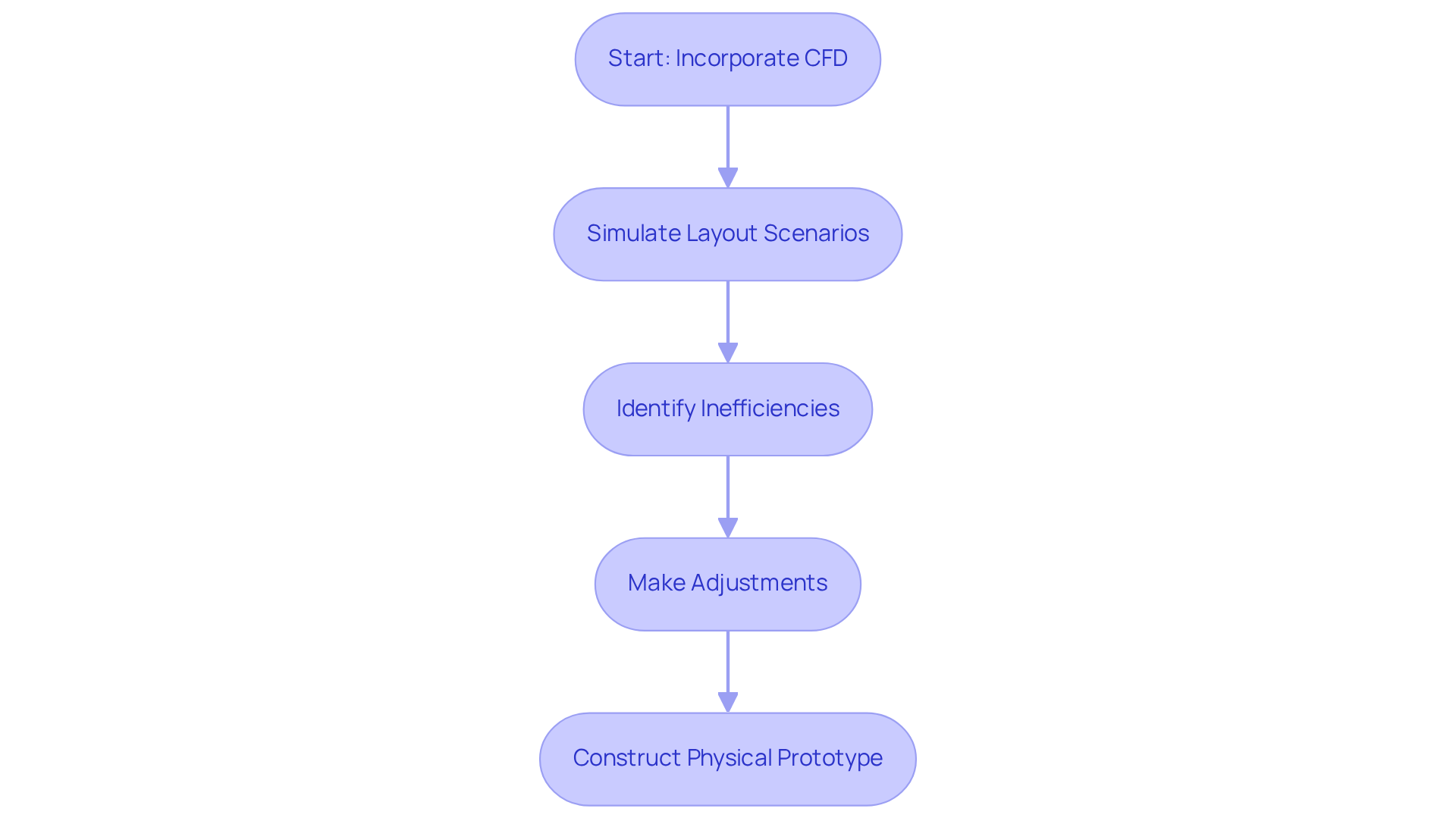

Computational Fluid Dynamics (CFD) stands as a crucial asset in industrial fan engineering, empowering engineers to visualize airflow patterns and enhance fan performance. By simulating diverse layout scenarios, CFD not only identifies potential inefficiencies but also facilitates necessary adjustments prior to the construction of physical prototypes. This proactive approach conserves both time and resources, ultimately leading to improved efficiency in fan structures.

Incorporating CFD into the industrial fan engineering design process allows engineers to make informed decisions, ensuring that each fan operates at its optimal capacity. The ability to foresee and rectify issues before they manifest in physical models is invaluable, particularly in a field where precision is paramount.

As you consider your next engineering project, reflect on how CFD can streamline your workflow and elevate your designs. Embracing this technology could very well be the key to unlocking enhanced performance and efficiency in industrial fan engineering systems.

Computer-Aided Design (CAD): Essential for Accurate Fan Modeling

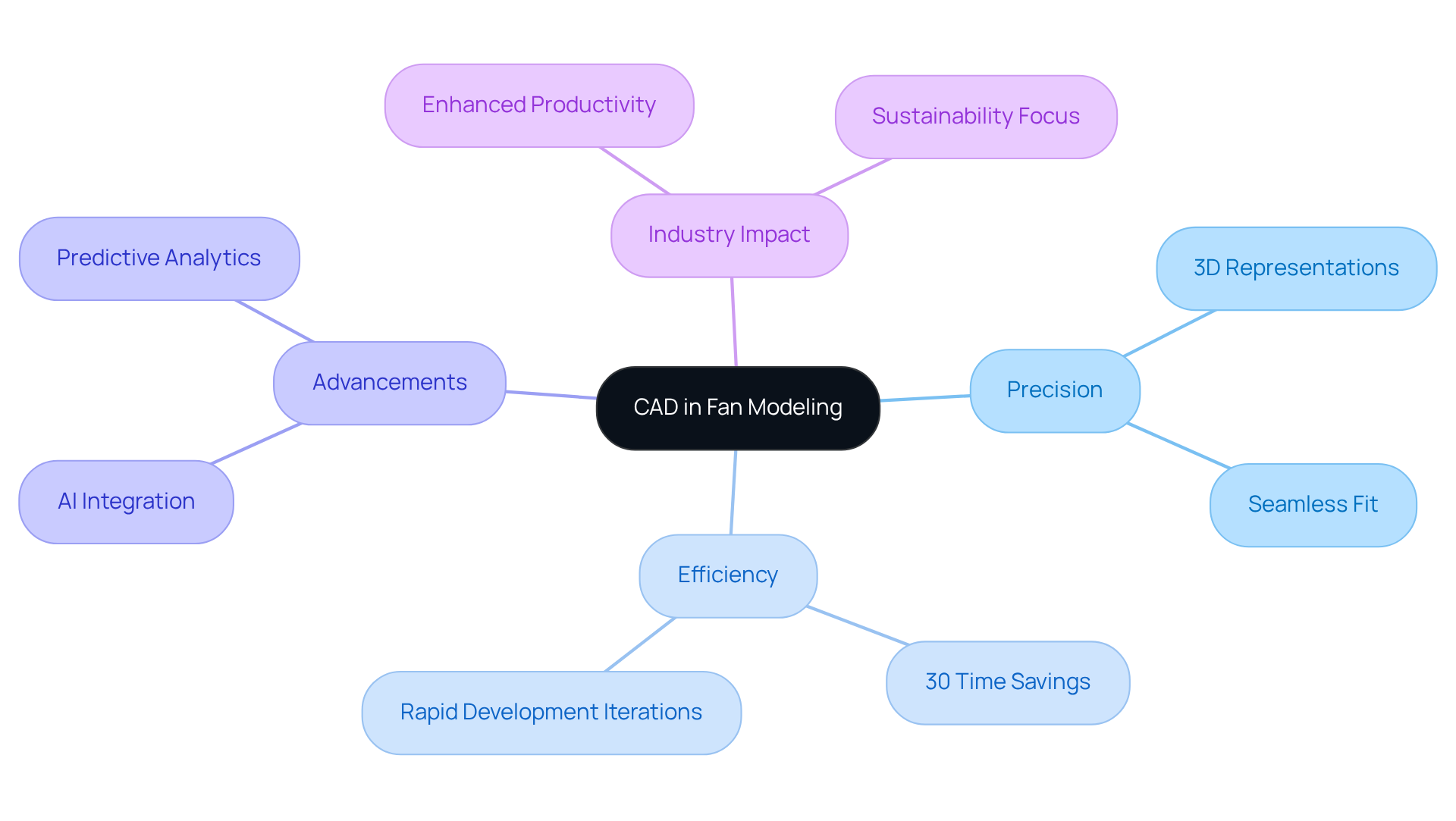

Computer-Aided Design (CAD) software is crucial for precise fan modeling, enabling professionals to craft intricate 3D representations of fan components. This precision is vital for ensuring that all parts fit together seamlessly and function as intended. CAD tools facilitate rapid development iterations, which are a necessity in the ever-evolving field of industrial fan engineering. Recent advancements in CAD technology reveal that professionals can save up to 30% in project time by leveraging these tools for fan modeling, significantly boosting productivity.

Moreover, the integration of AI within CAD systems introduces predictive analytics, further enhancing accuracy and efficiency in design. For example, contemporary CAD applications can automatically modify blade shapes and angles based on performance simulations, guaranteeing optimal airflow and cooling efficiency. As the industry evolves, it is imperative for professionals in industrial fan engineering to stay informed about the latest advancements in CAD software to push the boundaries of design.

Parametric Design Capabilities: Customize Fan Designs for Optimal Results

In industrial fan engineering, parametric capabilities are essential for professionals aiming to customize fan configurations to meet specific performance criteria. Engineers can significantly enhance airflow and efficiency in industrial fan engineering by adjusting parameters such as blade shape, size, and angle. This adaptability proves particularly beneficial in situations where traditional layouts fall short, allowing for tailored solutions that elevate overall performance.

Consider the impact of these capabilities in real-world applications. For instance, in industries where precision is paramount, the ability to modify designs through industrial fan engineering can lead to substantial improvements in operational efficiency. Engineers can analyze airflow patterns and make informed adjustments, ensuring that each configuration is optimized for its intended use.

Ultimately, embracing parametric design not only addresses immediate performance challenges but also fosters innovation. By leveraging these advanced capabilities, professionals can push the boundaries of what is possible, creating solutions that not only meet but exceed expectations. This proactive approach is crucial for staying competitive in a rapidly evolving landscape.

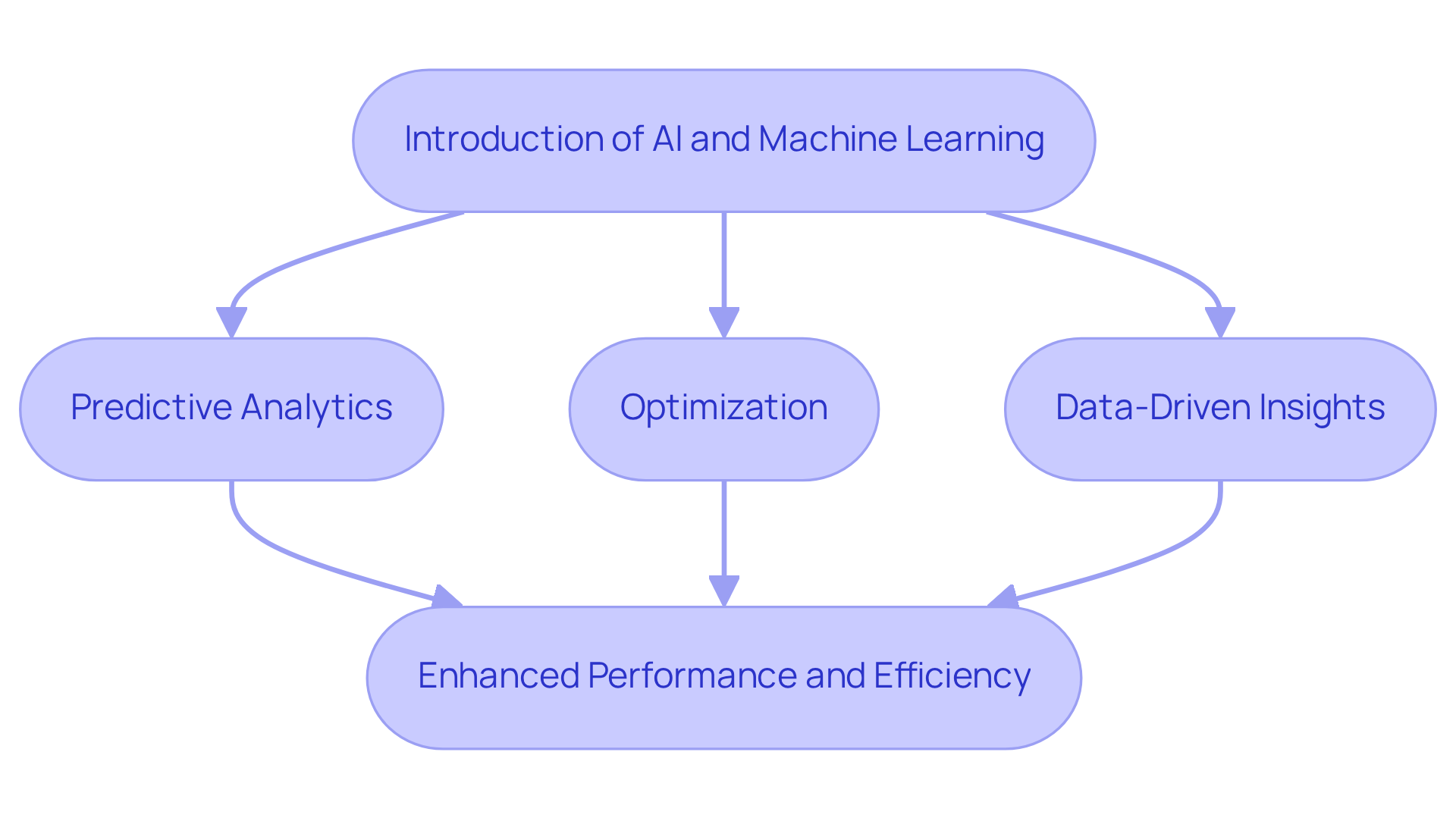

AI and Machine Learning: Revolutionize Fan Design Techniques

Artificial Intelligence (AI) and machine learning are revolutionizing fan creation techniques by enabling predictive analytics and optimization. These advanced technologies analyze vast amounts of data to identify patterns and suggest improvements, leading to more efficient fan systems.

By integrating AI into the creation process, professionals can significantly enhance performance, reduce energy consumption, and streamline development schedules. For instance, predictive analytics can forecast system demands, allowing for proactive adjustments that optimize operational efficiency.

Incorporating these technologies not only addresses current inefficiencies but also positions organizations to leverage data-driven insights for future innovations. As the industry evolves, embracing AI and machine learning will be crucial for staying competitive and achieving sustainable growth.

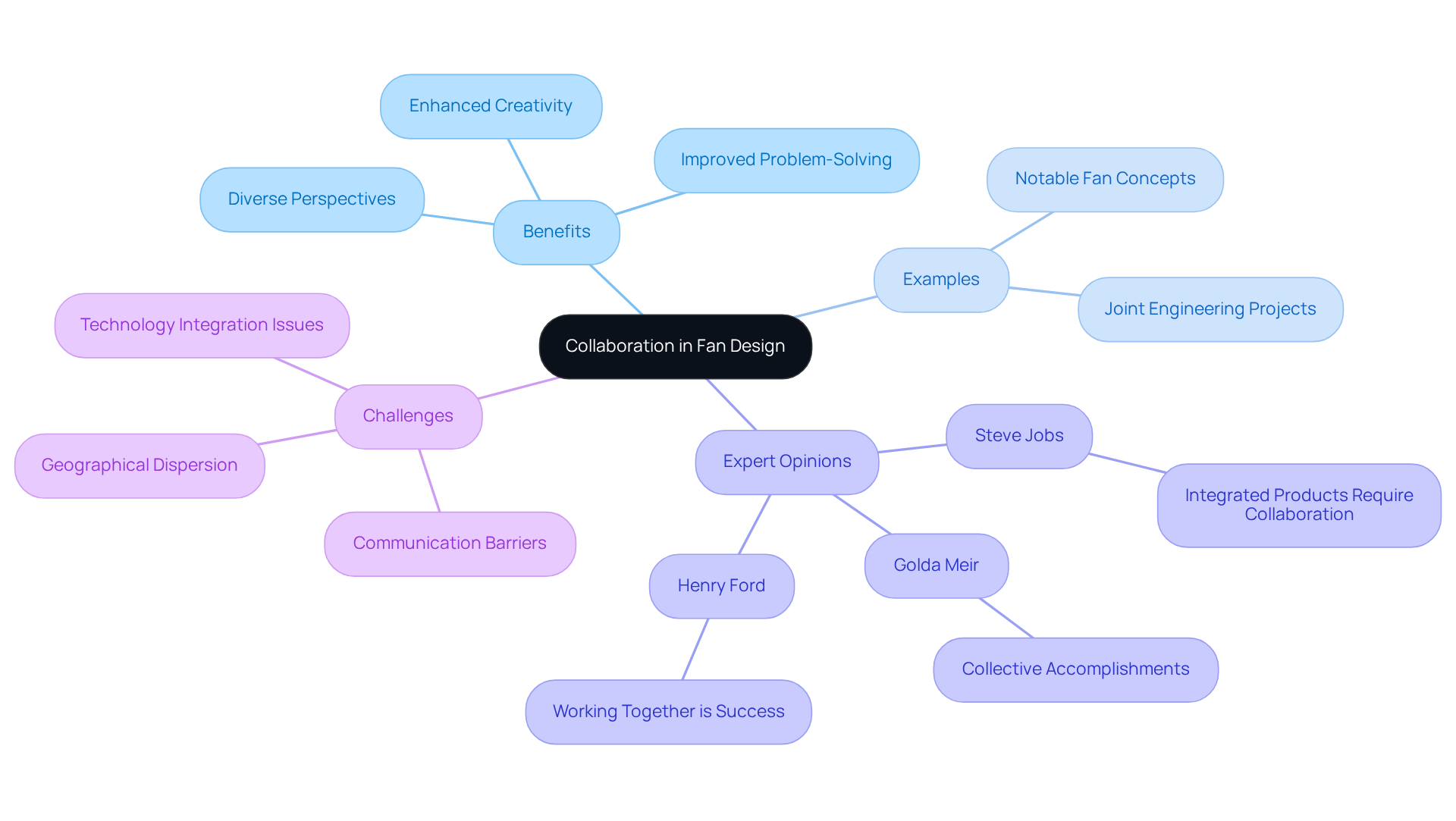

Collaboration and Sharing: Key to Innovative Fan Design Solutions

Collaboration and the sharing of ideas are essential for driving innovative fan creation solutions. When engineers unite, they tap into a wealth of diverse perspectives and expertise, allowing them to tackle complex challenges more effectively. Modern creation tools come equipped with features that foster collaboration, enabling teams to share layouts and provide real-time feedback. This collaborative approach not only sparks creativity but also results in more resilient and effective fan models.

Consider the emergence of cutting-edge fan concepts that have arisen from joint efforts. These examples illustrate how collaboration can lead to revolutionary engineering solutions. Experts in the field assert that integrating ideas from various stakeholders significantly enhances the overall quality and functionality of fan products, ultimately pushing the boundaries of what is achievable in fan engineering.

As Steve Jobs aptly noted, ‘Our method was to develop integrated products, and that meant our process had to be integrated and collaborative.’ This statement underscores the necessity of collaboration in achieving successful outcomes. However, challenges such as team members being dispersed across different locations can impede cooperation. Overcoming these barriers is crucial for fostering innovation in fan creation.

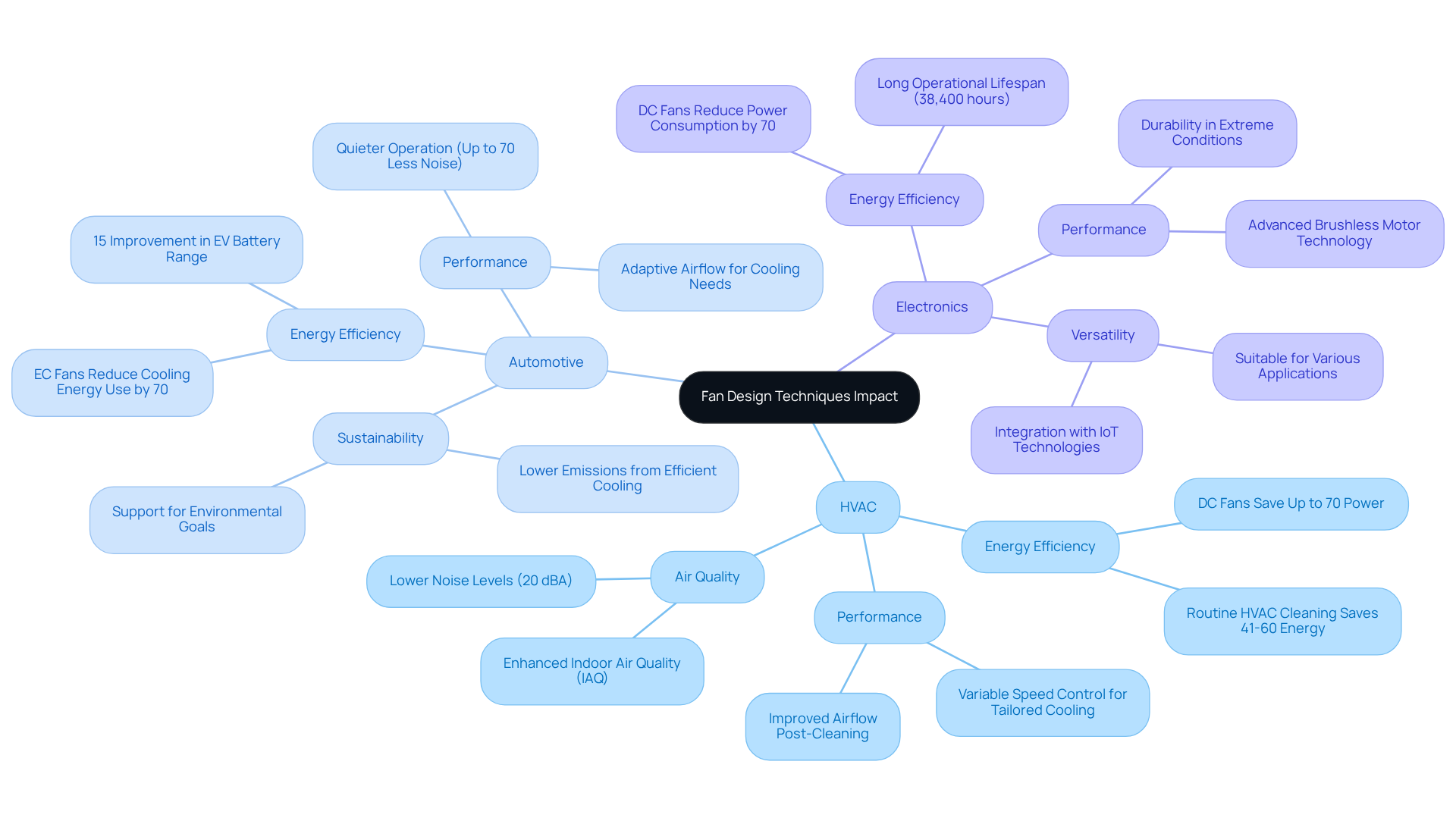

Industry Impact: How Fan Design Techniques Influence Multiple Sectors

Techniques in industrial fan engineering are crucial across various sectors, including HVAC, automotive, and electronics, significantly impacting energy efficiency and air quality. Efficient fan setups lead to substantial energy savings. DC cooling fans consume up to 70% less power than traditional AC units, while also enhancing overall performance and reliability. For example, utilizing variable speed DC devices can achieve energy savings of up to 30% compared to conventional systems, enabling engineers to customize cooling outputs to meet specific thermal requirements.

In the automotive industry, the integration of EC fan technology has resulted in a remarkable 15% improvement in battery range for electric vehicles, as highlighted in a specific case study. This illustrates how advanced fan configurations can directly enhance energy efficiency and vehicle performance. Additionally, these devices operate quietly, reducing noise levels by up to 70% compared to their AC counterparts, which is vital in sensitive environments such as hospitals and data centers.

The design of fan systems in industrial fan engineering also plays a pivotal role in improving air quality metrics. By optimizing airflow and minimizing energy consumption, effective devices in industrial fan engineering contribute to healthier indoor environments, aligning with the growing sustainability goals in engineering. With the market for DC cooling fans projected to reach USD 2.1 billion by 2033, and a compound annual growth rate (CAGR) of 7.5% from 2026 to 2033, it is clear that the shift towards energy-efficient fan solutions is not just a trend but a necessary evolution in the industry. Engineers who adopt these advancements will not only fulfill technical specifications but also support broader environmental objectives.

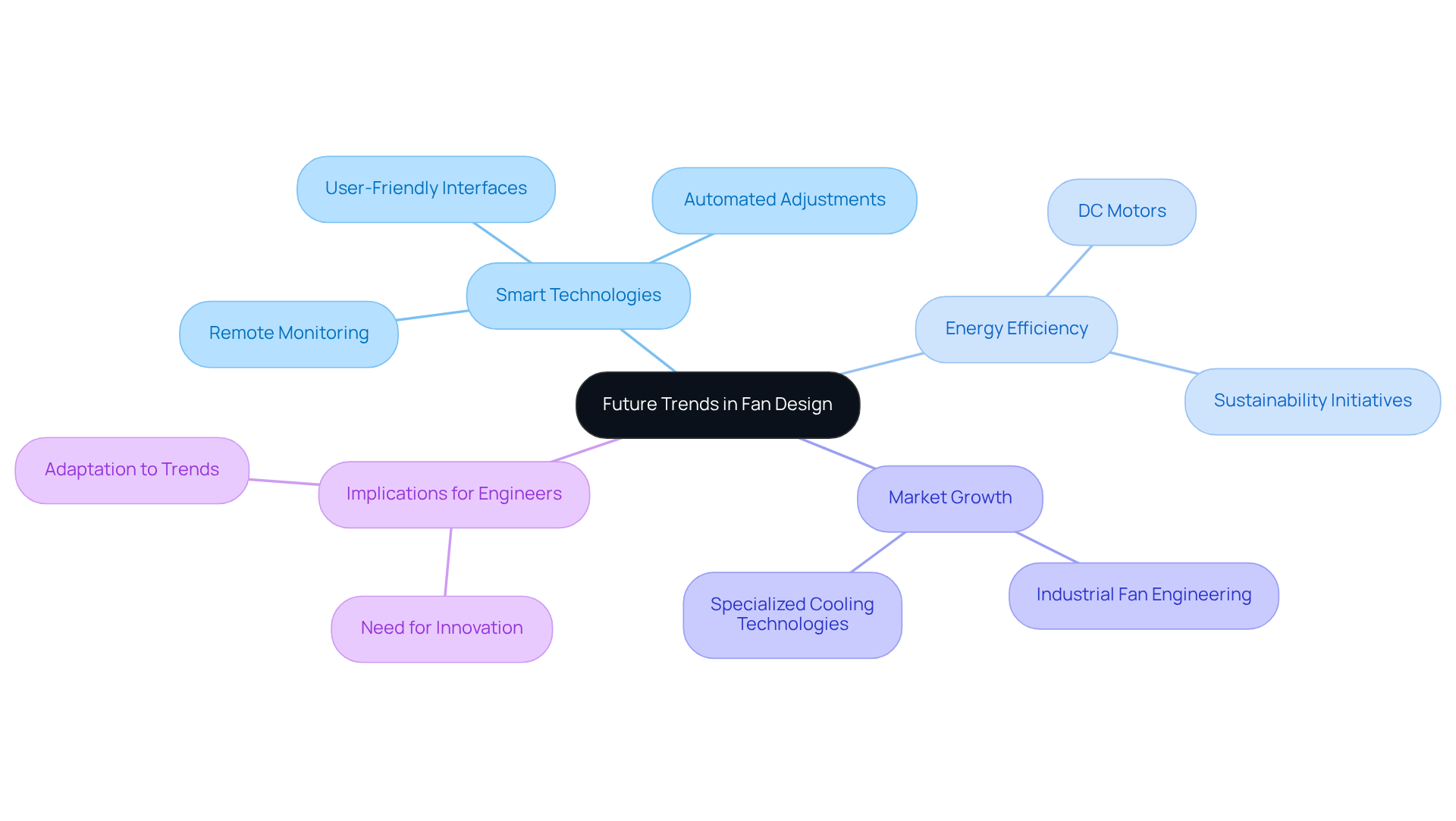

Future Trends in Fan Design: What Engineers Need to Know

The evolution of fan design is profoundly shaped by the integration of smart technologies, enhancing both operational efficiency and user convenience. These next-generation solutions incorporate features like remote monitoring and automated adjustments based on real-time data, ensuring optimal performance across various applications. For example, smart fan systems can seamlessly integrate with home automation networks, allowing users to control settings via smartphones. This reflects a growing trend toward user-friendly interfaces that prioritize accessibility.

Energy efficiency remains a critical focus, with DC motors consuming 70% less energy than standard motors while delivering comparable, if not superior, airflow. This transition not only reduces operational costs but also aligns with global sustainability initiatives, as manufacturers increasingly utilize recyclable materials in their products. In 2023, the industrial fan engineering segment represented over 42% of the fan mechanisms market, highlighting the essential role of advanced fan controls in sectors such as automotive and data centers. Furthermore, the specialized cooling technologies segment is witnessing a steady annual growth rate of 15%, underscoring the rising demand for customized cooling solutions.

As engineers navigate these trends, grasping the implications of smart technologies on industrial fan engineering is crucial. The surge in demand for innovative cooling solutions is particularly evident in specialized markets like medical devices and compact electronics, where tailored cooling solutions are imperative. Embracing these advancements is vital for developing fan technologies that are not only efficient but also environmentally conscious, ultimately shaping the future of industrial fan engineering.

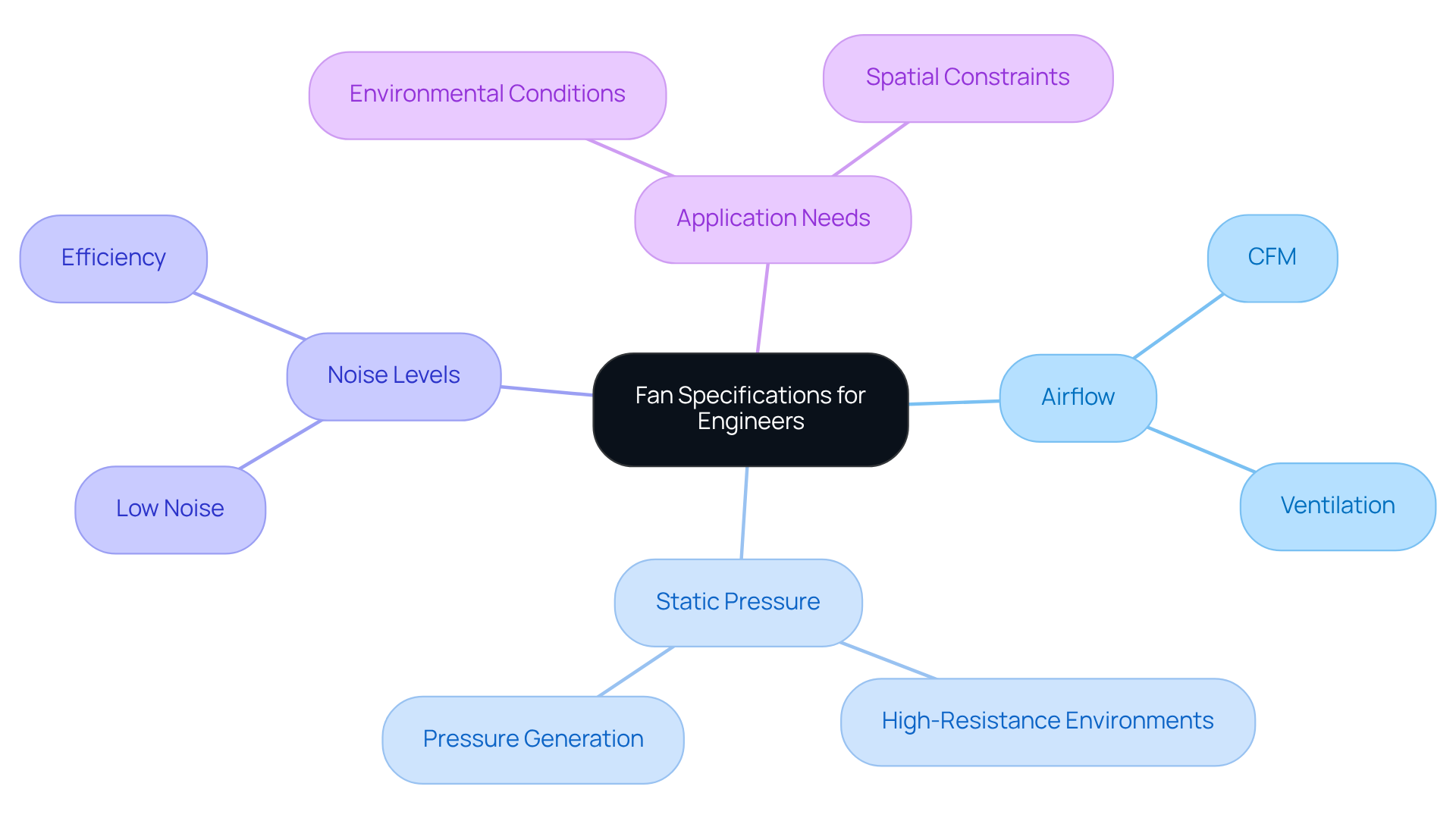

Selecting the Right Fan Specifications: A Guide for Engineers

Choosing the right specifications in industrial fan engineering is crucial for maximizing performance across various applications. In the field of industrial fan engineering, engineers must evaluate several critical factors, including airflow, measured in cubic feet per minute (CFM), static pressure, and noise levels. Airflow quantifies the volume of air a fan can move, which is vital for ensuring adequate ventilation and cooling. Static pressure, defined as the exertion by air within a system, reflects the resistance a fan must overcome to maintain airflow, making it a key consideration in high-resistance environments.

Gagner-Toomey Associates offers a comprehensive range of DC input Tube Axial units and Centrifugal Blowers, optimized for performance, efficiency, and low noise. Sizes vary from 15 to 280mm for Tube Axial units and 15 to 225mm for Centrifugal Blowers. Additionally, IP protection is available in most models upon request, enhancing their suitability for diverse applications in electronics, automotive, and industrial sectors.

Along with these metrics, developers should assess the specific needs of their applications, such as environmental conditions and spatial constraints. For instance, static pressure devices excel in high-resistance scenarios, generating substantial pressure to maintain airflow, while airflow machines are more effective in low-resistance settings where rapid air circulation is necessary. Understanding these dynamics in industrial fan engineering enables engineers to customize their fan choices, which enhances efficiency and reliability.

Real-world examples underscore the impact of proper fan selection on efficiency. The case study titled “Static Pressure Fans in High-Resistance Environments” emphasizes how these fans maintain airflow in constrained spaces, showcasing their importance in applications like electronics cooling. Engineers who carefully consider airflow needs and static pressure ratings have successfully enhanced ventilation systems, ensuring they meet performance demands without unnecessary energy consumption. By leveraging detailed performance data and adhering to best practices, engineers can achieve significant improvements in cooling effectiveness and operational efficiency.

Summary of Essential Tools for Industrial Fan Engineering Success

In summary, successful industrial fan engineering relies on a combination of advanced tools and technologies. Key instruments such as Computational Fluid Dynamics (CFD) play a crucial role in performance optimization, enhancing fan construction efficiency and energy conservation. Additionally, Computer-Aided Design (CAD) allows for precise modeling, ensuring accuracy in design.

The global fans and blowers market is projected to grow at a CAGR of 6.8% from 2025 to 2033, underscoring the increasing significance of these technologies in the industry. Furthermore, parametric capabilities enable customization to meet specific performance standards. The integration of AI and machine learning enhances processes, facilitating smarter decision-making.

Collaboration tools are essential for promoting teamwork, allowing professionals to work together effectively. For instance, case studies have demonstrated that optimized fan configurations in automotive applications lead to substantial energy savings, further emphasizing the practical benefits of employing advanced tools in fan development.

By harnessing these vital tools, engineers can achieve remarkable success in their fan design projects, aligning with industry trends that prioritize energy efficiency and sustainability.

Conclusion

Harnessing the right tools and technologies is crucial for success in industrial fan engineering. Advanced methodologies such as Computational Fluid Dynamics (CFD), Computer-Aided Design (CAD), and parametric design capabilities empower engineers to optimize performance, enhance efficiency, and customize solutions for various applications. Moreover, incorporating AI and machine learning streamlines processes and fosters innovation, ensuring fan systems meet the evolving demands of diverse sectors.

Key insights throughout this article underscore the importance of collaboration and idea-sharing among engineering teams, leading to more resilient and effective fan designs. Real-world applications illustrate the tangible benefits of utilizing these advanced tools, demonstrating how optimized configurations can drive significant energy savings and improve overall performance. As the industry evolves, staying informed about the latest technologies and methodologies is vital for engineers aiming to push the boundaries of fan design.

In conclusion, the future of industrial fan engineering hinges on the ability to adapt and innovate. By embracing essential tools and fostering a collaborative environment, engineers can enhance their designs and contribute to broader sustainability goals. As the market for advanced fan solutions expands, those who leverage these insights will be well-equipped to meet upcoming challenges and shape the future of efficient cooling technologies.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is known for innovative industrial fan engineering solutions specifically tailored for the electronics sector, providing access to cutting-edge technologies in cooling, power management, and interconnect solutions.

Which sectors does Gagner-Toomey Associates serve?

Gagner-Toomey Associates serves a wide array of sectors including Telecom, IoT, Automotive, and Medical.

How does Gagner-Toomey Associates enhance product longevity?

Recent advancements in motor efficiency and energy consumption enhance product longevity, while the integration of smart technologies transforms the user experience to be more intuitive and responsive.

What is the role of Computational Fluid Dynamics (CFD) in industrial fan engineering?

CFD is used to visualize airflow patterns and enhance fan performance by simulating different layout scenarios, identifying inefficiencies, and allowing necessary adjustments before physical prototypes are constructed.

How does CFD benefit the engineering process?

CFD conserves time and resources by enabling engineers to foresee and rectify issues before they manifest in physical models, ensuring that each fan operates at its optimal capacity.

What is the importance of Computer-Aided Design (CAD) in fan modeling?

CAD software is crucial for precise fan modeling, allowing professionals to create intricate 3D representations of fan components, ensuring that all parts fit together seamlessly and function as intended.

How does CAD technology improve project efficiency?

Recent advancements in CAD technology can save professionals up to 30% in project time by facilitating rapid development iterations, significantly boosting productivity.

What role does AI play in CAD systems for fan design?

AI integration within CAD systems introduces predictive analytics, enhancing accuracy and efficiency by automatically modifying blade shapes and angles based on performance simulations to ensure optimal airflow and cooling efficiency.