Overview

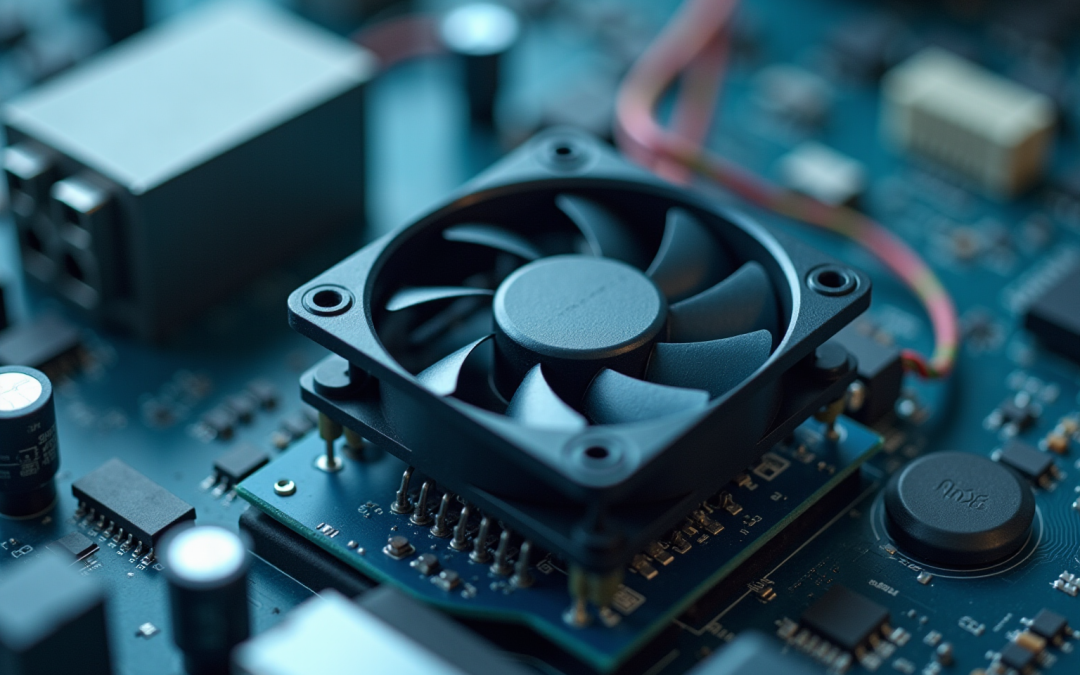

The primary objective of this article is to delineate the essential characteristics of 24V DC fans, particularly pertinent for electronics engineers. These fans are highlighted for their energy efficiency, durability, and customization options, establishing their significance in effective thermal management across a variety of electronic applications. Evidence supporting their energy savings, innovative designs, and compatibility with diverse power sources underscores their value in the field.

Introduction

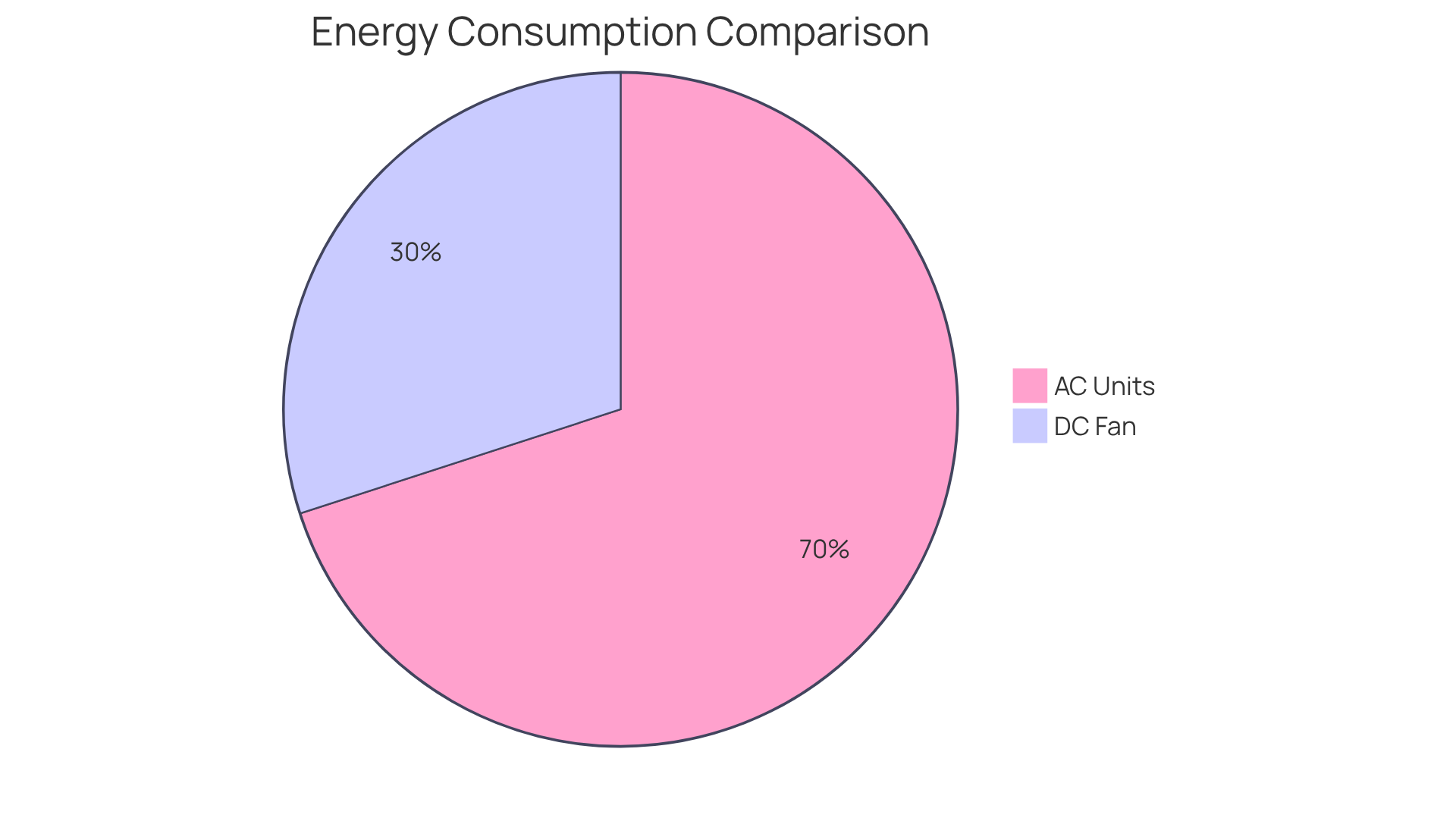

In the evolving landscape of electronics engineering, the necessity for efficient thermal management solutions has become paramount. At the forefront of this evolution are 24V DC fans, which play a crucial role in enhancing system performance. These fans not only deliver substantial energy savings—consuming up to 70% less power than traditional AC models—but also feature advanced capabilities that bolster reliability. Yet, with an overwhelming array of options, engineers face the challenge of identifying which features genuinely enhance the effectiveness of these cooling solutions.

This article explores the ten essential characteristics of 24V DC fans that every electronics engineer should consider, offering insights that pave the way for more informed and sustainable design decisions.

Gagner-Toomey Associates: Innovative Cooling Solutions for 24V DC Fans

Gagner-Toomey Associates stands at the forefront of , delivering an extensive array of meticulously crafted to meet the rigorous demands of the electronics sector. These innovative solutions play a crucial role in achieving optimal , significantly boosting the performance and longevity of electronic components. By collaborating with leading manufacturers, Gagner-Toomey empowers engineers with access to that enhance system reliability and efficiency.

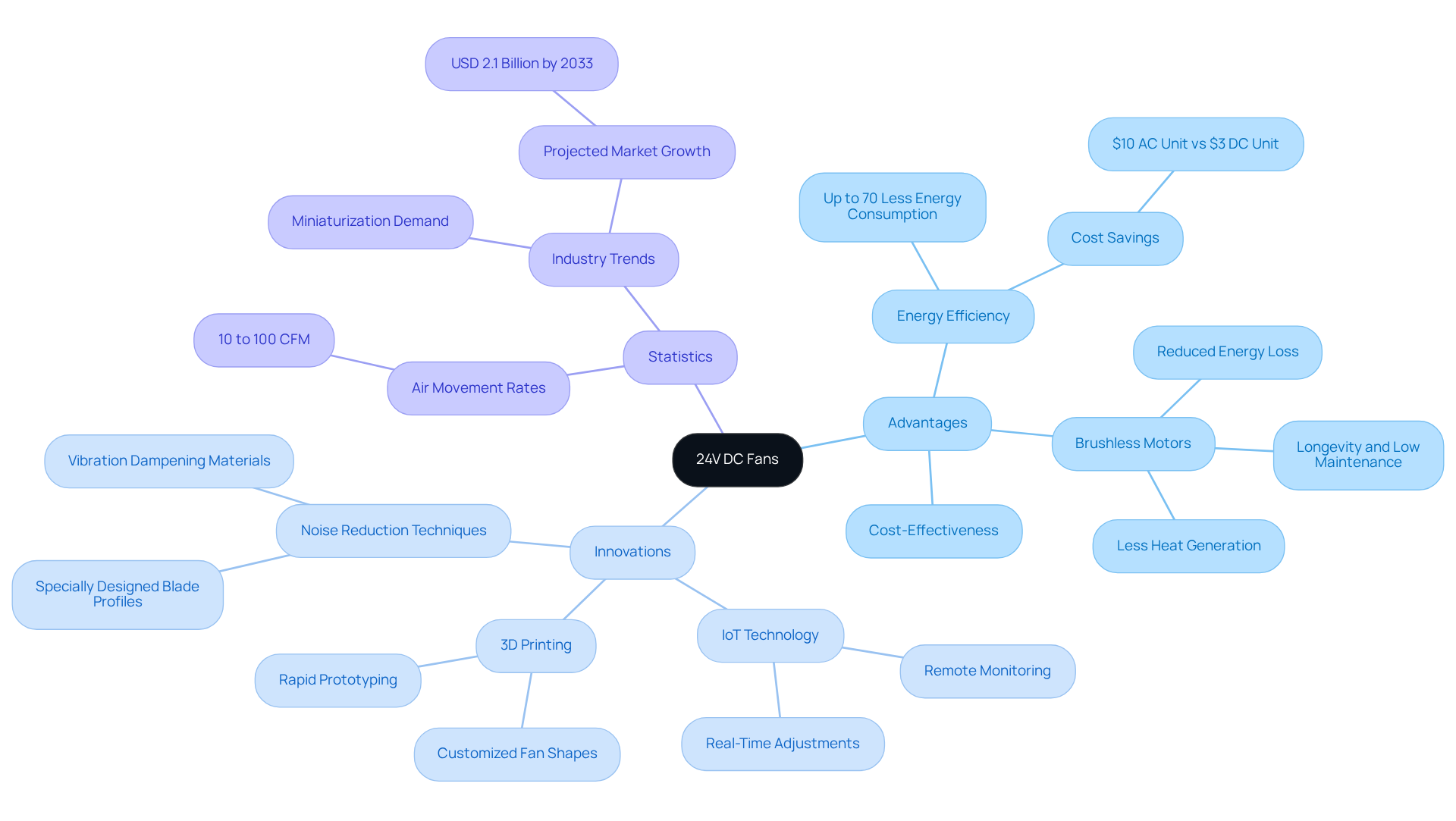

The advantages of a 24v dc fan are substantial. They utilize up to 70% less energy compared to their AC counterparts, rendering them a cost-effective option for commercial applications. Additionally, the integration of in these devices not only minimizes energy loss but also reduces heat generation, contributing to a more sustainable operation.

Recent innovations in fan design have introduced IoT technology, facilitating remote monitoring and real-time adjustments based on environmental conditions. This capability allows engineers to dynamically improve temperature management, ensuring systems remain within optimal ranges. Moreover, advancements such as 3D printing enable the development of customized fan shapes, enhancing airflow and pressure management.

Statistics underscore the efficiency of the 24v dc fan units in thermal management, with effective air movement rates typically ranging from 10 to 100 CFM for proficient electronic temperature regulation. As the industry trends toward miniaturization, the demand for continues to rise, making 24V DC fans essential components in modern electronic designs.

Expert insights highlight the importance of mastering heat exchanger thermal systems and comprehending the operational characteristics of various fan types. With Gagner-Toomey’s unwavering , engineers are exceptionally equipped to address the challenges of thermal management within their projects.

High Airflow Capacity: Ensuring Optimal Cooling Performance

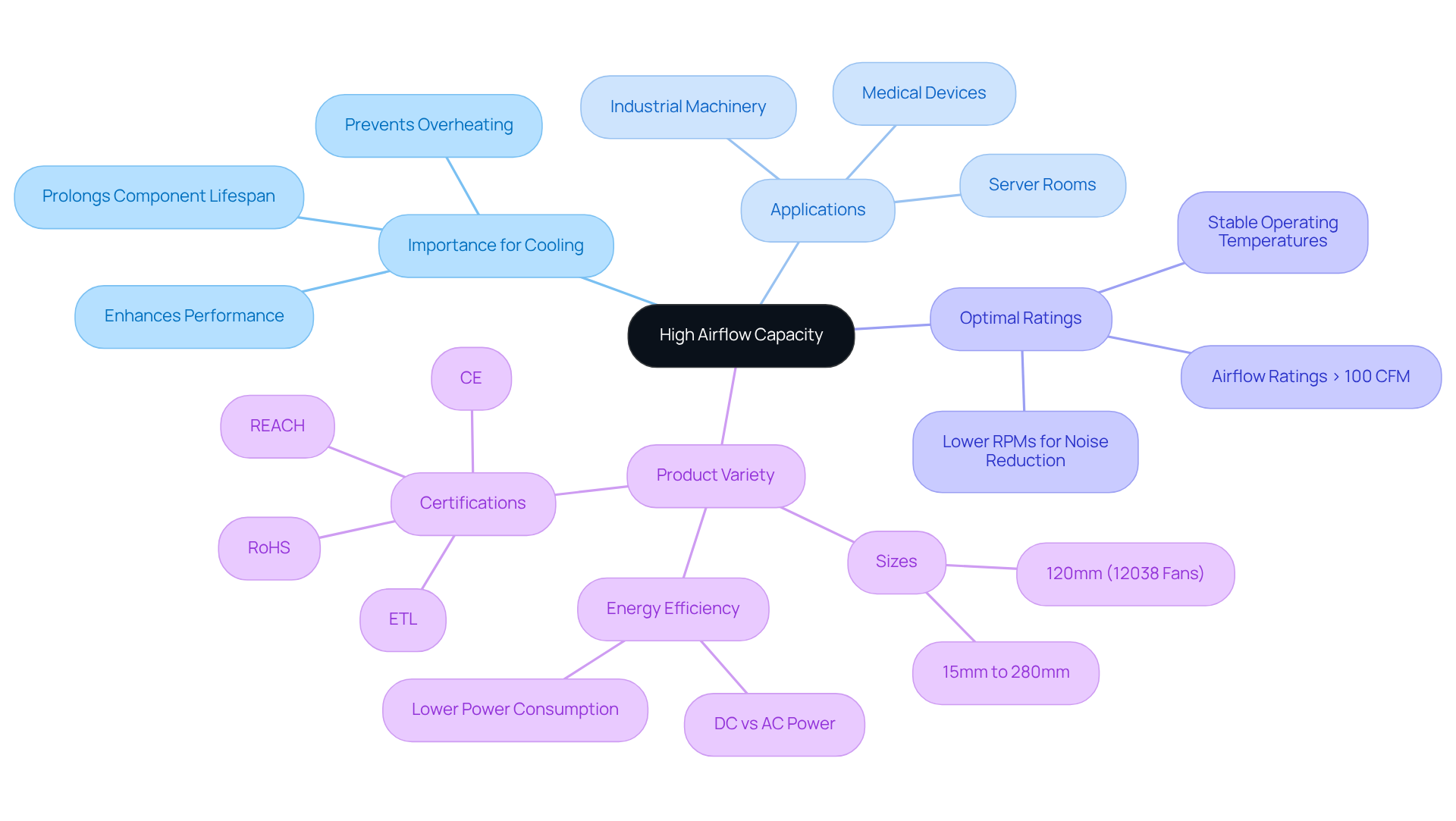

A defining characteristic of the 24v dc fan is its impressive airflow capacity, which is crucial for in electronic applications. Gagner-Toomey Associates, the world’s largest producer of standard and custom air-movers, meticulously designs these devices to move , ensuring efficient heat dissipation from electronic components.

For instance, devices with (Cubic Feet per Minute) are especially suitable for challenging environments such as server rooms and industrial machinery. The of the 24v dc fan not only mitigates the risk of overheating but also significantly enhances the performance and reliability of electronic systems.

Engineers consistently emphasize that , especially from a 24v dc fan, are vital for maintaining stable operating temperatures, which is essential for prolonging the lifespan of critical components. Recent advancements in cooling technology from Gagner-Toomey Associates further underscore the importance of these ratings, as they directly correlate with and system efficiency across various applications.

Additionally, ranging from 15 to 280mm, including tube axial units and centrifugal blowers. The 12038 supporters are acknowledged for their , using considerably less power compared to AC models, and they possess certifications such as CE, RoHS, REACH, and ETL, guaranteeing their safety and reliability in various applications.

Low Noise Operation: Enhancing User Comfort and System Efficiency

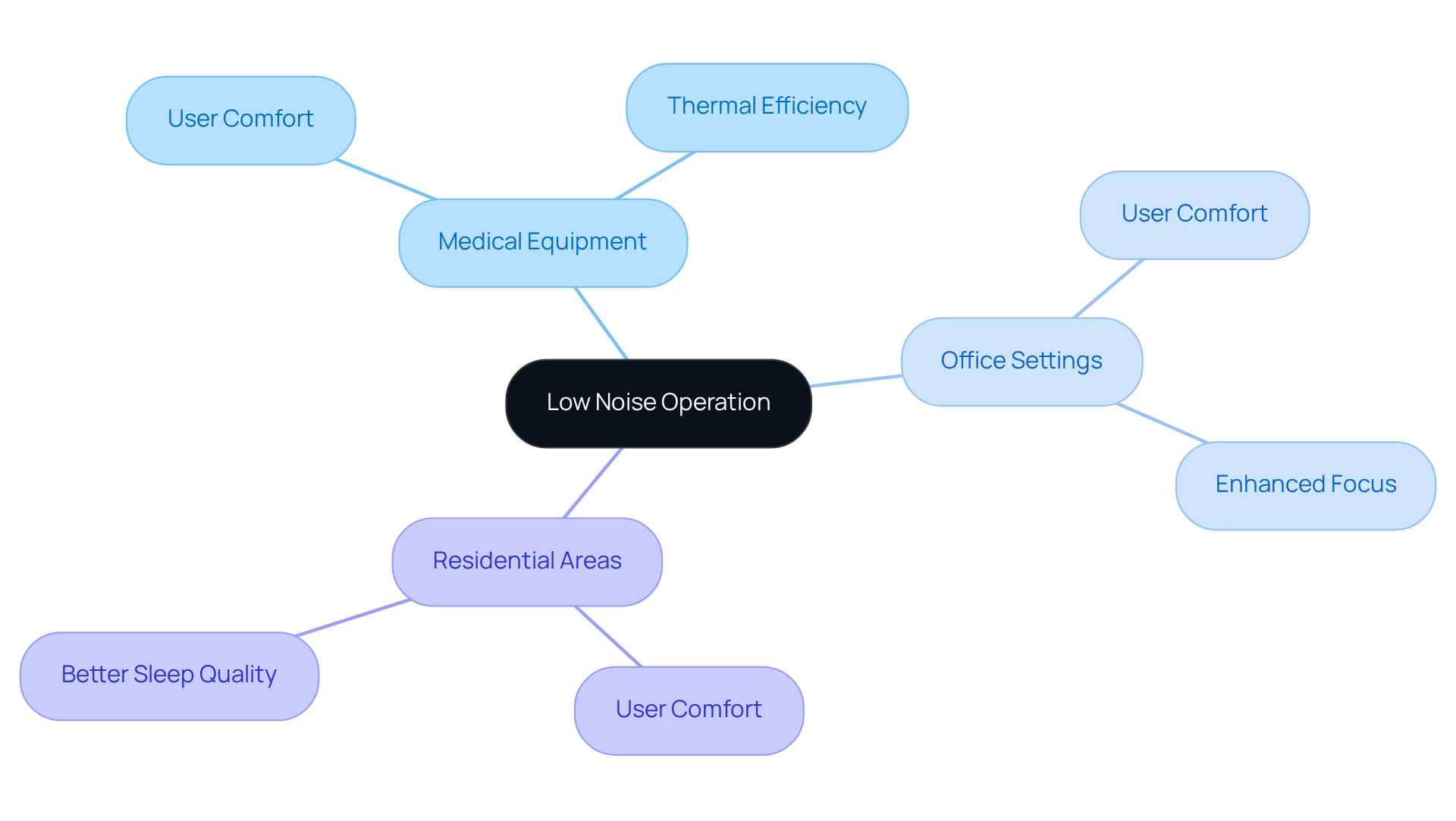

The is engineered for , making it ideal for environments where sound levels must be minimized. By employing advanced motor technologies and noise-dampening materials, these devices can achieve sound levels below 30 dBA. This capability proves particularly advantageous in applications such as:

- Medical equipment temperature regulation

- Office settings

- Residential areas

where excessive noise can hinder focus and comfort. Selecting devices such as a 24V DC fan that prioritize silent operation allows while ensuring optimal . Moreover, the anticipated growth of the , projected to reach USD 2.1 billion by 2033, highlights the increasing importance of within the industry. The incorporation of further facilitates this objective, enabling without the interference of noise. As industry experts have noted, “The advancements in are crucial for enhancing user experience in sensitive environments.

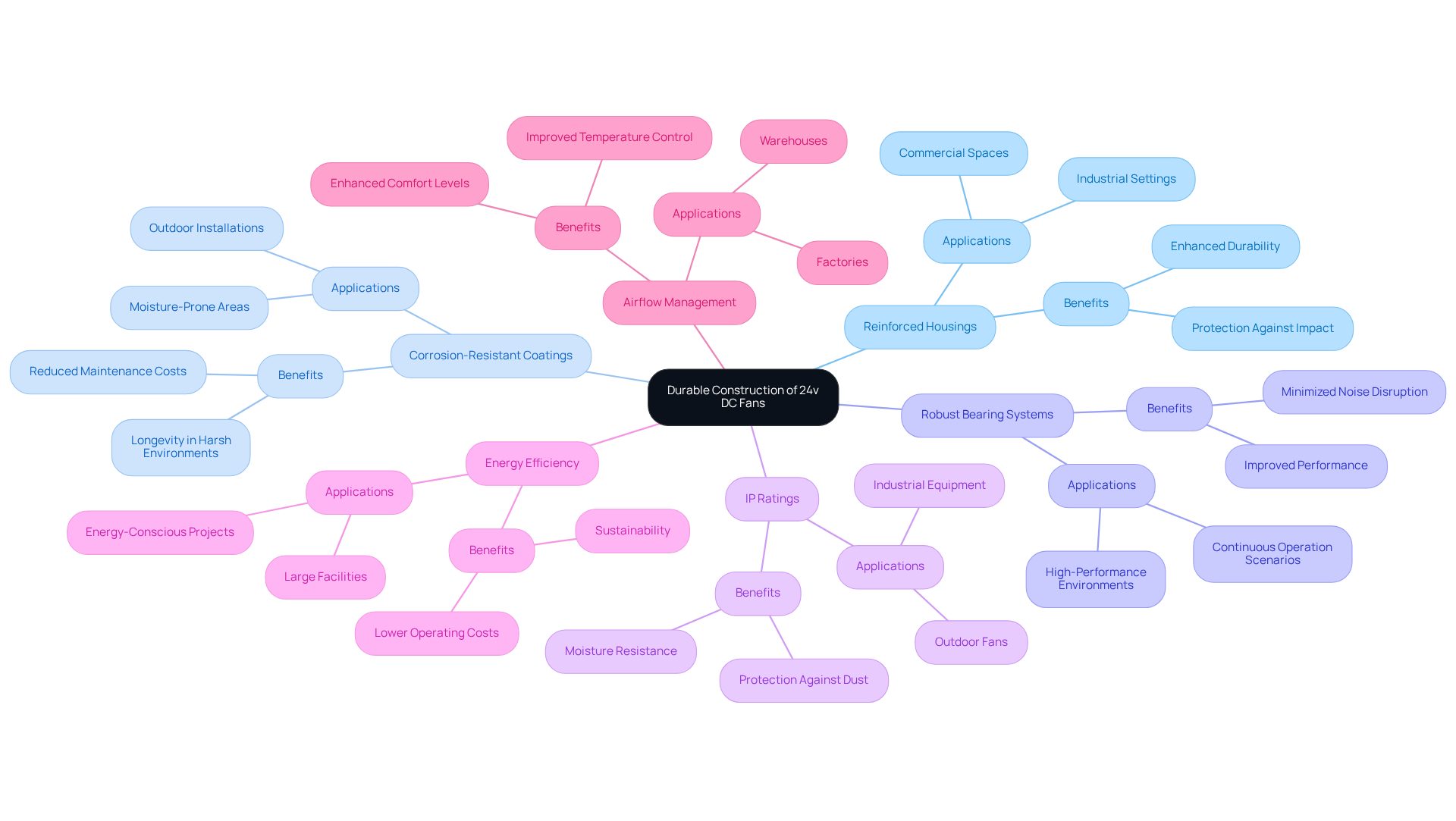

Durable Construction: Ensuring Longevity and Reliability

The construction of devices by Gagner-Toomey Associates is meticulously engineered for durability, utilizing that withstand demanding environments. Key features include:

- Reinforced housings

- Corrosion-resistant coatings

- Robust bearing systems

All of which of these devices. For instance, devices designed for frequently utilize IP-rated enclosures, which protect against dust and moisture, ensuring . The significance of IP ratings lies in their ability to indicate the level of protection against environmental factors, which is crucial for maintaining fan performance over time.

Gagner-Toomey’s exemplifies this approach, boasting an industry-leading airflow of 6,500 CFM while maintaining minimal noise disruption. Furthermore, its and zoning functionality—allowing for —make it a remarkable option for professionals in the field.

As Richard Boothman, Director of North American Sales for Modine, states, ‘Consistent circulation promotes a safer, healthier and more welcoming environment, ensuring productivity in industrial and commercial settings.’ This durability not only results in but also prolongs service life, making these devices a wise investment for professionals seeking efficiency and reliability in their .

Gagner-Toomey offers an extensive selection of fan sizes and types, including the 24v dc fan, ensuring that professionals can discover the ideal solution for their particular cooling requirements.

Energy Efficiency: Reducing Power Consumption and Costs

stands as a hallmark of the , engineered to consume less power while delivering . When compared to conventional AC units, DC models can by up to 70%. This significant reduction in energy consumption makes the 24v dc fan an appealing choice for .

Features such as:

- Variable speed control

enhance energy efficiency further, allowing devices to adjust their based on cooling requirements. Consequently, this not only lowers operational costs but also contributes to a diminished carbon footprint.

Compact Design: Facilitating Easy Integration into Systems

The represents a significant advancement for integration in space-constrained environments. With dimensions ranging from 40mm to 120mm, these devices are engineered to occupy without compromising performance. Their lightweight construction not only facilitates installation but also enables seamless integration into a variety of systems, spanning from consumer electronics to industrial machinery. This adaptability is vital, as technicians increasingly seek that enhance overall system design.

Importantly, DC enthusiasts deliver , rendering them ideal for . As noted by engineers at xMEMS, the integration of such is essential for improving in modern devices, particularly those demanding high performance in restricted areas.

Furthermore, the is anticipated to expand from USD 1.2 billion in 2024 to USD 2.1 billion by 2033, highlighting the growing importance of these units within the industry. Successful implementations of 24V DC fans across various environments demonstrate their ability to provide while maintaining the integrity of compact designs, ultimately leading to and reduced maintenance costs.

Additionally, the provision of variable voltage options and tachometer feedback for real-time monitoring bolsters their adaptability and reliability across diverse applications.

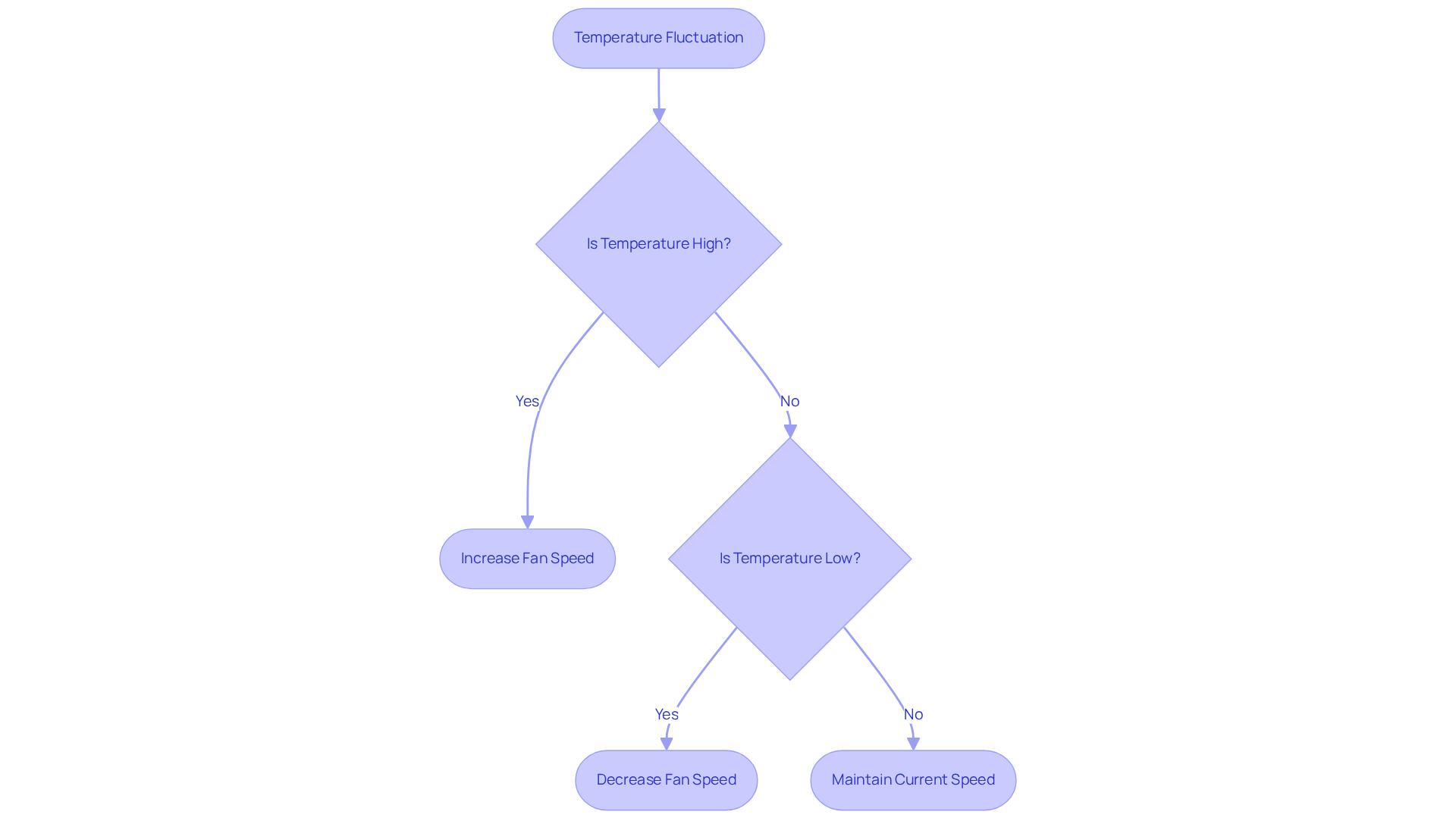

Variable Speed Control: Customizing Performance for Different Applications

stands as a pivotal feature in numerous devices using a , empowering engineers to tailor performance to meet specific . This functionality enables users to adjust speed in response to temperature fluctuations, ensuring that systems remain within .

For instance, in scenarios where heat production varies, variable speed blowers can augment airflow when required and reduce speed during periods of lower thermal loads. This not only results in but also extends the lifespan of the blower.

Such adaptability renders devices like the 24V DC fan appropriate for a , spanning from data centers to automotive systems.

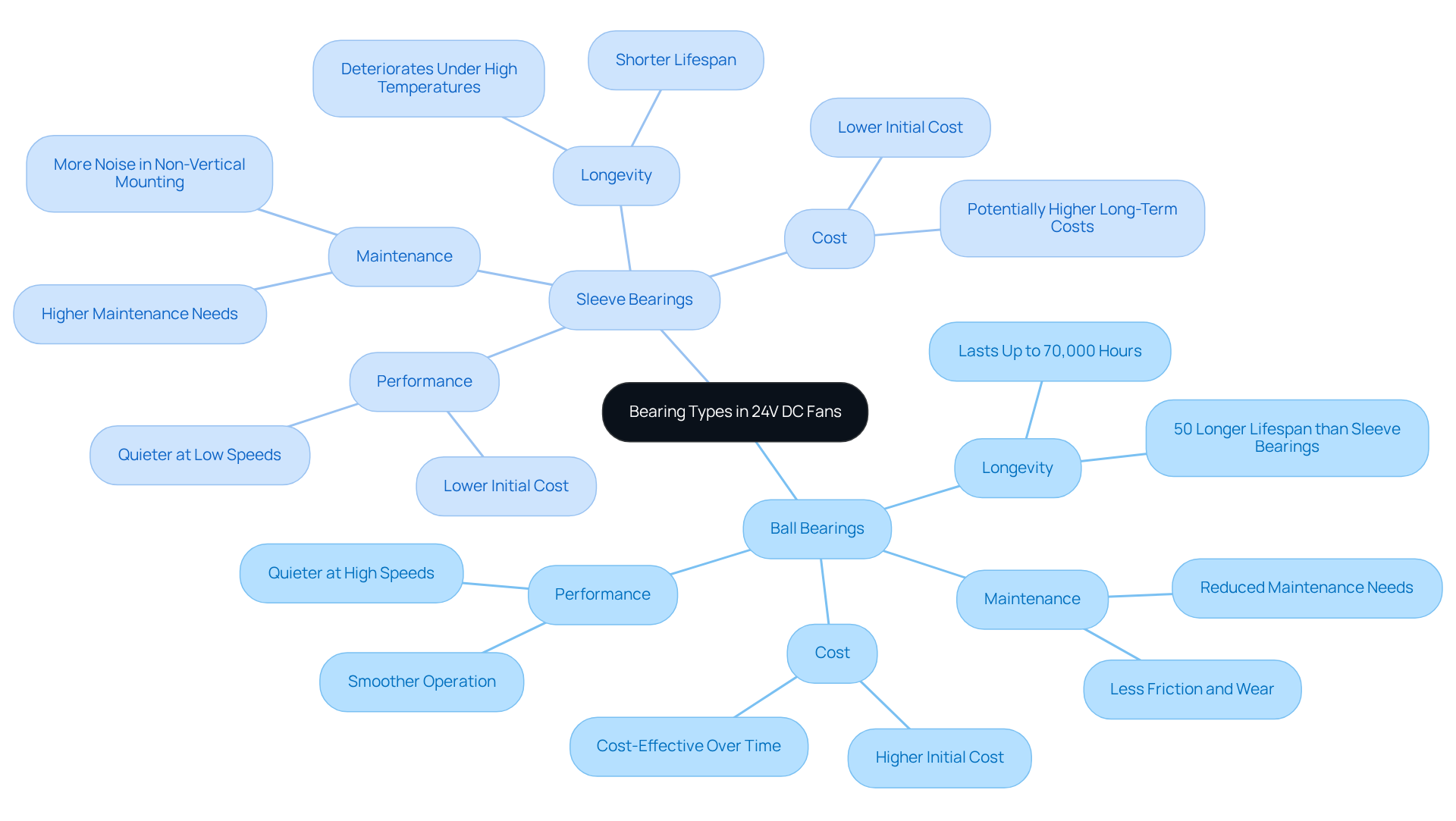

Quality Bearings: Enhancing Performance and Reducing Maintenance

The quality of bearings in is a critical factor influencing both performance and longevity. Fans equipped with operate more smoothly and quietly, effectively minimizing friction and wear. This results in and an extended service life.

For instance, according to NMB Technologies Corporation, can endure up to 50% longer than when functioning within ideal temperature ranges. Certain models, such as CUI’s omniCOOL units, have been reported to achieve lifespans exceeding 70,000 hours under specific conditions.

Conversely, while sleeve bearings may present a lower initial cost, they typically have shorter lifespans and can generate more noise, especially in non-vertical mounting positions. Traditionally, sleeve bearing devices were perceived as quieter at low speeds; however, advancements in ball bearing technology have enabled these systems to operate quietly even at higher speeds.

By opting for devices with , professionals can enhance reliability, reduce maintenance frequency, and ultimately ensure consistent performance in their applications. This strategic decision not only bolsters but also contributes to a more sustainable and cost-effective solution over time.

As emphasized by NMB Technologies Corporation, the reliability of a 24v dc fan is paramount in fan performance, highlighting the importance of bearing type selection for industry professionals.

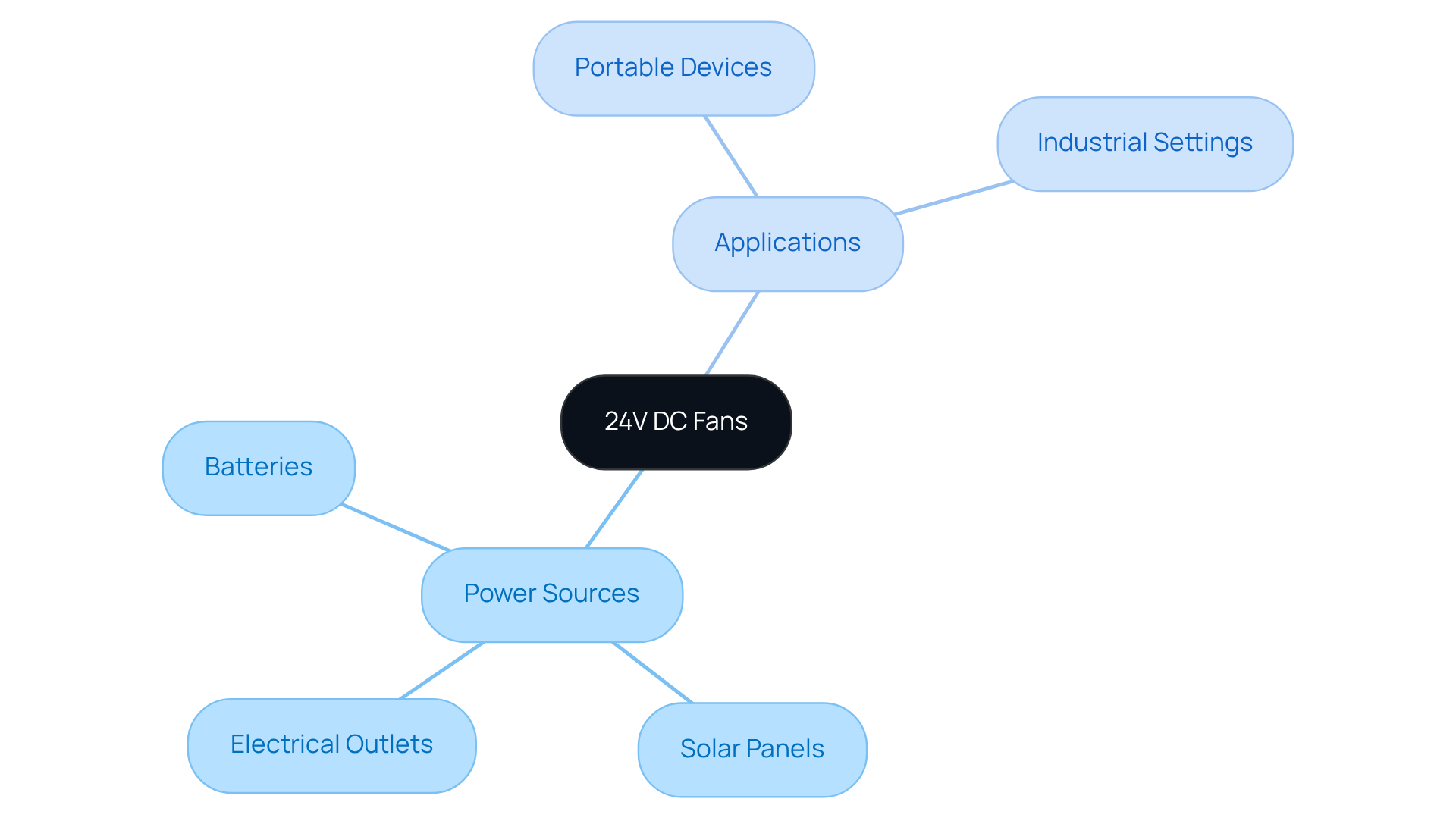

Power Source Compatibility: Supporting Diverse Applications

are engineered for compatibility with a variety of power sources, making them suitable for an extensive range of applications. These blowers can be powered by batteries, solar panels, or standard electrical outlets, enabling engineers to implement effective across diverse environments. Such adaptability is particularly advantageous for portable devices, where space and power constraints are paramount, as well as in fixed installations within industrial settings.

As Elon Musk aptly stated, ‘ that exists in the world,’ underscoring the innovative potential of these versatile solutions. The capability to operate with not only enhances the practicality of the 24V DC fan but also aligns with current market trends favoring in electronics.

Recent studies indicate that the demand for has surged by 30% over the past year, emphasizing their significance in contemporary electronic designs. A compelling case study showcasing the application of 24V DC fans in a solar-powered portable refrigeration unit for outdoor events further illustrates their and effectiveness in real-world scenarios.

Manufacturer Support and Warranty: Ensuring Peace of Mind for Engineers

When selecting a 24v dc fan, it is imperative for professionals to prioritize the level of offered. Effective support is essential for troubleshooting and optimizing fan performance, while a comprehensive warranty provides reassurance regarding product durability. Numerous leading manufacturers, including those represented by Gagner-Toomey Associates, extend . This enables professionals to depend confidently on their . Such dedication to customer satisfaction exemplifies the commitment of reputable manufacturers, underscoring the importance of investing in .

Moreover, Gagner-Toomey Associates fosters spanning sectors such as Telecom, Networking, and Medical. This ensures that professionals receive tailored to their specific needs. Engineers recognize that is critical when assessing , such as the 24v dc fan, as it not only protects their investments but also enhances overall system reliability. Gagner-Toomey Associates is steadfast in its that address the evolving requirements of engineers, ensuring they are equipped with the best tools available for their projects.

Conclusion

The significance of 24V DC fans in electronics engineering is paramount. These fans represent a pivotal advancement in thermal management technology, delivering energy efficiency, low noise operation, and a suite of features designed to enhance performance across various applications. By integrating innovative designs and materials, 24V DC fans not only bolster system reliability but also contribute to sustainability efforts within the industry.

Key attributes such as:

- High airflow capacity

- Durable construction

- Variable speed control

are essential elements that define the effectiveness of these cooling solutions. The ability to customize performance based on specific cooling needs, coupled with compatibility across diverse power sources, further underscores their versatility. Moreover, the emphasis on manufacturer support and warranty ensures that engineers can implement these solutions with confidence, knowing they are backed by reliable service.

In a landscape increasingly focused on energy efficiency and compact designs, the role of 24V DC fans is poised for expansion. Engineers are urged to view these advanced cooling solutions not merely as components, but as critical factors in the success of their electronic designs. By leveraging the benefits of 24V DC fans, professionals can enhance system performance, reduce operational costs, and contribute to a more sustainable future in technology.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized for its innovative cooling solutions, specifically its extensive range of 24V DC fans designed for the electronics sector, which enhance thermal management and boost the performance and longevity of electronic components.

What are the advantages of using 24V DC fans?

24V DC fans utilize up to 70% less energy compared to AC fans, making them cost-effective. They incorporate brushless DC motors, which minimize energy loss and heat generation, contributing to sustainable operation.

How does IoT technology enhance the functionality of 24V DC fans?

IoT technology allows for remote monitoring and real-time adjustments of the fans based on environmental conditions, enabling engineers to dynamically improve temperature management and maintain optimal system performance.

What airflow capacity do 24V DC fans typically have?

24V DC fans have effective air movement rates typically ranging from 10 to 100 CFM, which is essential for proficient electronic temperature regulation.

Why is high airflow capacity important in electronic applications?

High airflow capacity is crucial for effective cooling, especially in challenging environments like server rooms and industrial machinery, as it mitigates the risk of overheating and enhances the performance and reliability of electronic systems.

What sizes of 24V DC fans does Gagner-Toomey Associates offer?

Gagner-Toomey Associates provides a variety of fan sizes ranging from 15 to 280mm, including tube axial units and centrifugal blowers.

How does the noise level of 24V DC fans compare to other fans?

The 24V DC fans are designed for quiet operation, achieving sound levels below 30 dBA, making them suitable for noise-sensitive environments such as medical equipment, offices, and residential areas.

What is the projected growth of the DC cooling fan market?

The DC cooling fan market is projected to reach USD 2.1 billion by 2033, indicating the increasing importance of low noise operation in the industry.

What certifications do Gagner-Toomey’s 24V DC fans possess?

Gagner-Toomey’s 24V DC fans have certifications such as CE, RoHS, REACH, and ETL, which ensure their safety and reliability in various applications.