Introduction

Innovations in cooling technology are revolutionizing how engineers tackle high-temperature environments, particularly with the advent of high temp circulation fans. These sophisticated devices not only boost operational efficiency but also promise significant energy savings and enhanced performance across a range of applications. As industries increasingly emphasize sustainability and reliability, a critical question emerges: what key features must engineers consider to optimize the effectiveness of these fans in challenging conditions?

This article explores ten essential characteristics that define high temp circulation fans, providing insights that empower engineers to make informed decisions in their designs and implementations. By understanding these features, engineers can ensure that their cooling solutions meet the demands of modern industrial applications.

Gagner-Toomey Associates: Innovative Cooling Solutions for High Temp Circulation Fans

Gagner-Toomey Associates stands out as a leader in delivering advanced temperature regulation solutions specifically designed for high temp circulation fans. As the largest producer of both standard and custom air-movers globally, Gagner-Toomey provides an extensive selection of DC input tube axial fans and centrifugal blowers, all optimized for superior performance, efficiency, and minimal noise.

With deep expertise in temperature regulation technologies, Gagner-Toomey ensures that engineers receive reliable and effective products that meet the stringent demands of various sectors. By partnering with a wide range of manufacturers, the company plays a crucial role in developing innovative temperature control systems that significantly boost performance and efficiency in applications utilizing a high temp circulation fan.

Recent trends highlight the advantages of energy-efficient fans, particularly those employing brushless DC motors, which can cut energy consumption by up to 70% compared to traditional AC motors. This makes them a sustainable choice for high-heat environments. Moreover, successful implementations of advanced temperature regulation technologies, such as liquid systems capable of handling thermal loads exceeding 50 kW per rack, demonstrate the effectiveness of these solutions in optimizing operational efficiency.

As the electronics industry evolves, Gagner-Toomey remains at the forefront, equipping engineers with the latest advancements in cooling technology. This commitment not only enhances performance but also drives the industry towards more sustainable practices.

High-Efficiency EC Motors: Enhancing Performance and Energy Savings

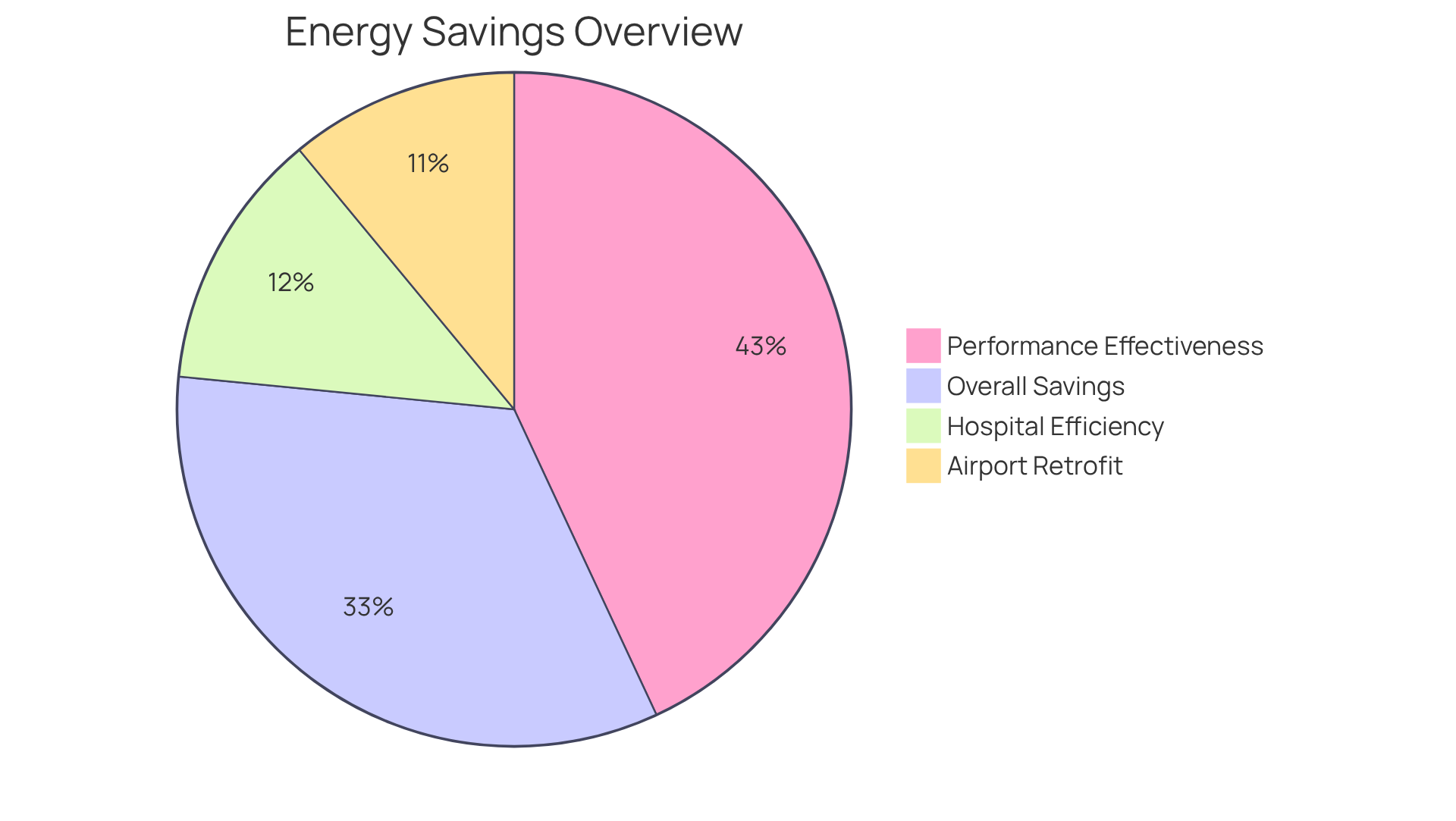

High-efficiency EC (Electronically Commutated) motors are revolutionizing high temp circulation fans by providing energy savings of up to 70% compared to traditional AC motors. These motors achieve effectiveness rates exceeding 90%, which significantly enhances operational performance. Their innovative design allows for precise speed control, adapting seamlessly to varying cooling demands – an essential feature in applications where airflow regulation is critical.

For example, a retrofit of an air handling unit in an airport showcased a remarkable 23% energy saving by switching from AC to EC motors, boosting performance from 51% to 66%. Similarly, hospitals have reported efficiency increases ranging from 10% to 42% after transitioning to EC motors in their fresh air fan units. This adaptability not only reduces energy expenses but also extends the lifespan of refrigeration systems, making EC motors an outstanding choice for engineers committed to sustainable and efficient solutions.

Temperature and Humidity Control: Essential Features for Optimal Performance

Efficient temperature and humidity regulation are essential for the optimal operation of a high temp circulation fan. These features not only prevent overheating but also ensure that the fan operates within its specified limits. By employing sophisticated control systems, engineers can dynamically adjust fan speeds based on real-time temperature and humidity measurements. This optimization of airflow significantly enhances efficiency.

When designing systems, engineers must prioritize these controls to guarantee reliability and performance in demanding conditions. The integration of advanced monitoring and adjustment mechanisms is crucial for maintaining operational integrity.

In summary, understanding and implementing effective temperature and humidity regulation strategies is vital for the success of devices like the high temp circulation fan. Engineers are encouraged to leverage these insights to enhance system design and performance.

Noise Reduction Technology: Ensuring Quiet Operation in High Temp Fans

Noise reduction technology is crucial in the design of high temp circulation fans. Engineers face the challenge of minimizing operational noise, and they can employ a variety of effective strategies to address this issue. For instance, the use of sound-absorbing materials, such as acoustic foam and mass-loaded vinyl, significantly dampens sound transmission. Additionally, optimizing blade designs to reduce turbulence and incorporating vibration dampening features can further enhance quiet operation.

Recent innovations in fan technology, including brushless DC motors and advanced speed control functions, provide engineers with the ability to adjust airflow while maintaining low noise levels. By prioritizing these noise reduction techniques, engineers not only improve user comfort but also ensure compliance with workplace regulations. This commitment to noise reduction ultimately enhances overall satisfaction in industrial applications, making it a vital consideration in engineering design.

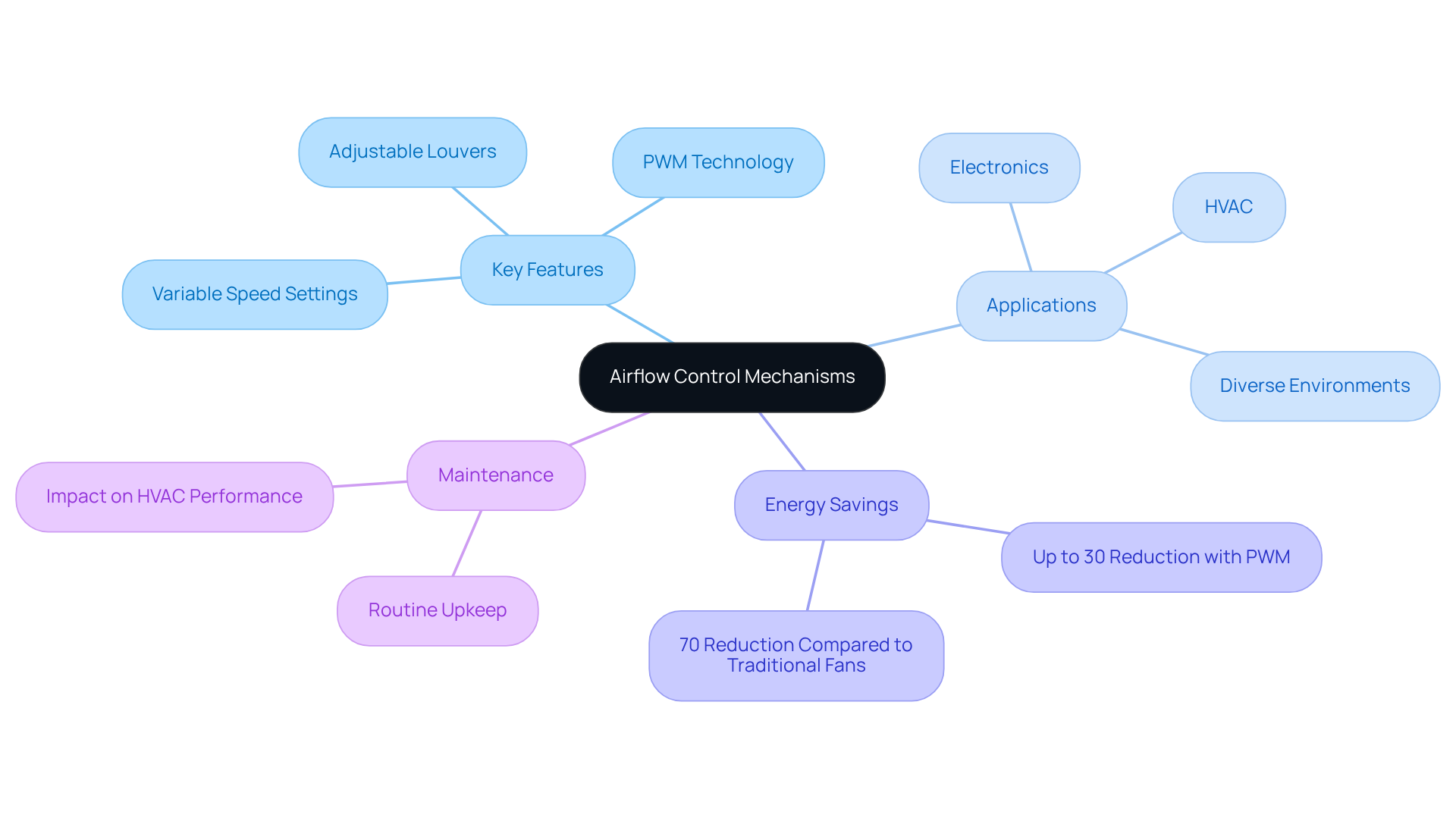

Airflow Control Mechanisms: Customizing Performance for Diverse Applications

Airflow control systems play a crucial role in optimizing the efficiency of high temp circulation fans. Gagner-Toomey Associates stands out as a leading supplier of innovative thermal management solutions tailored for electronics and beyond. Their extensive portfolio features both standard and custom DC input tube axial fans and centrifugal blowers, with sizes ranging from 15 to 280mm for tube axial fans and 15 to 225mm for centrifugal blowers, designed to cater to a wide array of application needs.

Key features such as adjustable louvers and variable speed settings empower engineers to tailor airflow precisely to their specifications. For instance, adjustable louvers can direct airflow exactly where it’s needed, enhancing temperature control and reducing energy consumption. Likewise, variable speed settings facilitate real-time adjustments based on thermal loads, resulting in substantial energy savings. Studies have shown that advanced PWM technology can lead to energy usage reductions of up to 30%.

Most models also offer IP protection upon request, ensuring reliability across diverse environments. Recent advancements in adjustable airflow technologies, including the integration of smart controls and sensors, have further enhanced these features, enabling more efficient cooling solutions. By incorporating a high temp circulation fan among these mechanisms, engineers can ensure optimal system performance in various settings, which ultimately drives better performance and lower operational costs.

Moreover, routine maintenance is vital for sustaining these efficiencies, as it can lead to additional reductions in energy consumption and improved HVAC performance.

Durable Construction Materials: Ensuring Longevity in High Temp Circulation Fans

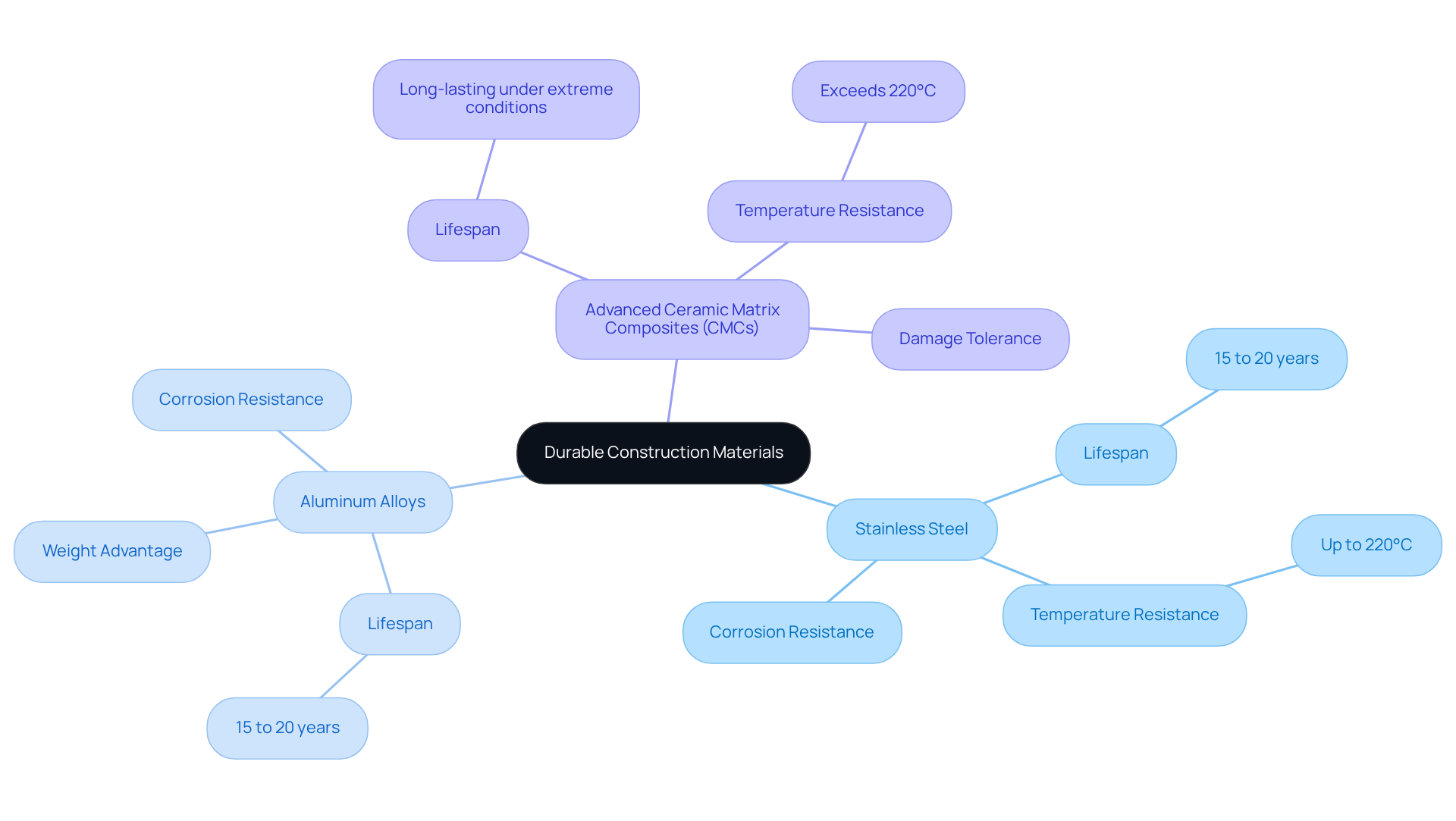

The durability of devices like the high temp circulation fan hinges on the materials used in their construction. Engineers must prioritize materials that can withstand extreme temperatures and corrosive environments, such as:

- stainless steel

- aluminum alloys

- advanced ceramic matrix composites (CMCs)

Gagner-Toomey Associates, recognized as the world’s largest manufacturer of standard and custom air-movers, underscores the significance of high-grade materials in their cooling solutions, which prominently feature high temp circulation fans along with an extensive product line of DC input Tube Axial fans and Centrifugal Blowers.

Fans crafted from high-grade stainless steel boast a lifespan of 15 to 20 years, while high temp circulation fans made from specialized composites are engineered to endure temperatures exceeding 220°C, making them particularly suitable for demanding applications. Additionally, the use of elevated-temperature grease in mechanical components is crucial, as highlighted in a case study, to extend their lifespan by preventing lubrication failure under thermal stress. Most models also provide IP protection upon request, further enhancing their reliability in harsh operational conditions.

Selecting the right materials is not just important; it directly impacts the fan’s effectiveness and reliability. This choice ultimately aids in compliance with safety regulations and boosts overall system performance.

Smart Technology Integration: Enhancing Control and Efficiency in Fan Operation

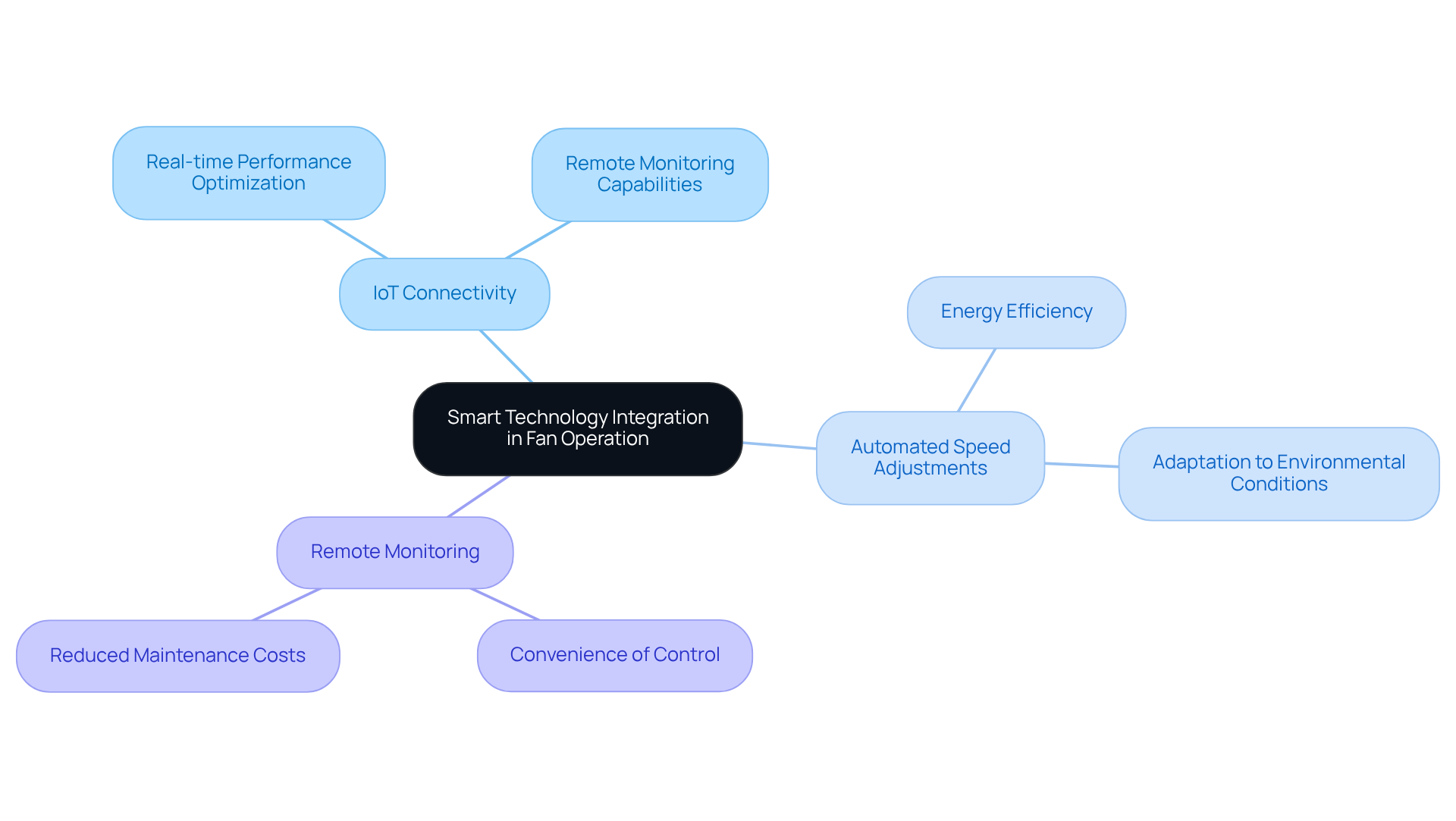

Incorporating intelligent technology into high temp circulation fan devices presents a compelling opportunity to enhance control and performance. With features such as IoT connectivity, automated speed adjustments, and remote monitoring capabilities, these devices enable real-time performance optimization. Engineers can leverage these advancements to create systems that adapt to changing environmental conditions, ultimately improving energy efficiency and reducing operational costs.

By embracing these technologies, professionals in the field can not only optimize their systems but also position themselves at the forefront of innovation in energy management. The integration of intelligent technology is not just a trend; it is a strategic move towards sustainable and cost-effective operations.

Safety Features: Protecting Users and Equipment in High Temp Environments

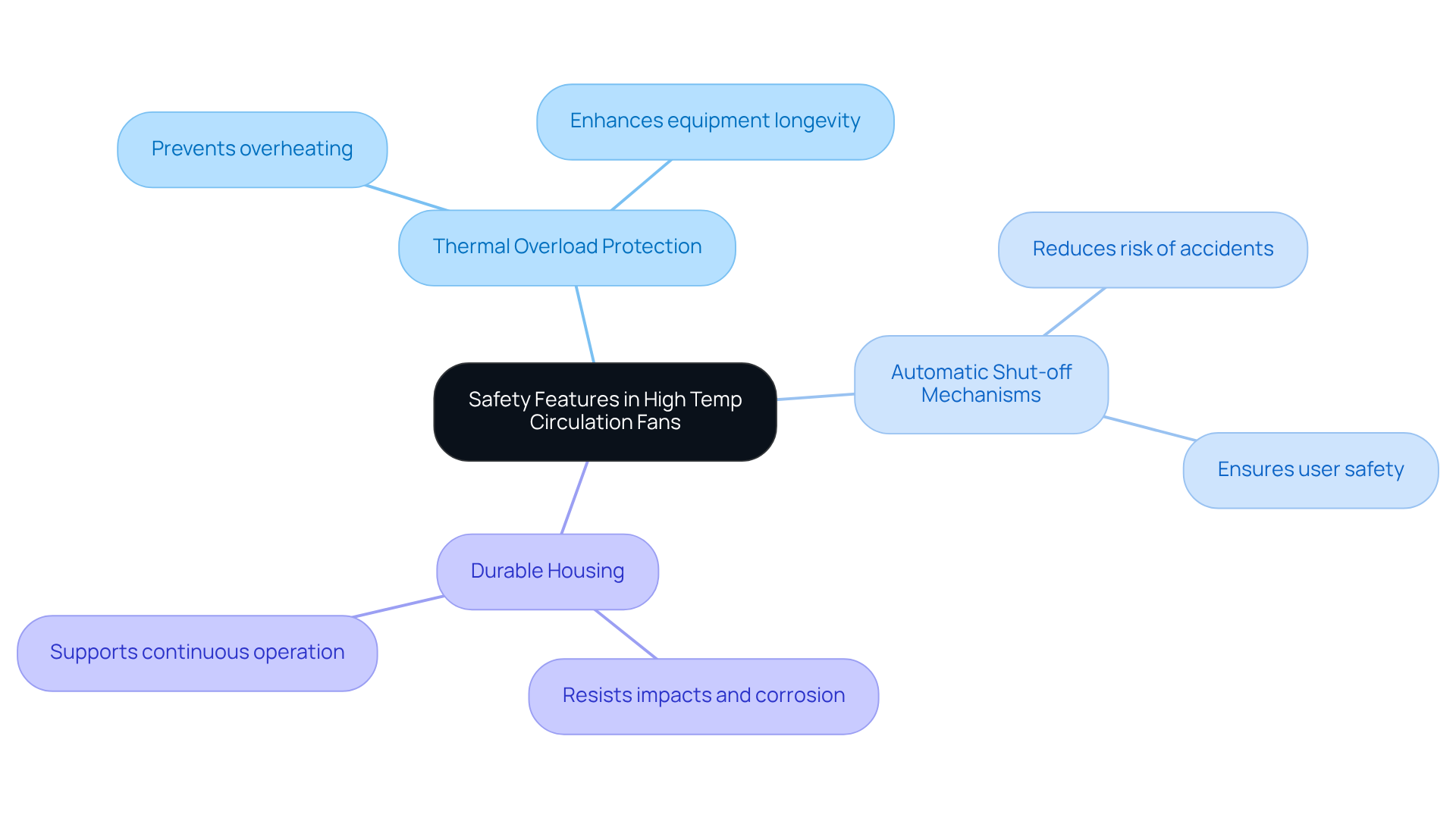

Safety features are paramount in the design of high temp circulation fans, especially those manufactured by Gagner-Toomey Associates, the leading producer of standard and custom air-movers worldwide. Engineers must integrate critical elements such as:

- Thermal overload protection

- Automatic shut-off mechanisms

- Durable housing

to avert accidents and prevent equipment damage.

These safety measures not only safeguard users but also bolster the reliability of systems utilizing a high temp circulation fan operating under extreme conditions, ensuring adherence to industry safety standards. Gagner-Toomey’s advanced designs, which prioritize performance and efficiency, further underscore the importance of these safety features, making their solutions ideal for elevated-temperature applications that utilize a high temp circulation fan.

Incorporating these safety features is not just a regulatory requirement; it is a commitment to excellence in engineering. By choosing Gagner-Toomey, you are investing in systems that prioritize safety without compromising on performance.

User-Friendly Installation and Maintenance: Simplifying Fan Operation

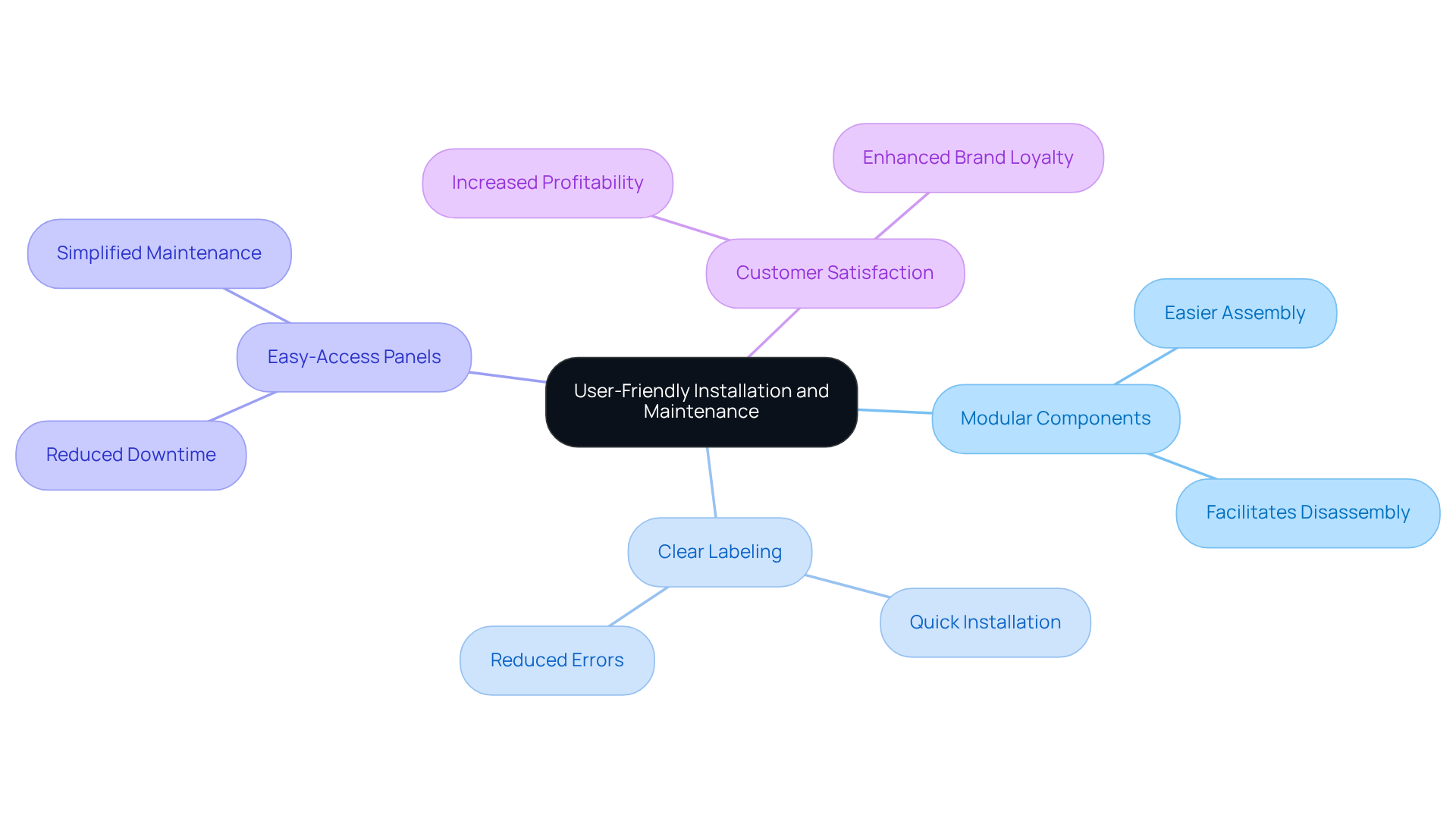

User-friendly installation and maintenance characteristics are crucial for the high temp circulation fan devices. Engineers must prioritize designs that incorporate modular components, facilitating easier assembly and disassembly. Clear labeling and straightforward assembly instructions are vital for quick installation. Moreover, integrating features like easy-access panels for maintenance can significantly reduce downtime, thereby enhancing the overall user experience.

This approach not only ensures that devices operate efficiently throughout their lifespan but also aligns with the latest trends in maintenance solutions. It ultimately aids engineers in their quest for dependable performance. Notably, a highly satisfied customer can generate 14 times more profit than a dissatisfied one, highlighting the importance of these user-friendly features in boosting customer satisfaction and operational efficiency.

In today’s competitive landscape, companies such as Acme Engineering & Manufacturing Corporation and Greenheck Fan Corporation are at the forefront of developing energy-efficient and eco-friendly ventilation solutions. Therefore, it is essential for engineers to consider these aspects in their designs.

Versatile Applications: Utilizing High Temp Circulation Fans Across Industries

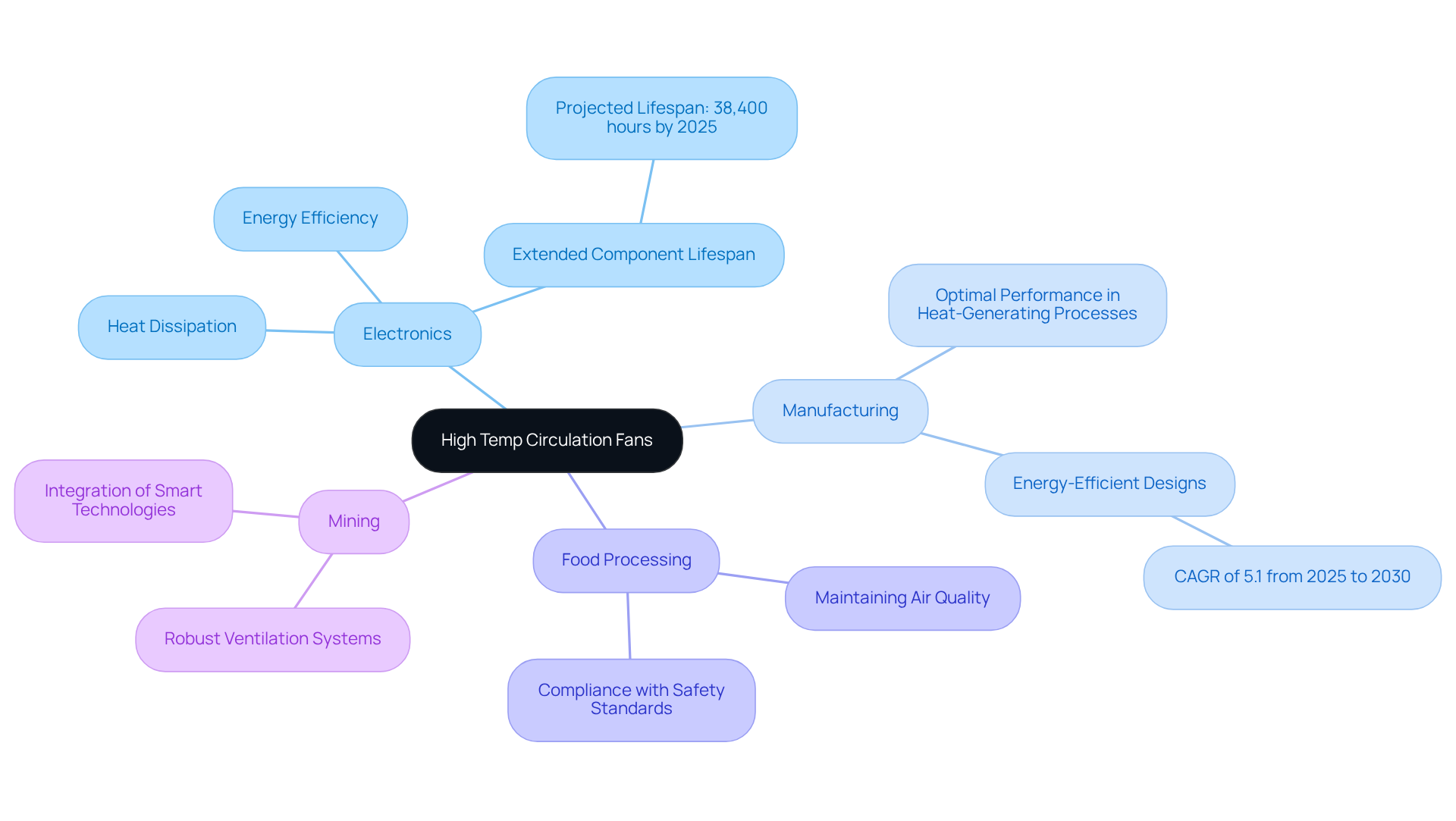

A high temp circulation fan is essential in a range of industries, including electronics, manufacturing, and food processing. These devices, like the high temp circulation fan, are engineered to perform effectively under extreme conditions, making them ideal for applications such as regulating electronic components, ventilating industrial ovens, and maintaining air quality in high-heat environments.

In the electronics sector, for instance, semiconductor heat dissipation devices are meticulously designed to manage temperature efficiently. This capability could potentially extend component lifetimes to over 38,400 hours by 2025, thanks to their superior thermal management. In manufacturing, these devices are vital for ensuring optimal performance in processes that generate significant heat, such as metalworking and food processing.

The rising demand for reliable cooling solutions that comply with stringent safety and environmental standards is driven by high temp circulation fans. Recent trends indicate a growing preference for energy-efficient designs, with axial airflow devices projected to expand at a CAGR of 5.1% from 2025 to 2030, attributed to their high airflow capabilities and reduced energy consumption.

Industries that utilize high temp circulation fans, particularly mining, are expected to experience the fastest growth due to the increasing need for robust ventilation systems. These sectors are increasingly focused on integrating smart technologies that enhance operational efficiency and adapt to varying thermal loads, ensuring compliance with evolving industry standards.

Moreover, the temperature regulation devices market is anticipated to reach approximately USD 22.83 billion by 2034, underscoring the growing significance of effective cooling solutions in today’s industrial landscape.

Conclusion

High temperature circulation fans are essential tools that meet the rigorous demands of various industries. These fans feature advanced technologies, including energy-efficient EC motors, precise temperature and humidity control, and durable construction materials. Such innovations not only enhance performance but also promote sustainability. By leveraging these technologies and prioritizing user-friendly designs, engineers can ensure these fans operate effectively in extreme conditions while minimizing operational costs.

The article has explored key insights into the benefits of high temperature circulation fans. Notably, significant energy savings can be achieved through brushless DC motors. Additionally, noise reduction technologies play a vital role in enhancing user comfort, while safety features are critical in protecting both users and equipment. The versatility of these fans across sectors such as electronics, manufacturing, and food processing underscores their essential contribution to operational efficiency and compliance with safety standards.

Embracing advancements in high temperature circulation fan technology is crucial for engineers aiming to optimize system performance and sustainability. As industries evolve, integrating smart technologies and energy-efficient solutions will be paramount in driving innovation. By prioritizing these features, professionals can enhance their designs and contribute to a more sustainable future in industrial cooling solutions.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized as a leader in providing advanced temperature regulation solutions specifically for high temp circulation fans. They are the largest producer of both standard and custom air-movers globally.

What types of products does Gagner-Toomey offer?

Gagner-Toomey offers a wide selection of DC input tube axial fans and centrifugal blowers, all optimized for superior performance, efficiency, and minimal noise.

How do Gagner-Toomey’s products benefit engineers?

Their products ensure that engineers receive reliable and effective solutions that meet the stringent demands of various sectors, significantly boosting performance and efficiency in applications utilizing high temp circulation fans.

What recent trends are highlighted in the cooling technology industry?

Recent trends emphasize the advantages of energy-efficient fans, particularly those using brushless DC motors, which can reduce energy consumption by up to 70% compared to traditional AC motors.

What are the benefits of using high-efficiency EC motors in high temp circulation fans?

High-efficiency EC motors provide energy savings of up to 70% compared to traditional AC motors, achieve effectiveness rates exceeding 90%, and allow for precise speed control, adapting to varying cooling demands.

Can you give an example of energy savings achieved by switching to EC motors?

A retrofit of an air handling unit in an airport resulted in a 23% energy saving by switching from AC to EC motors, increasing performance from 51% to 66%. Hospitals have also reported efficiency increases of 10% to 42% after similar transitions.

Why is temperature and humidity control important for high temp circulation fans?

Efficient temperature and humidity regulation is essential to prevent overheating and ensure that the fan operates within its specified limits. It enhances efficiency by allowing dynamic adjustments to fan speeds based on real-time measurements.

What should engineers prioritize when designing systems with high temp circulation fans?

Engineers should prioritize sophisticated control systems that allow for the dynamic adjustment of fan speeds based on temperature and humidity measurements to guarantee reliability and performance in demanding conditions.