Introduction

The demand for efficient cooling solutions in electronics has surged dramatically. At the forefront of this evolution are 48V fans, which have emerged as a pivotal technology in this landscape. These advanced fans not only promise significant energy savings – up to 70% less power consumption compared to traditional models – but also enhance overall system performance through superior thermal management.

However, as the industry evolves, engineers face the challenge of integrating these high-voltage fans into existing systems. Navigating compatibility and regulatory hurdles can be daunting. What are the key insights that can help professionals leverage the full potential of 48V fans in their designs?

Understanding these challenges and opportunities is crucial for engineers aiming to optimize their systems. By embracing the capabilities of 48V fans, professionals can not only improve energy efficiency but also drive innovation in their designs.

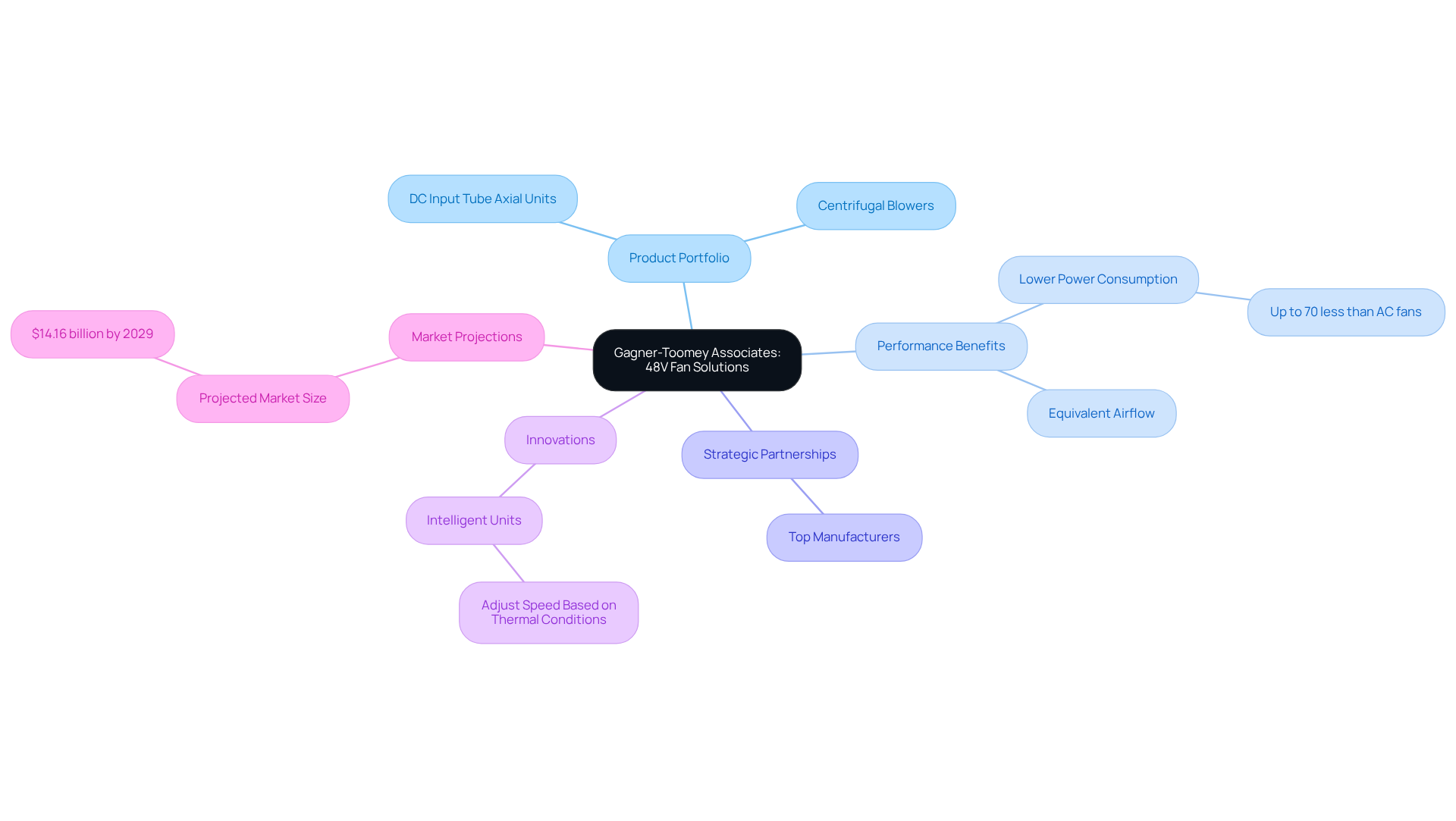

Gagner-Toomey Associates: Leading Provider of 48V Fan Solutions

Gagner-Toomey Associates is recognized as a top supplier of solutions for 48V fans, emphasizing high-performance thermal management systems designed for the electronics sector. Their extensive portfolio features advanced cooling technologies, including a wide range of DC input Tube Axial units and Centrifugal Blowers, designed to meet the rigorous demands of modern electronic applications. Notably, 48V fans provide significant performance benefits, featuring up to 70% lower power consumption compared to traditional AC fans while delivering equivalent airflow. This efficiency is vital in environments where effective thermal management is essential.

The firm’s dedication to quality is underscored by strategic partnerships with top manufacturers, ensuring engineers have access to state-of-the-art solutions featuring a 48V fan that enhance both performance and reliability. Recent innovations in 48V fan technology, including intelligent units that adjust speed based on thermal conditions, exemplify Gagner-Toomey’s commitment to advancing the boundaries of innovation. Successful implementations of these temperature control systems have proven their effectiveness across various applications, highlighting the critical importance of selecting the right fan for optimal performance.

As the market for advanced cooling solutions continues to expand, projected to reach $14.16 billion by 2029, Gagner-Toomey Associates remains at the forefront, equipping engineers with the essential tools to achieve superior thermal management in their designs.

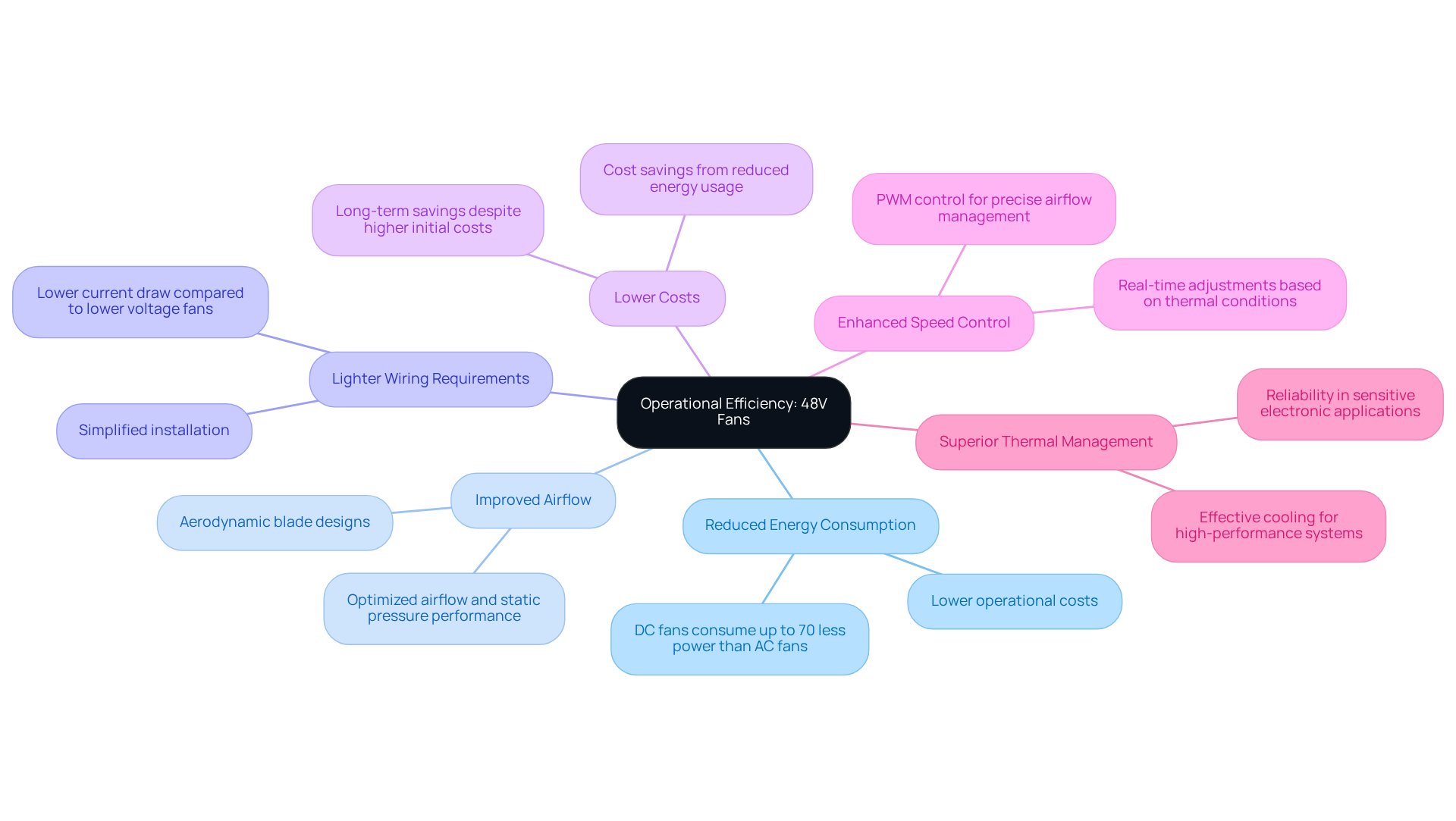

Operational Efficiency: Benefits of 48V Fans in Electronics

The 48V fan provides significant operational efficiency advantages, including reduced energy consumption and improved airflow. Operating at a higher voltage allows these devices to deliver the same performance as their lower voltage counterparts while drawing less current. This efficiency results in lighter wiring requirements and lower overall costs.

Moreover, the enhanced speed control features of the 48V fan facilitate superior thermal management, making them particularly suitable for high-performance electronic systems. By adopting a 48V fan technology, organizations can not only optimize their energy usage but also enhance the reliability and performance of their systems.

In conclusion, utilizing a 48V fan as part of the transition to 48V devices is a strategic move that can lead to substantial cost savings and improved operational efficiency. Embracing this technology positions businesses at the forefront of innovation in electronic systems.

Technical Specifications: Key Features of 48V Fans

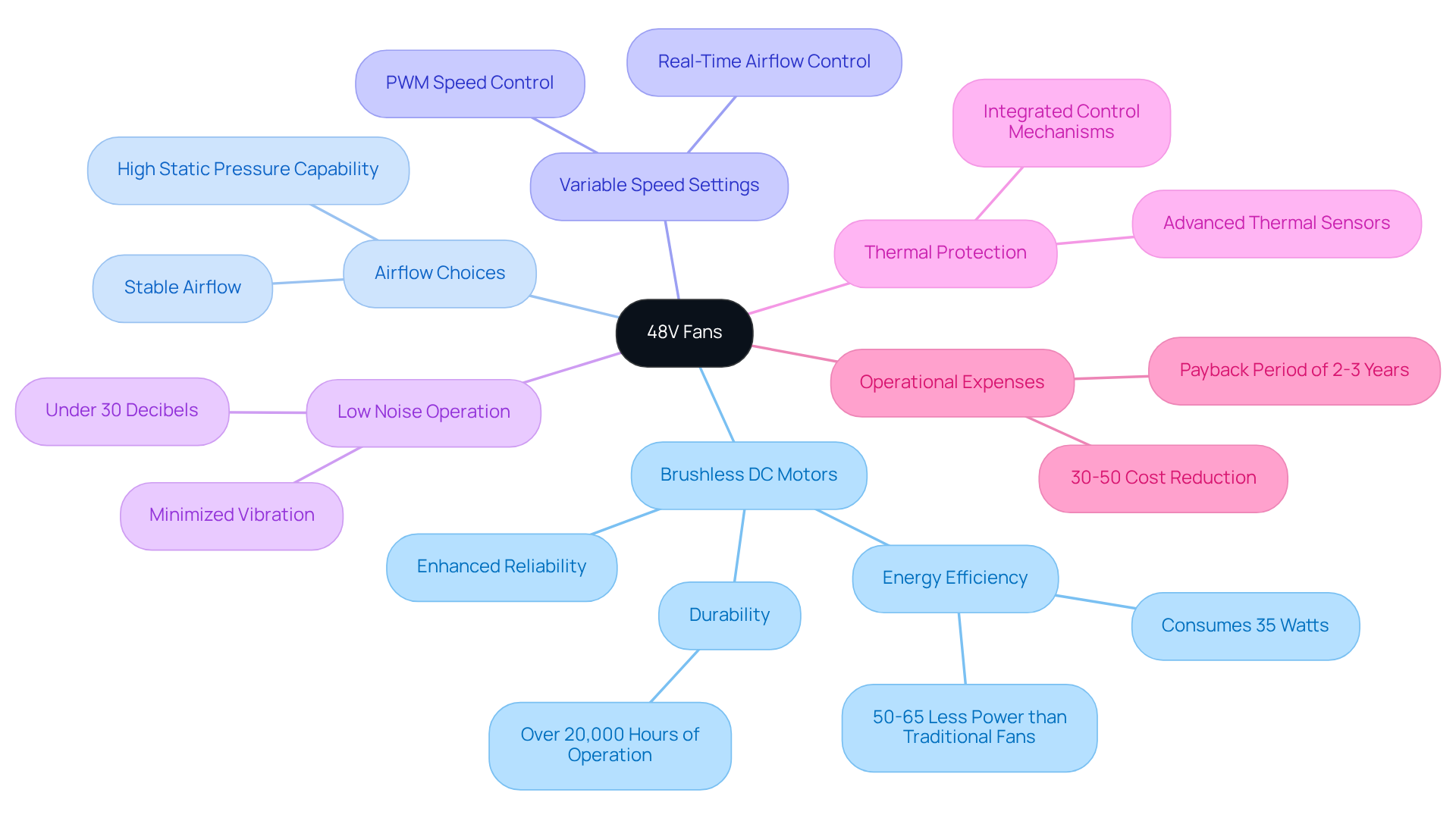

Unlocking the Power of 48V Units

The key characteristics of 48V units prominently include brushless DC motors, which significantly enhance both reliability and efficiency. These devices are engineered to provide a wide range of airflow choices, variable speed settings, and impressively low noise operation. In fact, numerous models achieve noise levels under 30 decibels, making them ideal for delicate environments.

Moreover, many models come equipped with advanced thermal protection and integrated control mechanisms, which bolster performance across diverse load conditions. This versatility allows the 48V fan units to excel in various applications, from data centers to automotive setups. Engineers have observed that integrating brushless DC motors in fan systems can lead to a remarkable 25% reduction in sudden shutdown incidents, underscoring their reliability in critical applications.

Furthermore, the operational expenses associated with these devices can be reduced by 30% to 50% compared to conventional models, highlighting their financial advantages. Overall, the combination of energy efficiency, low operational noise, and robust performance makes the 48V fan the preferred choice in modern electronic designs.

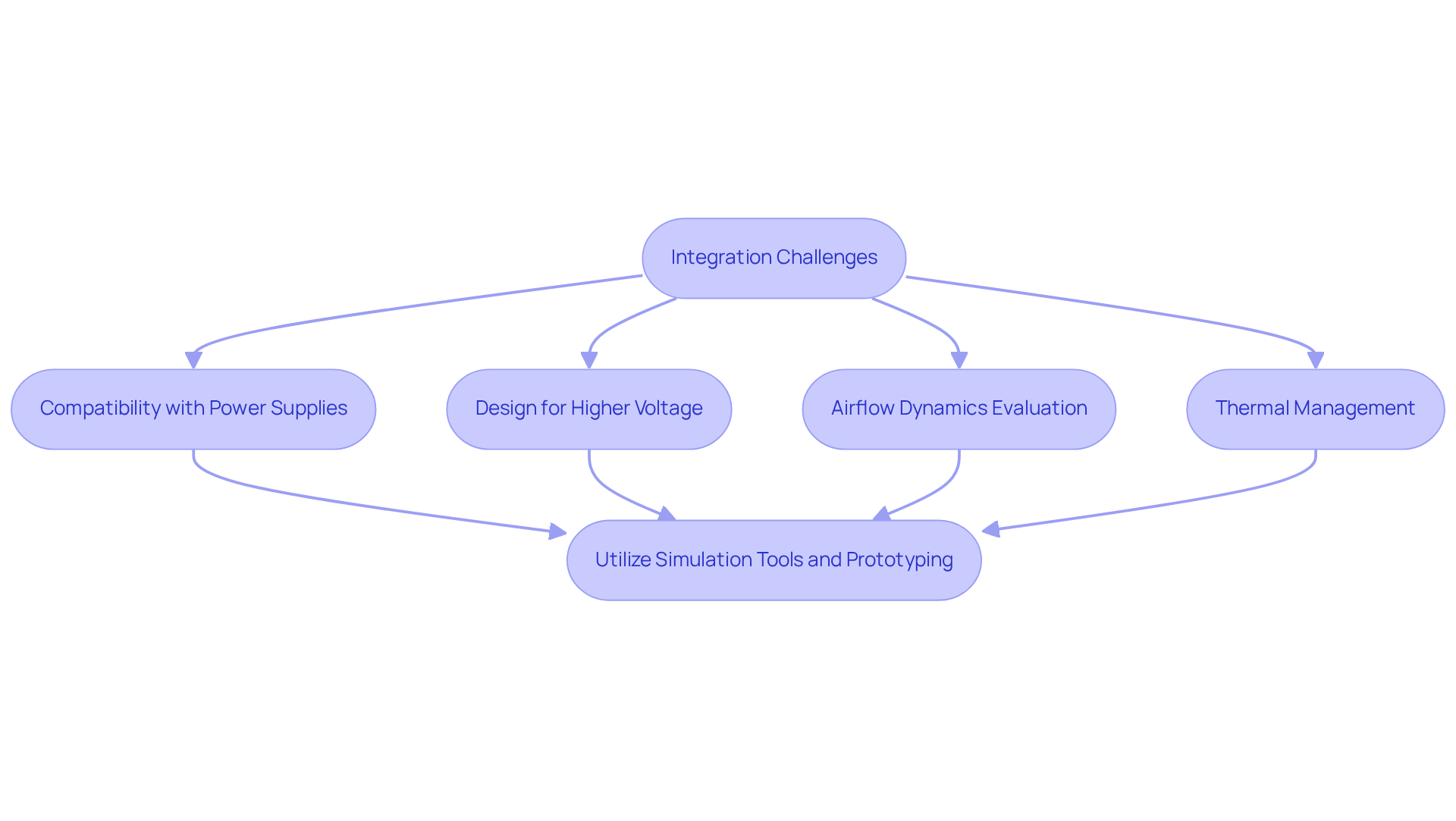

Integration Challenges: Implementing 48V Fans in Systems

Integrating a 48V fan into existing systems presents significant challenges, particularly regarding compatibility with current power supplies and control systems. Engineers must prioritize designs that accommodate these higher voltage levels, ensuring that safety and performance remain uncompromised. Additionally, a thorough evaluation of airflow dynamics and thermal management is essential for optimizing the efficiency of the 48V fan.

To address these challenges effectively, utilizing simulation tools and prototyping is crucial. These methods allow engineers to identify potential issues early in the design process, facilitating smoother integration and enhancing overall system performance. By adopting these strategies, professionals can navigate the complexities of systems involving the 48V fan with confidence.

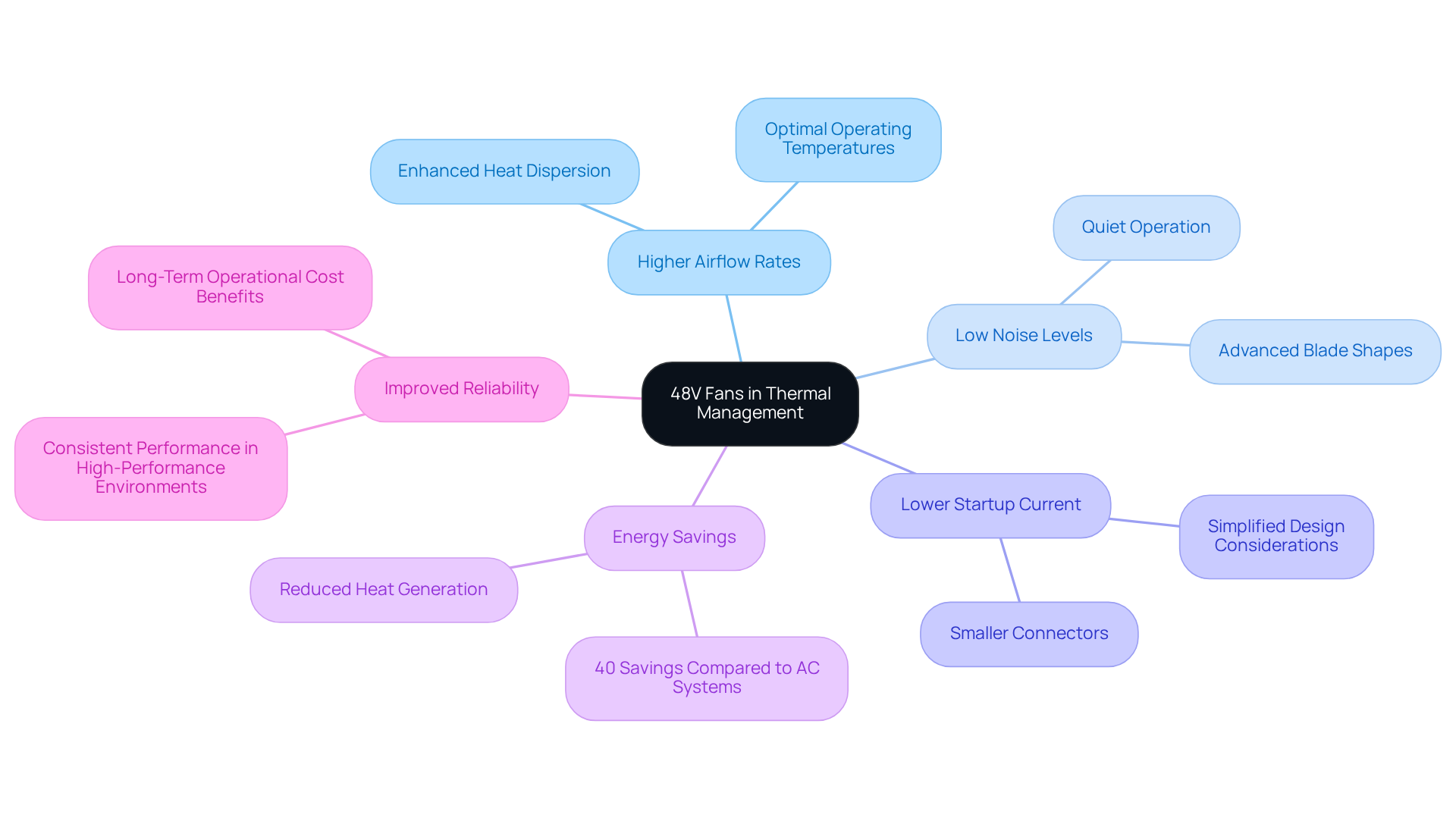

Cooling Efficiency: How 48V Fans Enhance Thermal Management

The use of a 48V fan is crucial for enhancing thermal management, delivering significantly higher airflow rates and superior temperature regulation. Their ability to operate at elevated speeds while keeping noise levels low makes them ideal for compact applications where heat generation is substantial. By effectively dispersing heat, 48V units help maintain optimal operating temperatures, leading to improved overall reliability.

Moreover, the startup current required for a 48V fan is considerably lower than that of a 12V fan. This allows for the use of smaller connectors, simplifying design considerations. Recent advancements in DC cooling technology have introduced innovations that enhance operational quietness and efficiency, resulting in energy savings of approximately 40% compared to traditional AC systems.

These improvements underscore the growing preference for 48V fan units in applications that require superior thermal management solutions, particularly in high-performance environments like data centers and industrial systems. As the industry evolves, embracing these advancements can lead to significant operational benefits.

Regulatory Compliance: Standards for 48V Fan Usage

Engineers implementing 48V devices face the critical challenge of navigating a complex landscape of regulatory standards, including UL, CE, and RoHS compliance. These standards are essential for ensuring safety and environmental sustainability. UL certification guarantees that products meet rigorous safety standards, while CE marking signifies conformity with European health, safety, and environmental protection legislation. Additionally, RoHS compliance restricts hazardous substances in electrical and electronic equipment, aligning with global sustainability goals.

The significance of these standards cannot be overstated. They not only protect end-users but also enhance product reliability and marketability. For instance, 48V fan devices designed for industrial applications must adhere to these compliance requirements to ensure safe operation in demanding environments. High-performance ventilators from leading manufacturers serve as prime examples of compliant products that have successfully passed UL and CE testing, as well as RoHS evaluations.

Industry experts emphasize the critical nature of these standards with statements like, “Safety is not a gadget but a state of mind,” highlighting that compliance is integral to the design process. Moreover, understanding the specific regulations applicable to sectors such as automotive or telecommunications is vital for engineers aiming to develop products that not only meet but exceed safety expectations. By prioritizing compliance, engineers can significantly contribute to the creation of safer, more efficient cooling solutions in the electronics industry, including the use of a 48V fan.

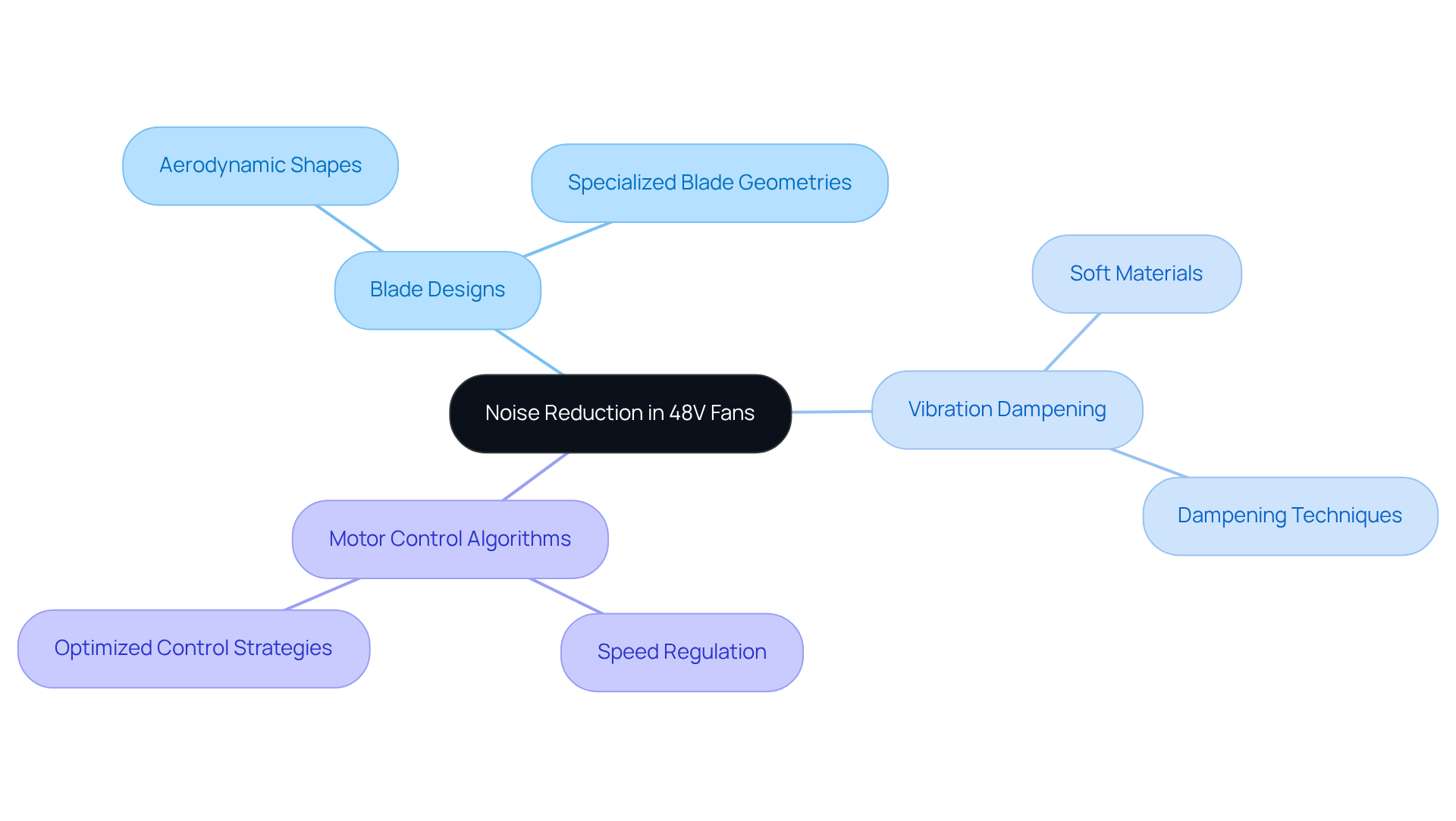

Noise Reduction: The Importance of Quiet Operation in 48V Fans

Noise reduction stands as a critical factor in the design of 48V fan devices, especially in environments where quiet operation is paramount, such as residential and office settings. Advanced blade designs, vibration dampening materials, and optimized motor control algorithms play a significant role in achieving lower noise levels.

Engineers must prioritize selecting devices that not only deliver low sound pressure levels but also maintain high airflow rates. This balance is essential for ensuring user comfort and operational efficiency. By focusing on these key aspects, professionals can enhance the overall performance of devices using a 48V fan while addressing the growing demand for quieter solutions in various applications.

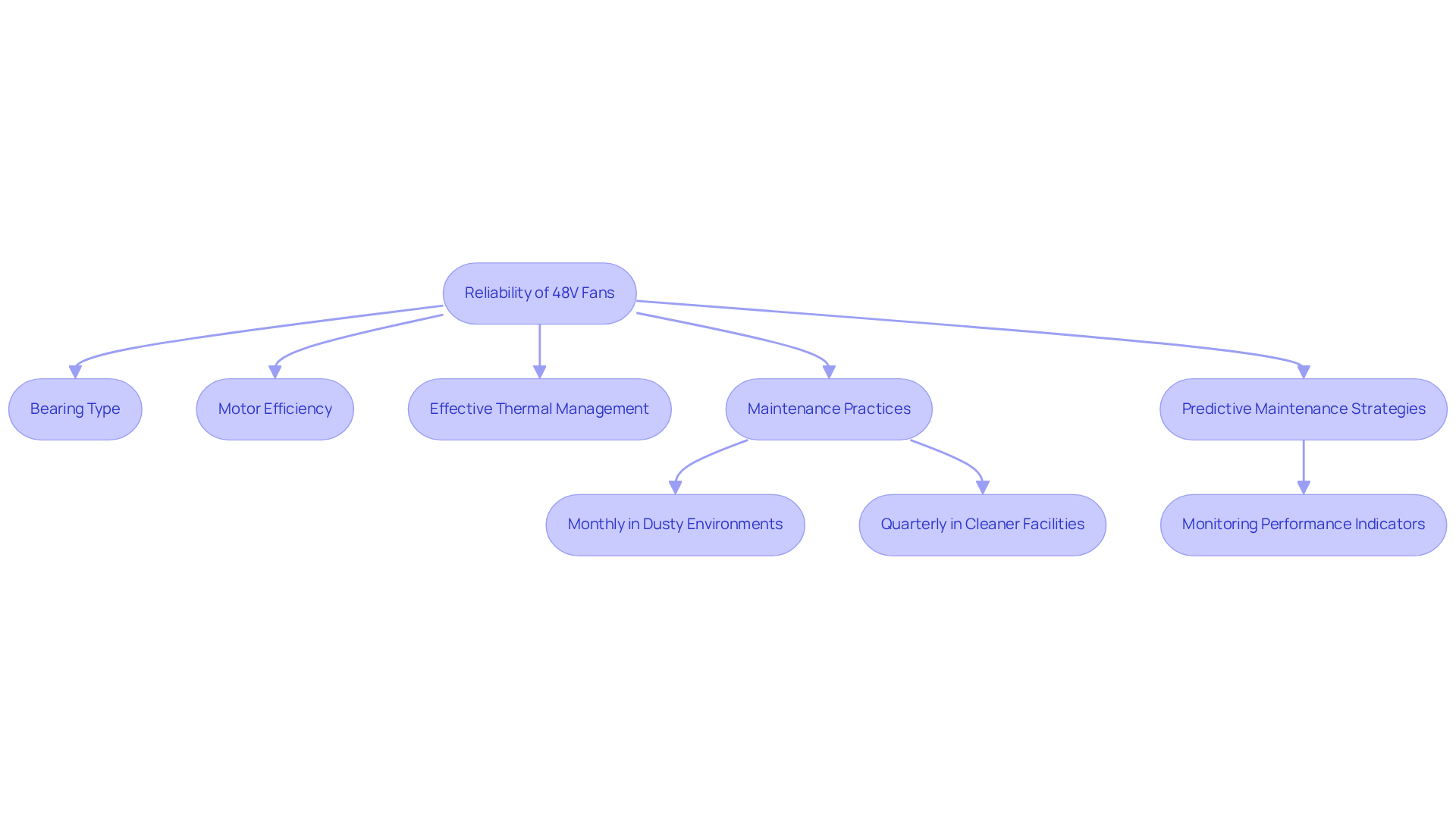

Reliability: Ensuring Long-Term Performance of 48V Fans

To ensure long-term performance, high-quality components and robust construction must be incorporated into the design of 48V fans. The reliability of these fans hinges on several critical factors, including:

- Bearing type

- Motor efficiency

- Effective thermal management

Regular maintenance practices are essential; for instance, lubrication and inspections should be scheduled:

- Monthly in dusty environments

- Quarterly in cleaner facilities

This proactive approach helps identify potential issues before they escalate into failures.

Engineers should consider adopting predictive maintenance strategies. By employing sensors to monitor performance indicators such as vibration and temperature in real-time, organizations can significantly enhance the lifespan of refrigeration units. As David Long, Vice President of Sales, aptly states, ‘Routine, proactive maintenance can add years to your fan’s life, improve energy efficiency, and prevent costly breakdowns.’ Ignoring maintenance can lead to operating a fan with worn or damaged components, which may inflict considerable damage on the entire mechanism. This often results in repair costs that exceed the expense of timely part replacements.

Technological Advancements: Innovations in 48V Fan Design

Recent advancements in the 48V fan design prominently feature the integration of smart technologies, especially IoT connectivity and sophisticated control algorithms. These innovations enable real-time monitoring and dynamic adjustments of fan performance, optimizing cooling based on specific system demands.

For instance, 48V fans that are IoT-enabled can communicate with other devices, facilitating enhanced temperature regulation and energy management. The adoption of advanced motor technologies has further enhanced efficiency, with some models achieving energy savings of up to 70% compared to traditional AC units, thanks to their ability to adjust performance based on real-time data.

Additionally, the use of high-quality materials has led to quieter operation, making these devices ideal for sound-sensitive environments. As the market for IoT technologies in temperature control solutions continues to expand, with a projected market growth rate of 12.4% over the next several years, engineers are encouraged to leverage these innovations to significantly enhance the performance and reliability of their systems.

Significantly, the dependability of DC ventilators can improve product reliability by as much as 30%, highlighting the practical effects of these advancements. This is a critical opportunity for professionals in the field to adopt these technologies and drive their systems toward greater efficiency and effectiveness.

Future Trends: The Evolution of 48V Fan Technology

The evolution of 48V fan technology is nearing significant advancements, largely driven by the increasing demand for energy-efficient and compact temperature regulation solutions. As industries increasingly prioritize sustainability, the adoption of variable speed fans is gaining momentum. Recent statistics reveal that over 80% of premium electronic devices now feature advanced cooling technologies. This transition not only boosts energy efficiency but also facilitates seamless integration with smart systems, optimizing performance across various applications.

Moreover, the incorporation of sustainable materials in fan design is becoming more prevalent, aligning with global sustainability goals. This shift underscores the importance of engineers embracing these trends to effectively address the challenges of thermal management. By doing so, they can ensure their designs remain competitive and efficient in a rapidly evolving market.

In conclusion, as the landscape of 48V fan technology continues to evolve, it is crucial for professionals in the field to stay informed and adapt to these changes. By leveraging the latest advancements, engineers can enhance their designs and contribute to a more sustainable future.

Conclusion

The exploration of 48V fans underscores their significant role in the electronics engineering landscape, particularly in enhancing thermal management and energy efficiency. By integrating these advanced cooling solutions, engineers can achieve superior performance while aligning their designs with sustainability goals, ensuring modern electronic systems operate effectively and reliably.

Key insights throughout the article highlight the operational advantages of 48V fans, including:

- Lower power consumption

- Improved airflow

- Reduced noise levels

The discussion on regulatory compliance emphasizes the critical importance of adhering to safety and environmental standards. Furthermore, the examination of integration challenges underscores the necessity for strategic planning and innovative solutions. Advancements in technology, such as IoT connectivity and smart control algorithms, position 48V fans as essential components for future electronic designs.

As the demand for energy-efficient solutions continues to rise, embracing the latest trends in 48V fan technology becomes imperative for engineers. Leveraging these innovations allows professionals to enhance the reliability and performance of their systems while contributing to a more sustainable future in the electronics industry. The journey toward optimizing thermal management through 48V fans is not merely a technical upgrade; it represents a commitment to efficiency, innovation, and environmental responsibility.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized as a leading provider of 48V fan solutions, focusing on high-performance thermal management systems for the electronics sector.

What are the advantages of using 48V fans?

48V fans offer significant performance benefits, including up to 70% lower power consumption compared to traditional AC fans while delivering equivalent airflow, making them essential for effective thermal management.

How does Gagner-Toomey Associates ensure the quality of its products?

The firm ensures quality through strategic partnerships with top manufacturers, providing engineers access to state-of-the-art solutions that enhance performance and reliability.

What recent innovations have been made in 48V fan technology?

Recent innovations include intelligent units that adjust speed based on thermal conditions, showcasing Gagner-Toomey’s commitment to advancing technology in thermal management.

What market trends are associated with advanced cooling solutions?

The market for advanced cooling solutions is projected to reach $14.16 billion by 2029, indicating a growing demand for effective thermal management systems.

What operational efficiency benefits do 48V fans provide?

48V fans reduce energy consumption, improve airflow, and allow for lighter wiring requirements, leading to lower overall costs and enhanced reliability in high-performance electronic systems.

What are the key technical specifications of 48V fans?

Key features include brushless DC motors for enhanced reliability, a wide range of airflow choices, variable speed settings, low noise operation (under 30 decibels), and advanced thermal protection.

How do 48V fans impact operational expenses?

The operational expenses associated with 48V fans can be reduced by 30% to 50% compared to conventional models, highlighting their financial advantages.

In what applications are 48V fans particularly effective?

48V fans excel in various applications, including data centers and automotive setups, due to their versatility and robust performance.