Overview

PWM control fans are indispensable for electronics engineers, offering precise speed regulation, energy efficiency, and noise reduction. By leveraging Pulse Width Modulation (PWM), these fans adeptly adjust the power delivered to the motor, ensuring optimal performance. Notably, PWM fans, featuring a four-pin connector, significantly outperform traditional DC fans, especially at lower speeds. This capability makes them particularly suitable for applications that demand effective cooling while minimizing noise levels.

Introduction

The evolution of fan technology has reached a pivotal point with the advent of Pulse Width Modulation (PWM) control fans, which present a sophisticated solution for regulating speed and enhancing efficiency. By leveraging PWM, engineers can achieve precise control over fan performance, leading to energy savings and reduced noise—an essential consideration in today’s electronic environments.

However, the transition from traditional DC fans to PWM systems raises pertinent questions about:

- Performance

- Implementation

- The genuine benefits of this advanced technology

What insights can electronics engineers glean from a deeper understanding of the nuances of PWM control fans, and how can these insights transform their designs?

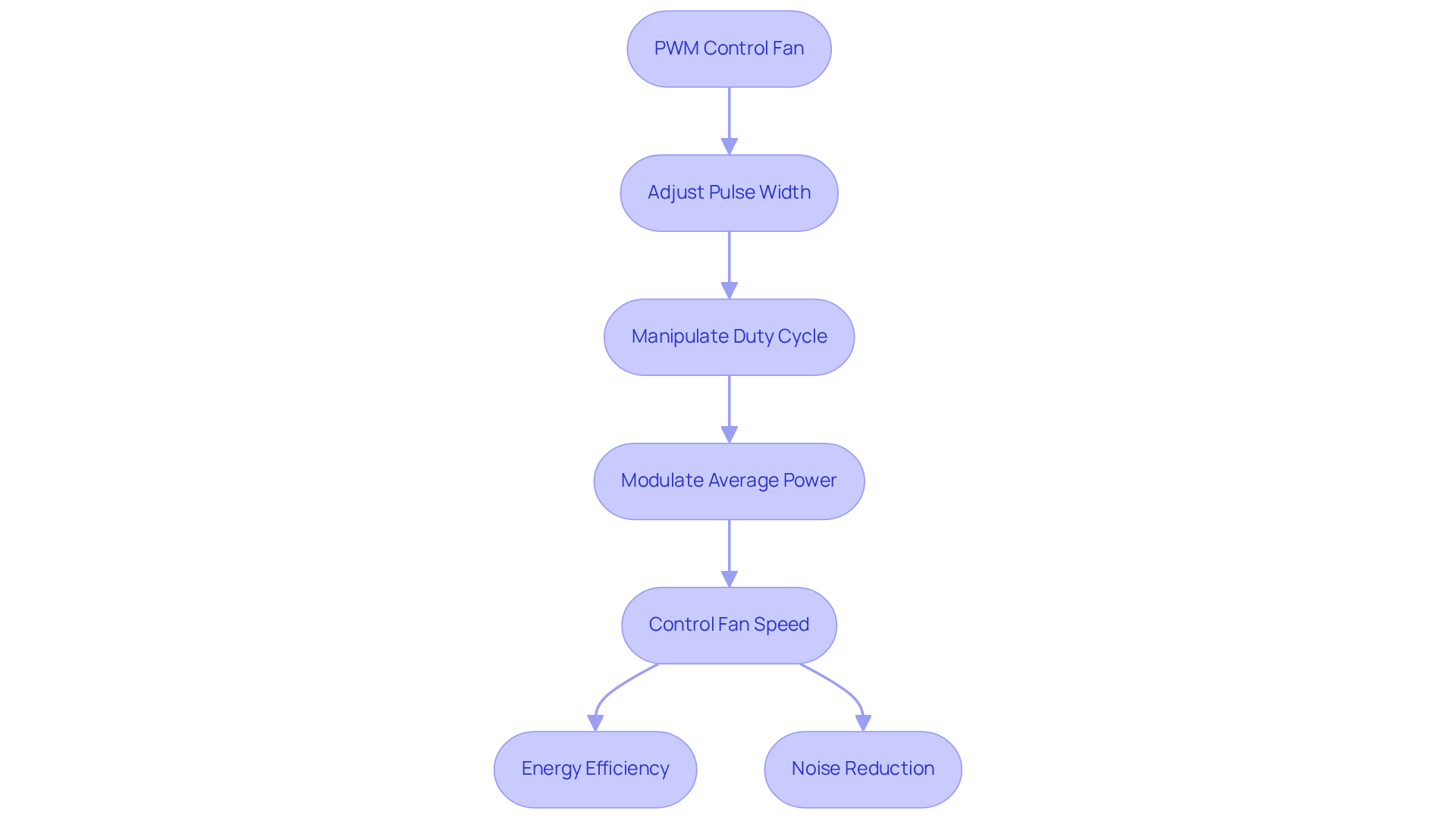

Define PWM and Its Role in Fan Control

The pwm control fan uses Pulse Width Modulation (PWM), a sophisticated method utilized to regulate the speed of ventilators by adjusting the width of the electrical pulses supplied to the motor. By manipulating the duty cycle of these pulses, engineers can effectively use pwm control fan to modulate the average power delivered to the fan, thereby enabling precise control over its rotation. This technique proves particularly advantageous in scenarios where energy efficiency and noise reduction are paramount.

Typically, a pwm control fan is equipped with a four-pin connector, with the fourth pin designated for the PWM signal, facilitating based on thermal requirements or system demands. This stands in contrast to conventional devices, which often operate at a fixed rate determined by the voltage supplied to them.

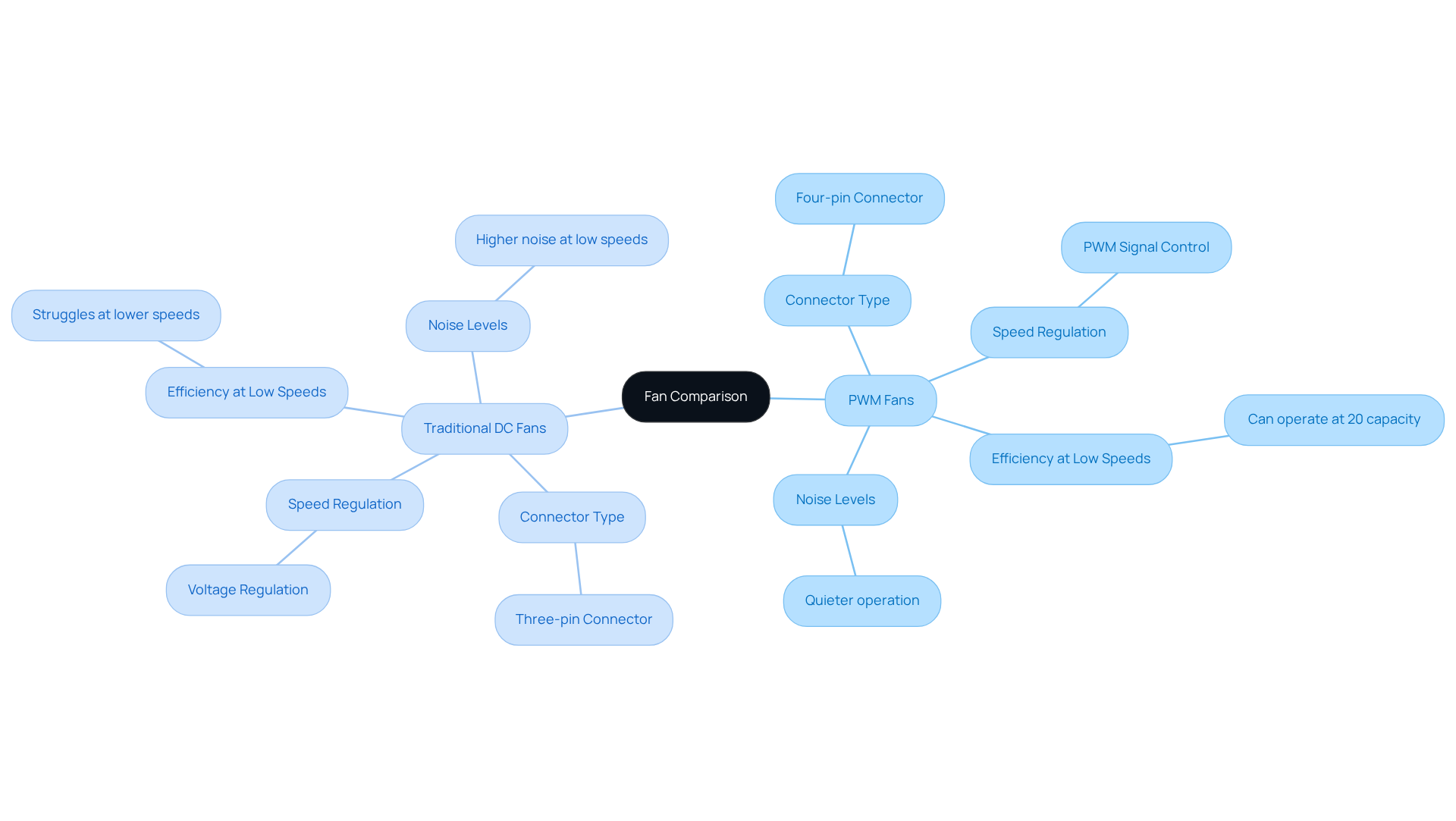

Compare PWM Fans with Traditional DC Fans

PWM units significantly differ from conventional DC units in their operational and regulatory mechanisms.

Conventional DC enthusiasts typically utilize a three-pin connector and rely on voltage regulation to adjust fan speed. This method can lead to inefficiencies; the fan may not perform optimally at lower speeds, resulting in .

Conversely, a PWM control fan incorporates a four-pin connector, where the additional pin transmits a PWM signal to the unit. This design allows for much finer control over the PWM control fan speed, enabling it to function effectively at lower levels without compromising performance.

PWM control fan units can achieve speeds as low as 20% of their maximum capacity, while traditional DC models often face challenges in maintaining efficiency at reduced velocities. Furthermore, PWM cooling devices tend to produce less noise, making them ideal for environments that require silent operation.

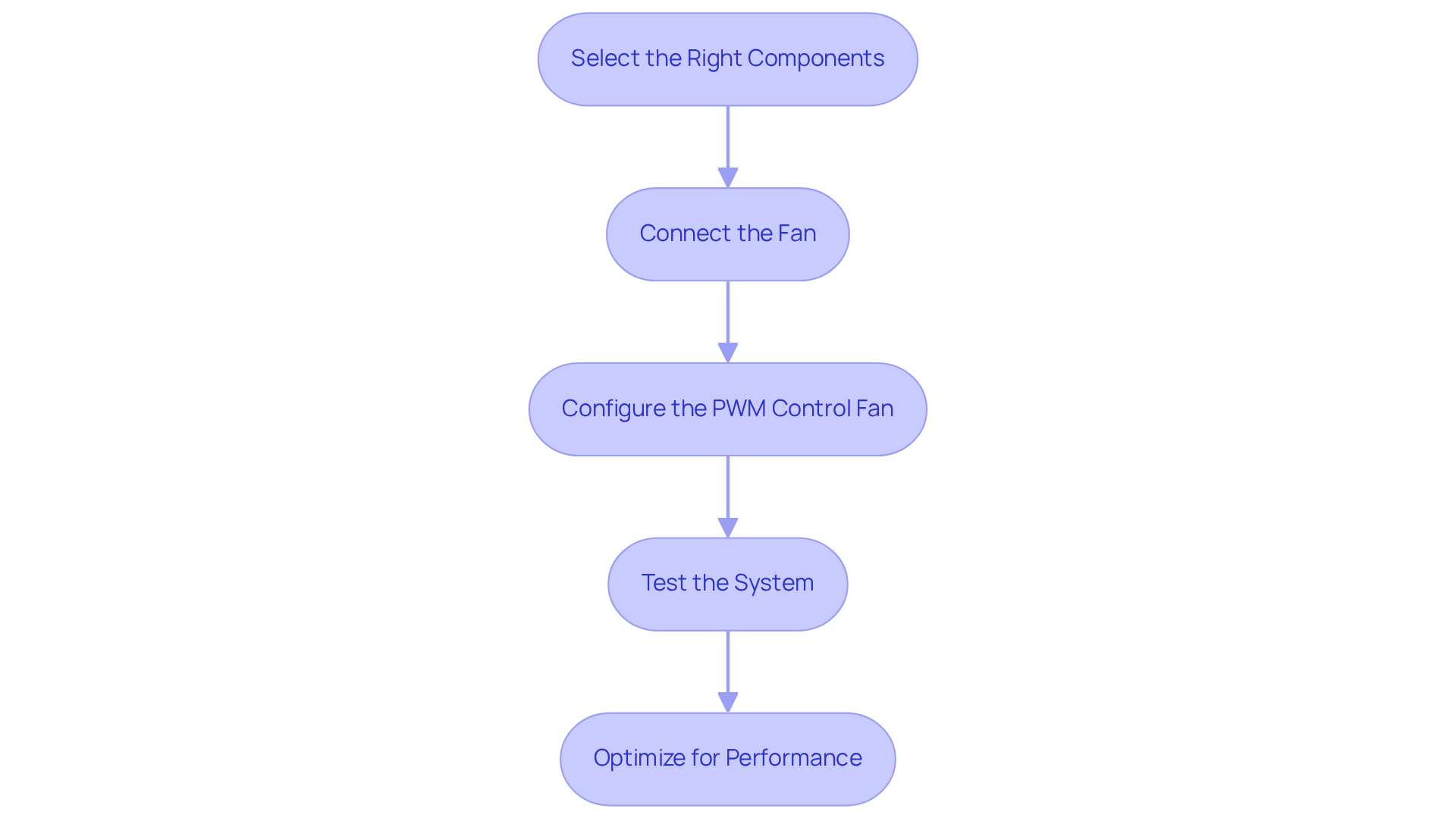

Implement PWM Control in Fan Systems

To implement PWM control in fan systems, follow these steps:

- Select the Right Components: Begin by ensuring you have , which are typically identifiable by their four-pin connectors. Choose a microcontroller or a [PWM control fan](https://gagner-toomey.com/what-is-a-pwm-fan-understanding-functionality-and-benefits) that is capable of generating the required PWM signal.

- Connect the Fan: Connect the fan’s power and ground pins directly to the power supply. Next, connect the PWM signal pin to the appropriate output pin on your microcontroller or controller.

- Configure the PWM control fan: Set up the PWM control fan signal within your microcontroller’s programming environment. Define the frequency for the PWM control fan, which typically ranges between 20 kHz and 25 kHz, and establish the duty cycle, as this will significantly influence the operation of the fan.

- Test the system: Power on the system and closely monitor the response of the PWM control fan to changes in the PWM signal. Adjust the duty cycle of the PWM control fan to observe variations in velocity, ensuring that the fan operates as intended.

- Optimize for Performance: Fine-tune the settings of the PWM control fan based on the specific cooling requirements of your application. Consider incorporating feedback systems, such as temperature sensors, to dynamically adjust the fan operation in response to thermal conditions.

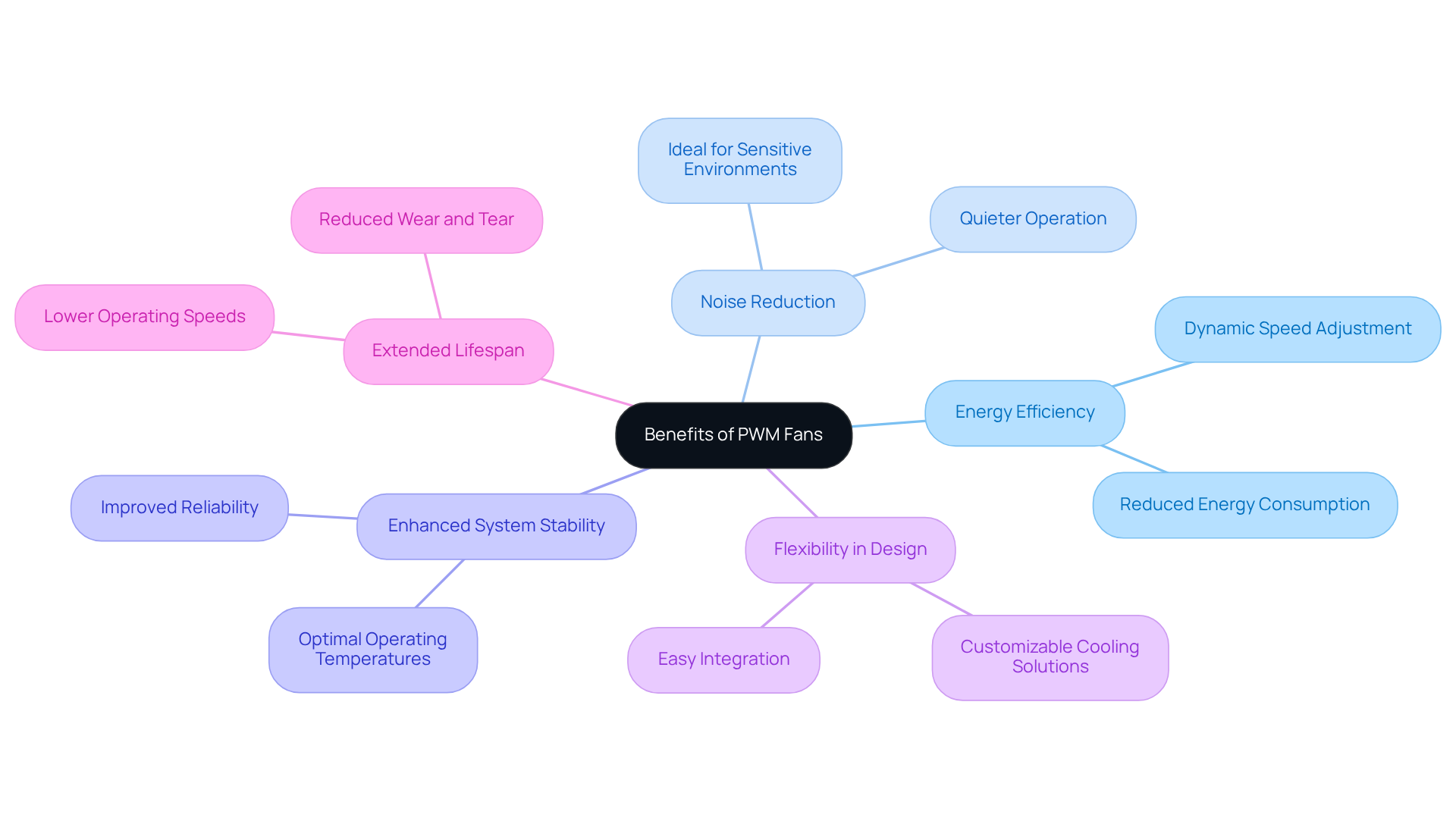

Explore Benefits of PWM Fans for Electronics Applications

PWM fans present several significant advantages for electronics applications:

- Energy Efficiency: By dynamically adjusting fan speed to meet real-time cooling demands, PWM fans markedly decrease energy consumption compared to traditional fans that typically operate at a constant speed.

- Noise Reduction: Operating more quietly, especially at lower speeds, a PWM control fan is ideal for environments where noise sensitivity is paramount, such as home theaters or data centers.

- Enhanced System Stability: With precise control over cooling, PWM control fans help maintain optimal operating temperatures, thereby improving the reliability and longevity of electronic components.

- Flexibility in Design: Easily integrated into diverse systems, the PWM control fan offers customizable cooling solutions tailored to specific application requirements.

- Extended Lifespan: By using a PWM control fan to function at lower speeds when maximum power is unnecessary, these fans experience reduced wear and tear, potentially extending their lifespan and lowering maintenance costs.

Conclusion

Utilizing Pulse Width Modulation (PWM) in fan control systems represents a transformative approach for electronics engineers, enabling precise speed regulation and enhanced energy efficiency. By adopting PWM technology, engineers can significantly improve the performance of cooling solutions, ensuring that fans operate optimally in response to varying thermal demands rather than fixed speeds.

Key insights discussed encompass the fundamental distinctions between PWM fans and traditional DC fans, illustrating how PWM fans achieve lower operational speeds without compromising efficiency or increasing noise levels. The implementation process for integrating PWM control into fan systems is outlined, underscoring the importance of selecting appropriate components and configuring settings for optimal performance. Furthermore, the myriad benefits of PWM fans, including energy savings, reduced noise, and enhanced system stability, highlight their value in contemporary electronics applications.

In conclusion, embracing PWM-controlled fans not only enhances functionality and efficiency in electronic devices but also fosters sustainability through reduced energy consumption. As technology continues to advance, the integration of PWM fans presents an opportunity for engineers to innovate and optimize designs, ultimately contributing to better-performing and longer-lasting electronic systems. Adopting these advanced cooling solutions can pave the way for more efficient and quieter environments, rendering them indispensable across various applications within the electronics industry.

Frequently Asked Questions

What is PWM in the context of fan control?

PWM stands for Pulse Width Modulation, which is a method used to regulate the speed of fans by adjusting the width of the electrical pulses supplied to the motor.

How does PWM control the speed of a fan?

PWM controls the speed of a fan by manipulating the duty cycle of the electrical pulses, allowing engineers to modulate the average power delivered to the fan for precise control over its rotation.

What are the advantages of using PWM for fan control?

The advantages of using PWM for fan control include improved energy efficiency and noise reduction, making it ideal for applications where these factors are important.

What type of connector is typically found on a PWM control fan?

A PWM control fan typically has a four-pin connector, with the fourth pin designated for the PWM signal, enabling dynamic speed adjustments based on thermal requirements or system demands.

How do PWM control fans differ from conventional fans?

Unlike conventional fans that operate at a fixed speed determined by the voltage supplied, PWM control fans can adjust their speed dynamically based on system needs.