Overview

This article delineates ten significant benefits of DC centrifugal fans for electronics cooling, emphasizing their:

- Energy efficiency

- Compact design

- Low noise operation

- Advanced control features

- Reliability

- Versatility

- Ease of installation

- Enhanced airflow performance

- Specific applications across various electronic devices

Each benefit is substantiated by evidence demonstrating how these fans enhance thermal management, lower operational costs, and improve the performance and longevity of electronic systems. Consequently, they emerge as a critical component in contemporary engineering solutions.

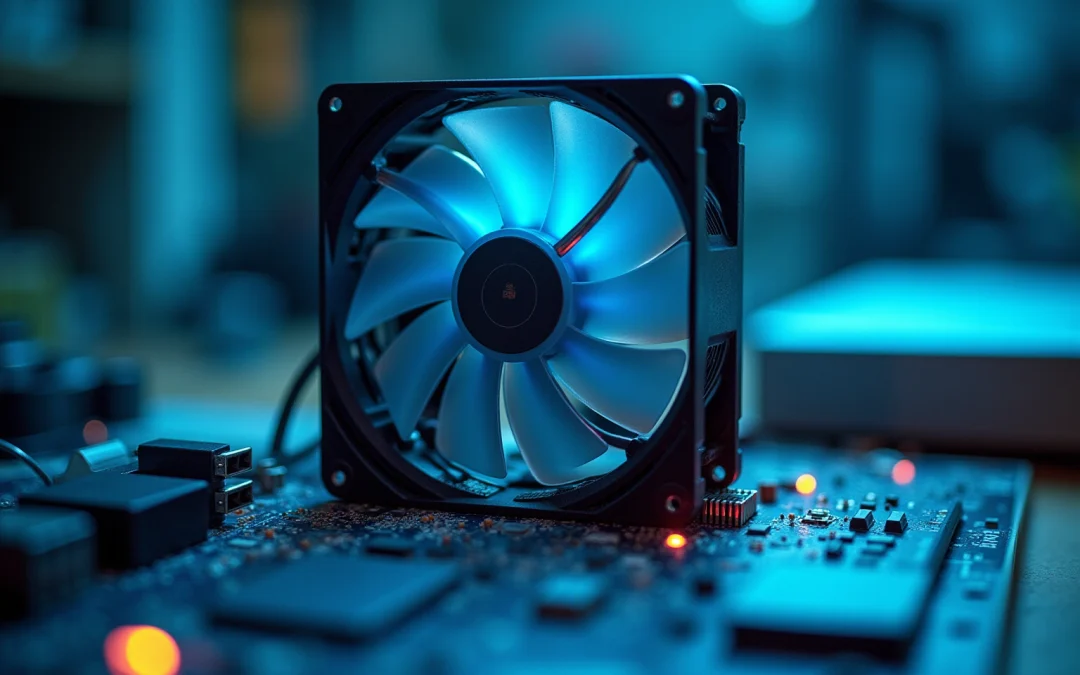

Introduction

DC centrifugal fans are transforming the realm of electronics cooling, providing innovative solutions that meet the growing demands for efficient thermal management. As electronic components become more complex, the necessity for effective heat dissipation has reached a critical juncture. This article explores the numerous advantages of these advanced cooling technologies, examining how they not only improve performance and reliability but also foster energy savings and mitigate environmental impact. With a plethora of options available, engineers must consider how to select the most suitable fan system for their specific applications.

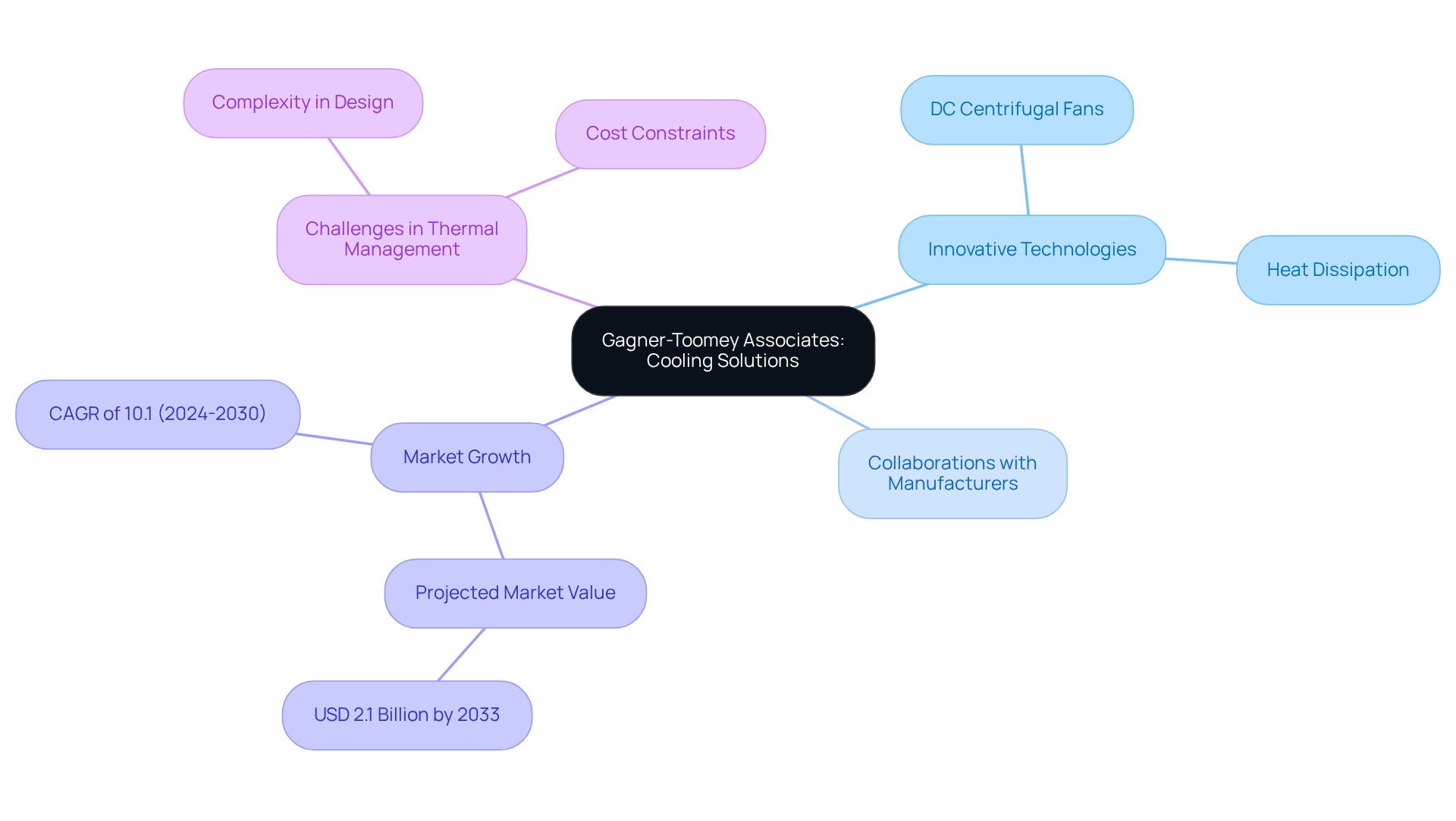

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics

Gagner-Toomey Associates stands at the forefront of advanced cooling solutions tailored for the electronics sector. By collaborating with a diverse array of manufacturers, the company empowers to , particularly in the realm of . These critical components are instrumental in , thereby significantly improving the performance and reliability of electronic devices.

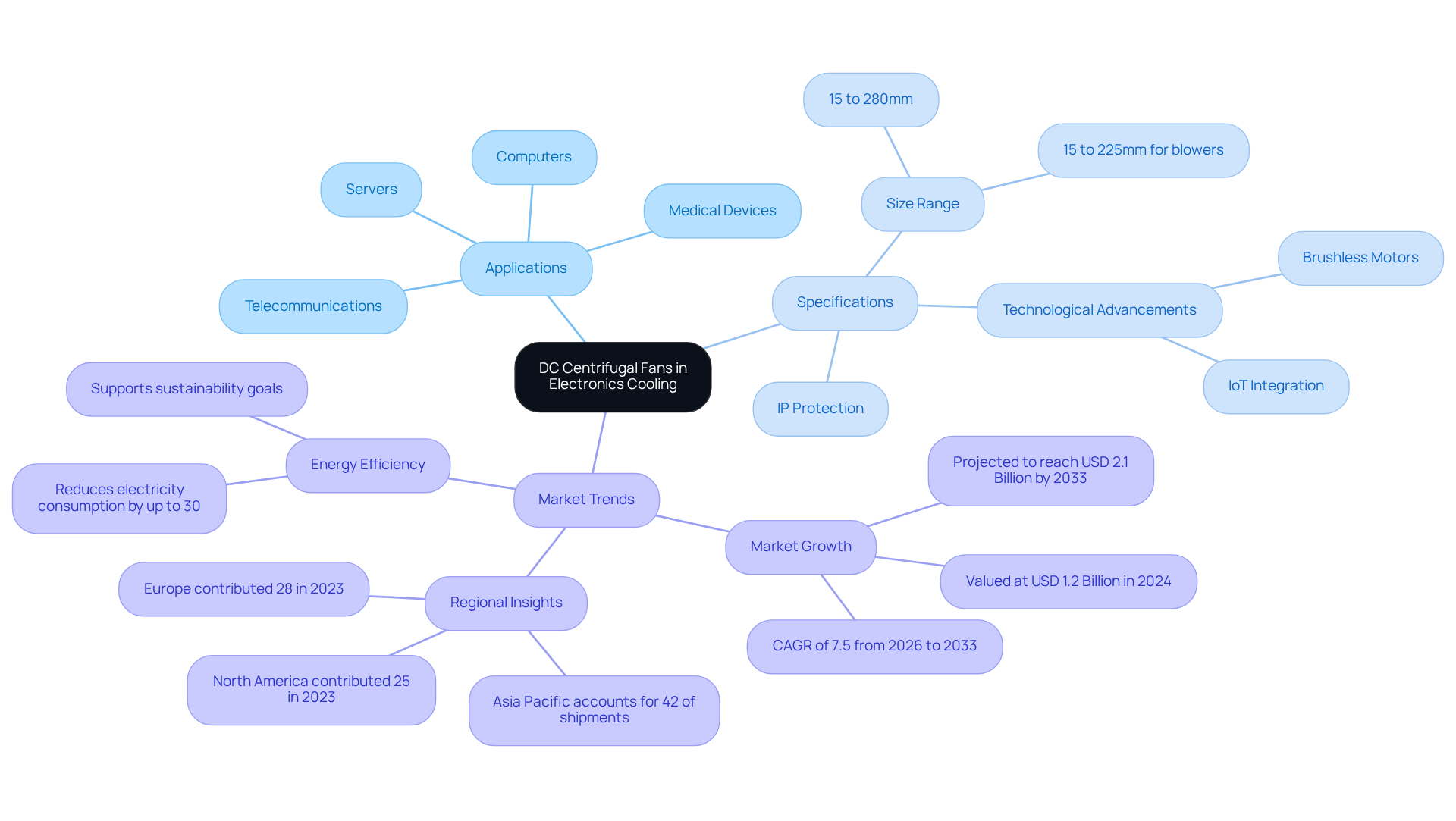

As the demand for efficient escalates—driven by the increasing complexity of electronic components—Gagner-Toomey is resolutely focused on addressing the intricate that engineers encounter today. Recent market analyses reveal that the is anticipated to reach USD 2.1 billion by 2033, highlighting a robust growth trajectory propelled by .

Industry leaders underscore that are vital for sustaining optimal device performance, thereby accentuating Gagner-Toomey’s unwavering commitment to innovation in this essential domain.

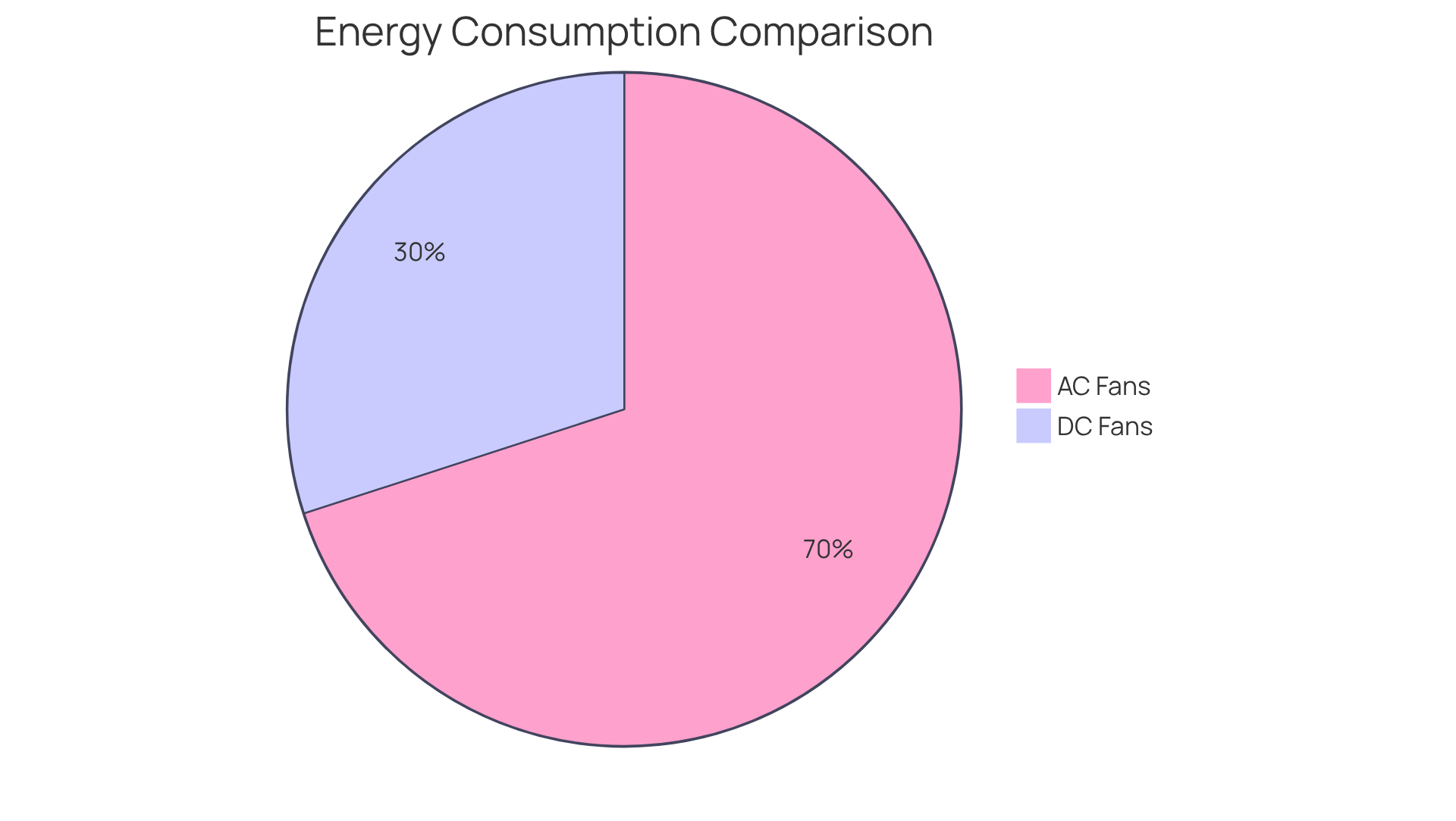

Energy Efficiency: Reduce Power Consumption with DC Centrifugal Fans

from Gagner-Toomey Associates are engineered for exceptional , operating with significantly reduced compared to traditional AC models. By leveraging , these devices achieve energy savings of up to 70%. This not only minimizes operational costs but also diminishes the carbon footprint, resonating with the growing demand for in electronics design.

For instance, integrating into temperature regulation systems can enhance , making them a preferred choice for engineers focused on design optimization.

Real-world applications demonstrate that have successfully reduced their energy expenses, underscoring the .

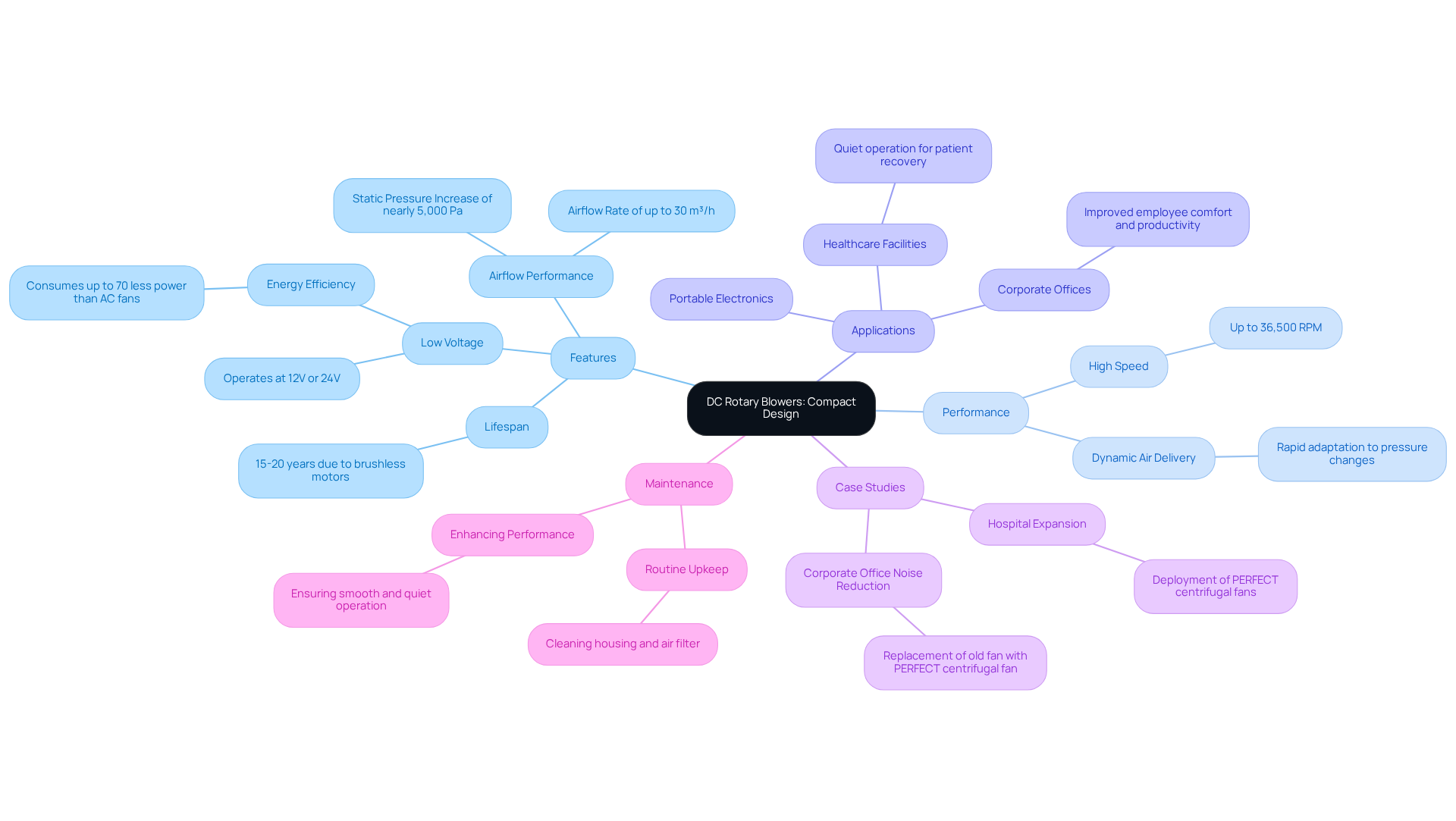

Compact Design: Optimize Space in Electronics Cooling Systems

stand out due to their , facilitating seamless integration into diverse electronic systems. Their minimal footprint permits installation in tighter enclosures without sacrificing airflow performance, making them particularly suitable for applications constrained by space. Typically operating at , such as 12V or 24V, these devices are optimized for environments where space is at a premium. This optimization empowers engineers to devise more , significantly enhancing in devices like computers, servers, and other electronic equipment.

For example, the RVE45 rotary blower, capable of achieving and a static pressure increase of nearly 5,000 Pa, exemplifies how can deliver exceptional performance even in limited environments. Moreover, DC devices generally boast a lifespan of 15-20 years or more, thanks to their brushless motors, ensuring .

Recent case studies underscore this trend; for instance, during a hospital expansion, the deployment of resulted in improved operational efficiency and reduced noise levels across various settings, including healthcare facilities and corporate offices. This trend illustrates the growing recognition of DC enthusiasts as a superior choice for optimizing space in electronic cooling systems.

To maintain their efficiency in challenging applications, routine upkeep is essential for ensuring the smooth and quiet operation of these devices. By prioritizing maintenance, users can enhance the performance and longevity of their DC rotary blowers.

Low Noise Operation: Enhance Comfort in Electronics Environments

present a compelling solution for environments where . With sound levels often falling below 30 dBA, these devices excel in providing while eliminating the intrusive noise commonly associated with . This characteristic is especially advantageous in settings such as office spaces, laboratories, and residential areas, where a tranquil atmosphere is paramount. By opting for DC rotor devices, that their systems enhance .

Advanced Control: Achieve Precise Airflow Management

signify a major advancement in , featuring advanced control options like and PWM (Pulse Width Modulation) capabilities. This innovative technology empowers engineers to , dynamically responding to thermal requirements and ensuring for electronic components.

By modulating fan speeds in accordance with temperature fluctuations, these systems not only but also significantly . For instance, can prolong the lifespan of electronic components by as much as 50%, as highlighted in a study conducted by the University of Toronto. Such precise control is indispensable for applications demanding meticulous thermal management, especially in environments where overheating poses a risk of system failures.

Furthermore, operate with greater quietness and efficiency, markedly reducing noise levels compared to conventional DC models, particularly under low-load conditions. This reduction in noise is critical for sustaining a comfortable working environment in data centers and other sensitive settings.

The capability to manage airflow effectively not only bolsters system stability but also mitigates the risk of thermal malfunctions, establishing as an essential component in contemporary cooling solutions. Additionally, PWM units are equipped with a 4-pin connector, facilitating dynamic speed adjustments that further enhance their performance in demanding applications.

Reliability: Ensure Long Service Life in Cooling Applications

are designed with meticulous engineering for exceptional durability, featuring robust components that guarantee an extended service life. Many models boast a of continuous operation, with the average lifespan in HVAC applications ranging from 50,000 to 70,000 hours. This positions them as a reliable choice for critical with DC centrifugal fans. Such reliability significantly and maintenance, enabling engineers to focus on other vital aspects of their projects. In industrial settings, where downtime can lead to considerable costs, this longevity is particularly vital.

Moreover, the incorporation of in DC centrifugal fans further enhances their reliability; oil-impregnated bearings typically last around 20,000 hours, double ball bearings approximately 50,000 hours, and hydraulic bearings about 30,000 hours. By prioritizing , and bolster overall productivity.

As Gary Masessa emphasizes, for assessing expected longevity offers a more precise gauge of reliability. Additionally, in sustaining the durability and efficacy of these devices, ensuring peak performance even under challenging conditions.

Versatility: Adapt DC Centrifugal Fans for Various Applications

exhibit remarkable adaptability, making them ideal for a diverse array of applications that extend beyond conventional electronics cooling. These devices are integral to , where they effectively cool engines and brakes while providing cabin ventilation, thereby . In , DC motors play a pivotal role in regulating temperature and ensuring optimal air circulation, which contributes to . Furthermore, they are vital in , such as ventilators and patient monitors, where their are of utmost importance.

The versatility of DC units empowers to deploy them in various environments, guaranteeing efficient cooling tailored to specific requirements. Their capacity to function effectively across different settings underscores their significance in any engineer’s toolkit. Notably, DC enthusiasts can achieve compared to traditional AC devices, operating with greater efficiency and minimizing energy loss through heat and friction. This positions them as a sustainable choice in today’s energy-conscious landscape. As industries increasingly prioritize energy efficiency and low-noise solutions, the demand for DC centrifugal fans continues to escalate, solidifying their role as essential components in modern engineering applications.

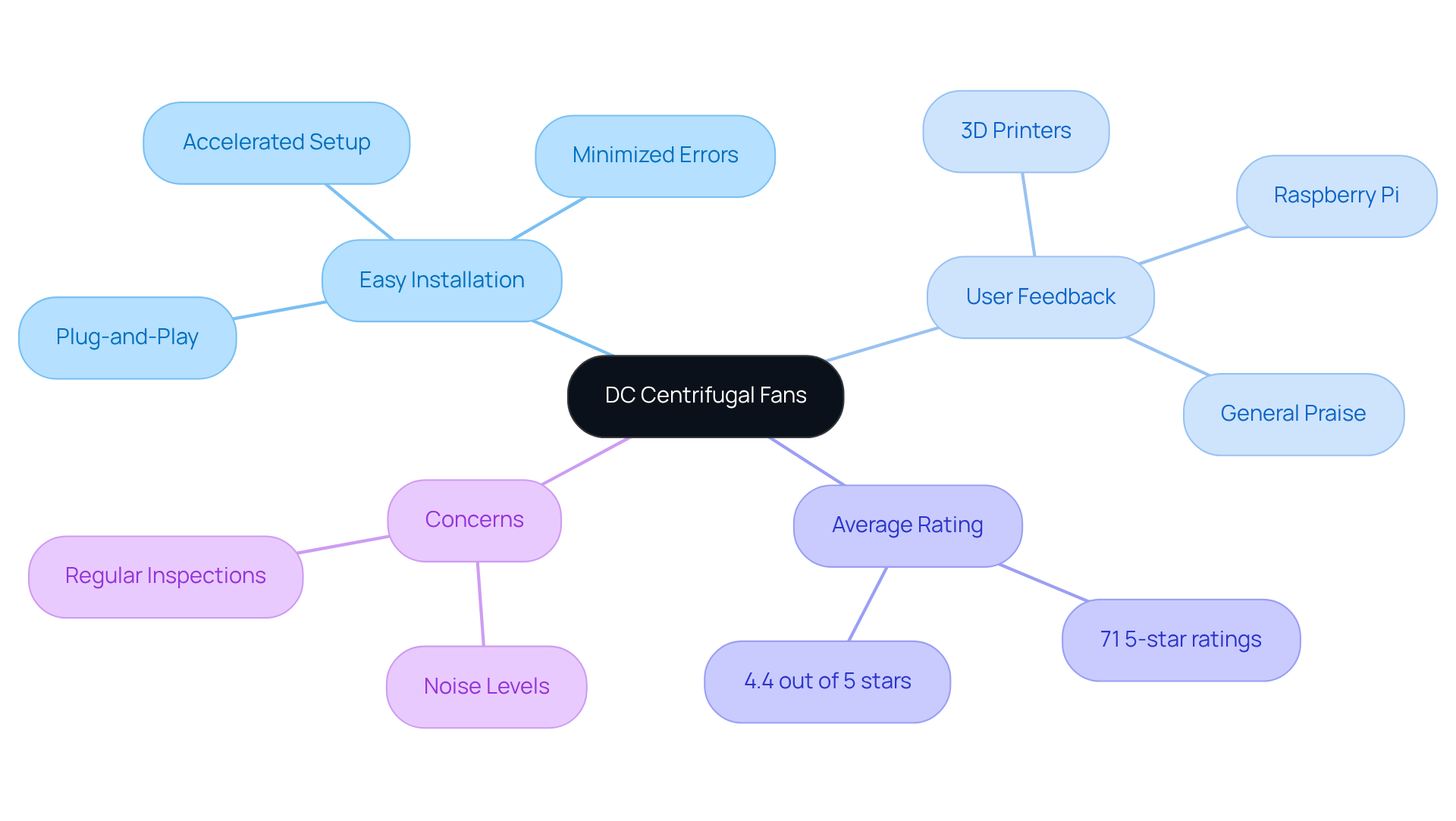

Easy Installation: Simplify Integration into Existing Systems

are engineered for effortless installation, boasting that facilitate . This design approach not only accelerates setup times but also minimizes the potential for , empowering engineers to focus on optimizing their projects.

User feedback consistently underscores the simplicity of installation, with many noting that these devices across various applications, from 3D printers to Raspberry Pi setups. For instance, one user reported that the units effectively cooled their devices while being straightforward to set up, reinforcing the practicality of these solutions.

With an average rating of 4.4 out of 5 stars based on over 700 reviews—71% of which are 5-star ratings—it is clear that [DC centrifugal fans](https://gagner-toomey.com/?p=8862) represent a seeking efficient solutions without the burden of complex setups.

Furthermore, regular inspection of the fan housing for corrosion or damage is crucial to . While numerous users praise the devices for their effectiveness, some have raised concerns regarding noise levels, an important consideration for engineers when selecting the most suitable model for their projects.

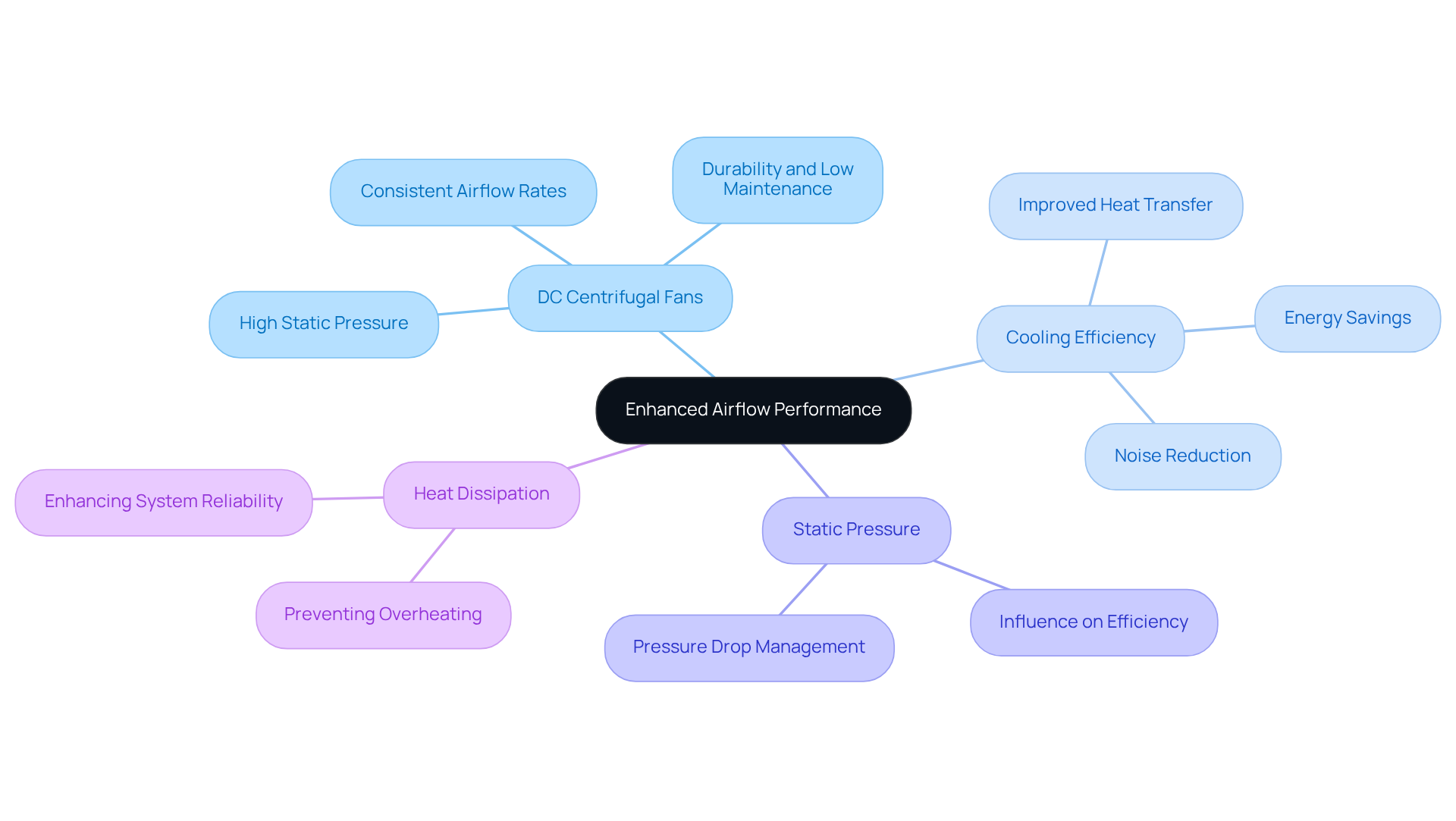

Enhanced Airflow Performance: Improve Cooling Efficiency

from Gagner-Toomey Associates are meticulously engineered to optimize airflow performance, providing high and consistent airflow rates that are essential for effective heat dissipation in electronic components. This capability is critical for maintaining devices within safe temperature thresholds, thereby that can lead to component failure and reduced system reliability.

As the world’s largest producer of standard and custom air-movers, of advanced , with research from Purdue indicating . Furthermore, the importance of static pressure cannot be overstated; it directly influences efficiency by ensuring adequate airflow against system resistance.

‘ DC centrifugal fans to sustain ideal thermal conditions in their designs, ultimately of electronic systems. As specialists emphasize, , reinforcing the significance of these devices in contemporary applications.

Specific Applications: Utilize DC Centrifugal Fans in Electronics Cooling

from Gagner-Toomey Associates are essential for the , as they are utilized in computers, servers, telecommunications equipment, and medical devices. Their compact design facilitates in confined spaces, underscoring their importance in modern electronic systems. For example, within power control cabinets and battery packs, these devices are indispensable for , significantly enhancing system performance and longevity.

of DC input tube axial units, available in sizes from 15 to 280mm, and blowers ranging from 15 to 225mm, with IP protection options available upon request. The market for DC centrifugal fans is witnessing robust growth, particularly within the telecommunications sector, driven by the increasing demand for . As urbanization intensifies, the necessity for reliable cooling in is increasingly urgent, with projections indicating a substantial rise in market value.

Moreover, , including brushless motors and IoT integration, are enhancing the effectiveness of DC centrifugal fans in critical applications, ensuring optimal thermal regulation and operational efficiency.

Conclusion

DC centrifugal fans represent a pivotal advancement in electronics cooling, offering a multitude of benefits that enhance both performance and sustainability. These innovative solutions from Gagner-Toomey Associates not only address the pressing need for efficient thermal management but also cater to the growing demand for energy-saving technologies in various electronic applications.

Key advantages of DC centrifugal fans include:

- Exceptional energy efficiency

- Compact design

- Low noise operation

- Advanced control capabilities

- Remarkable reliability

These fans excel in diverse applications, from computers and servers to medical devices and automotive systems, ensuring optimal cooling and airflow management. Their easy installation simplifies integration into existing setups, making them a preferred choice for engineers seeking effective solutions without the complexities of traditional systems.

Ultimately, the significance of DC centrifugal fans extends beyond mere functionality; they embody a commitment to innovation and sustainability in the electronics industry. As the market continues to evolve, embracing these advanced cooling technologies will be crucial for engineers and manufacturers aiming to enhance device performance while minimizing environmental impact. Investing in DC centrifugal fans is not just a choice for today but a step toward a more efficient and sustainable future in electronics cooling.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in advanced cooling solutions tailored for the electronics sector, particularly focusing on DC centrifugal fans for effective heat dissipation.

Why are DC centrifugal fans important for electronic devices?

DC centrifugal fans are crucial for effective heat dissipation, which significantly improves the performance and reliability of electronic devices, especially as electronic components become more complex.

What is the projected market growth for DC centrifugal fans?

The market for DC centrifugal fans is anticipated to reach USD 2.1 billion by 2033, driven by advancements in temperature control technologies.

How do Gagner-Toomey’s DC centrifugal fans contribute to energy efficiency?

Gagner-Toomey’s DC centrifugal fans are engineered for exceptional energy efficiency, achieving energy savings of up to 70% compared to traditional AC models, which reduces operational costs and carbon footprint.

What are the advantages of the compact design of DC rotary blowers?

The compact design of DC rotary blowers allows for seamless integration into tight electronic systems, optimizing space without sacrificing airflow performance, making them suitable for applications with limited space.

Can you provide an example of a DC rotary blower and its performance?

The RVE45 rotary blower can achieve airflow rates of up to 30 m³/h and a static pressure increase of nearly 5,000 Pa, demonstrating exceptional performance in compact environments.

What is the lifespan of DC devices from Gagner-Toomey?

DC devices from Gagner-Toomey typically boast a lifespan of 15-20 years or more due to their brushless motors, ensuring long-term reliability.

What is essential for maintaining the efficiency of DC rotary blowers?

Routine upkeep is essential for ensuring the smooth and quiet operation of DC rotary blowers, enhancing their performance and longevity in challenging applications.