Introduction

Mastering the design of fan systems is essential for engineers who seek to optimize performance and efficiency across various applications. This guide explores the critical steps and considerations that can significantly enhance fan system design, from grasping airflow dynamics to selecting the appropriate materials and technologies.

With numerous variables influencing outcomes, how can engineers ensure their designs not only meet specifications but also endure over time? By understanding these complexities, engineers can create robust systems that stand the test of time.

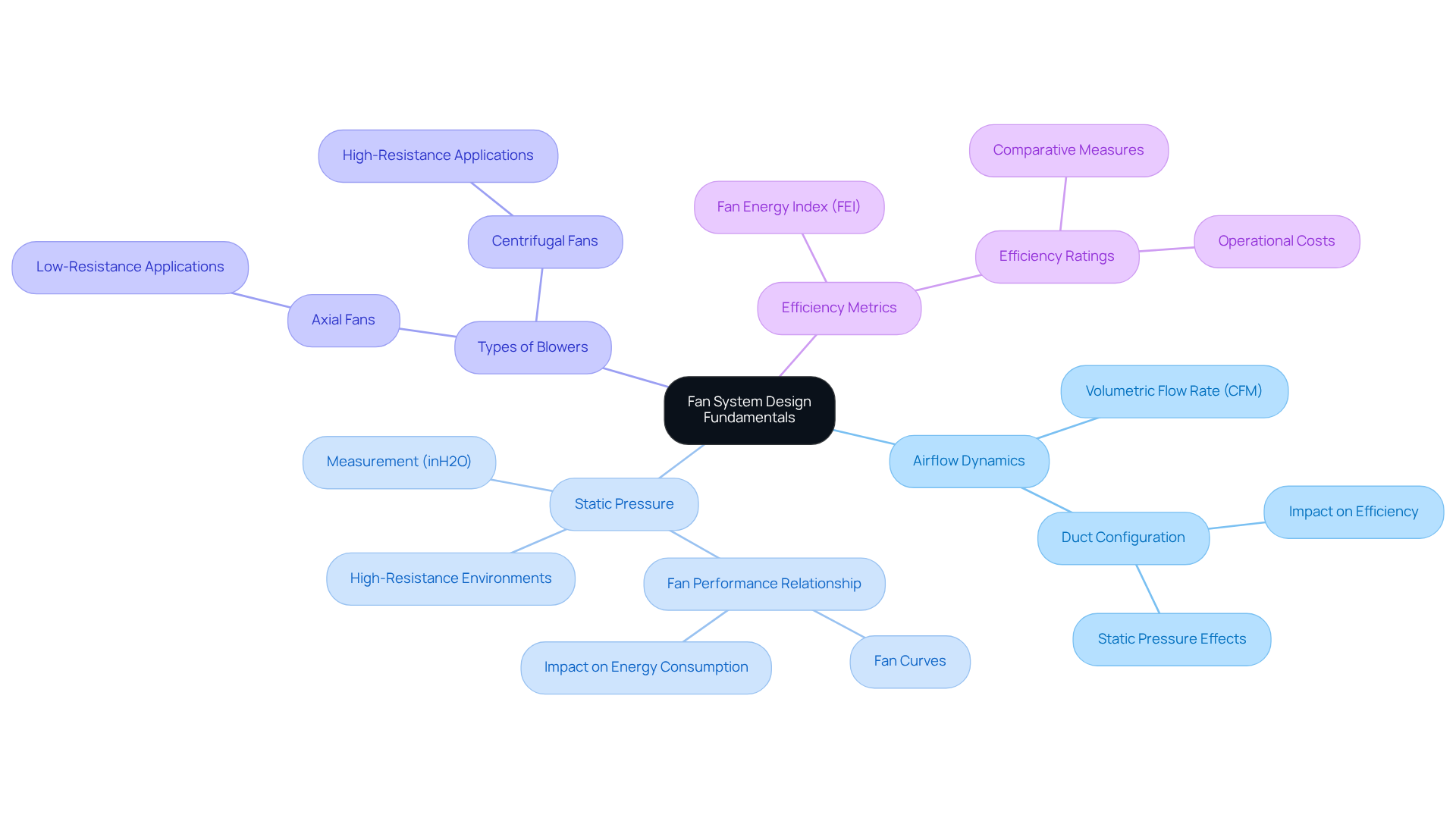

Understand the Fundamentals of Fan System Design

To master fan system design, engineers must first familiarize themselves with key concepts that are crucial for effective implementation:

-

Airflow Dynamics: Understanding how airflow is generated and controlled within a system is essential. This encompasses the volumetric flow rate (CFM), which frequently surpasses 100 CFM in high-performance fans. Additionally, the considerable effect of duct configuration on airflow efficiency cannot be overlooked. Ineffective duct design can lead to elevated static pressure, resulting in greater energy usage and diminished system efficiency.

-

Static Pressure: The relationship between airflow and static pressure is critical for determining fan performance. Static pressure, measured in inches of water column (inH2O), reflects the resistance a fan must overcome to move air through ducts and filters. Familiarizing oneself with the design of fan curves is vital, as they illustrate how static pressure affects airflow and efficiency. For instance, static pressure devices can keep CPU temperatures 3 degrees Celsius lower than ventilation units in radiator setups, showcasing their effectiveness in high-resistance environments.

-

Types of Blowers: Distinguishing between axial and centrifugal devices is essential. Axial fans excel in low-resistance settings, facilitating rapid air circulation, while centrifugal fans are designed to overcome significant static resistance, making them ideal for applications with restricted airflow paths.

-

Efficiency Metrics: Grasping the importance of fan efficiency ratings, including the Fan Energy Index (FEI), is essential for optimizing energy consumption and operational costs. The FEI provides a comparative measure of a fan’s efficiency at specific operating points, guiding engineers in selecting energy-efficient solutions that minimize operational expenses.

By mastering these fundamentals, engineers can create a strong basis for the effective design of fan configurations, ensuring optimal functionality and energy efficiency in their applications.

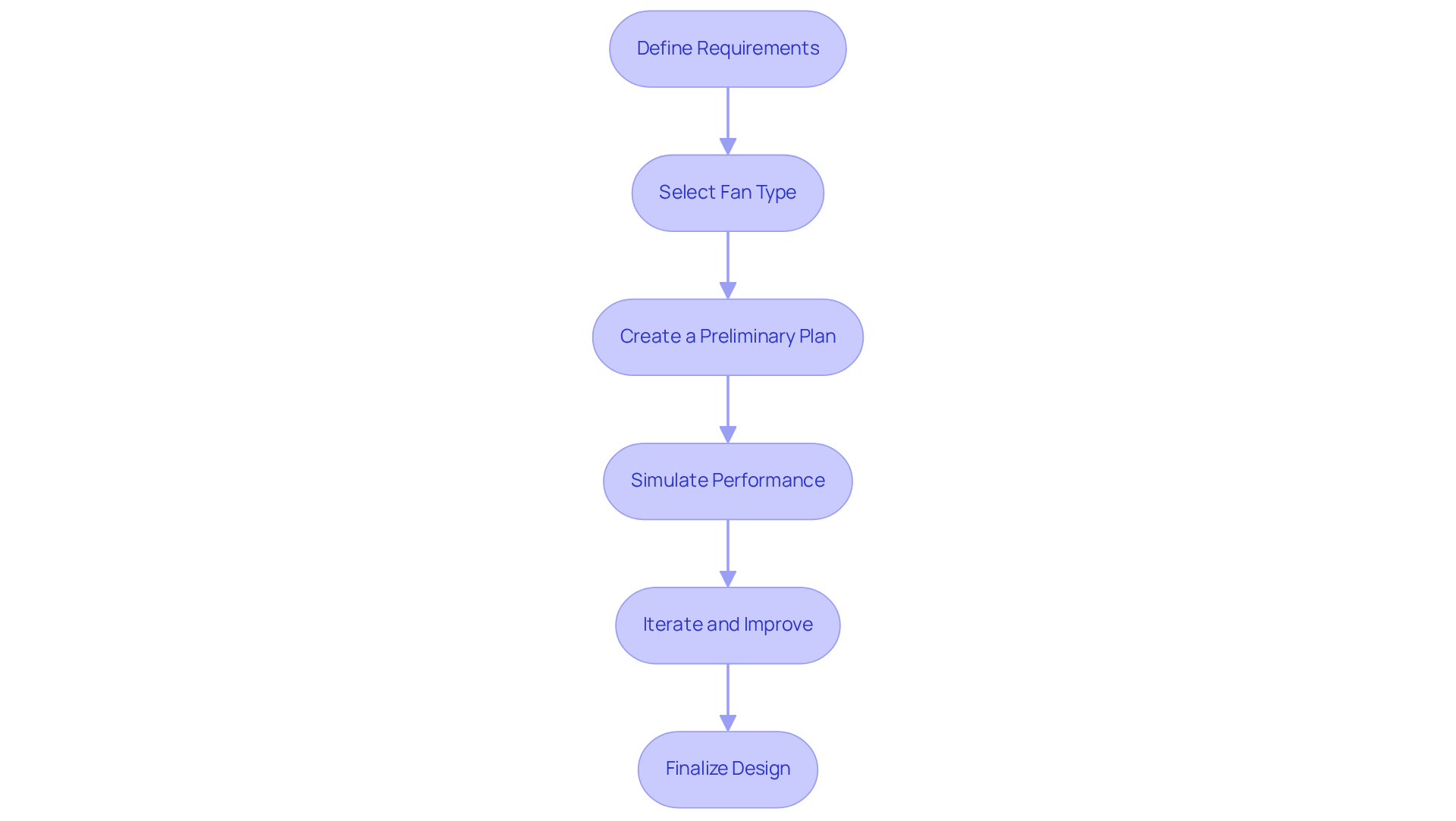

Follow a Step-by-Step Design Process for Fan Systems

To effectively design a fan system, it’s crucial to follow a structured approach:

- Define Requirements: Start by identifying the specific needs of your application. This includes understanding airflow requirements, pressure constraints, and environmental conditions that will impact performance.

- Select Fan Type: Based on the defined requirements, choose the appropriate fan type – axial or centrifugal – that best meets these criteria.

- Create a Preliminary Plan: Develop initial sketches and calculations. This should encompass fan size, blade shape, and motor specifications to ensure compatibility and efficiency.

- Simulate Performance: Utilize computational fluid dynamics (CFD) software to simulate airflow and pressure characteristics. This step allows for necessary adjustments before moving to physical prototyping, ensuring a more refined design.

- Iterate and Improve: Analyze the simulation outcomes and enhance the design accordingly. Focus on optimizing effectiveness, efficiency, and reliability to meet operational demands.

- Finalize Design: Prepare detailed engineering drawings and specifications for manufacturing, ensuring all aspects are covered for a successful implementation.

By adhering to this organized method, engineers can ensure that the design of fan systems effectively meets performance expectations and operational needs.

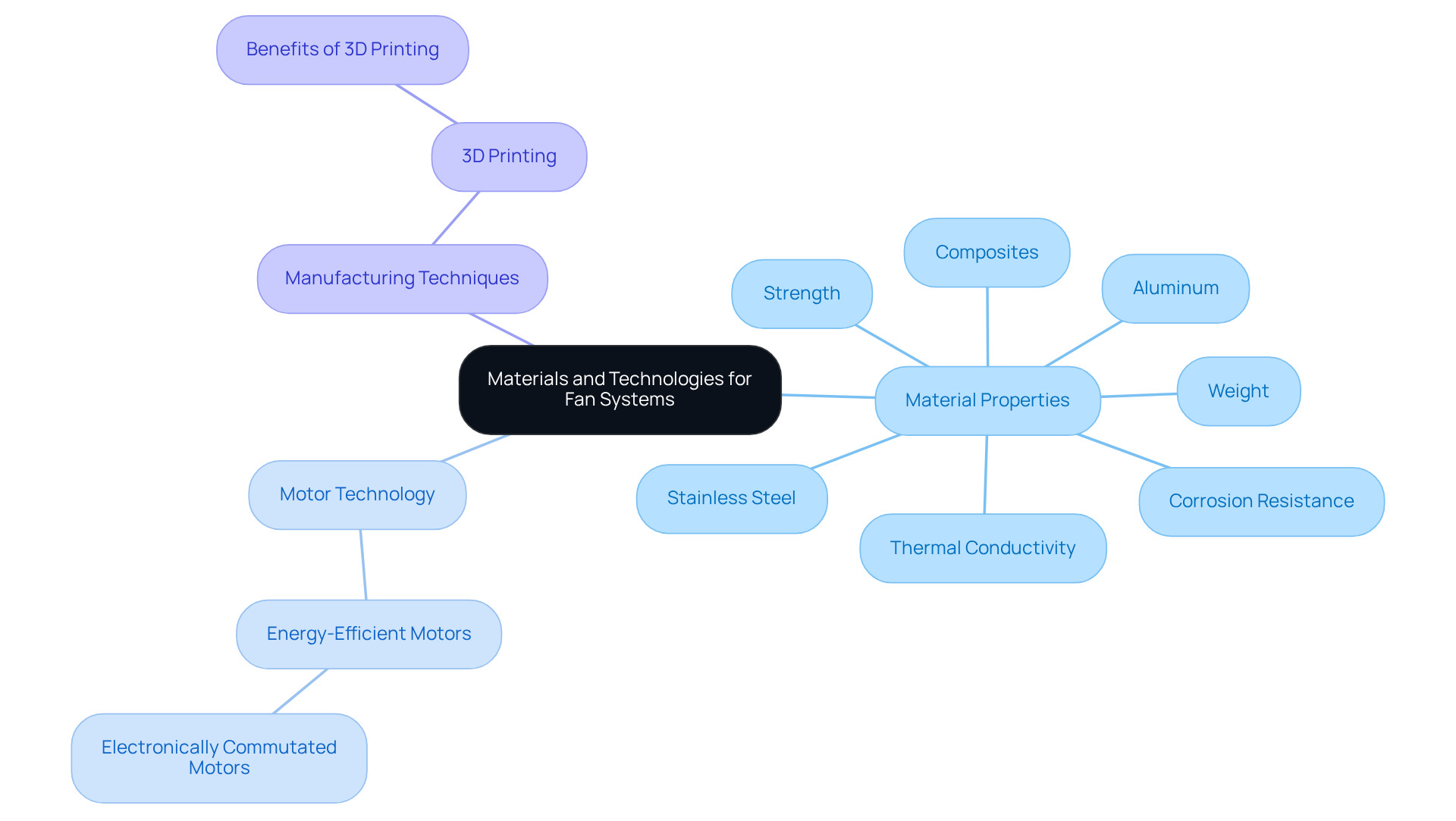

Select Materials and Technologies for Optimal Performance

When selecting materials and technologies for fan systems, engineers must prioritize several critical aspects:

-

Material Properties: It’s essential to assess materials based on their strength, weight, corrosion resistance, and thermal conductivity. Aluminum is often favored for lightweight applications, while stainless steel provides superior corrosion resistance. Composites are increasingly utilized for high-performance needs due to their durability and lightweight characteristics. The design of the fan, particularly its blade structure and configuration, plays a vital role in enhancing airflow while minimizing noise and vibration. Airfoil blades, which emulate the design of fan and aircraft wings, are recognized as the most efficient option, delivering smooth airflow with reduced drag. Backward-curved blades are also popular for their efficiency across various applications. According to TBC Supply, “Fans with airfoil-style blades, like airplane wings, are the most efficient.”

-

Motor Technology: Opting for energy-efficient motors, such as electronically commutated (EC) motors, can significantly enhance efficiency while lowering energy consumption. These motors are engineered to operate efficiently across a range of speeds, making them ideal for contemporary fan systems.

-

Manufacturing Techniques: Advanced manufacturing methods, including 3D printing, facilitate the creation of intricate geometries that can boost functionality. This technology allows for the production of customized blade designs that enhance airflow and efficiency.

Recent studies indicate that airfoil blades can substantially reduce energy consumption, establishing them as a preferred choice in industrial applications. By strategically selecting materials and technologies, engineers can markedly enhance the design of fan systems, thereby improving their functionality, reliability, energy efficiency, and operational effectiveness.

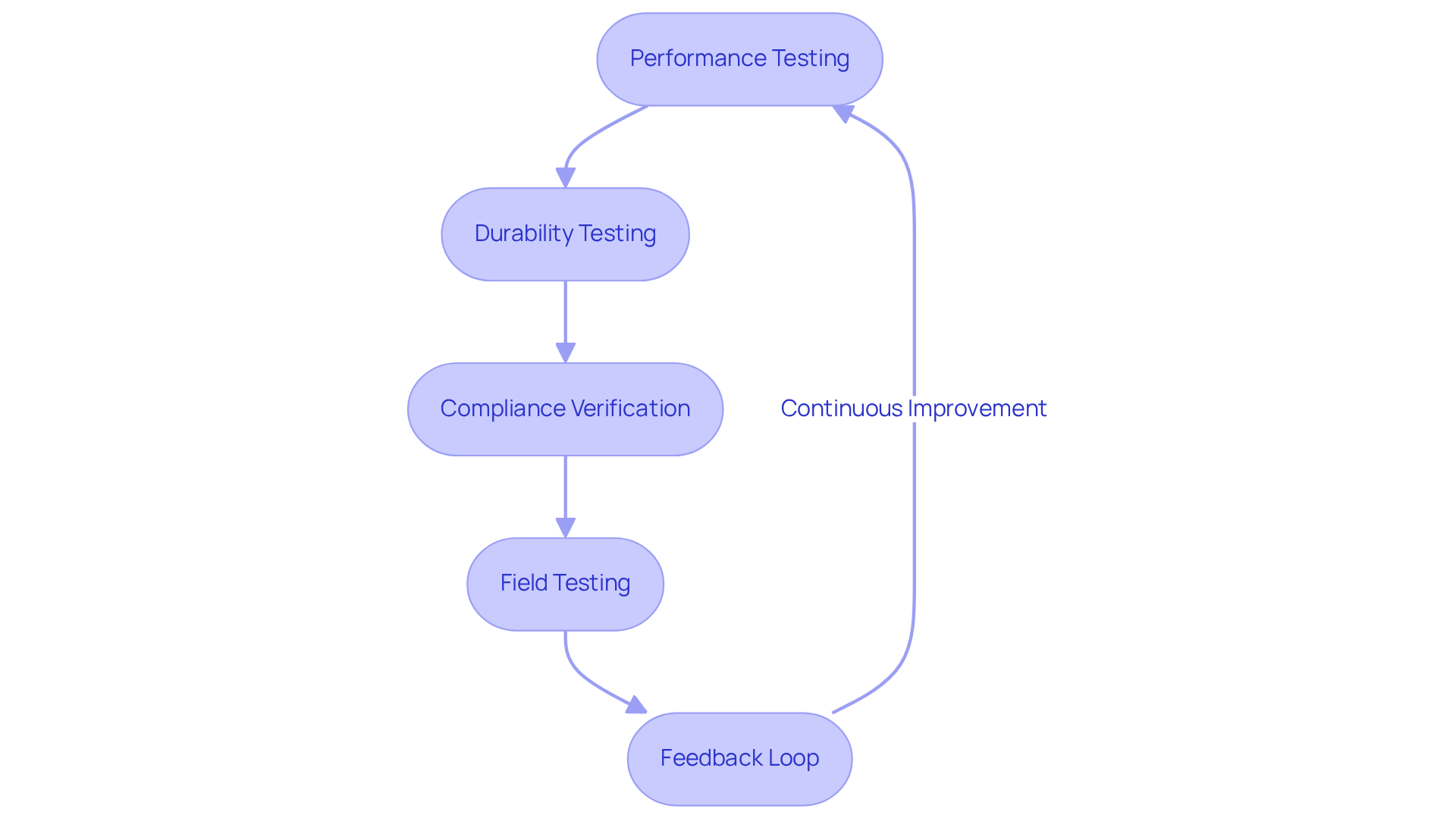

Conduct Testing and Validation for Reliability Assurance

To ensure the reliability of fan systems, it is essential to follow a structured approach to testing and validation:

-

Performance Testing: Begin by conducting tests that measure airflow, static pressure, and power consumption under various operating conditions. Utilize standardized methods, such as those outlined in AMCA or ISO guidelines, to ensure consistency and accuracy.

-

Durability Testing: Next, assess the fan’s operation over extended periods. This evaluation should include wear and tear assessments, as well as vibration and thermal cycling tests, to determine the fan’s long-term reliability.

-

Compliance Verification: It is crucial to ensure that the fan system meets all relevant industry standards and regulations. This includes a thorough review of safety and environmental considerations to guarantee compliance.

-

Field Testing: Conduct field tests in real operating environments. This step is vital to confirm the system’s effectiveness and to identify any discrepancies between predicted and actual results, allowing for necessary adjustments.

-

Feedback Loop: Finally, gather data from all testing phases to inform future designs and improvements. Establishing a continuous feedback loop for product development is key to enhancing reliability and performance.

By rigorously testing and validating the design of fan systems, engineers can assure reliability and performance, which ultimately leads to successful implementations.

Conclusion

Mastering the design of fan systems is not just a technical challenge; it’s an essential endeavor for engineers aiming to create effective and energy-efficient solutions. Understanding fundamental principles such as airflow dynamics, static pressure, fan types, and efficiency metrics lays a solid foundation for success. This knowledge enhances performance and contributes significantly to sustainable engineering practices.

The systematic process for fan system design begins with clearly defining requirements. Selecting the appropriate fan type is crucial, as is simulating performance through advanced tools. Moreover, the careful selection of materials and technologies is pivotal in optimizing functionality and reliability. Rigorous testing and validation ensure that the designed systems operate as intended, meeting both performance expectations and industry standards.

In conclusion, the journey to mastering fan system design is intricate yet rewarding. By adhering to best practices and leveraging the latest innovations in materials and technologies, engineers can markedly improve the efficiency and effectiveness of their designs. Embracing a continuous feedback loop throughout the testing and validation phases not only enhances current projects but also paves the way for future advancements in fan system engineering.

Frequently Asked Questions

What are the key concepts essential for fan system design?

The key concepts include airflow dynamics, static pressure, types of blowers, and efficiency metrics.

What is airflow dynamics and why is it important?

Airflow dynamics refers to how airflow is generated and controlled within a system, including the volumetric flow rate (CFM). It is important because duct configuration significantly affects airflow efficiency, and poor duct design can lead to increased energy usage and reduced system efficiency.

How does static pressure relate to fan performance?

Static pressure, measured in inches of water column (inH2O), represents the resistance a fan must overcome to move air through ducts and filters. Understanding the relationship between airflow and static pressure is crucial for determining fan performance and efficiency.

What are fan curves and why are they important?

Fan curves illustrate how static pressure affects airflow and efficiency. They are important because they help engineers understand how different static pressure levels impact fan performance, allowing for better design decisions.

What are the differences between axial and centrifugal fans?

Axial fans are designed for low-resistance environments and facilitate rapid air circulation, while centrifugal fans are built to overcome significant static resistance, making them suitable for applications with restricted airflow paths.

What is the Fan Energy Index (FEI) and why is it significant?

The Fan Energy Index (FEI) is a metric that measures a fan’s efficiency at specific operating points. It is significant because it helps engineers select energy-efficient solutions that reduce operational costs.

How can mastering these fundamentals benefit engineers?

Mastering these fundamentals allows engineers to create effective fan configurations that ensure optimal functionality and energy efficiency in their applications.