Overview

This article delves into the fundamental concepts, strategies, and compliance considerations that are crucial for designing effective fan systems. It underscores the significance of airflow, static pressure, noise levels, and proper installation techniques. These elements are supported by technical specifications and maintenance protocols, all aimed at ensuring optimal thermal management and adherence to regulatory standards in electronic applications.

Introduction

Mastering fan system design is essential for engineers responsible for managing heat in electronic devices, where effective airflow can decisively impact performance and prevent catastrophic failure. This article explores the core concepts, strategies, and compliance measures that are fundamental to successful fan system design, providing insights into airflow dynamics, technical specifications, and installation techniques. Given the multitude of variables involved, how can engineers ensure that their fan systems operate efficiently while adhering to regulatory standards and satisfying user expectations?

Explore Fundamental Concepts of Fan Systems

The effective management of heat within electronic devices relies heavily on fan systems, which operate on the principle of air movement to dissipate the heat generated by components. Gagner-Toomey Associates, recognized as the world’s largest manufacturer of standard and custom air-movers, offers an extensive product line of DC input tube axial fans and centrifugal blowers, optimized for performance, efficiency, and low noise. Most models also provide IP protection upon request, enhancing their applicability across various environments.

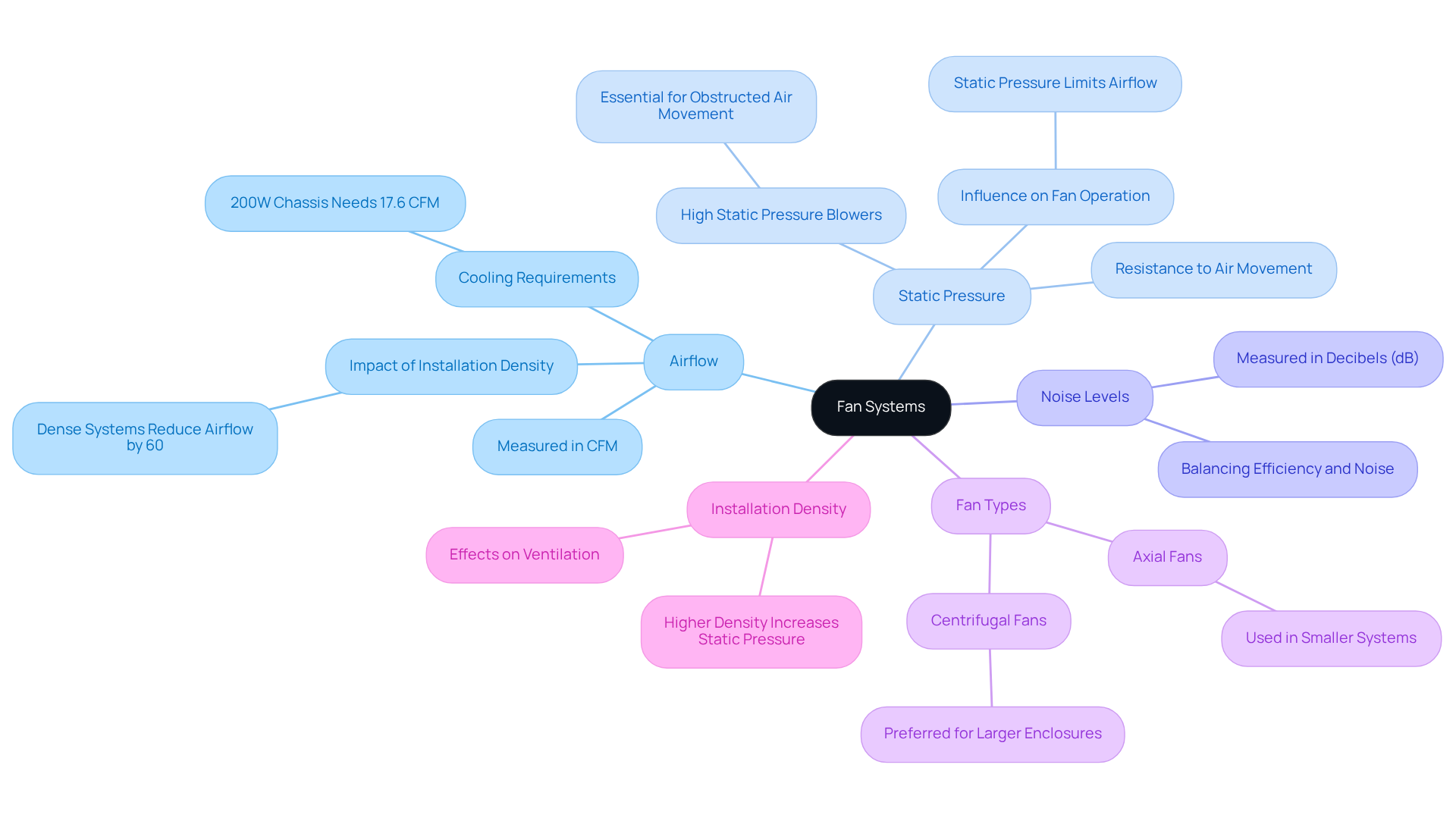

- Airflow is a critical factor, measured in cubic feet per minute (CFM), for ensuring adequate cooling. Engineers must assess the necessary air movement based on the heat output of components, as insufficient circulation can lead to overheating and a reduced lifespan of devices. For example, a chassis framework dissipating 200W of heat necessitates approximately 17.6 CFM to maintain a 20°C allowable temperature rise. This calculation underscores the importance of in relation to heat output.

- Static Pressure refers to the resistance to air movement within a system. High static pressure blowers, such as those provided by Gagner-Toomey, are essential in scenarios where a fan system is required to facilitate air movement obstructed by filters, ducts, or closely arranged elements. Static pressure ratings can vary significantly among different fan types; for instance, axial fans typically exhibit lower static pressure ratings compared to centrifugal fans, which are engineered for higher resistance environments. In practical applications, static pressure can significantly influence fan operation; in a partially enclosed setting, static pressure often restricts air movement, necessitating thoughtful design considerations to enhance ventilation. As Gagner-Toomey notes, ‘the actual movement of air and static pressure are determined by impedance,’ emphasizing the importance of these factors in the design of the fan system.

- Noise Levels, measured in decibels (dB), are another critical consideration in fan selection, particularly for consumer electronics. Engineers must strike a balance between efficiency and acceptable noise levels, as excessive noise can negatively impact user experience. Selecting devices with lower noise ratings while maintaining airflow efficiency is vital for high-quality designs.

- Fan Types encompass various configurations, such as axial and centrifugal fans, each serving distinct applications. Understanding the specific use cases for each type can enhance performance. For instance, Gagner-Toomey’s axial units are typically employed in smaller systems, while their centrifugal models are preferred for larger enclosures where greater static pressure is required. These fans find applications across sectors such as automotive, telecom, and industrial settings.

- Installation Density within an enclosure significantly affects ventilation and static pressure. Increased installation density can lead to elevated static pressure, thereby restricting air movement. Designers must consider this factor to ensure effective cooling.

By mastering these concepts, engineers can make informed decisions in designing a fan system, thereby ensuring efficient thermal management in their projects. Industry leaders emphasize that understanding the relationship between airflow and static pressure is essential for effective fan selection and performance.

Analyze Technical Specifications and Performance Metrics

When selecting fans for a system, particularly those from Gagner-Toomey Associates, it is vital to analyze their technical specifications:

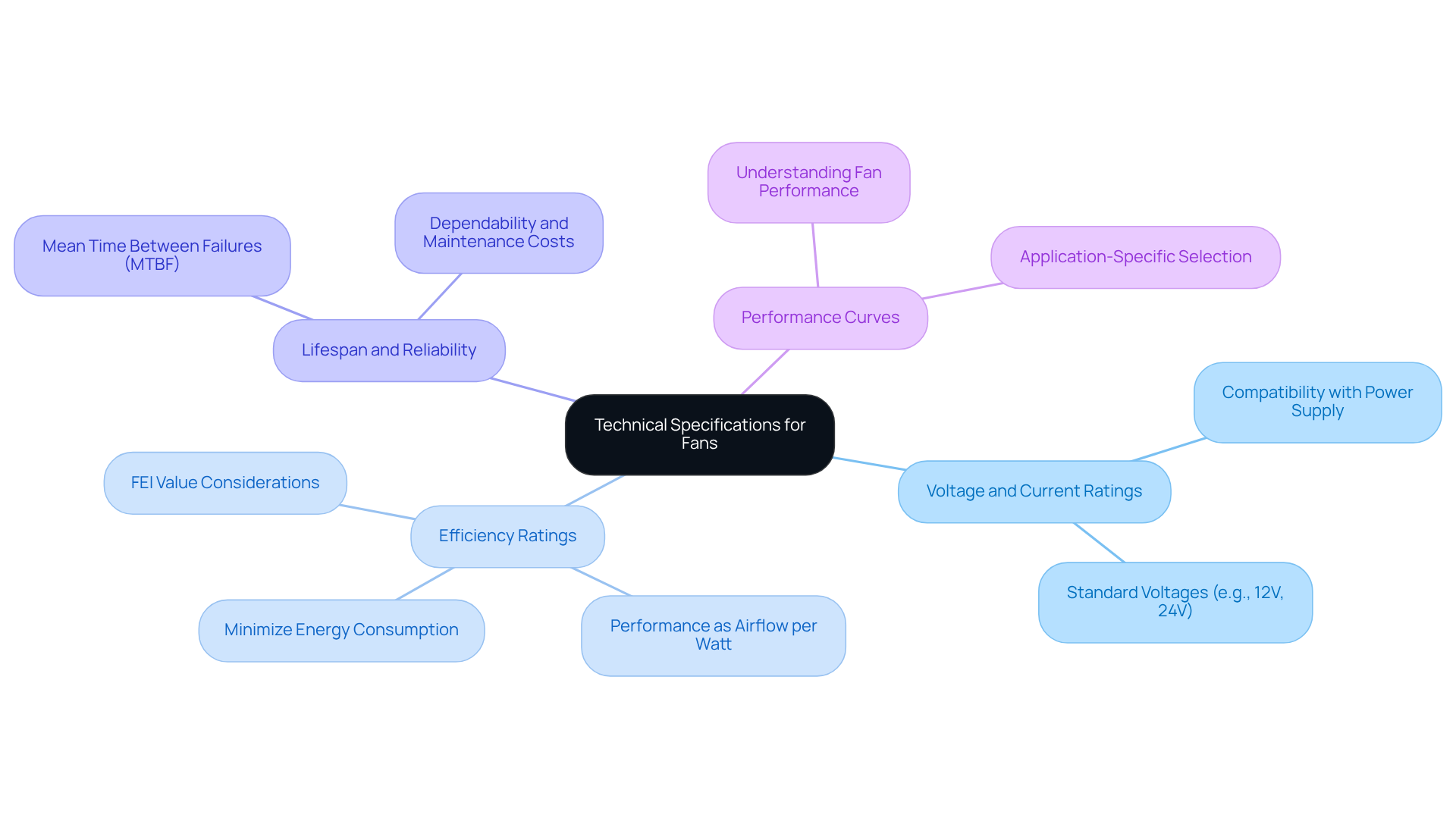

- Voltage and Current Ratings: Ensure compatibility with the power supply. Gagner-Toomey supporters typically operate at standard voltages (e.g., 12V, 24V), making them suitable for a variety of applications in electronics and automotive sectors.

- Efficiency Ratings: Look for devices with high efficiency to minimize energy consumption. Gagner-Toomey’s products are optimized for performance, often expressed as a percentage of airflow produced per watt of power consumed, ensuring effective cooling solutions.

- Lifespan and Reliability: Check the manufacturer’s rated lifespan, often indicated in hours (e.g., MTBF – Mean Time Between Failures). Gagner-Toomey devices are crafted for dependability, lowering upkeep expenses and improving longevity.

- Performance Curves: These graphs illustrate how a fan performs under varying conditions. Comprehending these curves aids in choosing the appropriate unit for particular applications, especially when taking into account Gagner-Toomey’s extensive range of DC input tube axial devices and centrifugal blowers.

By thoroughly analyzing these metrics, engineers can ensure that their fan system setups will perform reliably and efficiently under expected operating conditions, leveraging the advanced cooling solutions offered by Gagner-Toomey Associates.

Implement Design Strategies and Installation Techniques

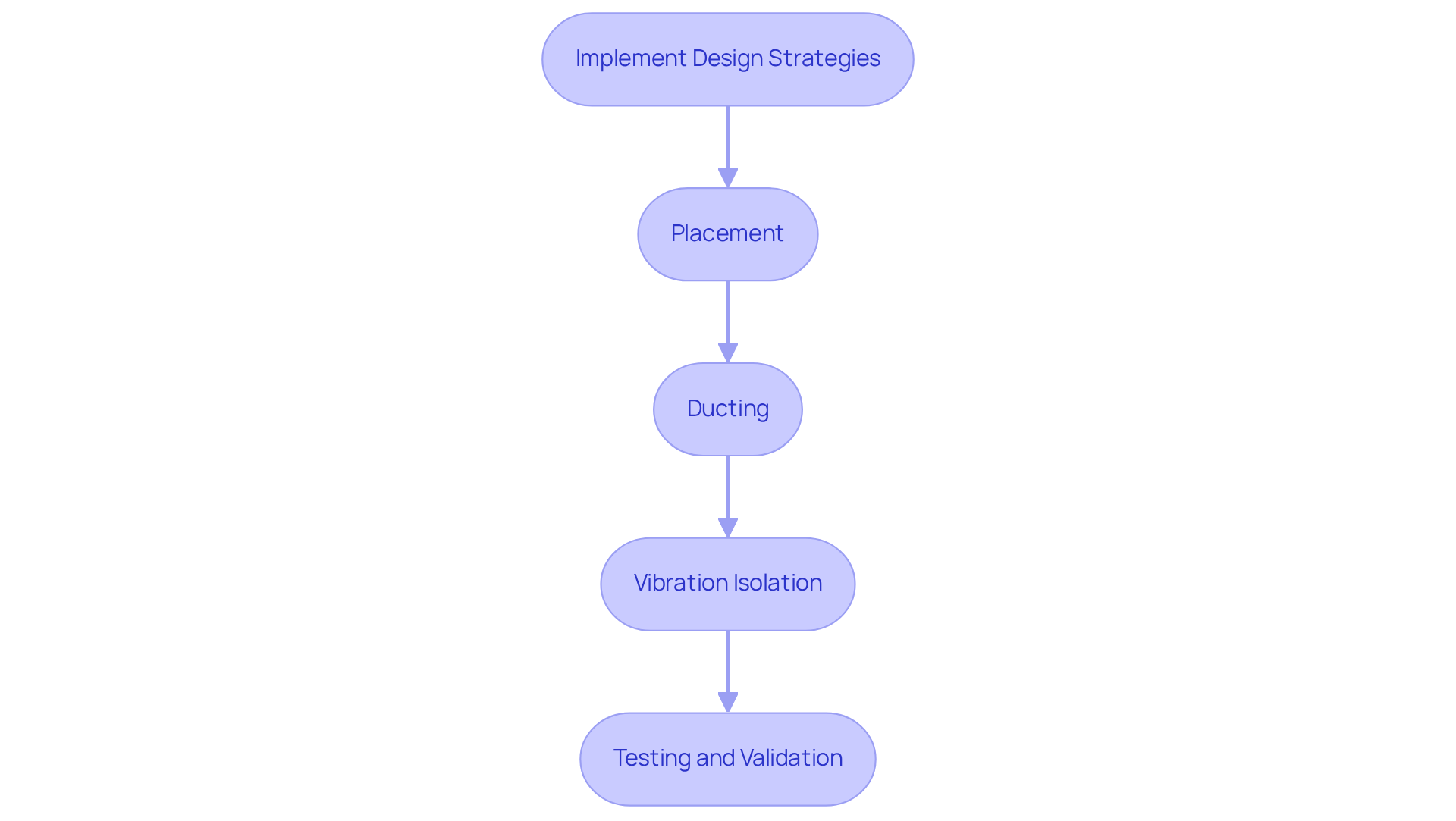

Implementing a fan system necessitates meticulous planning and execution to achieve optimal performance.

Placement: Strategically position fans to enhance airflow. The locations of inlets and outlets should be carefully selected to minimize turbulence and maximize cooling efficiency, ensuring that air is directed effectively throughout the system.

Ducting: Utilize ducting to accurately direct the movement of air to the required locations. Well-constructed ducts significantly enhance performance by diminishing resistance and . A case study on ducted fan engines tailored for UAV applications demonstrated that enhancing duct design resulted in a notable rise in efficiency (from 0.7 to 0.82) and thrust production (from 100 N to 120 N), underscoring the importance of ducting in fan design. Furthermore, the effective length of outlet ducting should be no less than 2.5 duct diameters when duct velocity is 2,500 fpm (13 m/s) or less, emphasizing the critical role of duct length in optimizing airflow.

Vibration Isolation: Employ vibration-dampening mounts during installation to mitigate noise and prevent mechanical wear on adjacent components. This practice not only enhances the durability of the fan mechanism but also contributes to a quieter operational environment.

Testing and Validation: Conduct thorough thermal testing post-installation to ensure the fan setup aligns with design specifications. Utilize thermal imaging techniques to identify hotspots, facilitating adjustments in fan placement to optimize cooling performance.

Engineers emphasize that effective ducting design is vital for optimizing air movement efficiency in a fan system. As one engineer noted, “The most crucial aspect is to align the fan traits with your setup’s flow and pressure needs.” By adhering to these strategies, engineers can ensure that their fan system is not only effective but also seamlessly integrated into the overall design, ultimately enhancing functionality in electronic applications.

Ensure Maintenance Protocols and Regulatory Compliance

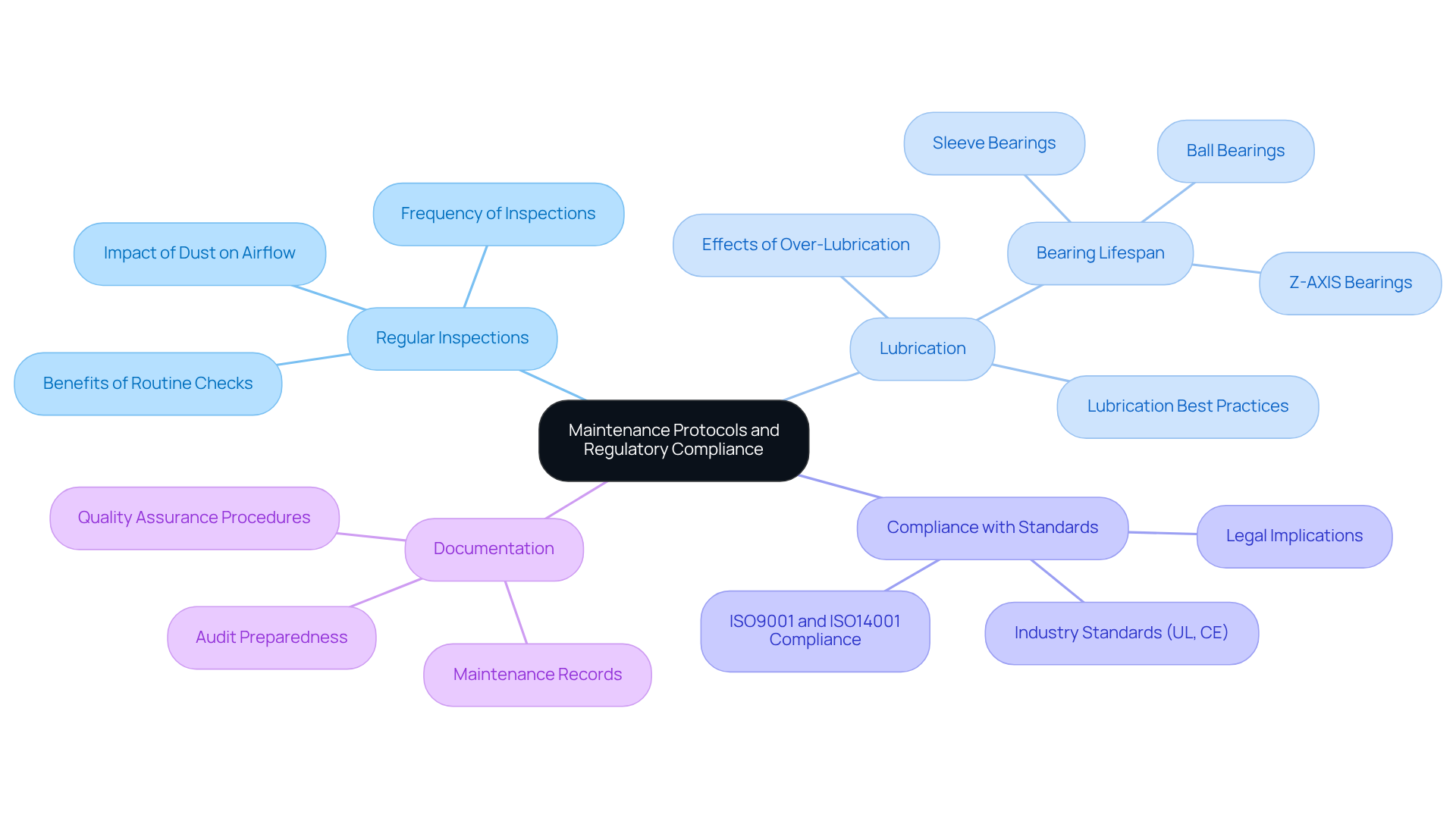

To maintain optimal performance and compliance, it is imperative to consider the following protocols:

- Regular Inspections: Schedule routine checks to ensure that fans are free from dust and debris, as these can significantly impede airflow and increase noise levels. Notably, a mere buildup of 0.02 inches of material on fan blades can reduce airflow by 30% and escalate energy consumption by 15%. Implementing regular inspections can markedly enhance both the longevity and efficiency of fans.

- Lubrication: Depending on the type of fan, regular lubrication is essential to minimize friction and extend lifespan. Proper lubrication can extend bearing life by 30-40%. For example, sleeve bearings, while cost-effective, are susceptible to lubrication issues that can lead to noise and eventual failure if not maintained properly. In contrast, fans equipped with ball bearings can last between 50,000 to 100,000 hours when adequately lubricated, compared to approximately 25,000 hours for sleeve bearings.

- Compliance with Standards: It is crucial to familiarize yourself with relevant industry standards (e.g., UL, CE) that govern fan units. Ensuring that all components meet these standards is vital to avoid legal complications and enhance safety. Additionally, adhering to ISO9001 and ISO14001 standards is essential for maintaining quality and environmental management in fan setups.

- Documentation: Keep meticulous records of maintenance activities and compliance checks. This documentation is vital for audits and , ensuring that all maintenance protocols are followed and that operations remain within regulatory requirements.

By implementing these maintenance protocols and ensuring compliance, engineers can significantly enhance the reliability and safety of their fan system, ultimately leading to reduced downtime and lower maintenance costs.

Conclusion

Mastering fan system design is essential for ensuring effective thermal management in electronic devices. This article has delved into the fundamental concepts, technical specifications, design strategies, and maintenance protocols vital for creating efficient fan systems. By emphasizing the interplay between airflow, static pressure, noise levels, and installation techniques, engineers can significantly enhance the performance and reliability of their cooling solutions.

Key insights, such as the importance of airflow measured in CFM, the impact of static pressure on fan operation, and the necessity of balancing noise levels with efficiency, have been thoroughly examined. Furthermore, the article highlights the significance of proper placement, ducting, and vibration isolation during installation. Regular maintenance and compliance with industry standards are also crucial to ensuring long-term reliability and safety.

In conclusion, the effective design and implementation of fan systems not only contribute to optimal thermal management but also play a pivotal role in the overall functionality of electronic devices. Engineers are urged to adopt best practices in fan system design and maintenance, ensuring that their systems are both compliant and efficient. By prioritizing these strategies, the longevity and performance of fan systems can be greatly enhanced, ultimately leading to improved user experiences and reduced operational costs.

Frequently Asked Questions

What is the primary function of fan systems in electronic devices?

Fan systems manage heat within electronic devices by facilitating air movement to dissipate heat generated by components.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is the world’s largest manufacturer of standard and custom air-movers, offering a wide range of DC input tube axial fans and centrifugal blowers optimized for performance, efficiency, and low noise.

How is airflow measured and why is it important?

Airflow is measured in cubic feet per minute (CFM) and is critical for ensuring adequate cooling. Engineers must assess the necessary air movement based on the heat output of components to prevent overheating and extend device lifespan.

What is static pressure and why does it matter in fan systems?

Static pressure refers to the resistance to air movement within a system. It is important because high static pressure blowers are needed in situations where air movement is obstructed, influencing fan operation and design considerations.

How do axial fans and centrifugal fans differ in terms of static pressure?

Axial fans typically have lower static pressure ratings compared to centrifugal fans, which are designed for higher resistance environments.

Why are noise levels important in fan selection?

Noise levels, measured in decibels (dB), are critical for consumer electronics as excessive noise can negatively impact user experience. Engineers must balance efficiency with acceptable noise levels.

What are the different types of fans and their applications?

The main types of fans are axial and centrifugal fans. Axial fans are often used in smaller systems, while centrifugal fans are preferred for larger enclosures requiring greater static pressure. They are utilized in various sectors such as automotive, telecom, and industrial settings.

How does installation density affect fan performance?

Increased installation density within an enclosure can elevate static pressure and restrict air movement, which designers must consider to ensure effective cooling.

What key concepts should engineers master for effective fan system design?

Engineers should understand the relationship between airflow and static pressure, as well as the specific use cases for different fan types to ensure efficient thermal management in their projects.