Overview

Centrifugal exhaust fan blowers present significant advantages for engineers, including:

- Energy efficiency

- Minimal maintenance requirements

- Superior cooling performance

These factors collectively lead to operational cost savings and enhanced reliability across various applications. The design of these fans emphasizes durability and versatility, making them adept for diverse environments. They ensure optimal airflow and safety, thereby underscoring their value as essential tools in engineering projects.

Introduction

Centrifugal exhaust fan blowers are transforming the engineering landscape by providing a multitude of advantages tailored to diverse industrial needs. These innovative devices not only enhance airflow and cooling efficiency but also promise substantial operational cost savings and improved safety measures.

As engineers navigate the complexities of modern applications, a critical question emerges: how can these advanced fans be effectively leveraged to optimize performance while minimizing environmental impact?

An exploration of the myriad benefits of centrifugal exhaust fan blowers reveals their essential role in driving engineering success across various sectors.

Gagner-Toomey Associates: Innovative Solutions for Centrifugal Exhaust Fans

Gagner-Toomey Associates positions itself as a leader in delivering innovative solutions for , effectively addressing a wide range of markets including Telecom, IoT, Automotive, and Medical. By presenting a portfolio of exceptional manufacturers, the company ensures that professionals are equipped with that significantly enhance airflow and cooling efficiency. Their unwavering is evident in their , establishing them as a .

As we approach 2025, the integration of advanced features such as:

- Aerodynamically optimized impellers

is set to redefine performance benchmarks in centrifugal exhaust fan blower systems, further solidifying their role in . Through a customer-centric approach and a profound understanding of the electronics industry’s demands, Gagner-Toomey Associates empowers engineers with in cooling, power management, and interconnect technologies.

Energy Efficiency: Reduce Operational Costs with Centrifugal Exhaust Fans

from Gagner-Toomey Associates are engineered for high , leading to . By harnessing , these fans effectively move large volumes of air while consuming less power. This efficiency not only lowers energy costs but also contributes to , making them an for professionals dedicated to sustainability.

Gagner-Toomey’s includes a variety of centrifugal exhaust fan blowers, all optimized for superior performance and low noise levels. This ensures that engineers have access to that are tailored for diverse applications in electronics and beyond.

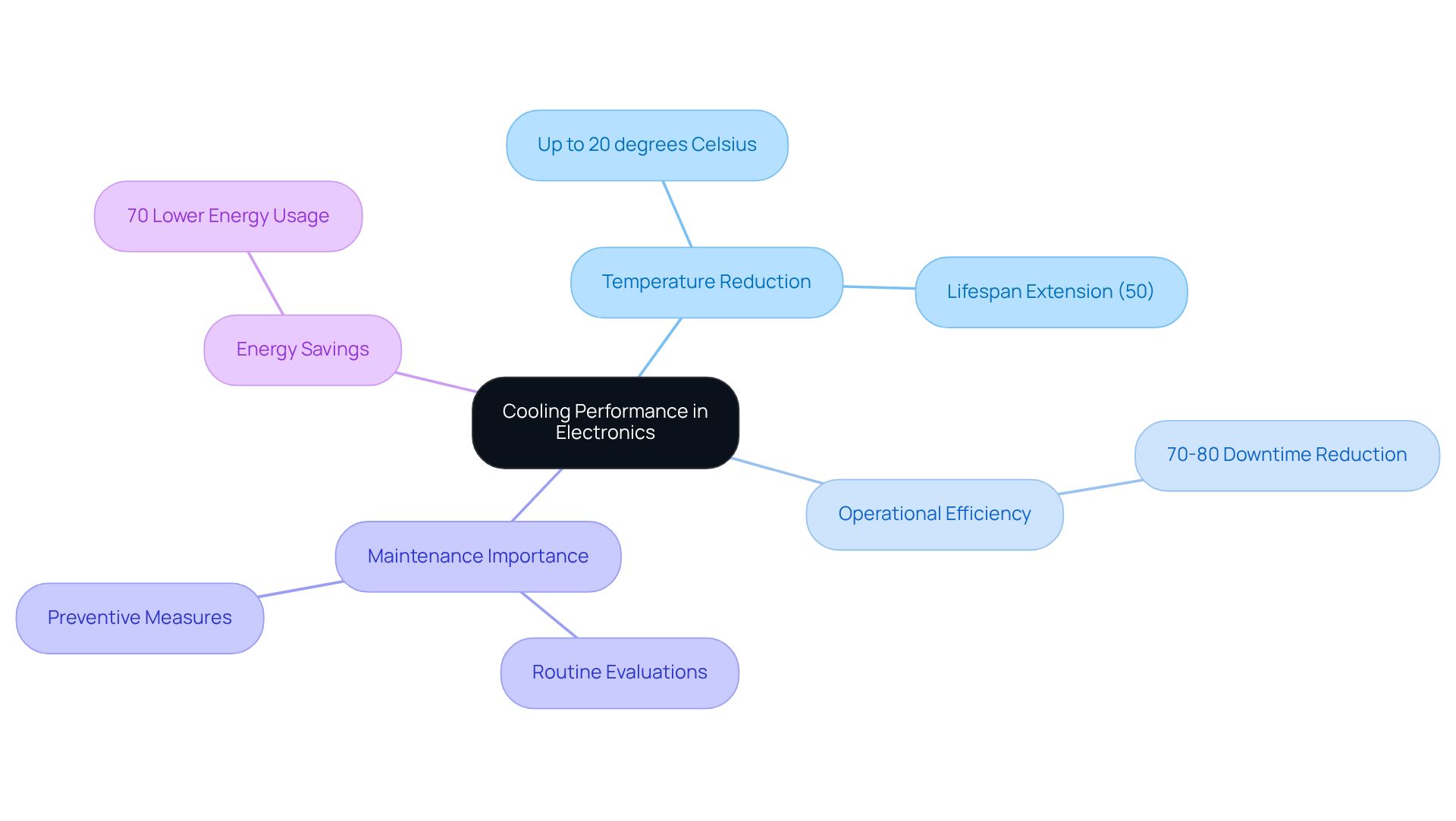

Cooling Performance: Maintain Optimal Temperatures in Electronics

are essential for maintaining . They effectively remove warm air while facilitating the entry of cooler air, thus that can lead to component failure. Their capability to provide consistent airflow ensures that sensitive electronic equipment operates within safe temperature ranges, enhancing both reliability and performance.

Centrifugal industrial blowers can achieve , playing a crucial role in preventing overheating, which can shorten the lifespan of electronic components by as much as 50%. Routine evaluations of these devices can reduce downtime associated with them by 70-80%, underscoring the .

Engineers emphasize that ensuring adequate airflow is vital; as one noted, ‘ is not just about performance—it’s about longevity and reliability in electronic devices.’

The application of centrifugal exhaust fan blowers in data centers exemplifies their effectiveness in , ensuring continuous operations. Furthermore, these devices can lower energy usage by as much as 70% compared to conventional models, making them an . By integrating these devices into electronic setups, professionals can significantly reduce the risk of overheating, ultimately .

Versatility: Adapt Centrifugal Exhaust Fans for Diverse Applications

s are noted for their exceptional versatility, making them ideal for a wide array of applications, from to industrial ventilation. Their innovative design facilitates seamless adaptation to diverse environments, including manufacturing plants, data centers, and commercial kitchens. This flexibility empowers engineers to implement tailored to the specific demands of each project.

For instance, in a large corporate office, the selection of forward-curved centrifugal devices minimized noise while ensuring adequate airflow, thereby creating a comfortable workspace. Furthermore, backward-curved centrifugal blowers are recognized for their into airflow, significantly reducing energy consumption.

The centrifugal exhaust fan blower has the ability to manage varying air volumes and pressure levels, making it indispensable in HVAC setups, where efficient air circulation, temperature control, and ventilation are paramount. Choosing the right centrifugal fan is critical for maximizing and minimizing noise, ensuring that .

As market demand for continues to rise, the positions them as a vital component in both commercial and industrial environments.

Low Maintenance: Simplify Operations with Centrifugal Exhaust Fans

stand out due to their , significantly simplifying operations. Designed for durability, these devices often feature sealed bearings and robust construction, effectively minimizing wear and tear. This design not only extends the lifespan of the fans—averaging between 50,000 to 70,000 hours in HVAC applications—but also .

Furthermore, the soft start feature of activates within 5 seconds after power on, and thereby . The ensures that the motor can endure locked rotor conditions for at least 72 hours at rated voltage, further enhancing reliability.

As a result, professionals can focus their time and resources on other critical project elements without the ongoing concern of fan maintenance. Maintenance experts frequently highlight the benefits of these , noting that the reduced downtime and upkeep costs associated with centrifugal exhaust fan blowers contribute to .

By integrating these devices into their systems, professionals can achieve a more efficient workflow, ultimately supporting the success of their projects. Additionally, when paired with EC motors, these devices can deliver up to 70% compared to conventional AC systems, making them an even more attractive option for engineers.

Durability: Ensure Long-Lasting Performance in Harsh Conditions

from Gagner-Toomey Associates are expertly engineered for exceptional durability, making them ideally suited for . Their robust construction incorporates , including stainless steel alloys and advanced polymers, significantly enhancing resistance to extreme temperatures, dust, and moisture. This resilience extends the lifespan of the devices and decreases the frequency of replacements, resulting in for businesses.

For instance, the CBS-71 Industrial centrifugal exhaust fan blower, which is part of , is designed to operate reliably in demanding conditions. It minimizes maintenance needs through innovations such as from equipped with sensors and IoT connectivity. Furthermore, the incorporation of helps prevent dust accumulation, further enhancing the fan’s longevity and reliability.

Consequently, technicians can depend on these devices to deliver , even in the most challenging environments.

Noise Reduction: Create Quieter Workspaces with Centrifugal Exhaust Fans

devices effectively tackle a significant challenge in various environments: the need for . Renowned for their ability to , centrifugal exhaust fan blowers present an where is paramount. Their innovative design , leading to sound levels that are markedly lower than those of other fan types. This characteristic is particularly advantageous in office settings, laboratories, and residential areas, where a is crucial for both productivity and comfort. By selecting a centrifugal exhaust fan blower, stakeholders can , ensuring that noise does not detract from performance or well-being.

Airflow Control: Optimize Performance with Centrifugal Exhaust Fans

Centrifugal exhaust fan blowers play a pivotal role in achieving , enabling engineers to tailor performance to meet specific requirements. The integration of allows for dynamic adjustments in fan speed, facilitating the fine-tuning of airflow for diverse applications. This enhanced control not only boosts but also ensures under varying conditions.

For example, the implementation of VFDs can yield in scenarios such as food processing plants by . Furthermore, VFDs offer a , which minimizes mechanical stress during operation and extends the lifespan of both the fan and motor.

Industry experts emphasize that this level of control is vital for in demanding environments, ultimately leading to improved and lower operational costs. Additionally, VFDs can be seamlessly integrated into existing systems, enhancing their functionality without the need for extensive modifications.

Safety: Prevent Overheating with Centrifugal Exhaust Fans

are crucial for ensuring where overheating poses significant risks. By effectively removing hot air and facilitating proper ventilation, centrifugal exhaust fan blowers play a critical role in and mitigating potential hazards. The centrifugal exhaust fan blower plays a crucial role in , which is essential for safeguarding both personnel and .

As Dan Peterson aptly stated, ‘Paper doesn’t save people – people save people,’ underscoring the necessity for proactive measures such as . Moreover, , equipping personnel with an understanding of the .

By integrating centrifugal exhaust fan blowers into operational protocols, technicians can significantly reduce the risk of overheating, thereby fostering a safer workplace.

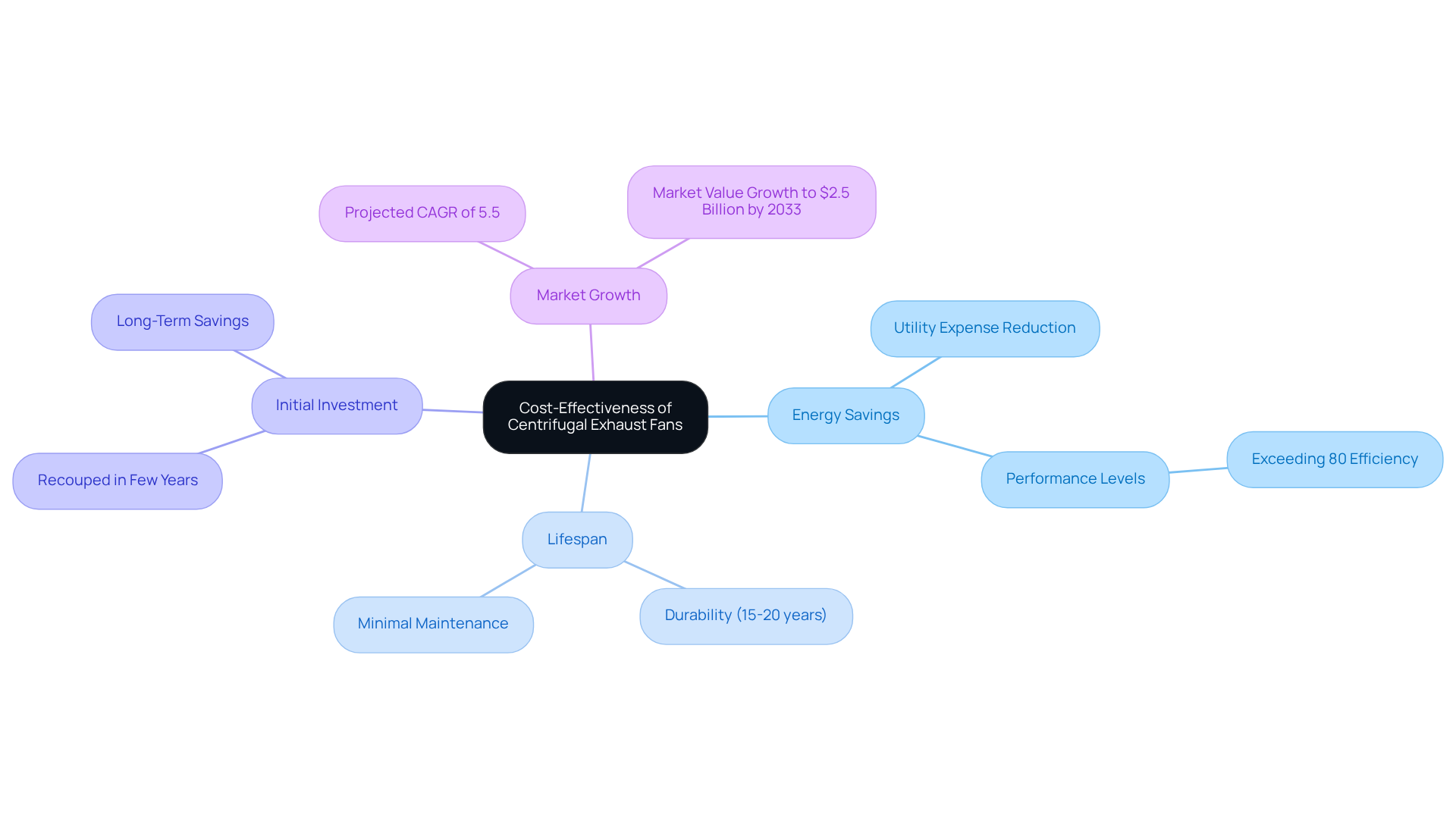

Cost-Effectiveness: Maximize Value with Centrifugal Exhaust Fans

s present a remarkably , delivering significant savings through their . By substantially reducing utility expenses, these devices not only diminish but also extend their lifespan, typically ranging from 15 to 20 years. This durability stems from their robust design, which minimizes the need for frequent replacements and maintenance.

The long-term advantages of investing in these devices are evident, as they can achieve under optimal conditions, leading to decreased energy consumption and enhanced productivity across various applications. Financial analysts emphasize that the initial investment in can be recouped within a few years. One analyst noted, “The cost savings from reduced energy usage render these devices a wise investment for any industrial application.”

Furthermore, the market for is projected to grow significantly at a compound annual growth rate of 5.5%, underscoring their increasing importance in industrial settings.

In summary, the centrifugal exhaust fan blower not only optimizes performance but also offers outstanding value, positioning it as an ideal choice for engineers in search of reliable and efficient solutions.

Conclusion

Centrifugal exhaust fan blowers present a myriad of advantages that substantially elevate engineering outcomes across various industries. By integrating these innovative devices, professionals can attain superior energy efficiency, effective cooling performance, and remarkable durability—elements that collectively contribute to optimized operations and reduced costs. The versatility of these fans facilitates seamless adaptation to diverse applications, ensuring that specific project demands are met with precision.

Key points throughout this discussion underscore that centrifugal exhaust fans not only diminish operational expenses through energy savings but also play a crucial role in maintaining optimal temperatures, thus preventing equipment failures. Their low maintenance requirements and robust construction further enhance their appeal, rendering them a reliable choice for engineers in search of long-lasting solutions. Moreover, the noise reduction capabilities of these fans foster quieter, more productive work environments, while their ability to control airflow guarantees optimal performance in any setting.

In light of these advantages, the adoption of centrifugal exhaust fan blowers emerges as a strategic investment for engineers striving to enhance operational efficiency and sustainability. By opting for these advanced solutions, professionals can bolster the performance and reliability of their systems, while also contributing to a safer and more eco-friendly workplace. Embracing the power of centrifugal exhaust fans transcends a mere technical decision; it embodies a commitment to innovation and excellence in engineering practices.

Frequently Asked Questions

What markets does Gagner-Toomey Associates serve with its centrifugal exhaust fan solutions?

Gagner-Toomey Associates serves a wide range of markets including Telecom, IoT, Automotive, and Medical.

What features are being integrated into centrifugal exhaust fan blower systems by 2025?

By 2025, features such as aerodynamically optimized impellers and energy-efficient EC motors are set to be integrated into centrifugal exhaust fan blower systems.

How do Gagner-Toomey Associates’ centrifugal exhaust fans contribute to energy efficiency?

Their centrifugal exhaust fans are engineered with advanced motor technologies and optimized blade designs, allowing them to move large volumes of air while consuming less power, thus reducing operational expenses and carbon footprints.

What role do centrifugal exhaust fans play in maintaining optimal temperatures in electronic systems?

They effectively remove warm air and facilitate the entry of cooler air, preventing overheating and ensuring that sensitive electronic equipment operates within safe temperature ranges.

How much can centrifugal exhaust fans reduce temperatures in electronic systems?

Centrifugal industrial blowers can achieve average temperature reductions of up to 20 degrees Celsius.

What impact does routine maintenance have on centrifugal exhaust fans?

Routine evaluations can reduce downtime associated with these devices by 70-80%, which is crucial for preserving their efficiency.

How do centrifugal exhaust fans affect the lifespan of electronic components?

Proper airflow from these fans can prevent overheating, which can shorten the lifespan of electronic components by as much as 50%.

What is the energy usage comparison between centrifugal exhaust fans and conventional models?

Centrifugal exhaust fans can lower energy usage by as much as 70% compared to conventional models.

In what specific application are centrifugal exhaust fans particularly effective?

They are particularly effective in data centers for regulating heat produced by servers, ensuring continuous operations.