Overview

Forward curved centrifugal fans are specialized devices engineered to efficiently move air through centrifugal force. This makes them particularly suitable for applications that require high airflow at low pressure, such as HVAC systems and ventilation. The advantages of these fans are noteworthy; they offer high airflow capacity and low noise levels.

However, it is crucial to acknowledge their limitations, including:

- Subpar performance in high-pressure scenarios

- Susceptibility to airflow separation

This underscores the importance of careful application selection to maximize their effectiveness.

Introduction

Forward curved centrifugal fans are integral to a multitude of industries, distinguished by their innovative design that maximizes airflow while minimizing noise. These fans excel in applications that demand high airflow at low pressure, rendering them essential in HVAC systems, ventilation, and various industrial processes. However, despite their advantages, challenges such as performance limitations in high-pressure environments pose critical questions regarding their suitability for specific tasks. Understanding the mechanics and applications of these fans is crucial for enhancing performance and efficiency across diverse settings.

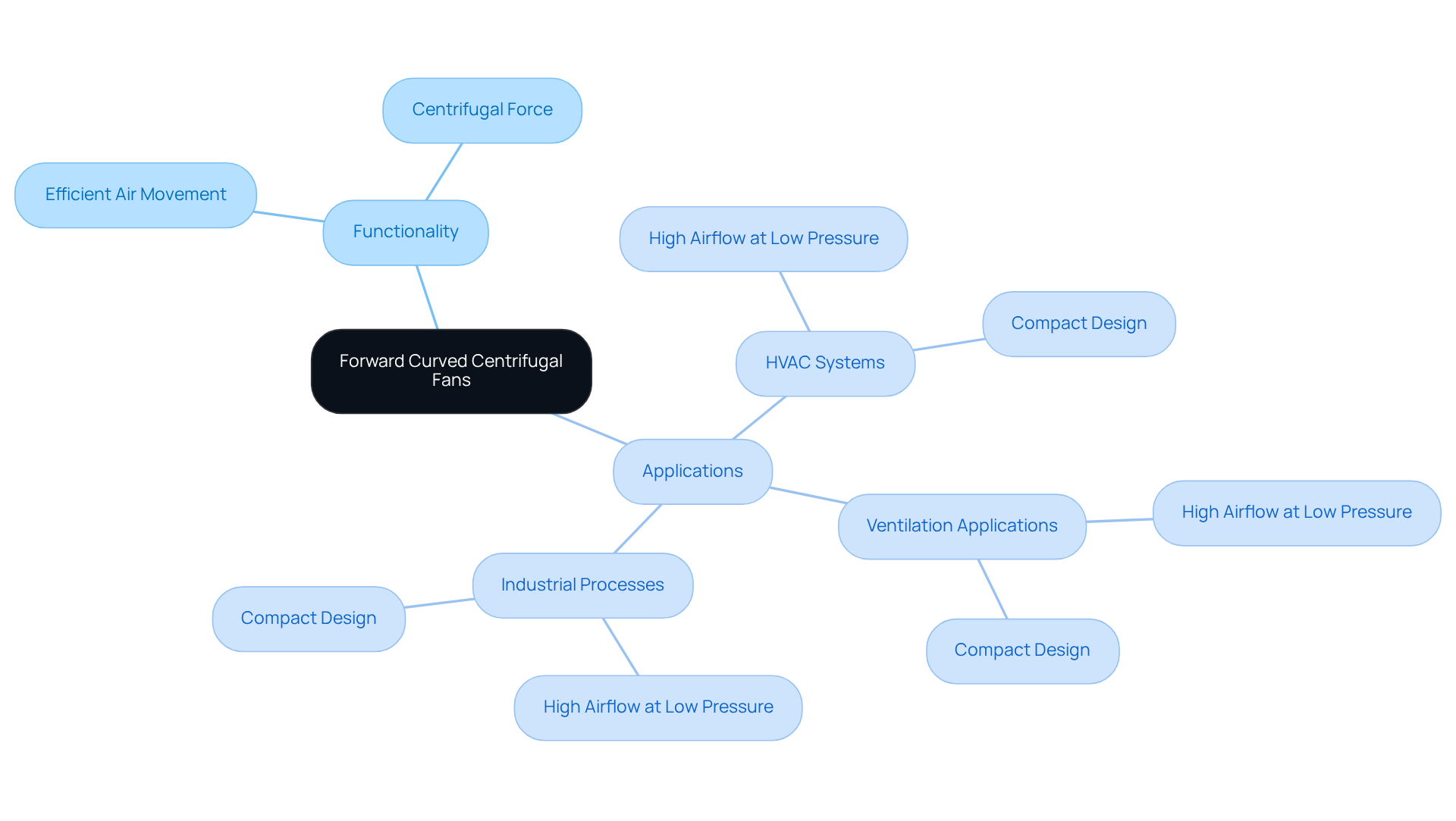

Define Forward Curved Centrifugal Fans and Their Functionality

s represent a specialized category of devices characterized by blades that arc in the direction of rotation. This innovative design facilitates the through the application of centrifugal force. As the impeller rotates, air enters the fan axially and is subsequently discharged radially, resulting in an increase in flow velocity.

These units, specifically the forward curved centrifugal fan, are predominantly employed in scenarios that require , making them ideally suited for:

- Ventilation applications

- Various industrial processes

Their , coupled with the capability to handle , positions them as a preferred choice across diverse settings, including both residential and commercial environments.

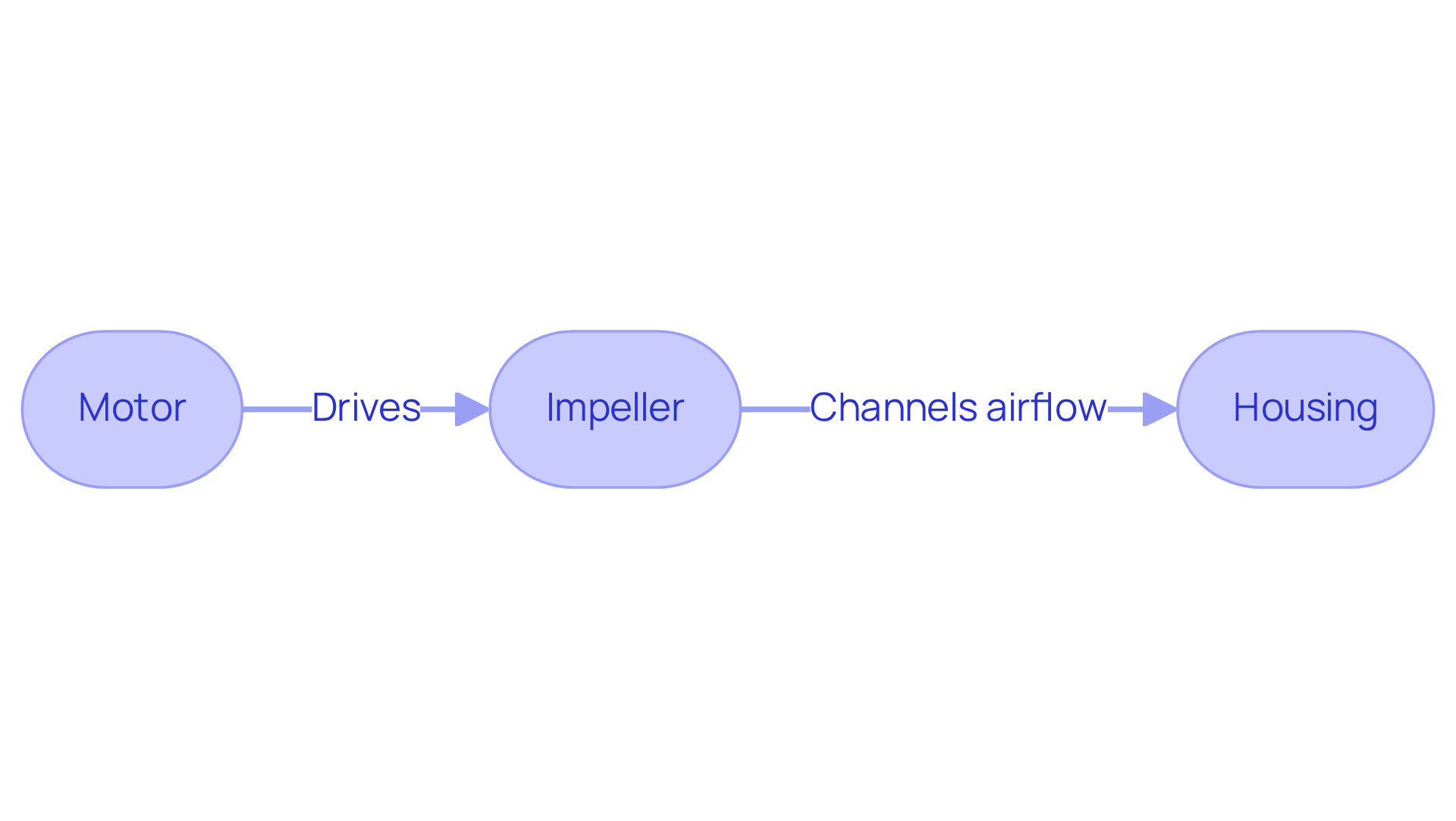

Explain the Mechanics of Forward Curved Centrifugal Fans

The mechanics of the are anchored by several key components:

- The impeller

- Housing

- Motor

The impeller consists of multiple blades angled forward, which facilitates . When the motor drives the impeller, it generates a that propels air outward. The housing is meticulously designed to channel airflow, minimizing turbulence and maximizing efficiency. The angle and curvature of the blades of the forward curved centrifugal fan are paramount; they are while simultaneously . This sophisticated design empowers forward-bending blowers to excel in low-pressure environments, allowing them to sustain without incurring excessive energy consumption.

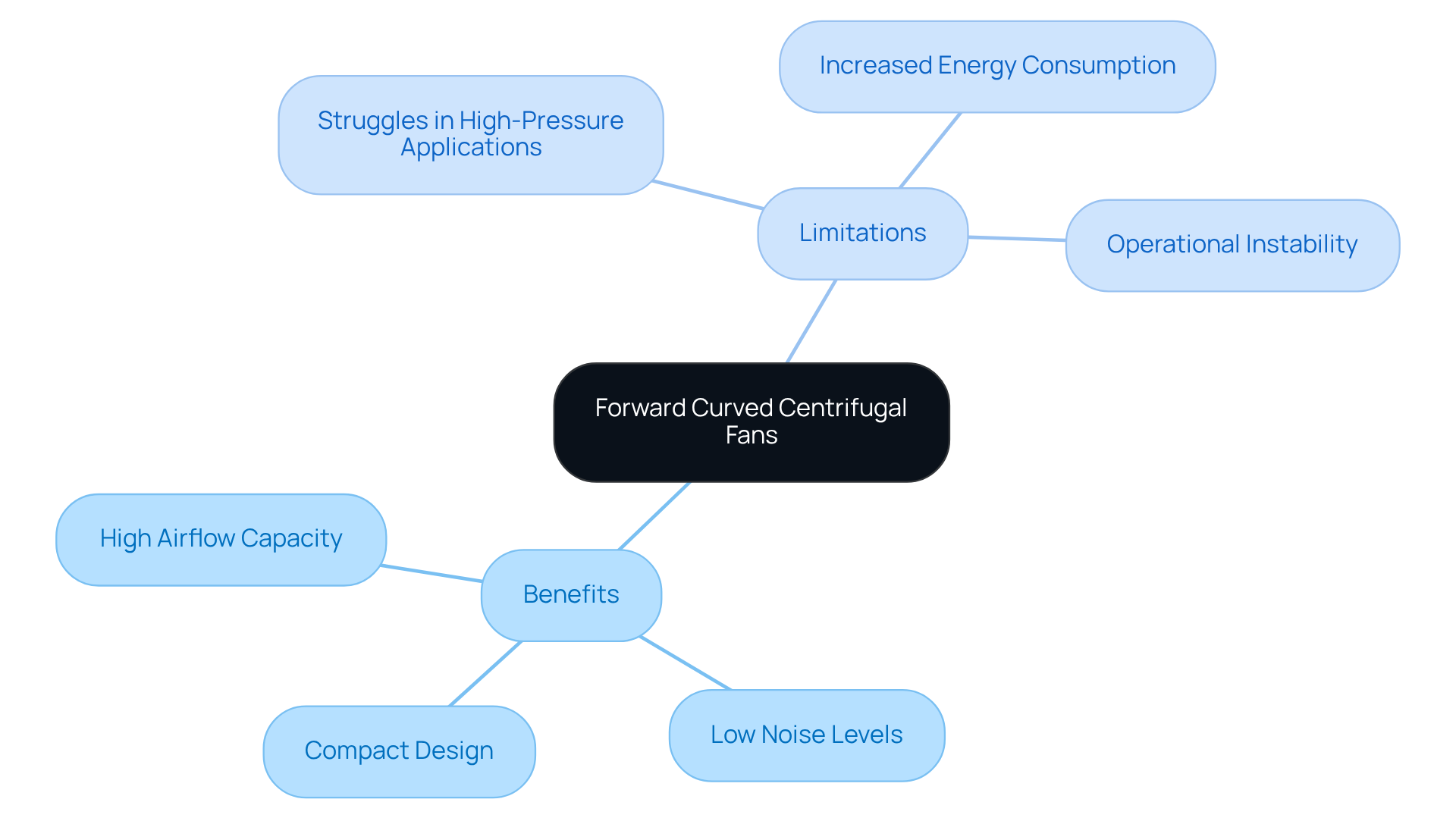

Assess the Benefits and Limitations of Forward Curved Fans

The numerous advantages of include , low noise levels, and a compact design. These forward curved centrifugal fans are excellent at moving large volumes of air efficiently, making them ideal for applications that demand . Their design minimizes turbulence, resulting in quieter operation compared to other fan types, which is particularly beneficial in . In fact, forward curved centrifugal fans are very quiet, making them ideal for tranquil locations. Additionally, the enable simpler setup in confined areas, improving their adaptability in different uses.

Despite these benefits, notable limitations warrant careful consideration. Forward curved centrifugal fans struggle in , where backward curved fans typically outperform forward curved centrifugal fans. This inefficiency can lead to increased energy consumption and . Furthermore, under certain conditions, airflow may separate from the blades, resulting in reduced performance and potential operational instability. These devices can also be less effective in settings with high dust or debris levels, as particulates may obstruct the blades, further reducing airflow and efficiency.

Industry insights emphasize the importance of understanding these limitations. Zhehong Li states that ‘ are crucial for improving fan performance,’ underscoring the necessity of evaluating fan choice based on specific usage requirements. Moreover, the projected size of the India ventilation fan market is USD 167.7 million in 2023, illustrating the growing demand for efficient fan technologies. Case studies demonstrate that while forward curved centrifugal fans are appropriate for numerous applications, such as in electronics cooling, their restrictions in high-pressure situations necessitate a comprehensive assessment to ensure optimal performance and reliability.

Identify Common Applications for Forward Curved Centrifugal Fans

are integral to a variety of applications, demonstrating their versatility and efficiency in different sectors.

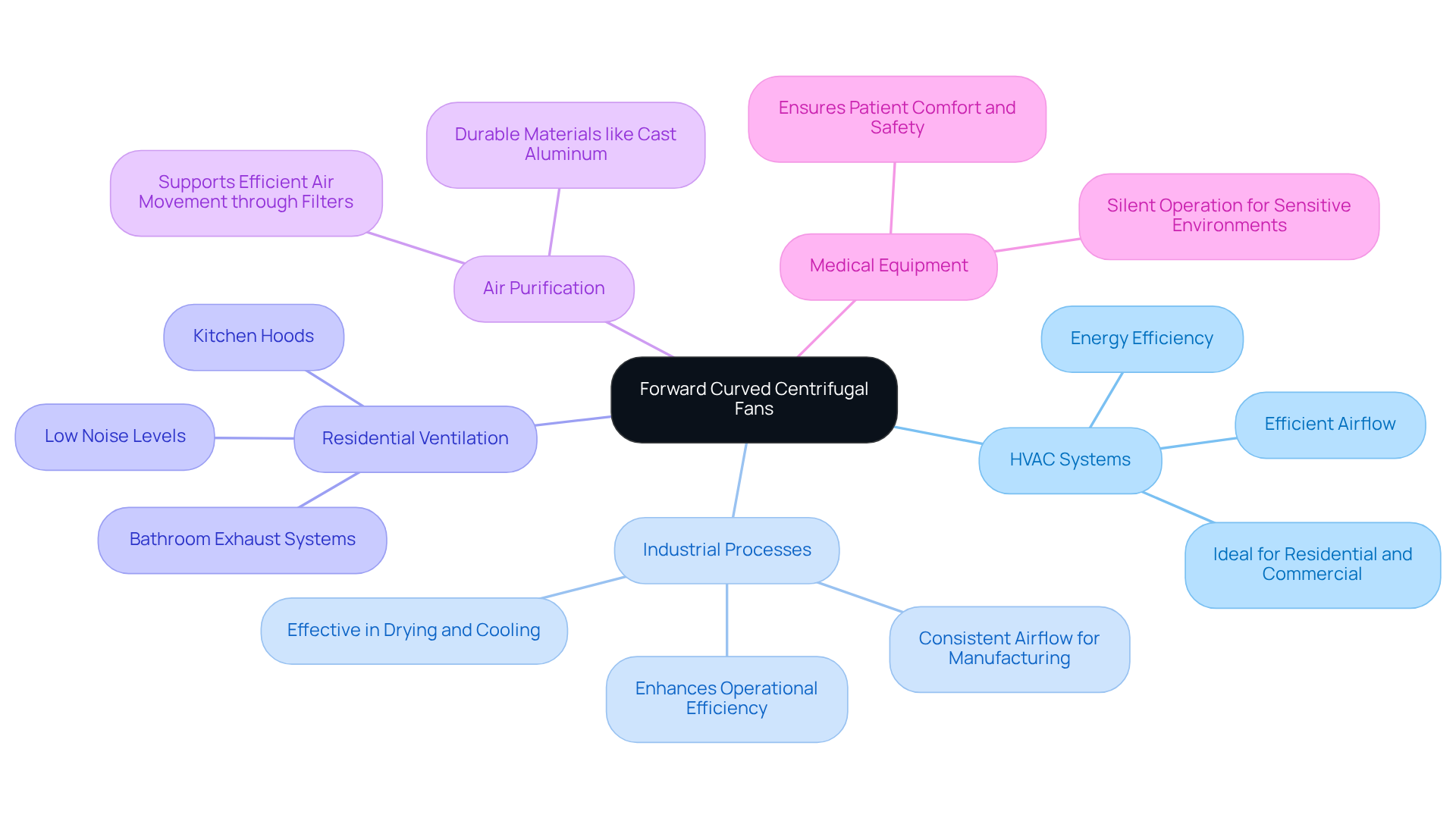

: The forward curved centrifugal fan is a staple in heating, ventilation, and air conditioning systems, delivering efficient airflow essential for both cooling and heating processes. Their design facilitates , making them ideal for both residential and commercial environments. According to industry standards, forward bent blowers are frequently utilized in and low to medium static applications, contributing significantly to .

In industrial processes, the forward curved centrifugal fan plays a crucial role in manufacturing that requires , such as drying and cooling. Their capability to maintain steady air circulation enhances operational efficiency and product quality. Real-world applications demonstrate their effectiveness across various industrial settings, ensuring optimal performance.

In residential ventilation, forward curved centrifugal fans are commonly found in and kitchen hoods, favored for their low noise levels and high airflow capabilities. This characteristic makes them particularly suitable for residential settings, where comfort and quiet operation are paramount. HVAC experts emphasize the importance of selecting devices that balance noise and airflow, especially in residential environments.

- Air Purification: These devices excel in , contributing to the maintenance of clean air in both commercial and industrial environments. Their design supports the efficient movement of air through filters, ensuring optimal . The durability of materials such as cast aluminum and stainless steel enhances their reliability in demanding applications.

- Medical Equipment: The silent operation of forward curved centrifugal fans renders them ideal for use in and settings where noise minimization is critical. Their dependability in maintaining airflow without disturbing sensitive environments is invaluable in healthcare applications. Industry insights indicate a growing adoption of forward curved fans in medical equipment, underscoring their role in ensuring patient comfort and safety.

Conclusion

Forward curved centrifugal fans stand as essential devices that exemplify efficiency in air movement, particularly in applications demanding high airflow at low pressure. Their distinctive design, characterized by blades curving in the direction of rotation, facilitates effective air propulsion, establishing them as a preferred choice across various settings, including HVAC systems, industrial processes, and residential ventilation.

This article thoroughly examined the mechanics of these fans, highlighting critical components such as:

- Impeller

- Housing

- Motor

The advantages of forward curved centrifugal fans, including high airflow capacity and low noise levels, were juxtaposed with their limitations, especially in high-pressure scenarios. Furthermore, the discussion underscored the necessity of understanding these constraints to ensure optimal performance across diverse applications, ranging from air purification to medical equipment.

In conclusion, acknowledging the strengths and weaknesses of forward curved centrifugal fans is crucial for selecting the right fan to meet specific needs. As industries persist in pursuing efficient airflow solutions, the demand for these fans is poised to increase. It is imperative for professionals to remain informed about their mechanics and applications. Embracing this knowledge not only enhances operational efficiency but also contributes to improved air quality and comfort in various environments.

Frequently Asked Questions

What are forward curved centrifugal fans?

Forward curved centrifugal fans are devices characterized by blades that arc in the direction of rotation, designed to efficiently move air using centrifugal force.

How do forward curved centrifugal fans function?

As the impeller of the fan rotates, air enters the fan axially and is discharged radially, which increases the flow velocity of the air.

What are the primary applications of forward curved centrifugal fans?

They are primarily used in HVAC systems, ventilation applications, and various industrial processes that require high airflow at low pressure.

What advantages do forward curved centrifugal fans offer?

Their compact design and ability to handle substantial volumes of air make them a preferred choice for both residential and commercial environments.