Overview

The key benefits of 12 volt blowers for electronics engineers are significant:

- Enhanced cooling efficiency

- Energy savings

- Improved performance across diverse applications

These blowers effectively manage heat in electronic components, which is crucial for reducing power consumption. Additionally, their adaptability makes them suitable for numerous sectors, including automotive and medical. This versatility demonstrates their critical role in maintaining device reliability and longevity, ultimately ensuring optimal performance in various technological environments.

Introduction

The world of electronics is undergoing rapid evolution, with engineers persistently pursuing innovative solutions to elevate performance and efficiency. Among the most indispensable tools in their arsenal are 12 volt blowers, which present a multitude of benefits across diverse applications, ranging from cooling sensitive components to optimizing airflow in ventilation systems. However, as the demand for energy-efficient and compact designs intensifies, how can engineers ensure they are maximizing the potential of these devices? This article explores the seven key advantages of 12 volt blowers, offering insights that have the potential to transform the approach of electronics engineers in their projects.

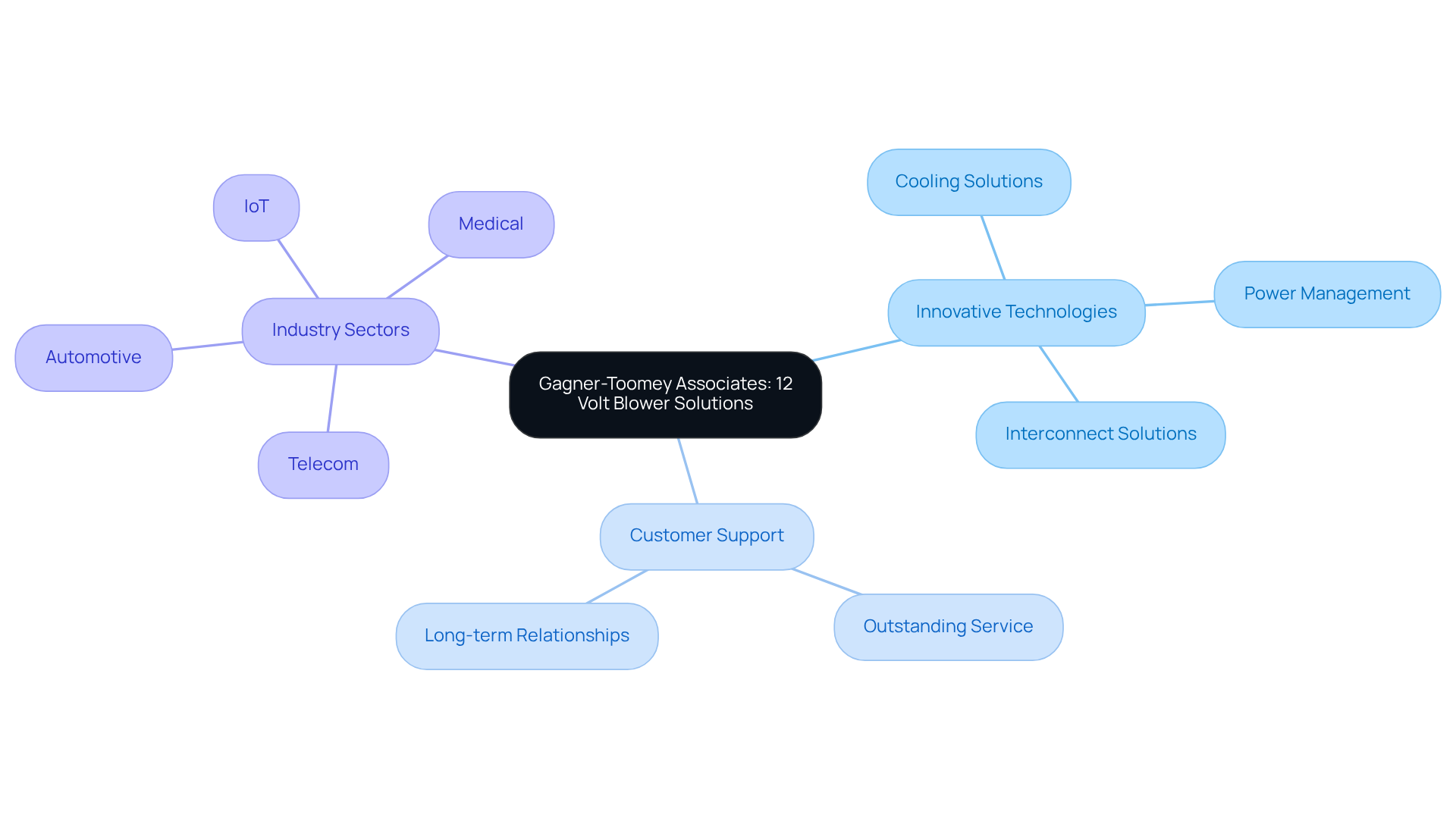

Gagner-Toomey Associates: Innovative Solutions for 12 Volt Blower Applications

Gagner-Toomey Associates stands at the forefront of delivering innovative solutions tailored specifically for 12 volt blower applications. By representing a diverse array of exceptional manufacturers, they guarantee that engineers have access to state-of-the-art technologies in cooling, power management, and interconnect solutions, all aimed at enhancing performance and efficiency. Their unwavering commitment to outstanding customer support is a fundamental aspect of their organizational culture, reinforcing the significant value they provide to engineers.

With profound insights into the electronics industry and enduring relationships with clients, Gagner-Toomey Associates is strategically positioned to facilitate the development of products that comply with rigorous industry standards across various sectors, including:

- Telecom

- Automotive

- IoT

- Medical

Cooling Electronic Components: Utilizing 12 Volt Blowers for Effective Heat Management

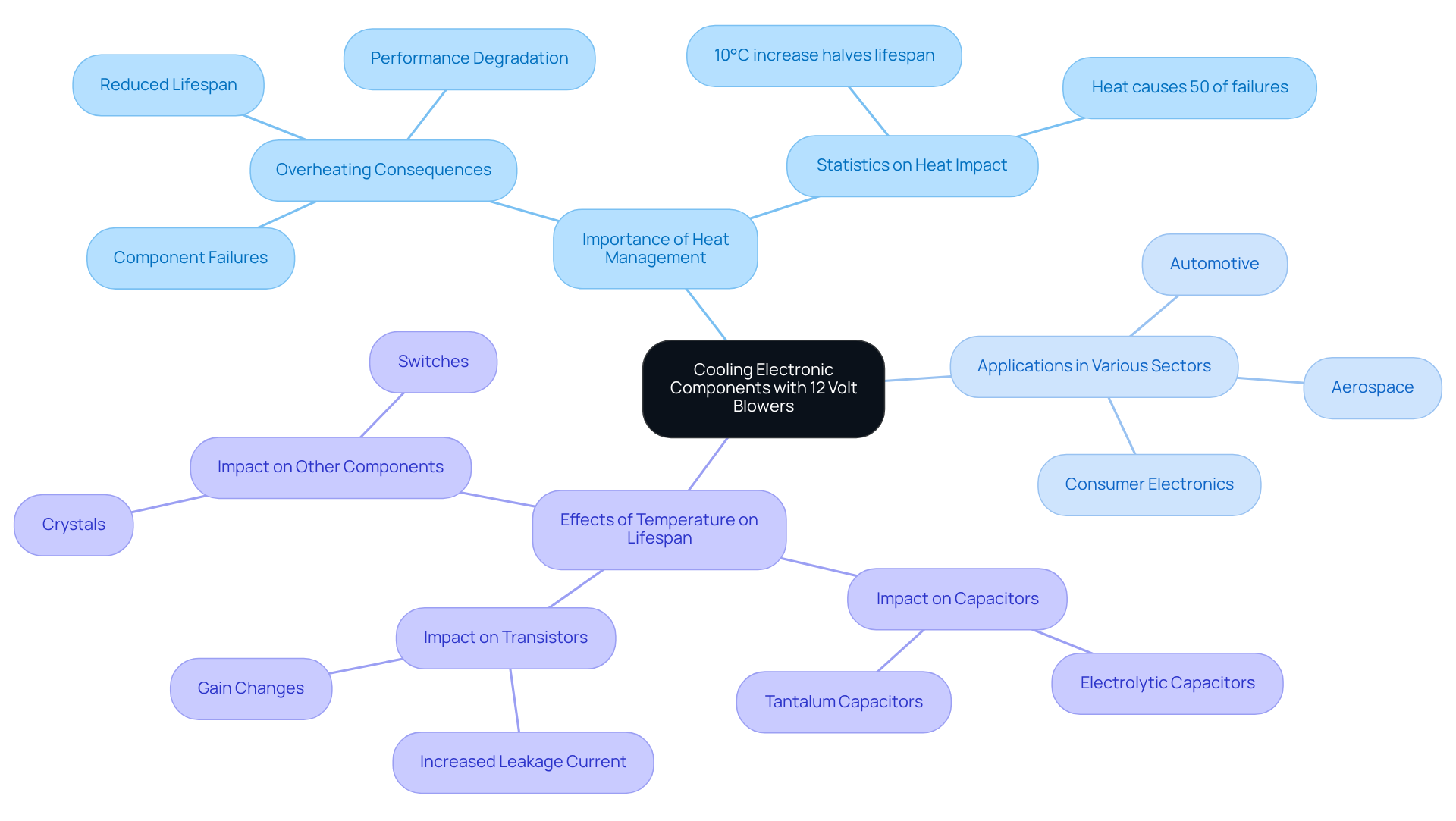

12-volt fans are essential in cooling electronic components by efficiently dispersing heat generated during operation. Maintaining optimal temperatures is crucial, as overheating can lead to significant component failures, with heat responsible for over 50% of electronic equipment malfunctions, according to a study by the US Air Force Avionics Integrity Program. These fans are particularly advantageous due to their compact size and energy efficiency, making them ideal for applications in confined spaces such as computer enclosures and automotive systems.

The practical applications of 12-volt fans illustrate their effectiveness in heat management. In sectors like aerospace and defense, where electronic devices must endure extreme temperatures, the implementation of reliable cooling solutions is vital. Companies utilizing a 12 volt blower report improved performance and extended longevity of their electronic components, as this blower helps mitigate the risks associated with elevated temperatures. High temperatures can lead to issues such as electrolyte leakage in capacitors and increased leakage current in transistors, underscoring the importance of effective cooling strategies.

As we approach 2025, the significance of heat management in electronics cannot be overstated. With devices becoming more compact and powerful, the heat generated continues to rise, necessitating effective cooling solutions. Expert insights emphasize that proper thermal management not only boosts performance but also significantly prolongs the lifespan of electronic components. For instance, a temperature increase of just 10°C can reduce a device’s lifespan by half, whereas a 10°C decrease can potentially double it, highlighting the critical importance of efficient thermal management. By employing a 12 volt blower, engineers can effectively avert overheating, ensuring that their devices operate within safe temperature ranges and maintain reliability over time.

Enhancing Airflow: The Role of 12 Volt Blowers in Ventilation Systems

The 12 volt blower plays a vital role in enhancing airflow within ventilation systems, significantly affecting the effectiveness of electronic cooling. By delivering directed airflow, these devices ensure that electronic components operate at optimal temperatures, which is essential for both performance and longevity. Gagner-Toomey Associates, the largest producer of standard and custom air-movers worldwide, offers an extensive selection of DC input fans, ranging from 15 to 225mm. This range improves air circulation in HVAC units, resulting in enhanced overall efficiency and occupant comfort.

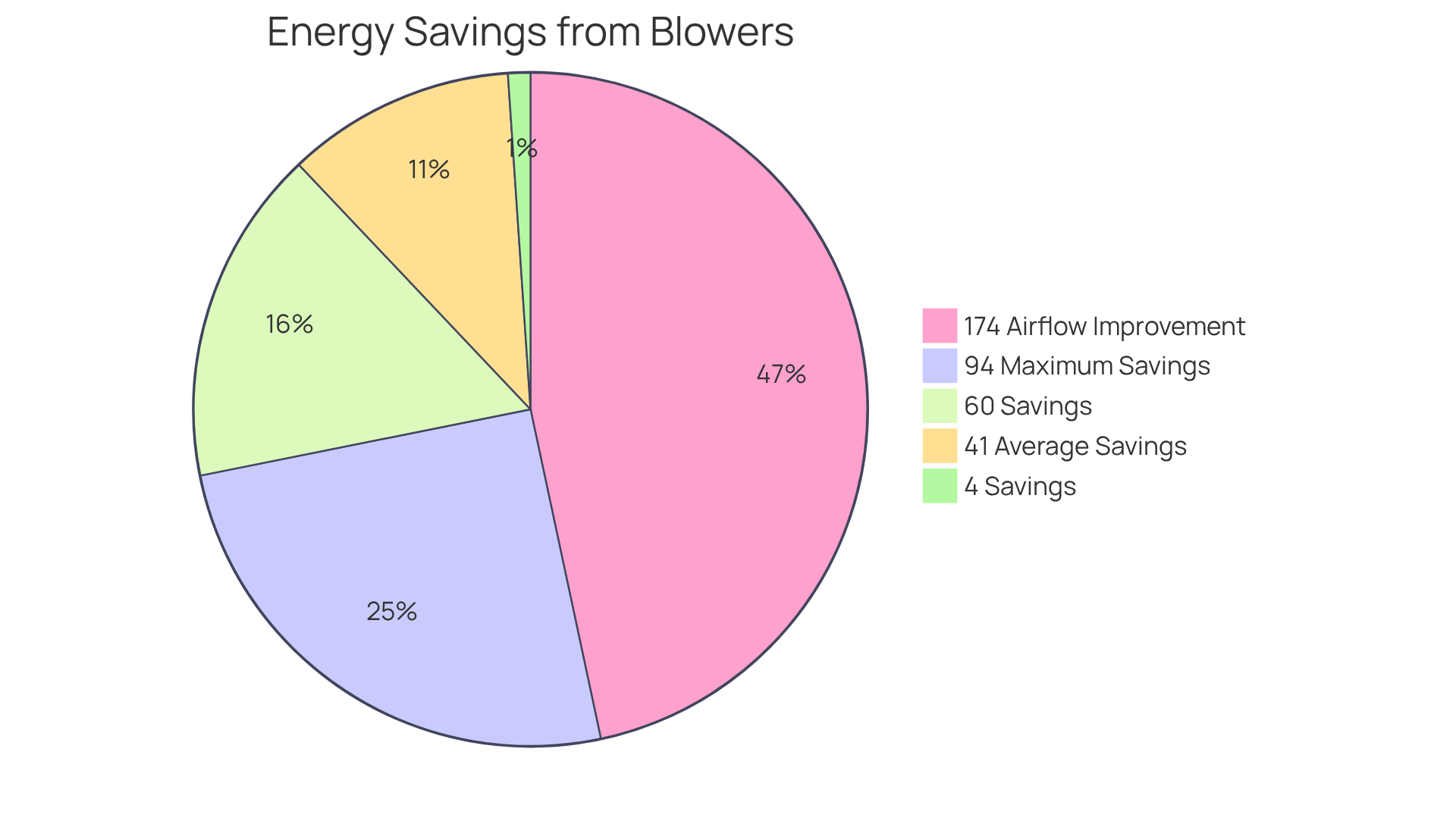

Research indicates that efficient airflow control can reduce energy consumption in HVAC systems by as much as 50%, underscoring the importance of fans in energy-saving designs. Expert evaluations highlight that the integration of 12 volt blowers can lead to substantial improvements in airflow rates, with certain configurations showing increases of up to 174% in supply airflow following cleaning and optimization. Such enhancements not only boost cooling efficiency but also contribute to a more stable indoor environment, thereby minimizing the risk of overheating and equipment failures.

For instance, across various HVAC applications, the adoption of 12 volt blowers has demonstrated significant energy savings, with daily relative energy savings for fan energy consumption ranging from 4% to 94%. These figures illustrate the potential of the 12 volt blower to transform ventilation systems, establishing it as a crucial component for electronics engineers committed to optimizing efficiency and reliability in their designs.

Power Management: Leveraging 12 Volt Blowers for Energy Efficiency

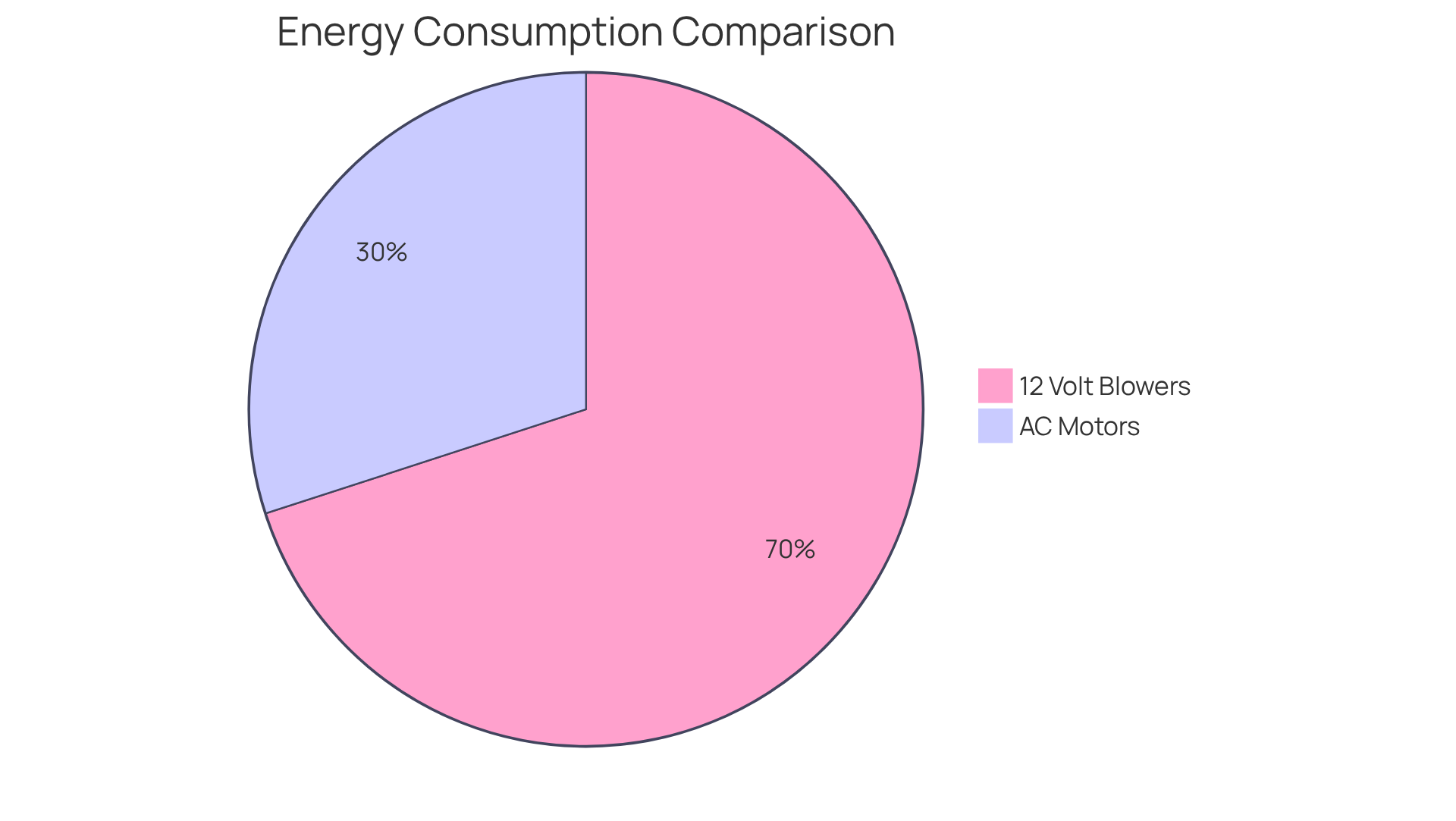

Utilizing a 12 volt blower in power management applications significantly enhances energy efficiency. These devices consume less power compared to conventional AC fans, making them ideal for battery-operated gadgets where energy efficiency is critical. Energy-efficient fans can achieve up to a 70% reduction in power usage relative to conventional AC motors, which not only lowers electricity consumption but also reduces operational expenses and environmental impact. By optimizing airflow with minimal energy expenditure, engineers can design more sustainable and cost-effective electronic solutions.

Practical applications illustrate that the 12 volt blower is increasingly integrated into devices such as portable cooling units and automotive electronics, where effective energy management is essential. As Bill Nowicki, a nuclear industry veteran, emphasizes, “The shift towards energy-efficient technologies is not just a trend; it’s a necessity for sustainable development in the electronics industry.”

Furthermore, advancements in fan technology, including variable speed options and smart technology integration, further enhance the efficiency and versatility of these systems.

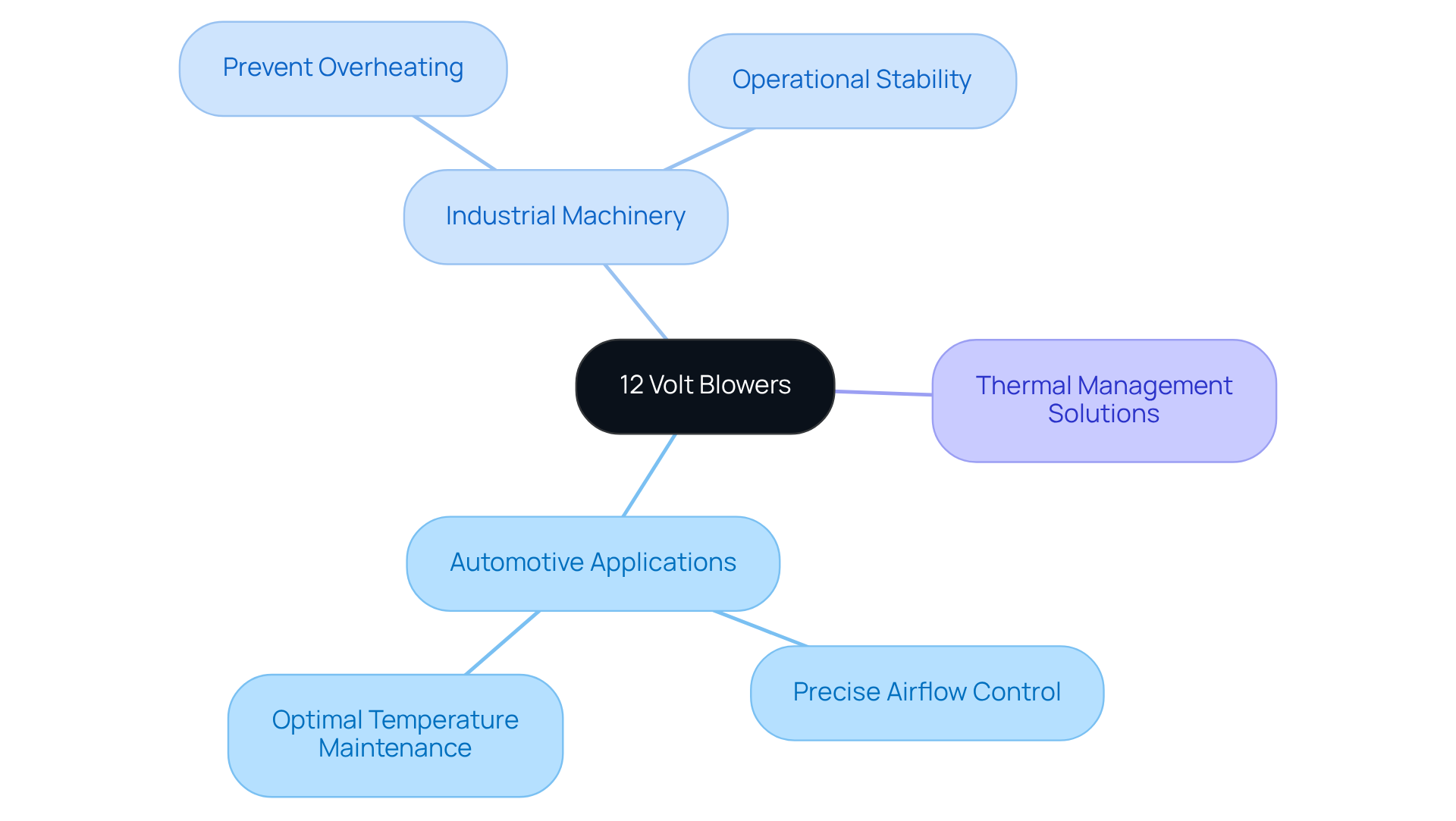

Timing Systems: Integrating 12 Volt Blowers for Precision Control

Incorporating a 12 volt blower into timing mechanisms is essential for achieving precise airflow and efficient temperature control. This precision is particularly vital in automotive applications, where the maintenance of optimal operating conditions can significantly impact performance and reliability.

For example, in high-performance vehicles, precise airflow control is critical to ensuring that engine components remain within their ideal temperature ranges, thereby enhancing both efficiency and longevity. Additionally, in industrial machinery, the capability to regulate airflow accurately can prevent overheating and bolster operational stability.

As the automotive sector increasingly prioritizes advanced thermal management solutions, the role of the 12 volt blower becomes even more pivotal in supporting these systems, driving innovation and enhancing performance across various applications.

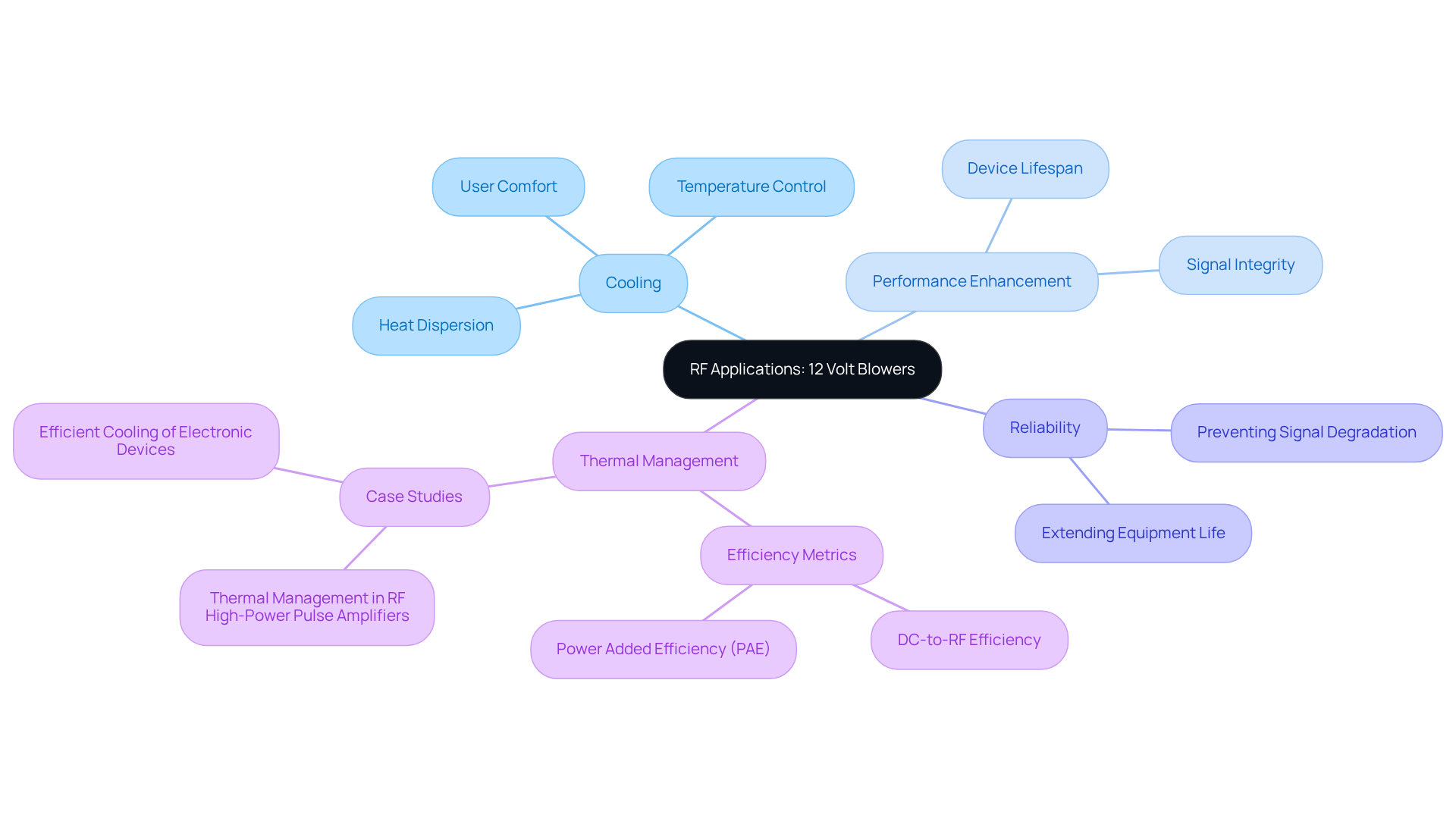

RF Applications: Cooling Solutions with 12 Volt Blowers for Enhanced Performance

In RF applications, the use of a 12 volt blower is indispensable for effective cooling, significantly enhancing both performance and reliability. These devices effectively disperse heat produced by RF amplifiers and other elements, guaranteeing that operating temperatures remain within ideal limits.

Maintaining appropriate temperatures is crucial as it prevents signal degradation, preserving the integrity of RF signals. Moreover, effective cooling solutions can extend the lifespan of RF equipment; case studies demonstrate that the implementation of advanced cooling methods can result in a temperature reduction of up to 8.5°C. This improvement not only enhances user comfort but also contributes to the overall service life of the devices.

As one RF engineer noted, “We learned the hard way that you can’t ignore thermal management.” With RF setups increasingly demanding greater efficiency and reliability, engineers aiming to enhance performance and address thermal issues find that incorporating a 12 volt blower into design plans becomes essential.

Additionally, addressing the inefficiencies in RF amplifiers that lead to heat generation is critical, as these inefficiencies can significantly impact performance metrics such as DC-to-RF efficiency and Power Added Efficiency (PAE).

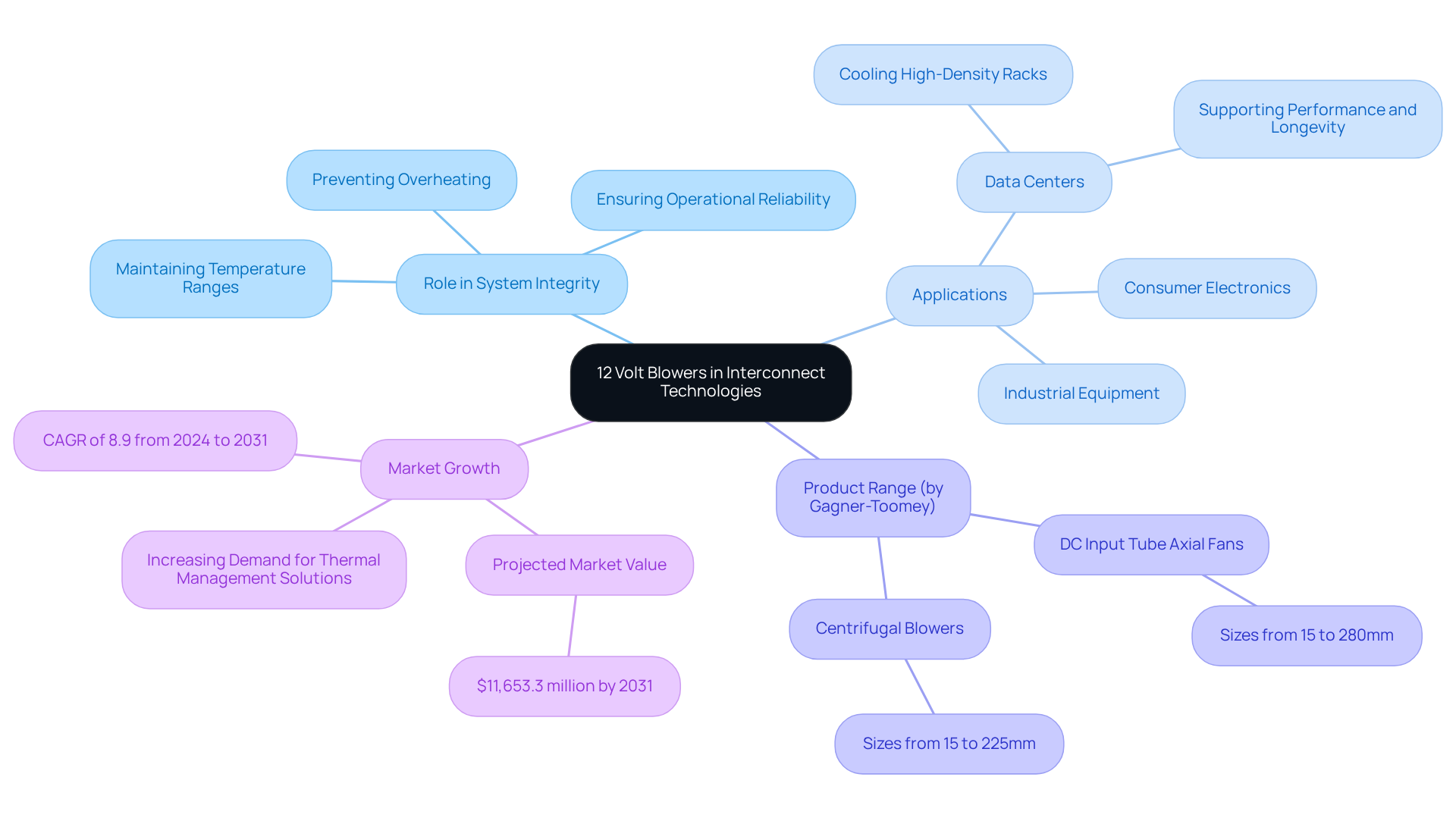

Interconnect Technologies: Supporting System Integrity with 12 Volt Blowers

The integrity of interconnect technologies is maintained by 12 volt blower fans, ensuring that electronic components operate within their designated temperature ranges. The efficient cooling provided by these devices is crucial in preventing overheating, which can lead to connection failures and operational malfunctions. This necessity is particularly pronounced in high-density electronic systems, where limited space complicates thermal management.

As the demand for advanced electronics continues to escalate, the significance of the 12 volt blower becomes increasingly pronounced. For example, in data centers, where racks may host thousands of cores and consume substantial power, maintaining optimal temperatures is vital for both performance and longevity.

Gagner-Toomey Associates, a leading supplier of cutting-edge cooling technologies, offers a diverse range of DC input tube axial fans and centrifugal devices, optimized for performance and efficiency, making them ideal for such applications. These products range in size from 15 to 280mm for tube axial fans and 15 to 225mm for centrifugal blowers, ensuring versatility across various applications.

Experts emphasize that without adequate cooling methods, the reliability of interconnects diminishes, potentially resulting in costly downtimes and repairs. Furthermore, the Global Electronics Thermal Management Solutions market is projected to reach $11,653.3 million by 2031, growing at a CAGR of 8.9% from 2024 to 2031, underscoring the increasing necessity for effective thermal management solutions.

Therefore, integrating 12 volt blowers from Gagner-Toomey into design layouts not only enhances thermal regulation but also upholds the overall integrity of electronic frameworks, ensuring compliance with the stringent requirements of contemporary applications.

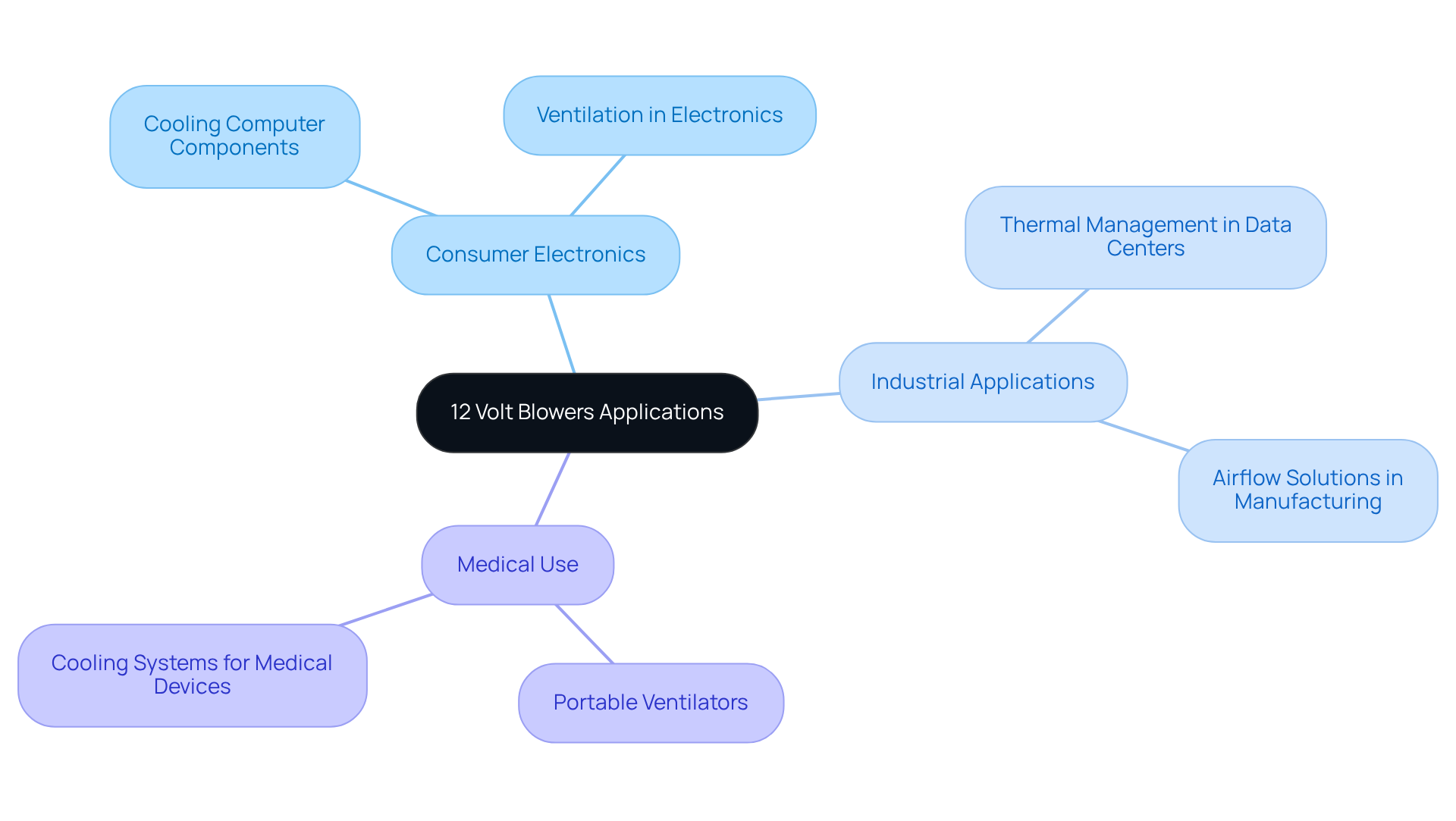

Versatile Applications: The Multifunctional Role of 12 Volt Blowers in Electronics

The adaptability of the 12 volt blower is evident across numerous applications within the electronics sector. From cooling computer components to providing ventilation in automotive systems, these devices demonstrate remarkable versatility in diverse settings. Their compact design and energy efficiency render them ideal for both consumer electronics and industrial applications, underscoring their multifunctional capabilities.

Real-world examples further illustrate their importance: in data centers, the 12 volt blower plays a crucial role in effective thermal management, preventing overheating of sensitive equipment. Furthermore, in the medical field, they find application in portable ventilators, highlighting their adaptability to various environments.

According to the U.S. Department of Energy, the market for energy-efficient devices, including DC fans, is projected to experience substantial growth, signaling a shift towards sustainable technologies. Additionally, the Leaf Blower Market is expected to reach USD 51.94 billion by 2029, reflecting a rising demand for effective alternatives. Experts agree that ongoing advancements in ventilation technology will enhance their performance, establishing them as essential tools for engineers seeking reliable solutions in both consumer and industrial domains.

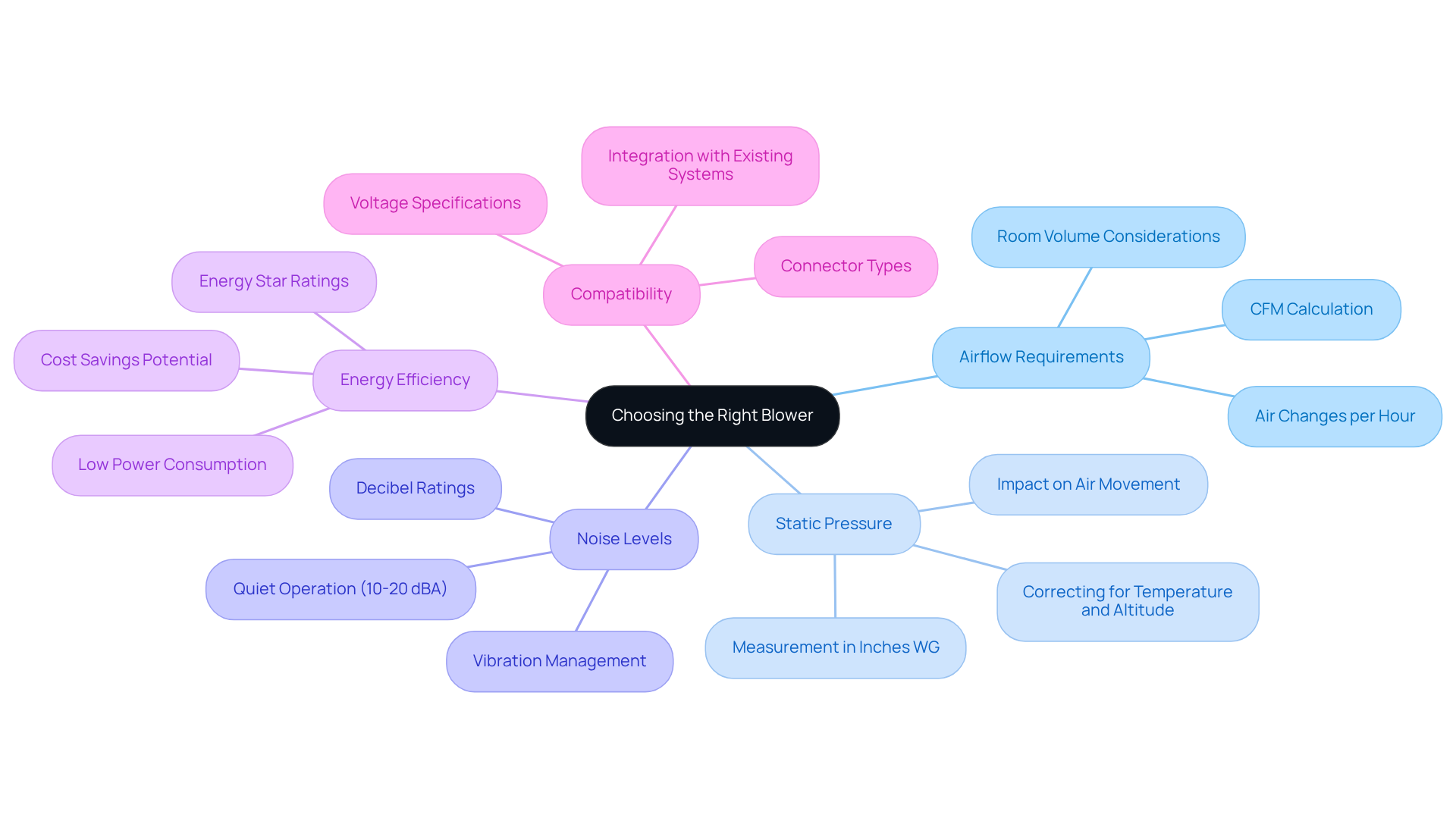

Choosing the Right Blower: Key Considerations for 12 Volt Applications

Selecting the right 12 volt blower for electronic applications is a pivotal decision that hinges on several critical factors. Engineers must meticulously evaluate airflow requirements, typically quantified in cubic feet per minute (CFM), to guarantee sufficient cooling for their specific projects. For instance, determining the necessary CFM can be accomplished using the formula:

- CFM = (Room Volume in cubic feet) x (Air Changes per Hour) / 60

- CFM = Air Velocity (ft/min) x Cross-Sectional Area (ft²)

This calculation is essential for averting overheating, particularly in high-heat environments like telecom data servers.

Another significant consideration is static pressure, which affects the device’s ability to move air through ducts and other components. A thorough understanding of static pressure requirements, measured in inches of water gauge (WG), is crucial for optimizing performance. Additionally, noise levels must not be disregarded; quiet blowers operating at noise levels as low as 10-20 dBA are optimal for sensitive environments, such as home theaters or medical facilities. The increasing demand for efficient cooling solutions in the electronics sector is projected to grow at a CAGR of 5.9%, underscoring the importance of energy-efficient alternatives.

Energy consumption is a further critical factor, with a rising demand for energy-efficient solutions. Investing in low power consumption devices can yield significant savings on operational costs, with potential reductions of up to 3% for every degree the thermostat is adjusted. Furthermore, ensuring compatibility with existing frameworks and ease of integration is vital for successful implementation, facilitating a seamless fit into the overall design.

In conclusion, engineers should prioritize the following factors when selecting a 12 volt blower for their applications:

- Airflow requirements

- Static pressure

- Noise levels

- Energy efficiency

- Compatibility

By thoughtfully considering these factors, they can significantly enhance the performance and reliability of their electronic systems.

Future Innovations: The Evolving Role of 12 Volt Blowers in Electronics Engineering

The future of 12 Volt fans in electronics engineering is set to witness groundbreaking innovations, driven by advancements in materials, motor designs, and energy efficiency. As the demand for compact and efficient cooling systems escalates, manufacturers are expected to introduce more intelligent fans that incorporate IoT functionalities. This integration will enable real-time monitoring and control, significantly enhancing both performance and operational efficiency. Moreover, the adoption of IoT technology is anticipated to optimize energy consumption, aligning with the increasing focus on sustainability within electronic systems.

For instance, the global market for high-speed fans is projected to reach USD 950.5 million by 2025, underscoring a robust demand for energy-efficient solutions. Additionally, innovations in materials and designs are resulting in lighter, more durable devices capable of withstanding the rigors of modern applications. These advancements position 12 volt blowers as essential elements in the continuous evolution of engineering solutions, ensuring they stay integral to the future of electronics.

Conclusion

The exploration of 12 volt blowers reveals their essential role in enhancing the performance and reliability of electronic systems. These devices not only provide effective cooling solutions but also contribute significantly to energy efficiency and overall operational effectiveness in various engineering applications. By leveraging advanced technologies, engineers can ensure that their electronic components operate within optimal temperature ranges, thereby extending their lifespan and improving functionality.

Key advantages of 12 volt blowers include:

- Their compact design

- Energy efficiency

- Versatility across multiple sectors such as telecommunications, automotive, and medical applications

The integration of these blowers facilitates better airflow management, which is crucial for maintaining system integrity and preventing overheating. Additionally, as the demand for energy-efficient solutions continues to grow, the adoption of 12 volt blowers is becoming increasingly vital for sustainable development in the electronics industry.

Looking ahead, the future of 12 volt blowers is promising, with innovations in technology set to enhance their capabilities further. As engineers continue to prioritize efficient thermal management and energy consumption, the role of 12 volt blowers will undoubtedly evolve, driving advancements in electronic design and applications. Embracing these technologies not only addresses current challenges but also positions engineers at the forefront of innovation in the ever-advancing field of electronics.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is known for delivering innovative solutions specifically tailored for 12 volt blower applications, providing access to state-of-the-art technologies in cooling, power management, and interconnect solutions.

What industries does Gagner-Toomey Associates serve?

Gagner-Toomey Associates serves various industries, including Telecom, Automotive, IoT, and Medical.

Why are 12-volt fans important for electronic components?

12-volt fans are important for cooling electronic components as they efficiently disperse heat generated during operation, preventing overheating, which is responsible for over 50% of electronic equipment malfunctions.

What are the advantages of using 12-volt blowers in confined spaces?

The advantages of using 12-volt blowers in confined spaces include their compact size and energy efficiency, making them ideal for applications such as computer enclosures and automotive systems.

How does temperature affect the lifespan of electronic devices?

A temperature increase of just 10°C can reduce a device’s lifespan by half, while a 10°C decrease can potentially double it, highlighting the importance of effective thermal management.

What role do 12 volt blowers play in ventilation systems?

12 volt blowers enhance airflow within ventilation systems, significantly affecting the effectiveness of electronic cooling and ensuring that electronic components operate at optimal temperatures.

How can 12 volt blowers improve HVAC system efficiency?

12 volt blowers can improve HVAC system efficiency by reducing energy consumption by as much as 50% and enhancing overall air circulation, which contributes to occupant comfort.

What are the energy savings associated with 12 volt blowers in HVAC applications?

The adoption of 12 volt blowers in HVAC applications has demonstrated daily relative energy savings for fan energy consumption ranging from 4% to 94%.