Overview

The article delineates the essential factors to consider when selecting the appropriate wind blower fan. It emphasizes key aspects such as:

- Airflow requirements

- Noise levels

- Energy efficiency

- Size

- Durability

- Compatibility

- Airflow direction

- Manufacturer reputation

- Customer support

Each factor is substantiated with practical advice and examples, underscoring their significance in achieving optimal performance and reliability in electronic applications.

Introduction

Selecting the appropriate wind blower fan is crucial for enhancing the performance and efficiency of electronic systems; however, many fail to recognize the pivotal factors that inform this decision. As the demand for effective cooling solutions in the electronics sector continues to rise, it becomes essential to comprehend how to choose a fan that satisfies specific requirements for airflow, noise, and energy efficiency. What challenges emerge in the quest to balance these varied needs, and how can engineers guarantee they are making well-informed choices? This article explores nine fundamental considerations that will equip readers to confidently navigate the intricacies of wind blower fan selection.

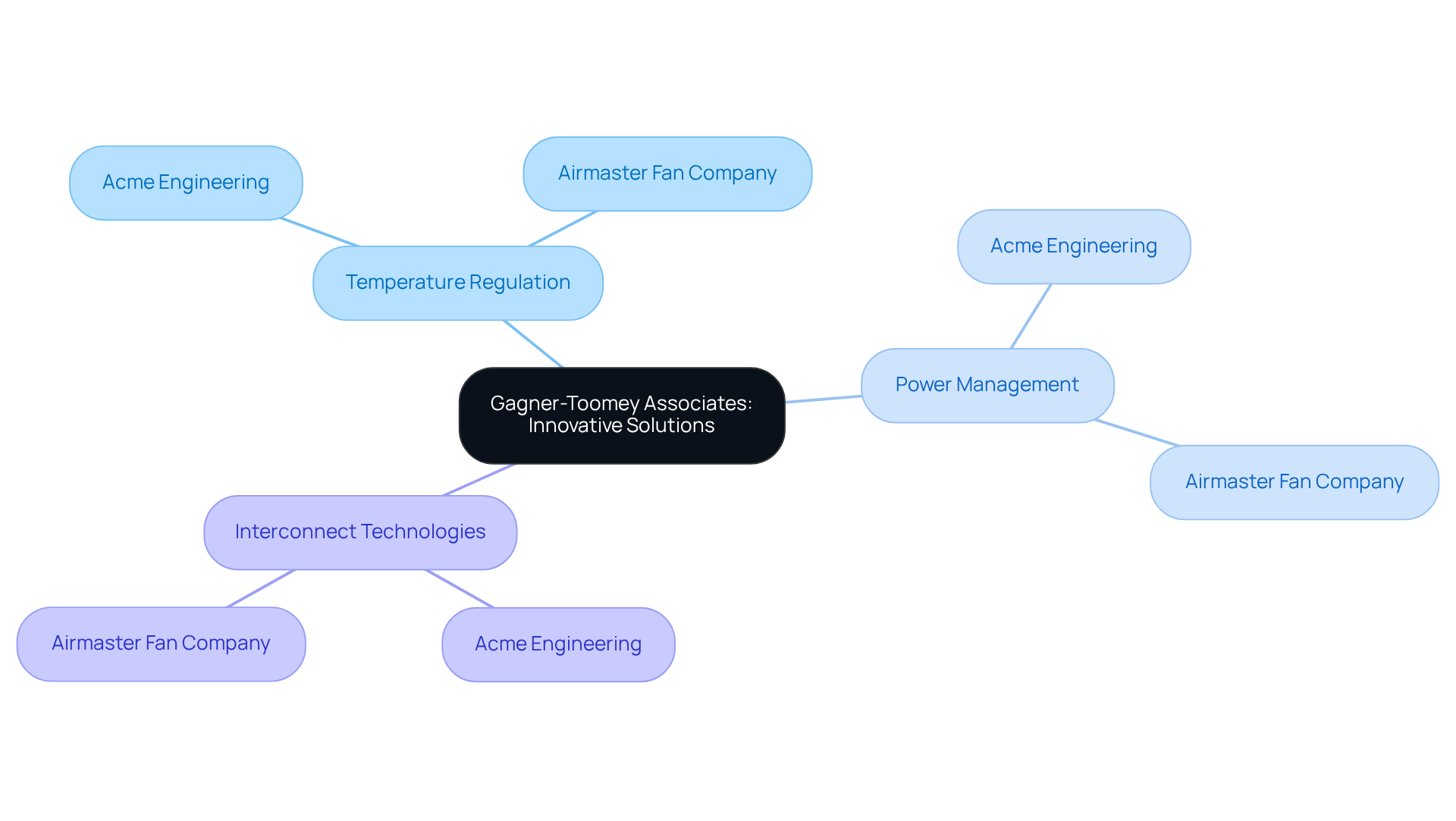

Gagner-Toomey Associates: Innovative Solutions for Wind Blower Fans in Electronics

Gagner-Toomey Associates excels in providing cutting-edge solutions specifically designed for wind blower fans in the electronics industry. By concentrating on essential sectors such as temperature regulation, power management, and interconnect technologies, the company showcases a diverse portfolio of prominent manufacturers, including Acme Engineering and Airmaster Fan Company. This strategic alignment not only addresses the growing demand for efficient cooling solutions—projected to grow at a CAGR of 5.9%—but also supports engineers in overcoming complex challenges.

With a steadfast commitment to excellence, Gagner-Toomey guarantees that clients obtain the necessary expertise and resources to create . As Tommy Lasorda aptly stated, ‘The difference between the impossible and the possible lies in a person’s determination.’ This philosophy resonates with Gagner-Toomey’s mission to empower engineers in their innovative endeavors.

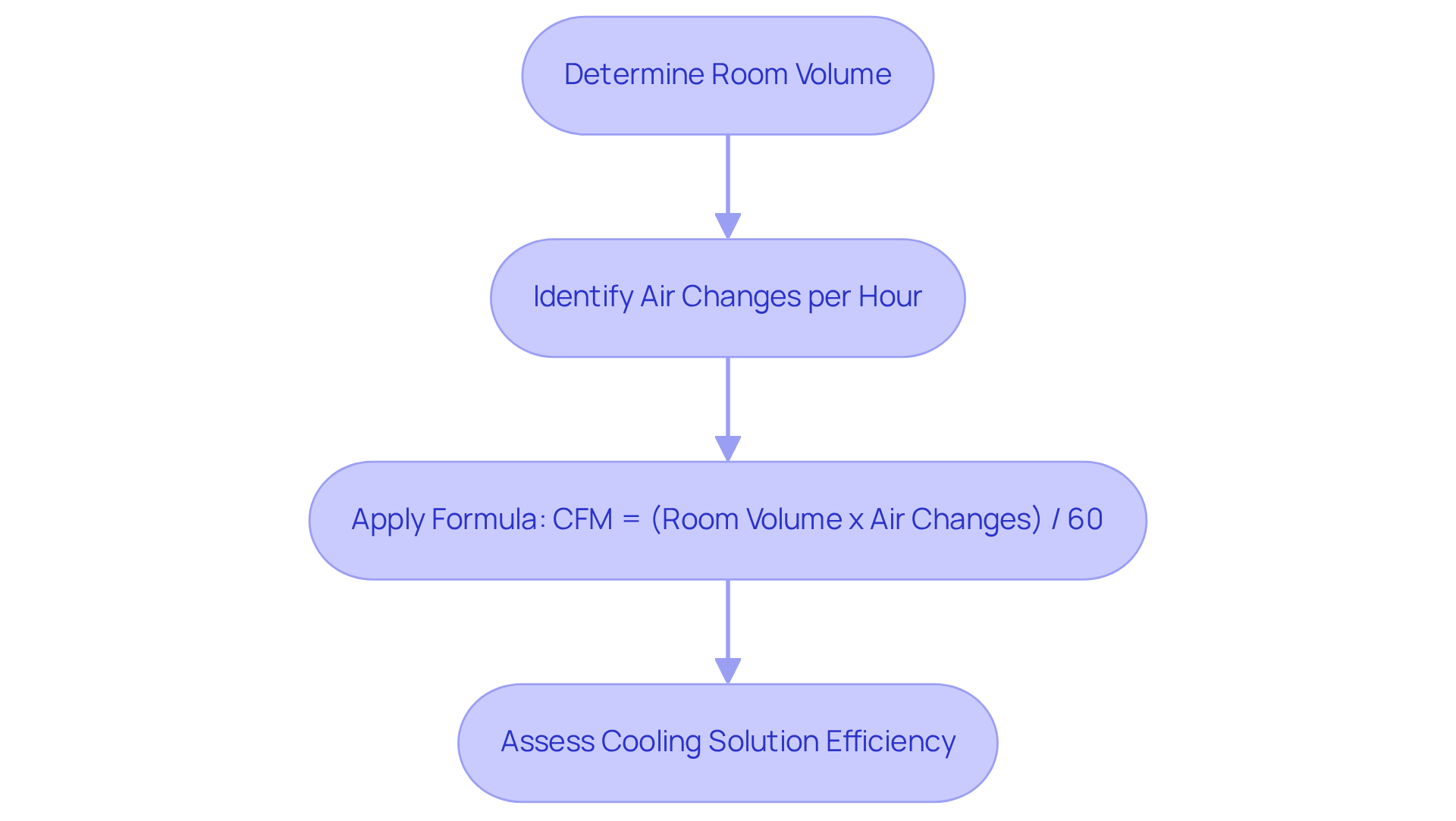

Assess Airflow Requirements: Determine the Necessary CFM for Your Project

To accurately assess the essential ventilation requirements for your electronics project, it is imperative to (Cubic Feet per Minute) based on both the room size and the heat generated by the components. The formula to employ is:

CFM = (Room Volume in cubic feet) x (Air Changes per Hour) / 60

This calculation is critical, as it ensures that the selected fan can effectively cool the equipment, thus preventing overheating and maintaining optimal performance. Recent studies underscore that understanding airflow needs is vital for electronic devices, particularly in environments where heat production is significant. For instance, in telecom data servers, high-performance temperature control solutions are essential to avert system failures due to overheating. By applying this formula and taking into account the specific requirements of your project, you can guarantee that your cooling solution is both efficient and reliable.

Evaluate Noise Levels: Choose a Fan That Meets Your Sound Tolerance

When selecting a fan, evaluating its is crucial, typically measured in decibels (dB). In environments where sound sensitivity is paramount—such as offices, residential areas, or medical facilities—opting for devices with lower dB ratings is essential. Quiet devices, designed to operate at noise levels as low as 10-20 dBA, cater specifically to these applications, ensuring minimal disruption.

Seek specifications that emphasize silent performance; manufacturers provide the noise levels of cooling devices in decibels, aiding consumers in making informed decisions. Moreover, consider models equipped with advanced technologies, such as brushless DC motors and optimized blade designs, to further mitigate sound output.

For instance, the be quiet! Pure Wings 2 120mm PWM Cooling Device has garnered acclaim for its near-silent performance, making it an exemplary choice for sensitive environments. It is important to note that silent fans typically exhibit lower airflow (CFM) than standard fans due to their reduced RPM operation.

Integrating anti-vibration mounts, usually made of rubber or silicone, can significantly diminish vibrations, further enhancing the silent function of refrigeration units. By prioritizing noise reduction in fan selection, you can sustain a comfortable atmosphere while ensuring effective cooling performance. In specific applications, such as home theaters, incorporating quiet ventilation systems can yield a noise reduction of up to 30%.

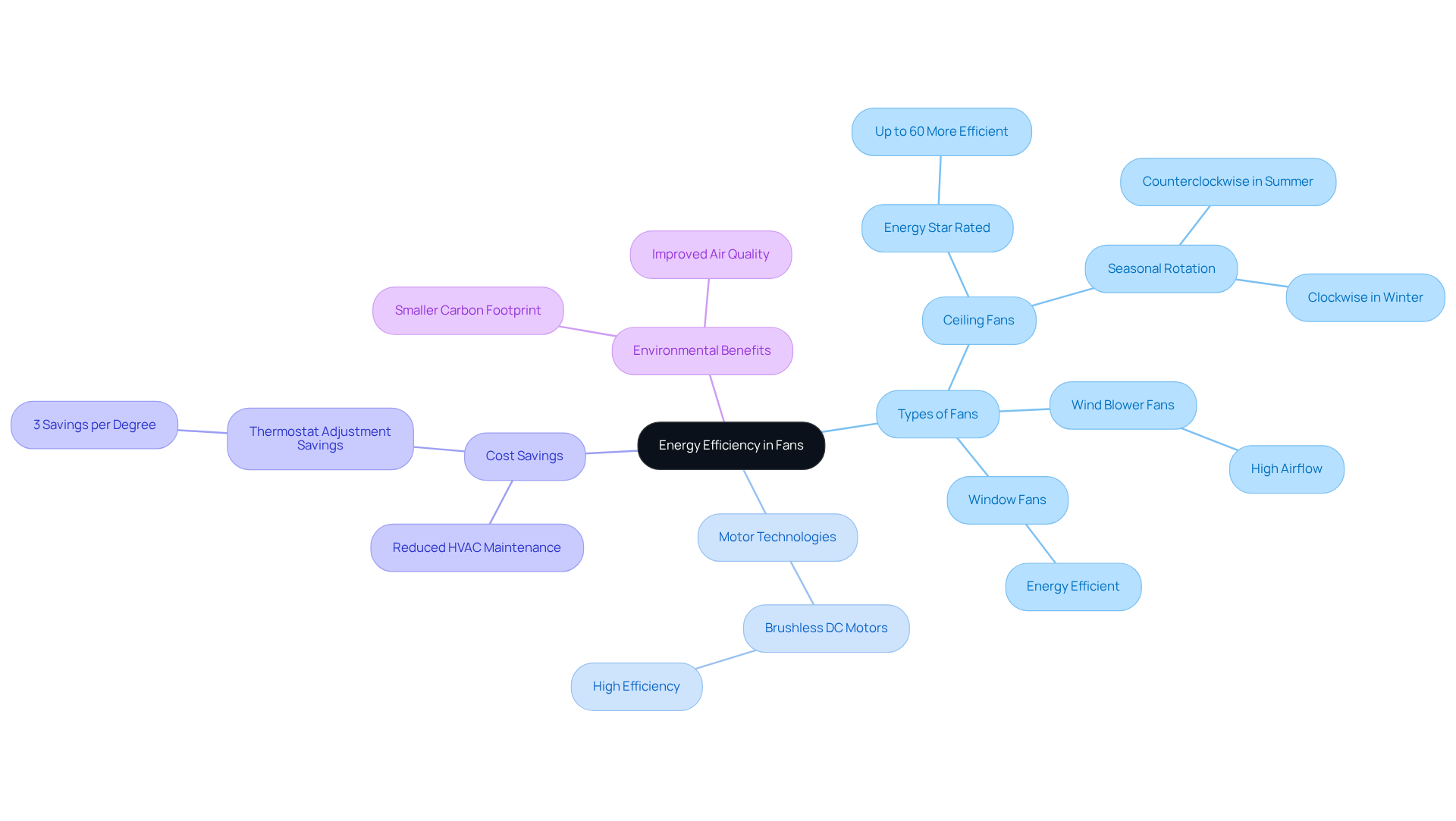

Prioritize Energy Efficiency: Select Fans with Low Power Consumption

Choosing devices designed for energy efficiency is essential for lowering power consumption and operational expenses. Ceiling fans, recognized as the most effective type of wind blower fan, should be prioritized. Wind blower fans with are particularly beneficial, as they can be up to 60% more efficient than conventional models. Additionally, advanced motor technologies, such as brushless DC motors, deliver high airflow while consuming less energy. This not only contributes to a smaller carbon footprint but also enhances the overall efficiency of electronic systems.

By investing in low power consumption devices, businesses can achieve significant savings on energy costs, with potential reductions of up to 3% for every degree the thermostat is adjusted. Remaining knowledgeable about the latest trends in energy efficiency, such as the increasing popularity of smart fans that adjust to room conditions, can further enhance temperature regulation solutions in various applications.

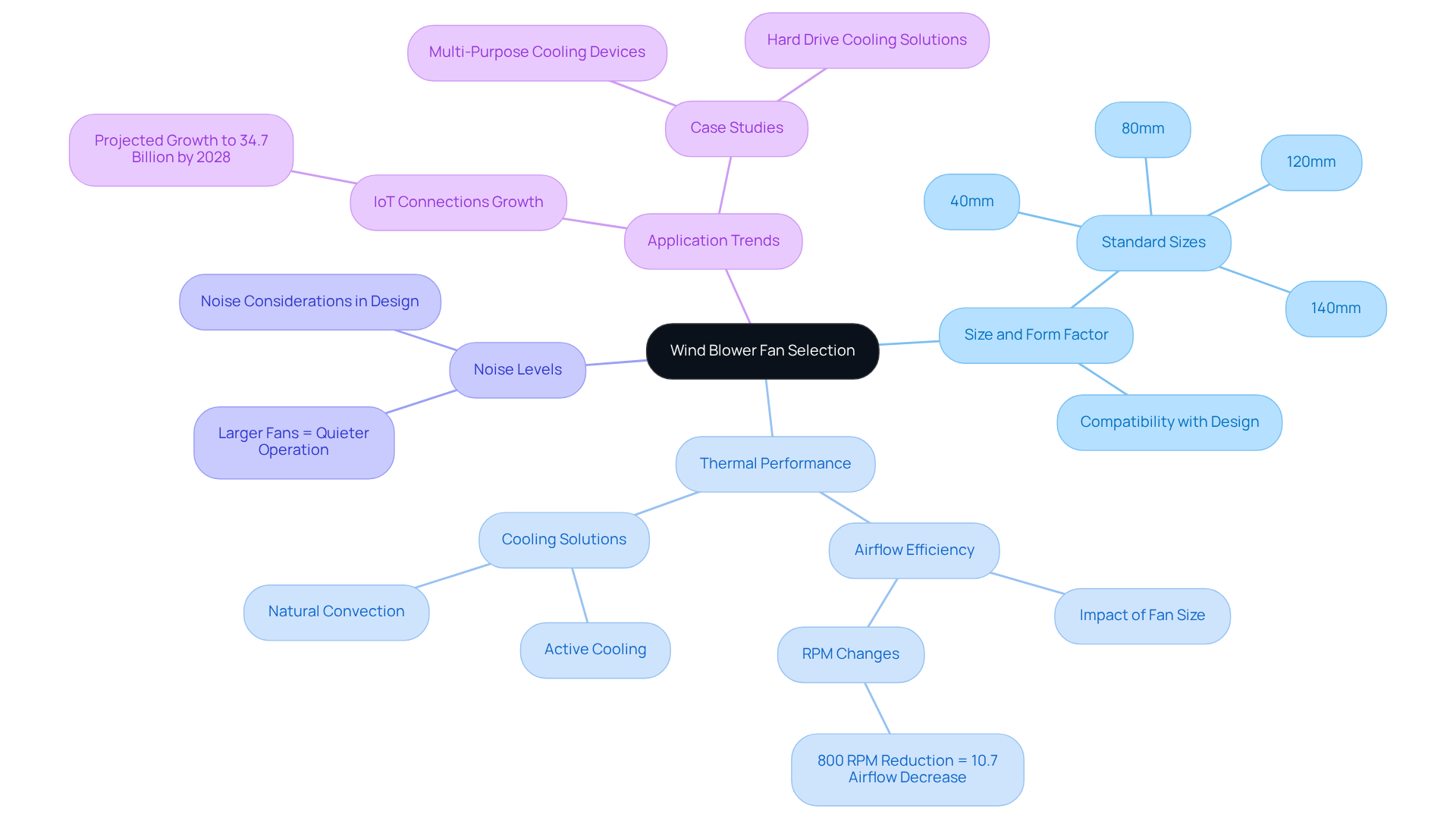

Consider Size and Form Factor: Ensure Compatibility with Your Design

Selecting the appropriate wind blower fan size and shape is critical for optimizing thermal performance in electronic designs. Start by measuring the available space and assessing mounting options to ensure compatibility with your design specifications. Fans are available in various sizes, including standard measurements like 40mm, 80mm, 120mm, and 140mm, offering flexibility for installation within enclosures while ensuring adequate ventilation. Proper sizing is vital to prevent flow restrictions, which can significantly impact cooling efficiency.

For instance, larger units typically operate more quietly while providing the same air movement as smaller types; reducing the speed by approximately 800 RPM can result in a 10.7% decrease in air circulation. This illustrates the relationship between blade size, speed, and , positioning larger units as ideal for noise-sensitive applications. Additionally, advanced blade configurations, such as airfoil designs, can generate higher static pressure while minimizing noise, further improving thermal efficiency.

As the demand for effective thermal management increases, particularly with the surge in IoT connections, it becomes increasingly crucial to grasp the latest trends in fan form factors. Successful implementations of wind blower fans in electronic designs, as exemplified by the ‘Multi-Purpose Cooling Devices’ case study, highlight the necessity of selecting the right size to meet specific thermal needs.

Furthermore, overheating can diminish the lifespan of electronic components by up to 50%, emphasizing the paramount importance of reliable cooling solutions. By utilizing Gagner-Toomey Associates’ resources, engineers can streamline the selection process, ensuring optimal performance and reliability in their projects while taking into account environmental factors such as temperature range and humidity levels.

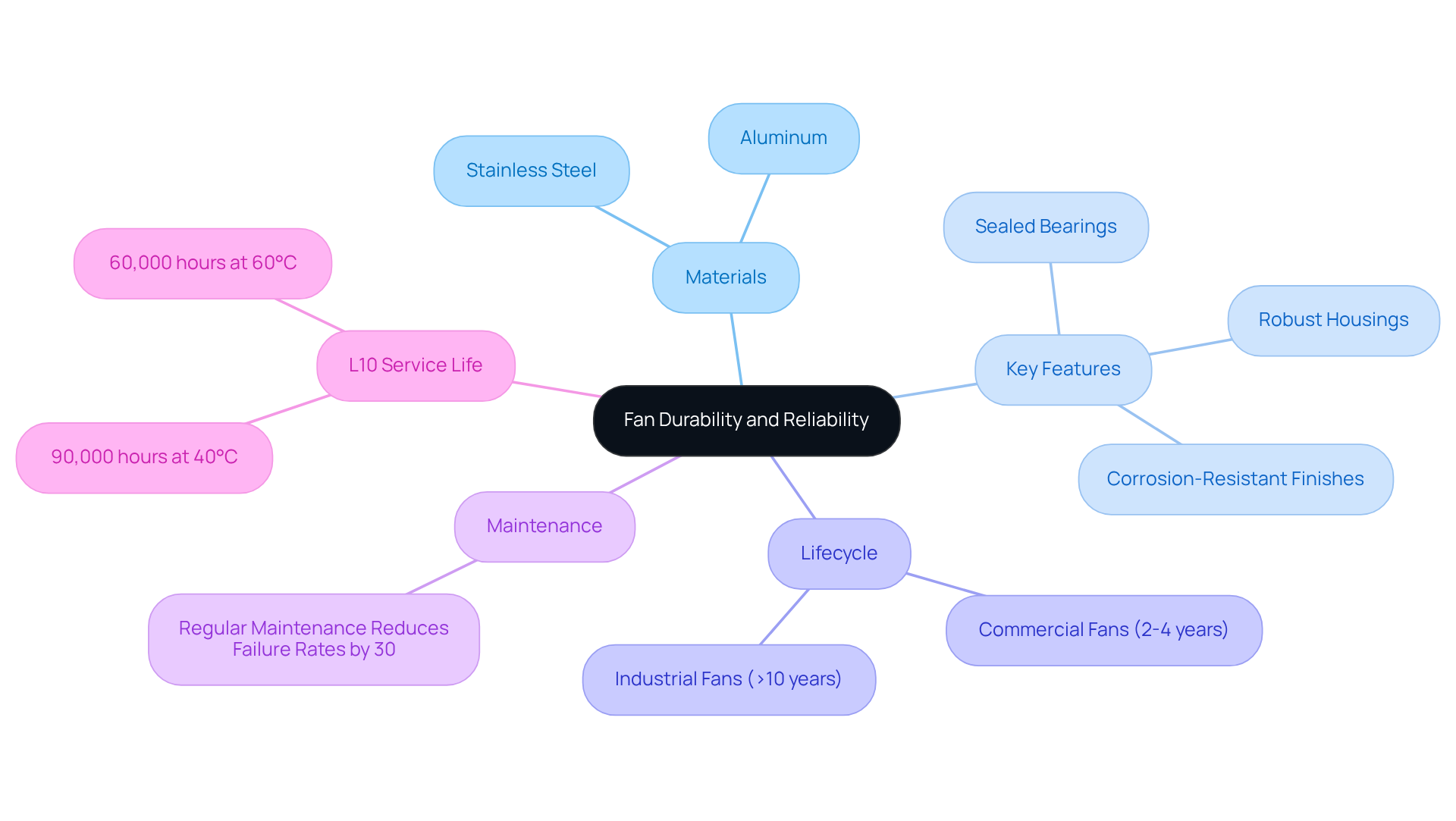

Ensure Durability: Choose Fans Built for Longevity and Reliability

Select devices constructed from capable of withstanding the rigors of continuous use. Key features to prioritize include:

- Sealed bearings

- Robust housings

- Corrosion-resistant finishes

Industrial-grade fans typically exhibit higher durability ratings, rendering them suitable for environments characterized by elevated dust or moisture levels, thereby ensuring long-term reliability. Common materials utilized in fan construction encompass stainless steel and aluminum, both recognized for their strength and corrosion resistance.

Moreover, the lifecycle of commercial units generally ranges from 2 to 4 years, whereas industrial models can exceed 10 years, highlighting the advantages of opting for industrial-grade solutions when durability is paramount. Data indicates that regular maintenance can diminish fan failure rates by as much as 30%, underscoring the importance of selecting reliable components.

Additionally, the L10 service life rating, reflecting the anticipated operational hours before 90% of fans fail and based on the lifespan of grease and bearings, serves as a critical metric when assessing fan longevity. By prioritizing these factors, engineers can secure long-term reliability and optimal performance in their temperature regulation systems.

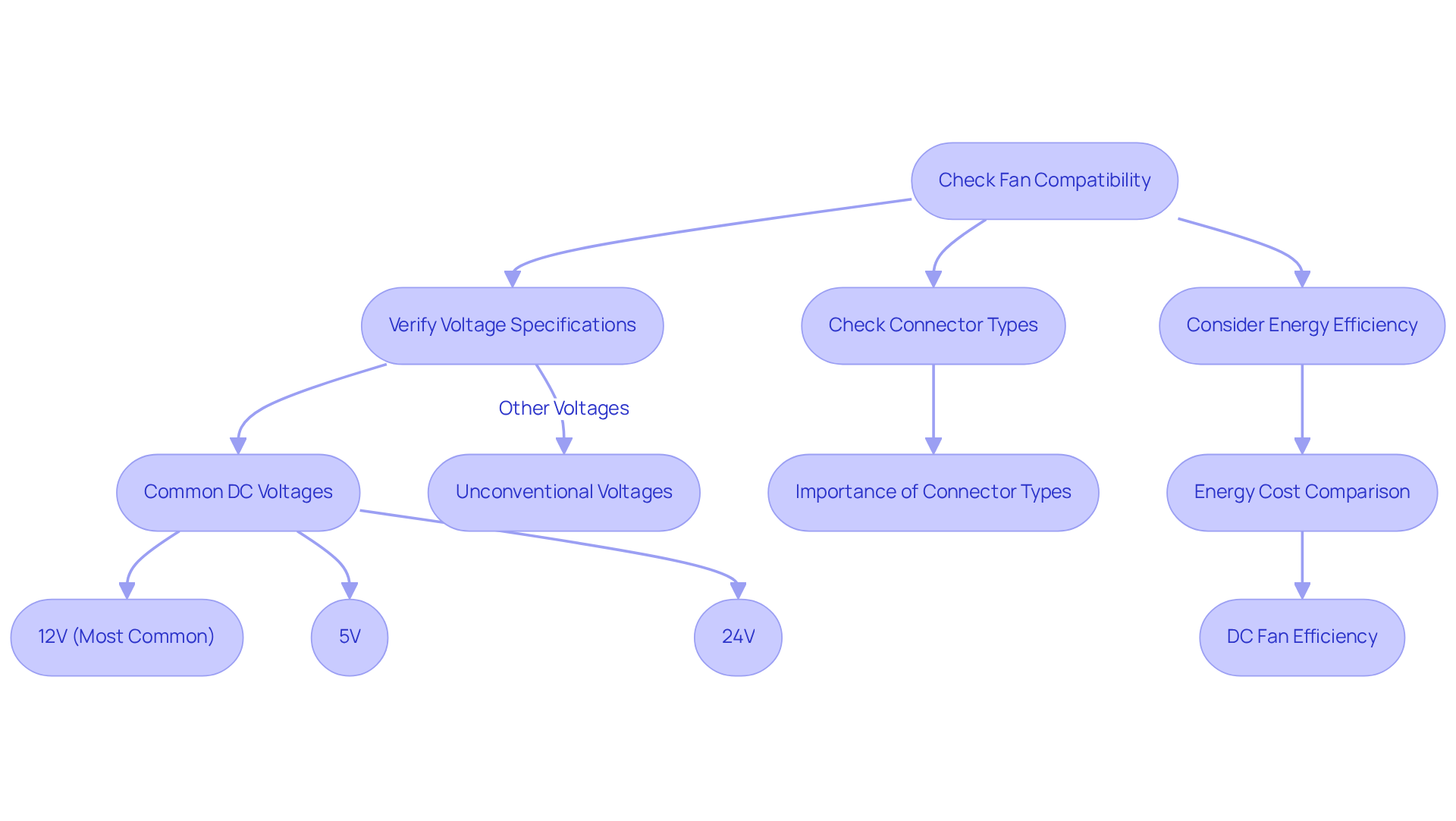

Check Compatibility: Ensure the Fan Works with Your Existing Electronics

Before completing your fan choice, it is crucial to confirm its compatibility with your current electronic setups. Begin by verifying the voltage specifications, as typical DC voltages for cooling devices include 5V, 12V, and 24V, with 12V being the most prevalent across different sectors. Additionally, consider unconventional DC voltages such as 3.3V, 48V, 6V, 9V, 16V, 28V, and 64V to provide a comprehensive overview of available options.

Furthermore, pay attention to the connector types; for instance, the JST PH Connector Series has a current rating of 2A, which is essential for ensuring a secure connection and optimal performance. As Gary Masessa notes, “this advantage will become more apparent when you consider your connector/contact selection and trace widths on your PCB that supplies power to the fan as they can both be reduced in size.” Understanding these can prevent costly modifications during installation.

Integrating a wind blower fan that is compatible with your system’s voltage and connector types can save both time and resources. Successful integrations frequently occur when supporters are chosen based on these criteria, enabling smooth operation without significant modifications.

Moreover, it’s crucial to mention that AC units can use up to $10 worth of electricity to achieve the same air movement result as a DC unit costing $3, emphasizing the energy efficiency advantages of selecting the appropriate device.

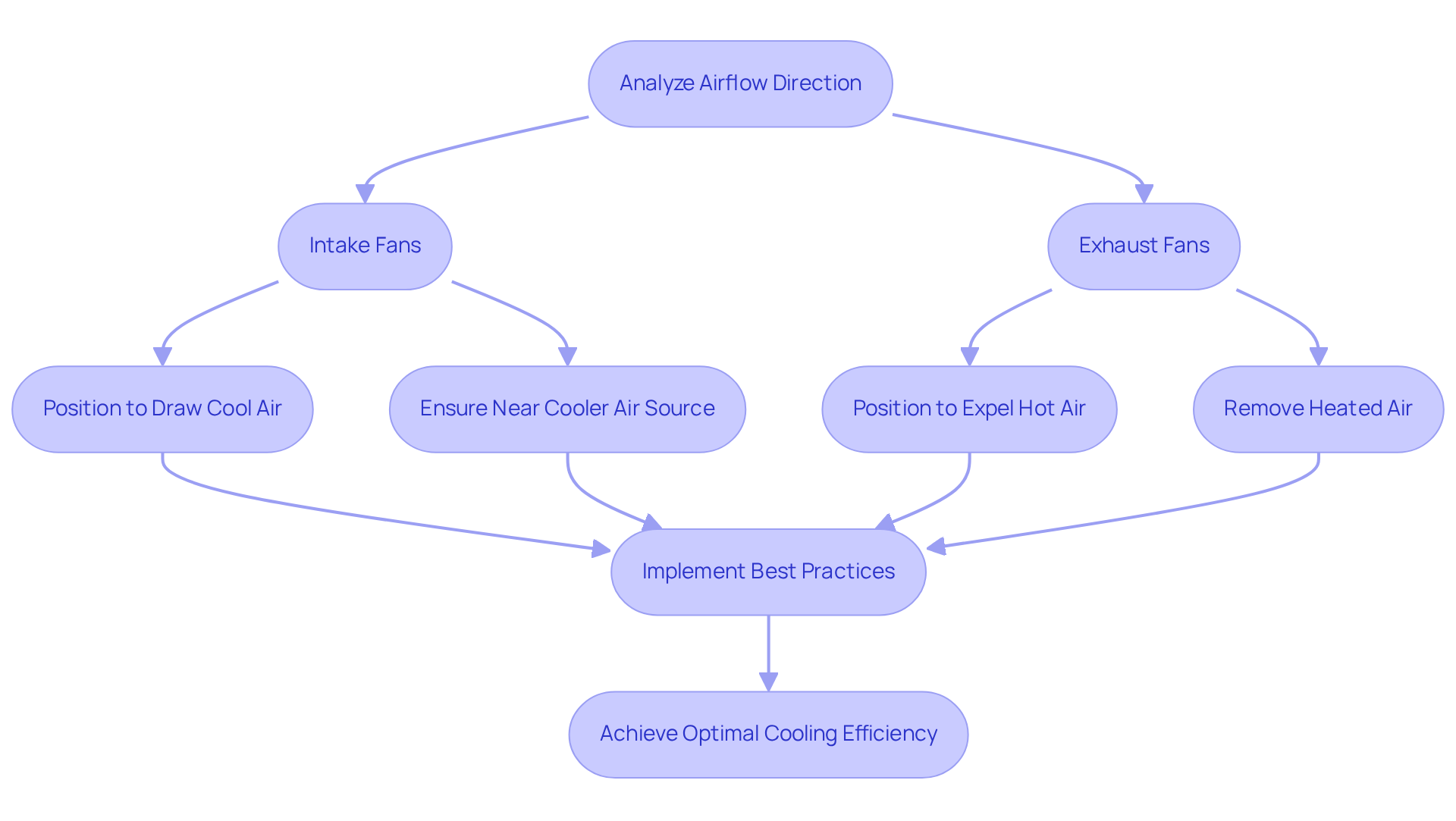

Analyze Airflow Direction: Optimize Cooling with Proper Fan Orientation

Maximizing cooling efficiency with a wind blower fan hinges on the proper direction of airflow. It is essential to evaluate whether your application requires intake or exhaust systems, such as a wind blower fan, and to place them appropriately.

- Intake fans, such as a wind blower fan, should be strategically positioned to draw cool air into the system.

- Exhaust fans are designed to expel hot air.

This intentional arrangement not only enhances circulation but also assists in maintaining for electronic components with the help of a wind blower fan. For instance, in data centers, effective orientation of the wind blower fan can significantly reduce energy consumption.

The QTS initiative, which implemented airflow management measures, achieved a PUE reduction that resulted in approximately $60,000 in savings over two months, underscoring the impact of proper fan placement.

Implementing best practices, such as ensuring that intake vents are situated near cooler air sources and utilizing a wind blower fan to facilitate the removal of heated air through properly arranged exhaust vents, can lead to substantial efficiency gains.

Moreover, case studies have demonstrated that the appropriate positioning of a wind blower fan can yield energy savings of up to 20%, highlighting the significance of careful design in temperature control.

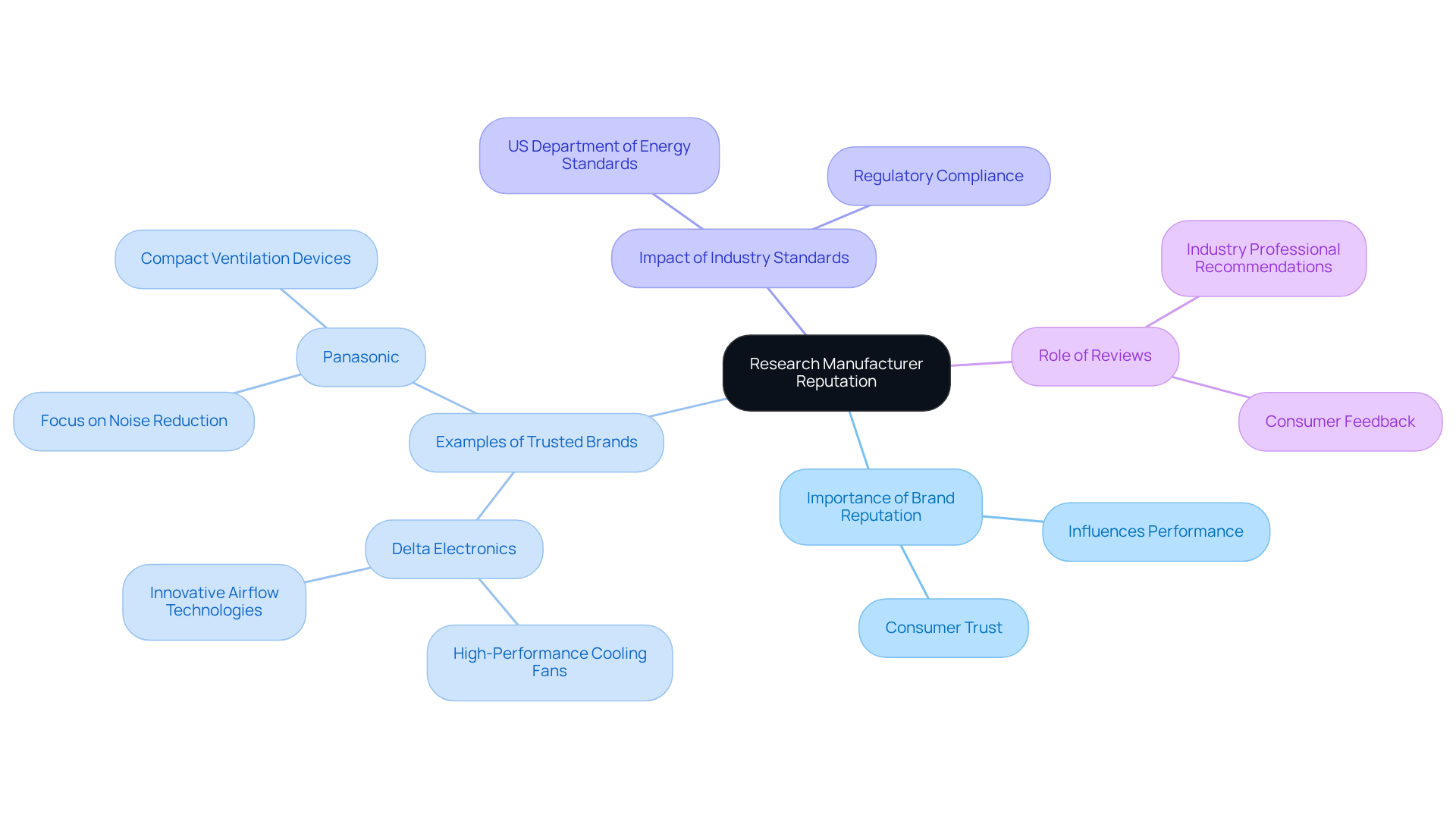

Research Manufacturer Reputation: Choose Trusted Brands for Quality Assurance

When selecting a fan, it is crucial to conduct thorough research into the within the industry. Opt for brands that are recognized for their quality and reliability, alongside those that provide robust warranties and customer support. For instance, companies like Delta Electronics, which introduced a new range of high-performance ventilation units for data centers in July 2024, and Panasonic, known for their compact ventilation devices for consumer electronics, have established themselves as leaders in the ventilation market. They are acknowledged for their innovative designs and unwavering dedication to performance.

Moreover, the US Department of Energy’s new efficiency standards for HVAC units, revealed in August 2024, underscore the increasing demand for advanced cooling fans, making brand reliability even more essential. Reading reviews and seeking recommendations from industry professionals can significantly aid in making informed decisions. This diligence ensures that you select a fan that not only meets but exceeds your performance expectations, ultimately enhancing the efficiency of your electronic applications. As emphasized by industry specialists, the quality of a fan can directly influence the overall dependability of electronic devices, making brand choice a critical element in your purchasing process.

Evaluate Customer Support: Select Brands That Offer Reliable Assistance

When selecting a wind blower fan, it is essential to prioritize brands that offer , encompassing technical assistance, warranty services, and easy access to replacement parts. A manufacturer with a robust support framework can effectively resolve issues, ensuring your fan operates optimally throughout its lifespan. This support is particularly crucial in complex electronic systems, where timely assistance can significantly mitigate costly downtime.

Richard James, Director of CX, emphasizes this point: “With a passion for research and continuous learning, technology should augment, not replace, what makes us human.” This sentiment highlights the necessity of human-centric support in technical fields.

Statistics reveal that:

- 89% of companies with above-average customer experiences outperform their competitors financially, underscoring the value of investing in reliable customer service.

- 73% of customers remain loyal to brands due to friendly service representatives, illustrating the importance of a supportive customer experience.

By choosing a brand that prioritizes customer support, you not only enhance the longevity of your equipment but also cultivate a more efficient operational environment. Additionally, staying informed about the latest trends in fan manufacturer customer service can provide insights into how brands are evolving to meet customer needs, ensuring you make an informed choice.

Conclusion

Selecting the appropriate wind blower fan is crucial for achieving optimal performance in electronic applications. By thoroughly evaluating factors such as:

- Airflow requirements

- Noise levels

- Energy efficiency

- Size

- Durability

- Compatibility

- Airflow direction

- Manufacturer reputation

- Customer support

engineers and consumers are empowered to make informed decisions that significantly enhance the longevity and reliability of their systems.

This article has shared key insights that underscore the importance of:

- Calculating the necessary CFM for effective cooling

- Choosing fans that meet sound tolerance levels

- Prioritizing energy efficiency

- Ensuring compatibility with existing electronic setups

Moreover, understanding airflow direction and opting for reputable manufacturers can profoundly influence overall performance and user satisfaction.

The importance of selecting the right wind blower fan transcends immediate cooling needs; it is integral to the efficiency and functionality of electronic devices. By applying these considerations, stakeholders can not only improve their current projects but also contribute to a more sustainable and effective approach to electronic cooling solutions. Engaging with trusted brands and leveraging expert resources like Gagner-Toomey Associates further empowers engineers to achieve innovative results in their designs.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in providing innovative solutions for wind blower fans in the electronics industry, focusing on temperature regulation, power management, and interconnect technologies.

What is the projected growth rate for cooling solutions in the electronics industry?

The demand for efficient cooling solutions in the electronics industry is projected to grow at a CAGR of 5.9%.

How can one assess airflow requirements for an electronics project?

To assess airflow requirements, calculate the necessary CFM (Cubic Feet per Minute) using the formula: CFM = (Room Volume in cubic feet) x (Air Changes per Hour) / 60.

Why is understanding airflow needs important for electronic devices?

Understanding airflow needs is vital to prevent overheating and maintain optimal performance, especially in environments with significant heat production, such as telecom data servers.

What should be considered when evaluating noise levels for fans?

When evaluating noise levels, consider the decibel (dB) rating of the fan, especially in sound-sensitive environments. Opt for fans with lower dB ratings to minimize disruption.

What are some features of quiet fans?

Quiet fans often operate at noise levels as low as 10-20 dBA and may include advanced technologies like brushless DC motors and optimized blade designs to reduce sound output.

Can you provide an example of a fan known for its silent performance?

The be quiet! Pure Wings 2 120mm PWM Cooling Device is an example of a fan that has received acclaim for its near-silent performance.

How can anti-vibration mounts contribute to the performance of cooling devices?

Anti-vibration mounts, typically made of rubber or silicone, can significantly reduce vibrations, enhancing the silent function of refrigeration units and improving overall performance.

What impact can quiet ventilation systems have in specific applications?

In applications like home theaters, incorporating quiet ventilation systems can yield a noise reduction of up to 30%, contributing to a more comfortable atmosphere while ensuring effective cooling.