Overview

The article highlights the essential features of 5V fans that are critical for electronics projects, encompassing key aspects such as:

- Airflow efficiency

- Noise levels

- Speed control

- Thermal management

Each feature is substantiated with evidence and relevant examples, illustrating how these fans significantly enhance performance, energy efficiency, and overall reliability in electronic applications. This underscores their vital role in contemporary technology designs, prompting readers to recognize their importance in optimizing electronic systems.

Introduction

In the rapidly evolving landscape of electronics, effective thermal management presents a critical challenge for engineers and designers. As power demands of modern devices escalate, the implementation of 5V fans emerges as a pivotal solution to ensure optimal performance and longevity of electronic components. This article explores ten essential features of 5V fans, detailing their benefits and the challenges associated with their integration.

How can engineers navigate these complexities to fully harness the potential of 5V fans in their projects?

Gagner-Toomey Associates: Innovative Cooling Solutions for 5V Fans

Gagner-Toomey Associates stands at the forefront of innovative specifically designed for the electronics sector, with a pronounced focus on . These compact and efficient devices are instrumental in optimizing the performance and through .

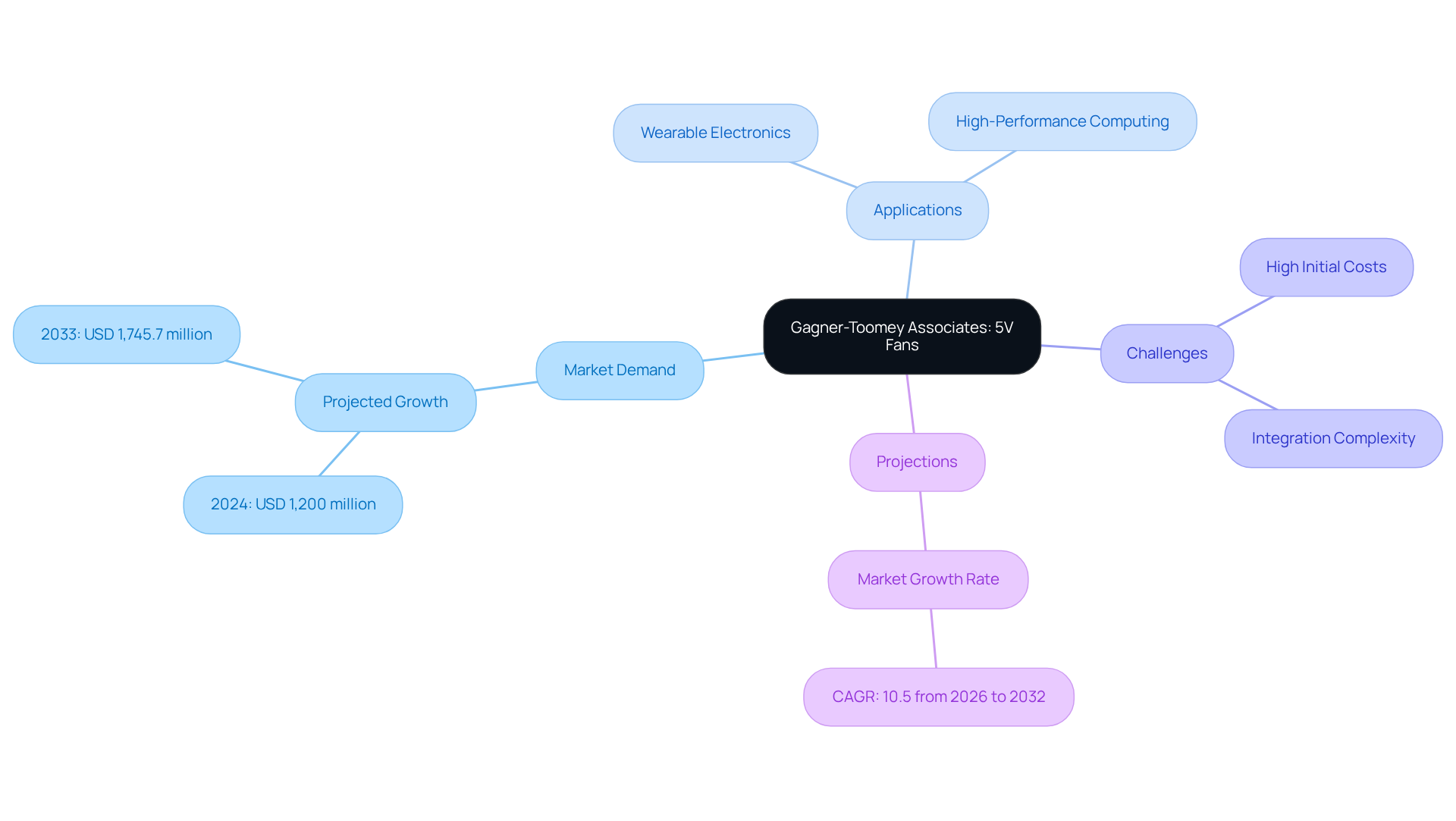

The demand for efficient temperature control solutions is on the rise, particularly in industries such as computing and telecommunications, where . Projections indicate that the global market for consumer electronics components is set to grow from approximately USD 1,200 million in 2024 to USD 1,745.7 million by 2033, highlighting an increasing reliance on , including the use of 5V fans.

Gagner-Toomey’s extensive portfolio of manufacturers enables engineers to seamlessly integrate these cutting-edge temperature control technologies into their projects, thereby ensuring optimal thermal management. Successful applications of 5V fans have showcased their effectiveness across various domains, including wearable electronics and high-performance computing, underscoring their critical role in contemporary electronics design.

Nevertheless, challenges such as high initial costs and the complexity of integrating these advanced temperature regulation solutions into existing systems may impede widespread adoption. Industry experts assert that as technological advancements continue, the implementation of sophisticated cooling solutions, such as 5V fans, will be essential to tackle the thermal management challenges posed by increasingly powerful electronic devices.

Airflow Efficiency: Maximizing Performance in 5V Fans

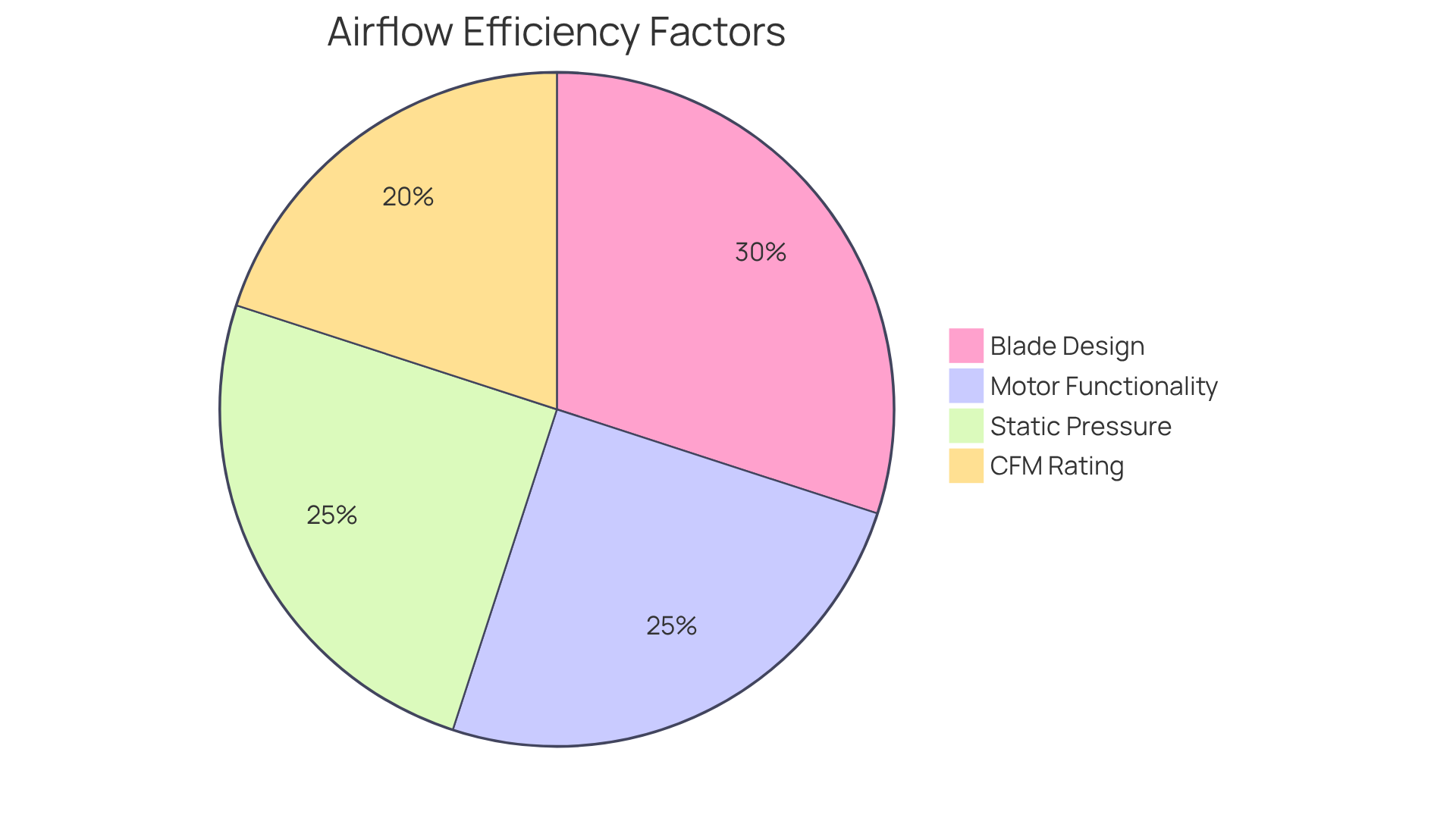

Enhancing in depends on refining the blade design and improving motor functionality. Fans equipped with meticulously engineered blades can significantly improve airflow while simultaneously . When selecting a fan, it is essential to prioritize those with a relative to their power draw, as this metric indicates . Furthermore, the fan’s is crucial; for instance, the boasts a rating of 0.359 inchH2O, reflecting its ability to push air through restrictive environments, such as heatsinks or enclosures.

For context, exhaust fans typically range from 50 to 500 CFM depending on the application, underscoring the importance of selecting the right fan for specific needs. Customer feedback highlights that the Delta fan has effectively reduced the temperature of devices, such as a set-top box, by 9 degrees, showcasing its practical cooling performance. Understanding these factors empowers engineers to make informed decisions, ensuring in their electronic projects, especially when using a 5V fan.

Noise Levels: Ensuring Quiet Operation in 5V Fans

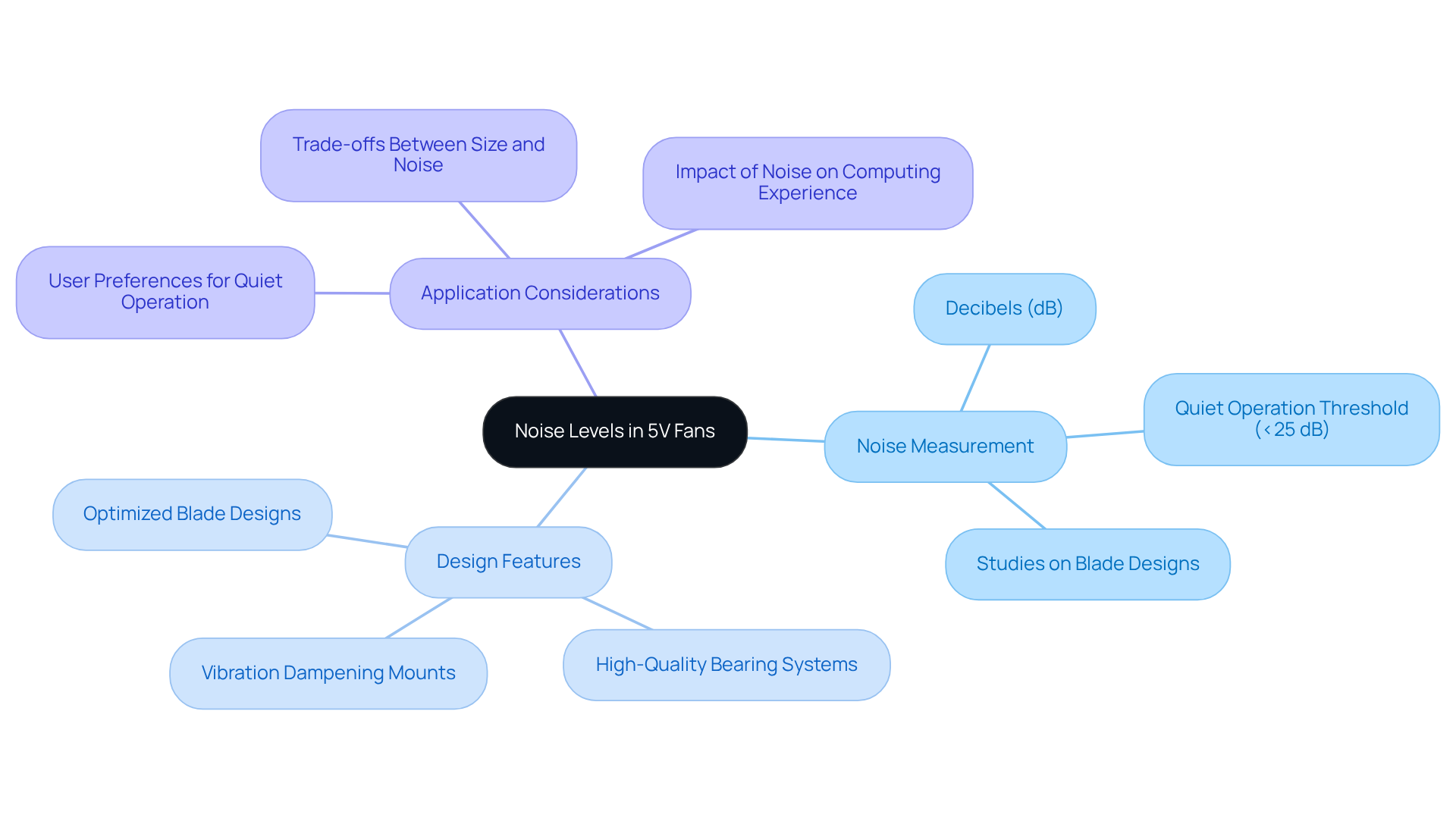

When selecting a 5v fan, it is crucial to consider its , typically measured in decibels (dB). Fans designed with —such as optimized blade designs and high-quality bearing systems—can achieve significantly .

For applications where is paramount, seek fans with a , as this threshold is commonly linked to minimal disruption in sensitive environments. Additionally, incorporating can further diminish perceived , thereby enhancing the overall acoustic quality of your projects.

Recent studies reveal that can lower noise levels by up to 4.6 dBA at the blade passing frequency, underscoring the effectiveness of innovative fan designs in facilitating quieter operation. By prioritizing these features, engineers can ensure their not only meet operational standards but also foster a more .

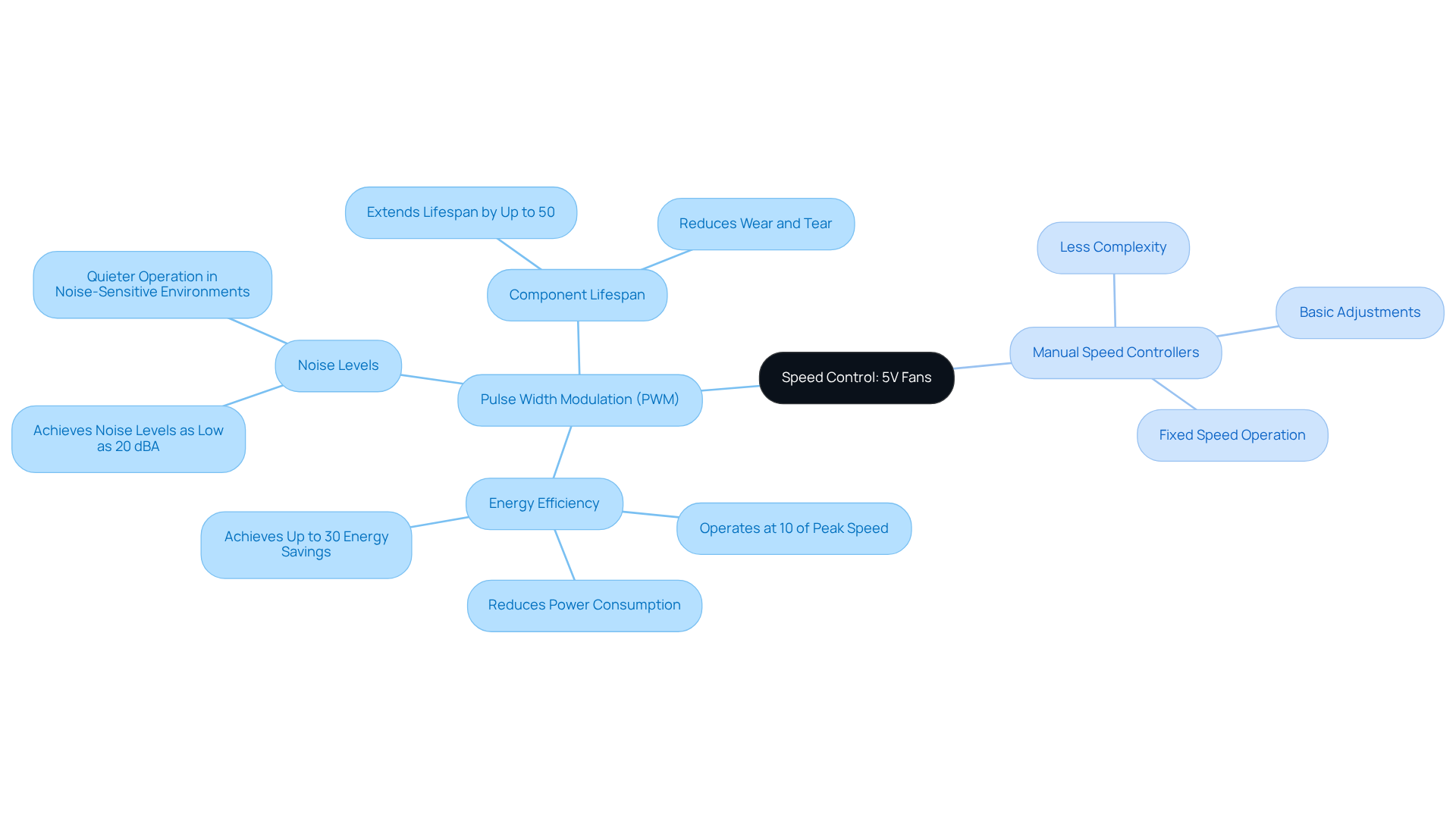

Speed Control: Customizing Performance of 5V Fans

5v fans equipped with empower users to customize their performance based on thermal demands. Among the various methods for regulating fan speed, Pulse Width Modulation (PWM) emerges as a premier choice, facilitating precise adjustments that significantly enhance .

can function at speeds as low as 10% of peak speed, which not only improves operational efficiency but also by up to 50%. This adaptability proves particularly beneficial in , where is essential; PWM units can achieve noise levels as low as 20 dBA, compared to over 30 dBA for traditional models.

For scenarios that require less dynamic control, manual speed controllers offer a straightforward alternative, allowing for basic adjustments without the intricacies of PWM. Ultimately, selecting devices that support not only optimizes performance but also aligns with sustainability goals by .

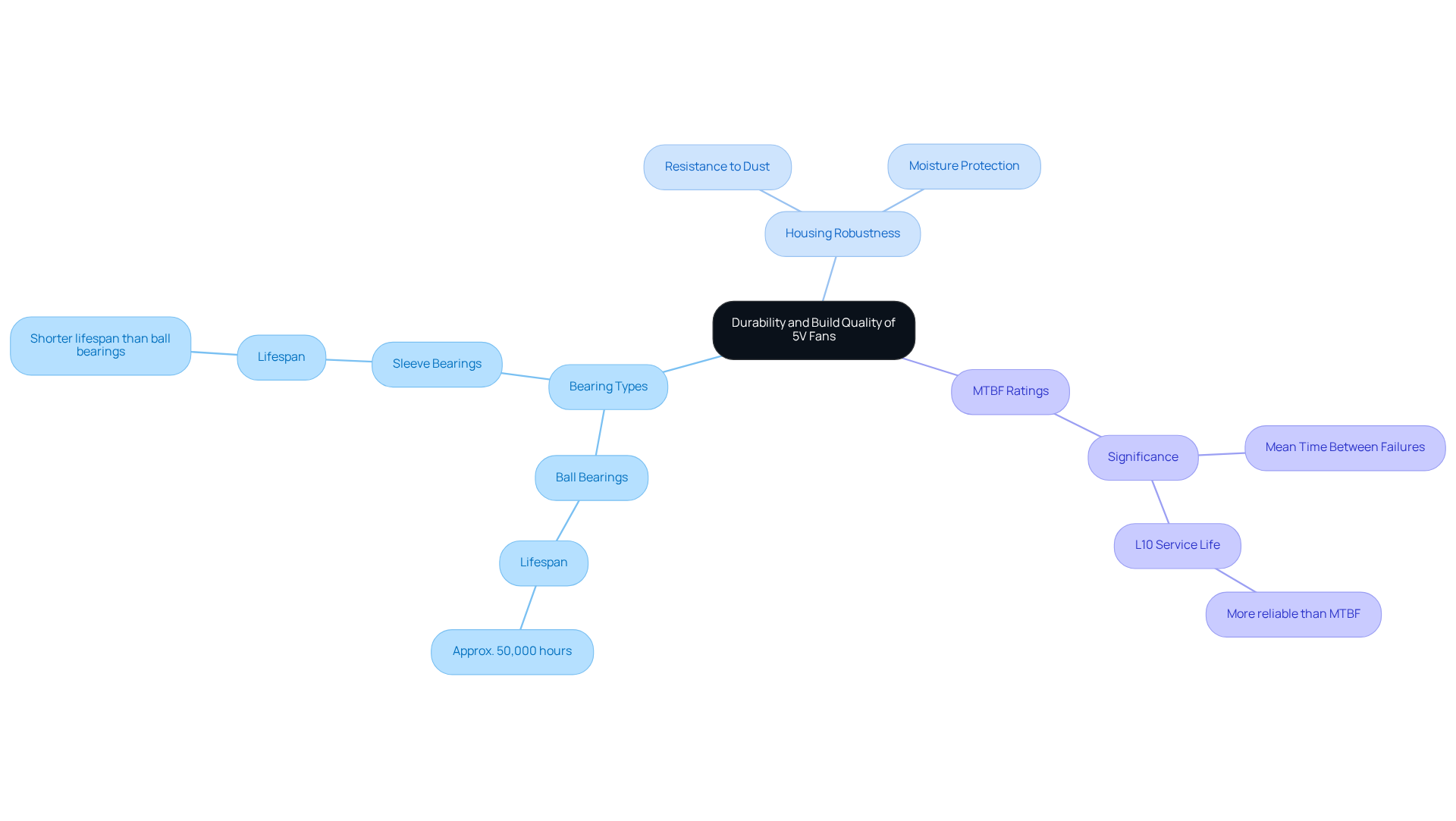

Durability and Build Quality: Ensuring Longevity of 5V Fans

When evaluating devices powered by a , it is crucial to consider their build quality and materials. Devices with fans made from , such as ball bearings, typically exhibit . Additionally, prioritize devices featuring like dust and moisture. Manufacturers often provide (MTBF) ratings, which serve as a valuable metric for of the 5V fan. By focusing on these , you can make informed decisions that enhance the reliability and performance of your devices.

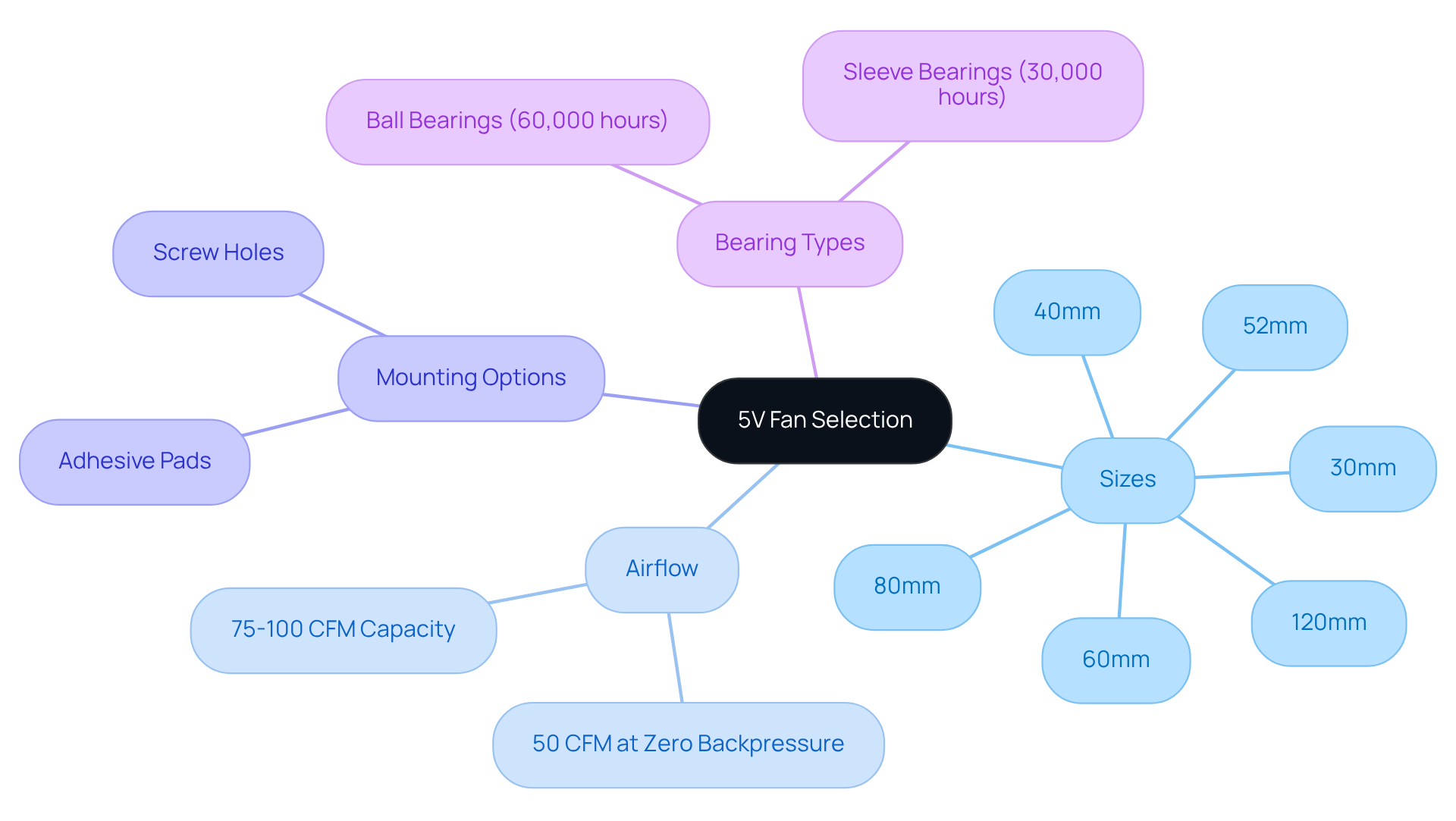

Size and Form Factor: Fitting 5V Fans into Your Projects

are available in various sizes, typically ranging from 30mm to 120mm in diameter, with common dimensions including 40mm, 52mm, 60mm, 80mm, and 120mm. Selecting the is essential to ensure compatibility with the available space in your project.

For example, compact models measuring 30mm are ideal for confined areas, whereas larger fans significantly improve . To achieve optimal performance, it is important to consider ; a of 50 CFM at zero backpressure should ideally be chosen with a capacity of 75-100 CFM to accommodate any operating backpressure.

Additionally, consider the available such as screw holes or adhesive pads, which facilitate straightforward installation. These devices are designed for easy setup and include mounting holes for added convenience. Choosing the correct size of a 5v fan not only guarantees but also of your electronics project.

Furthermore, it is vital to evaluate ; ball bearings typically offer over 60,000 hours of lifecycle, while sleeve bearings provide only 30,000 hours, which is a critical consideration for durability in your selection.

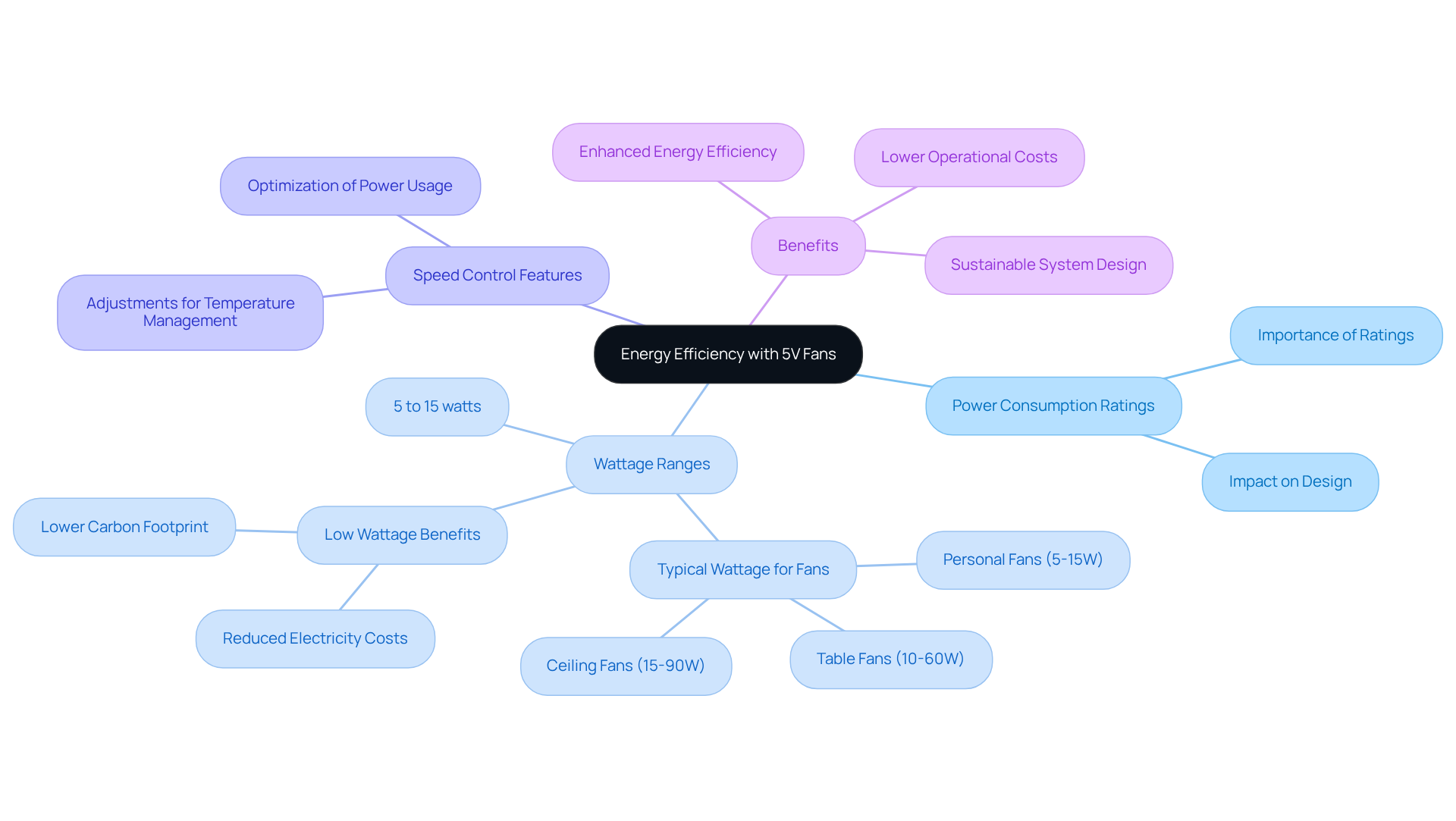

Power Consumption: Enhancing Energy Efficiency with 5V Fans

When selecting devices that include a , it is crucial to consider their , typically expressed in watts. Effective ventilators significantly reduce the overall power consumption of electronic systems. Choose fans with that still provide ; for example, personal fans generally consume between 5 to 15 watts, making them suitable for .

Moreover, incorporating speed control features allows for further optimization of , enabling adjustments based on specific temperature management needs. This approach not only enhances but also contributes to a more sustainable system, as reduced energy consumption leads to lower operational costs and a diminished carbon footprint.

By implementing these strategies, the efficiency of their while simultaneously lowering energy expenses.

Compatibility: Integrating 5V Fans into Diverse Systems

Meticulously with a variety of electronic systems, including , Arduino, and other microcontroller platforms, are . It is imperative to ensure that the fan’s align with your system’s specifications to prevent damage and guarantee .

For instance, the , renowned for its efficiency, features a Heptaperf™ impeller optimized for a balance between power and quiet operation. Common connector types include standard 2-pin and 3-pin configurations, facilitating straightforward integration. However, for proprietary connectors, adapters may be necessary to establish a proper connection. Utilizing the can simplify this connection process, allowing for greater flexibility in .

Additionally, the 5V fan, which is a Square USB model priced at $4.95, is available in multiple sizes, making it a versatile option for various projects. Understanding these elements is crucial for engineers aiming to into diverse technological systems.

As noted by ElectroPeak, “We stand behind the quality of our products and offer a 30-day money back guarantee,” reinforcing the reliability of these components.

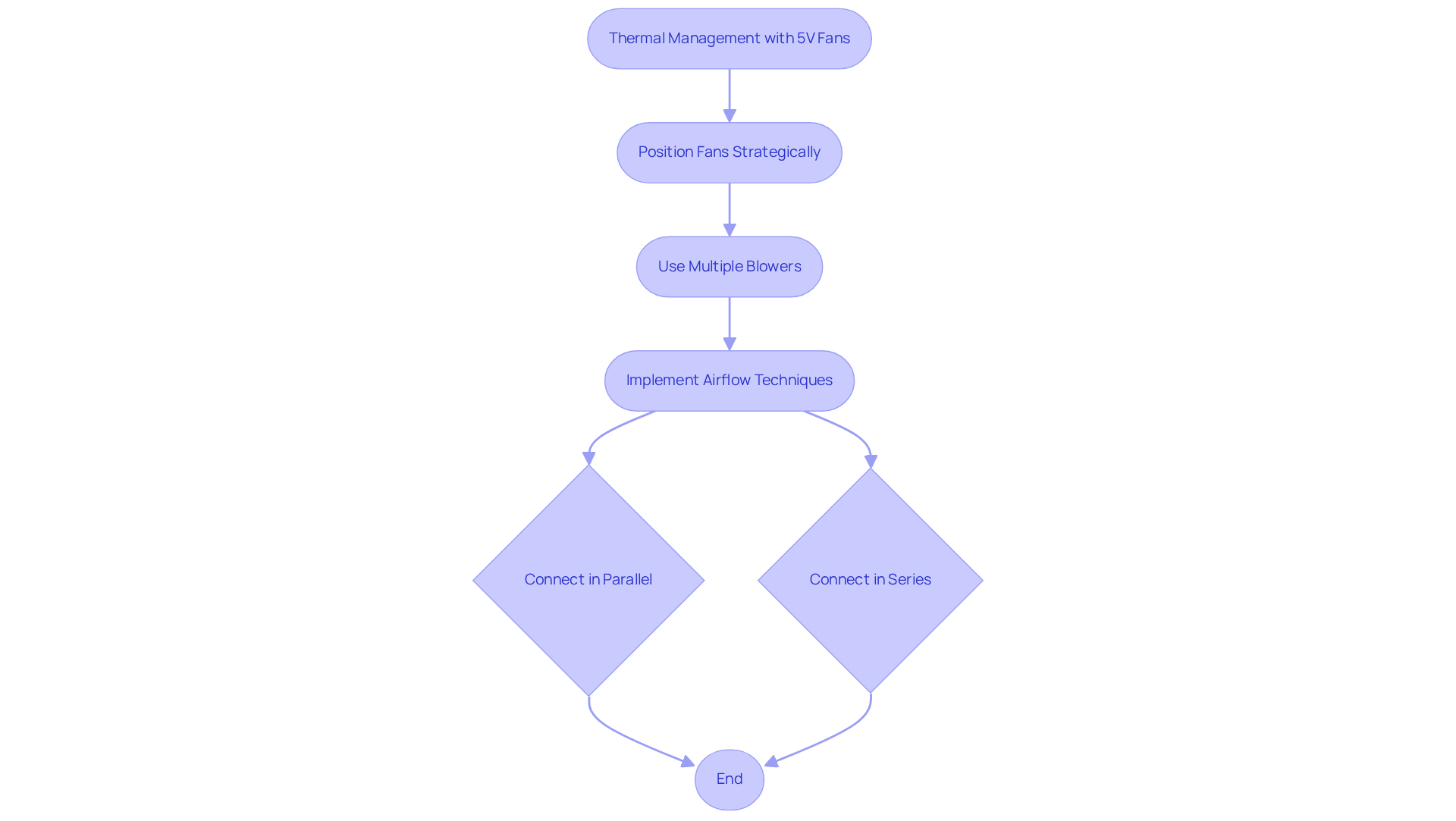

Thermal Management: Maintaining Optimal Conditions with 5V Fans

are essential for , ensuring that electronic components operate within optimal temperature ranges. To enhance their efficiency in , it is imperative to position ventilators strategically to direct airflow over heat-producing elements, such as CPUs and power supplies.

Utilizing can establish a , which helps prevent hotspots and promotes consistent temperature regulation throughout the assembly. Research indicates that maintaining with a 5V fan can significantly reduce the risk of electronic equipment malfunction, as over 55% of failures are attributed to .

Implementing efficient airflow techniques, such as positioning blowers at key intersections and employing a combination of parallel and series setups, can greatly improve temperature regulation. For instance, :

- Connect blowers in parallel to increase the volume flow rate.

- Connect blowers in series to enhance static pressure, thereby optimizing the .

By adopting these strategies, engineers can ensure the of electronic devices.

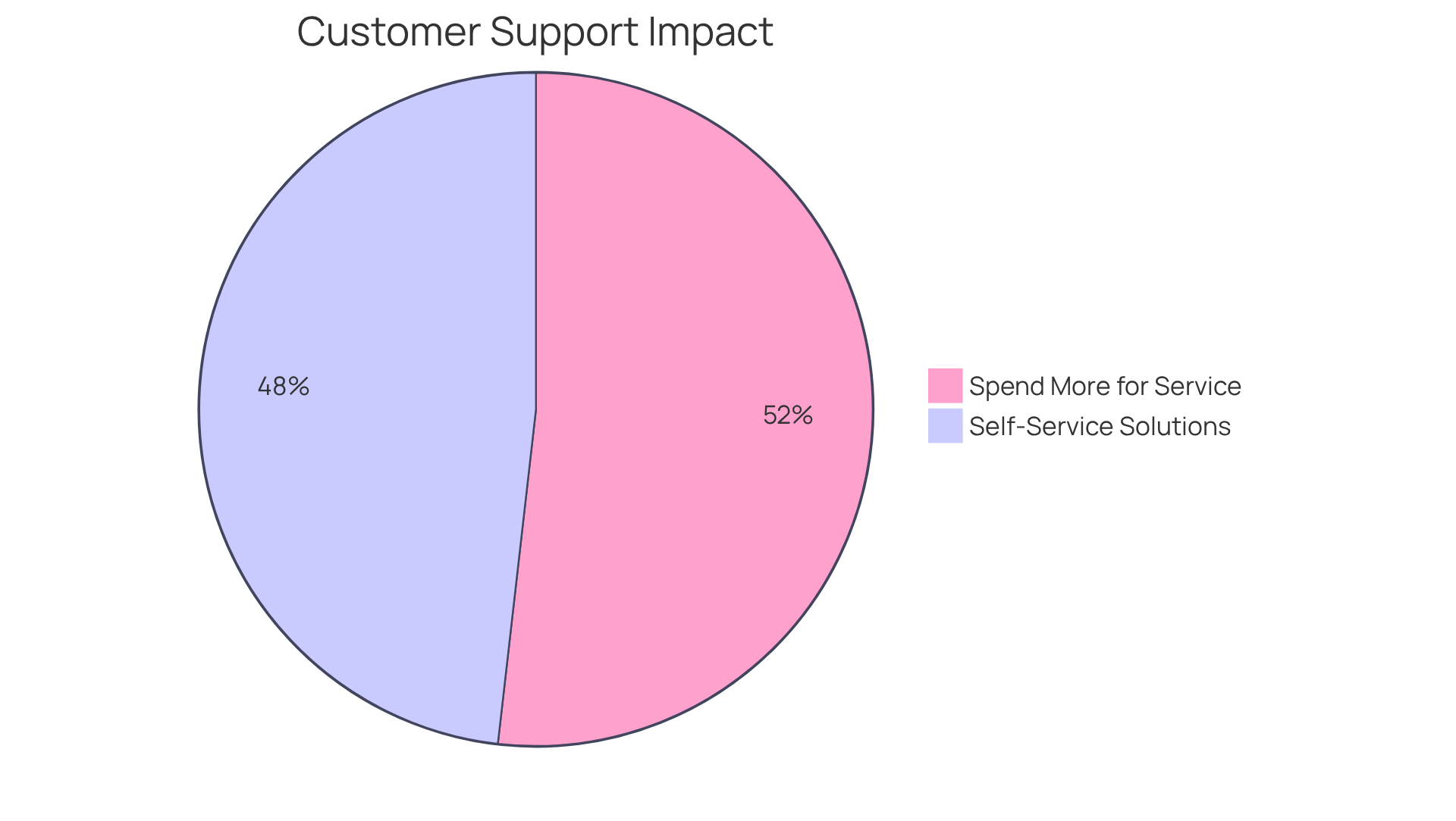

Customer Support: Enhancing User Experience with 5V Fans

When selecting 5V devices, the quality of provided by the manufacturer is paramount. Reliable support plays a vital role in helping users troubleshoot issues, acquire replacement parts, and access essential . Manufacturers that deliver —including detailed , FAQs, and responsive —significantly enhance user satisfaction. Notably, studies indicate that 86% of customers are more inclined to increase their spending with brands that offer . Furthermore, 80% of high-performing service organizations provide self-service solutions, underscoring the effectiveness of support resources in elevating . This level of support not only facilitates the successful integration of fans into projects but also cultivates a positive user experience, encouraging repeat business and fostering brand loyalty. Ultimately, serves as a key differentiator in the electronics industry, empowering users to maximize the performance and reliability of their .

Conclusion

The significance of 5V fans in electronics projects is paramount, as they play a pivotal role in ensuring optimal thermal management and enhancing the performance of electronic components. These compact devices are essential for effective heat dissipation and contribute to the longevity and reliability of systems across various applications, from computing to telecommunications.

Key features such as:

- Airflow efficiency

- Noise levels

- Speed control

- Durability

- Compatibility

are critical considerations when integrating 5V fans into projects. Advancements in blade design, motor functionality, and noise reduction technologies have improved performance while maintaining a quiet operation. Additionally, the emphasis on energy efficiency and the importance of customer support highlight the holistic approach needed when selecting the right cooling solutions.

As electronic devices continue to evolve and generate more heat, the adoption of innovative cooling technologies, like 5V fans, becomes increasingly vital. Engineers and hobbyists alike are encouraged to leverage these insights to optimize their projects, ensuring effective thermal management alongside a sustainable and user-friendly experience. By prioritizing the right specifications and support, the full potential of 5V fans can be realized, paving the way for enhanced performance in the ever-growing landscape of electronics.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is known for innovative temperature control solutions specifically designed for the electronics sector, with a focus on 5V fans that optimize performance and extend the longevity of electronic components through effective heat dissipation management.

Why is there an increasing demand for temperature control solutions?

There is a rising demand for efficient temperature control solutions in industries such as computing and telecommunications, where high-performance devices generate significant heat. The global market for consumer electronics thermal management components is projected to grow from approximately USD 1,200 million in 2024 to USD 1,745.7 million by 2033.

What applications have successfully utilized 5V fans?

Successful applications of 5V fans include wearable electronics and high-performance computing, demonstrating their critical role in contemporary electronics design.

What challenges are associated with the adoption of advanced cooling solutions?

Challenges include high initial costs and the complexity of integrating advanced temperature regulation solutions into existing systems, which may hinder widespread adoption.

How can airflow efficiency be maximized in 5V fans?

Airflow efficiency can be maximized by refining blade design and improving motor functionality. Selecting fans with a high cubic feet per minute (CFM) rating relative to their power draw and considering the fan’s static pressure rating are essential for effective airflow capabilities.

What is a notable example of a 5V fan and its performance?

The Delta Electronics AFB0412HH fan is a notable example, boasting a static pressure rating of 0.359 inchH2O, which reflects its ability to push air through restrictive environments. Customer feedback indicates it has effectively reduced the temperature of devices, such as a set-top box, by 9 degrees.

How important are noise levels when selecting a 5V fan?

Noise levels are crucial when selecting a 5V fan, typically measured in decibels (dB). For quiet operation, fans with a noise rating below 25 dB are recommended, as this level is linked to minimal disruption in sensitive environments.

What technologies can help reduce noise levels in 5V fans?

Advanced noise reduction technologies, such as optimized blade designs and high-quality bearing systems, can significantly lower noise outputs. Additionally, using vibration dampening mounts can further decrease perceived noise levels.

What impact can blade design have on fan noise levels?

Optimized unevenly spaced blades can lower noise levels by up to 4.6 dBA at the blade passing frequency, showcasing the effectiveness of innovative fan designs in achieving quieter operation.