Overview

The article delineates ten compelling benefits of EC axial fans for electronics engineers, underscoring their energy efficiency, reliability, versatility, and seamless integration into electronic systems. These advantages are substantiated by substantial evidence of significant power savings, prolonged lifespans, and adaptability across diverse applications. This demonstrates how EC axial fans not only enhance performance but also align with sustainability objectives within the electronics industry.

Introduction

EC axial fans are rapidly emerging as a cornerstone in the realm of electronics cooling, propelled by their remarkable efficiency and innovative design. Engineers are increasingly recognizing the myriad benefits these fans offer, ranging from substantial energy savings to enhanced reliability and versatility across various applications. However, as the demand for sustainable and effective cooling solutions escalates, a critical challenge arises: how can engineers seamlessly integrate these advanced technologies into existing systems while maximizing their performance and minimizing costs?

This article explores ten key advantages of EC axial fans, illuminating their transformative potential in modern electronics engineering.

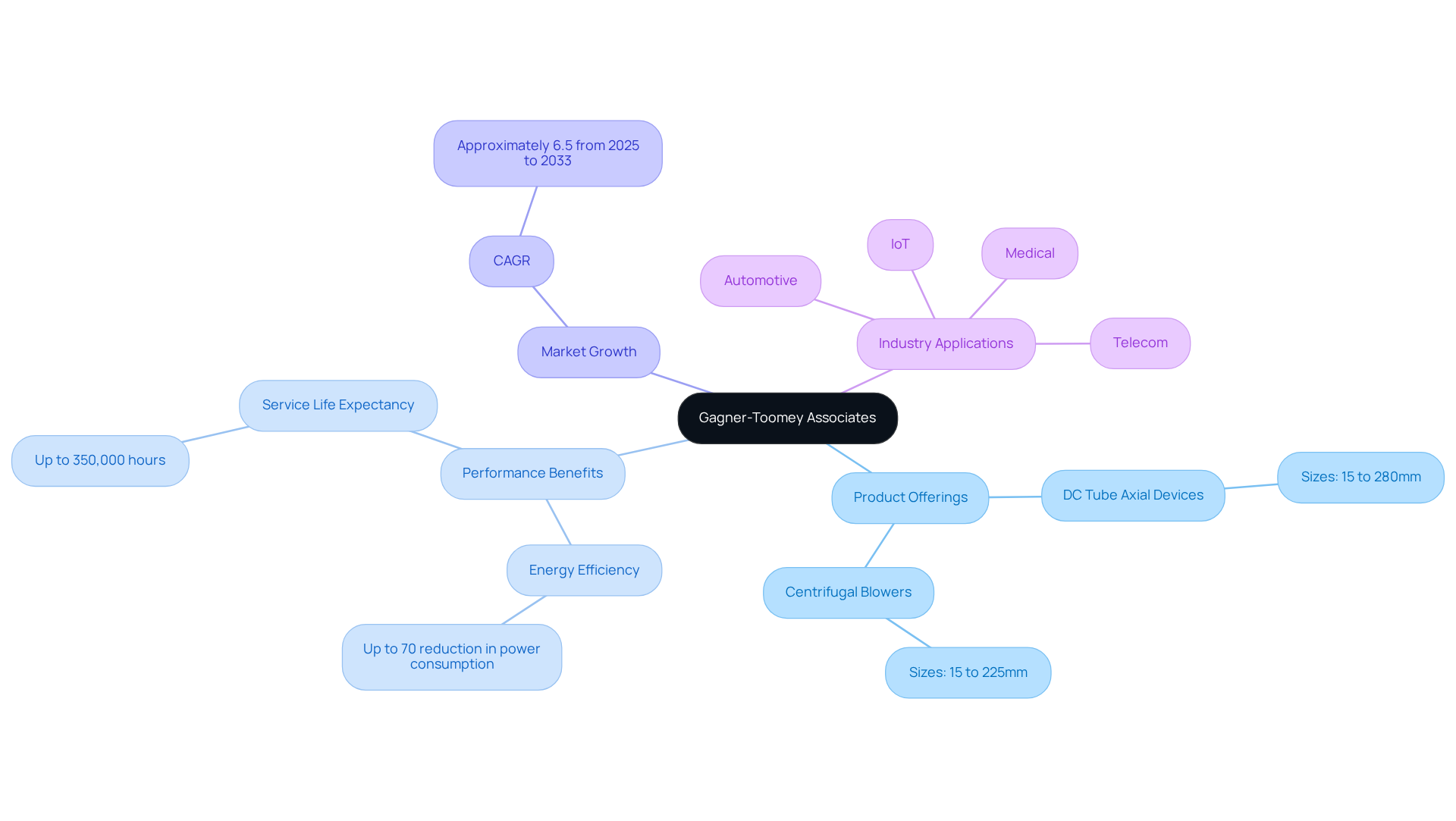

Gagner-Toomey Associates: Leading Provider of EC Axial Fans for Electronics Cooling

Gagner-Toomey Associates stands out as a premier supplier of EC axial fans and comprehensive temperature regulation solutions specifically designed for the electronics industry. As the largest manufacturer globally of both standard and custom air-movers, Gagner-Toomey guarantees that engineers have access to high-performance products optimized for energy efficiency and reliability. Their extensive product portfolio includes:

- DC input Tube Axial devices ranging from 15 to 280mm

- DC input Centrifugal Blowers from 15 to 225mm

This effectively addresses diverse ventilation requirements. This commitment to innovation is essential, particularly as the demand for efficient cooling solutions continues to escalate in modern electronics applications. Notably, EC axial fans are recognized for their ability to drastically reduce power consumption—by as much as 70% compared to traditional systems—while ensuring optimal airflow. Furthermore, advancements in fan technology, including integrated smart functionalities, enhance operational efficiency and enable real-time monitoring.

The EC fan market is projected to grow at a CAGR of approximately 6.5% from 2025 to 2033, indicating robust future prospects. Additionally, advanced radial blower models can achieve a service life expectancy of up to 350,000 hours, highlighting the durability of Gagner-Toomey’s offerings. With a profound understanding of various markets such as Telecom, Automotive, IoT, and Medical, Gagner-Toomey’s commitment to and consultative solutions positions them as a reliable partner for engineers aiming to incorporate the latest technologies into their designs.

An engineer remarked, ‘The evolution of refrigeration technologies is critical for addressing the demands of modern electronics, where efficiency and compactness are of utmost importance.

Energy Efficiency: How EC Axial Fans Reduce Power Consumption

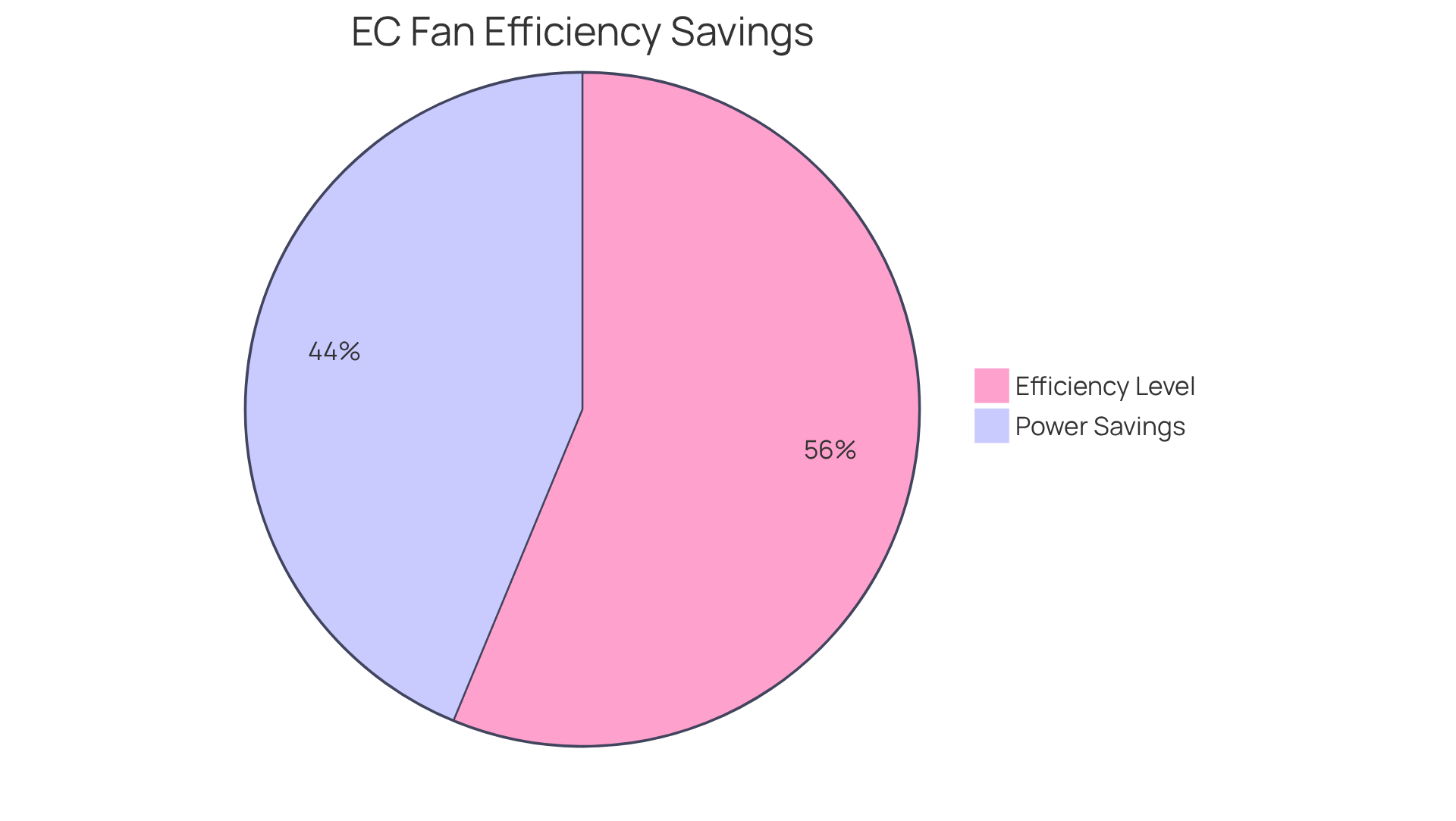

EC axial fans are known for their exceptional power efficiency, achieving effectiveness levels of up to 90% compared to traditional AC units. This remarkable efficiency translates into substantial , particularly in critical cooling applications.

By leveraging EC axial fans and electronically commutated motors, these devices minimize power losses and enhance airflow, leading to lower operational expenses and a reduced carbon footprint. Power-saving blowers can decrease power usage by as much as 70% relative to conventional AC motors, underscoring their capacity to significantly cut electricity costs while boosting system efficiency.

Companies that have integrated EC rotary ventilators into their HVAC systems report savings of up to 70%. Experts in the field assert that replacing traditional AC units with EC axial fans not only conserves energy but also reduces maintenance time and long-term costs, positioning EC axial fans as a strategic choice for engineers focused on enhancing energy efficiency.

Furthermore, EC ducted units maintain relatively constant efficiency across various speeds, in contrast to AC motors that peak at a single speed. The adaptability of EC centrifugal units further enhances their appeal, allowing for seamless integration into existing setups without necessitating major modifications.

Reliability: The Consistent Performance of EC Axial Fans

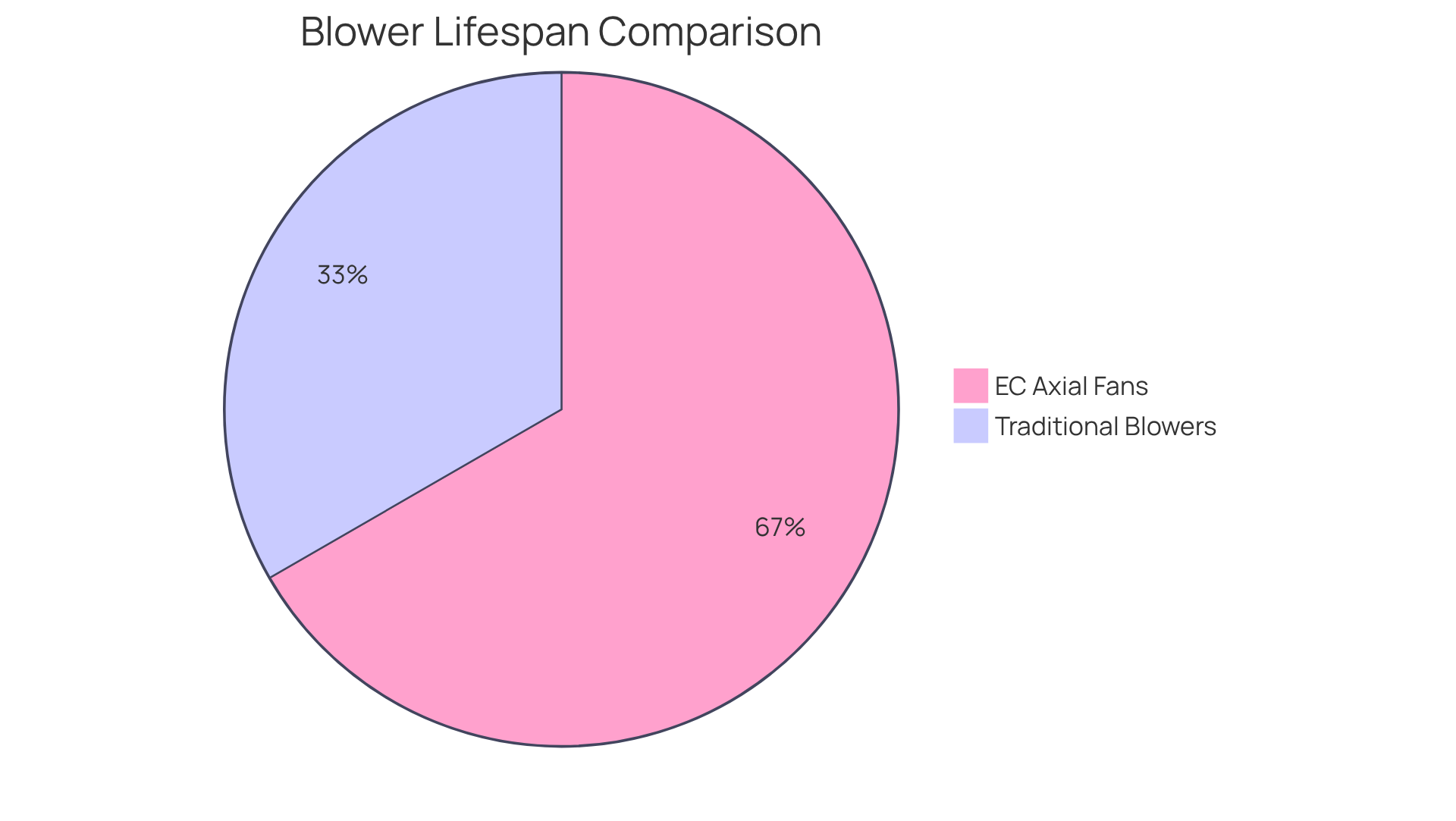

EC electric blowers exemplify reliability and durability, designed meticulously to minimize the likelihood of malfunction. Their robust structures and fewer moving components compared to traditional devices lead to significantly less mechanical wear, resulting in extended lifespans and lower maintenance needs. Typically, these advanced blowers can operate for 80,000 to 100,000 hours, effectively of conventional models.

Engineers note that while traditional blowers may last around 40,000 to 50,000 hours, the enhanced durability of EC models translates into substantial long-term cost savings. Furthermore, cutting-edge motor technology underpins their reliability, ensuring stable operation across a range of load conditions. This level of dependability is critical in essential applications such as data centers and telecommunications, where maintaining constant temperature control is of utmost importance.

For instance, during a recent project at a major data center, engineers found that EC fans consistently performed well even under peak load conditions, establishing them as a prime choice for high-efficiency temperature regulation solutions. Additionally, reports on performance consistency indicate that EC axial fans operate effectively in demanding environments, further solidifying their reputation as a trustworthy solution for temperature regulation.

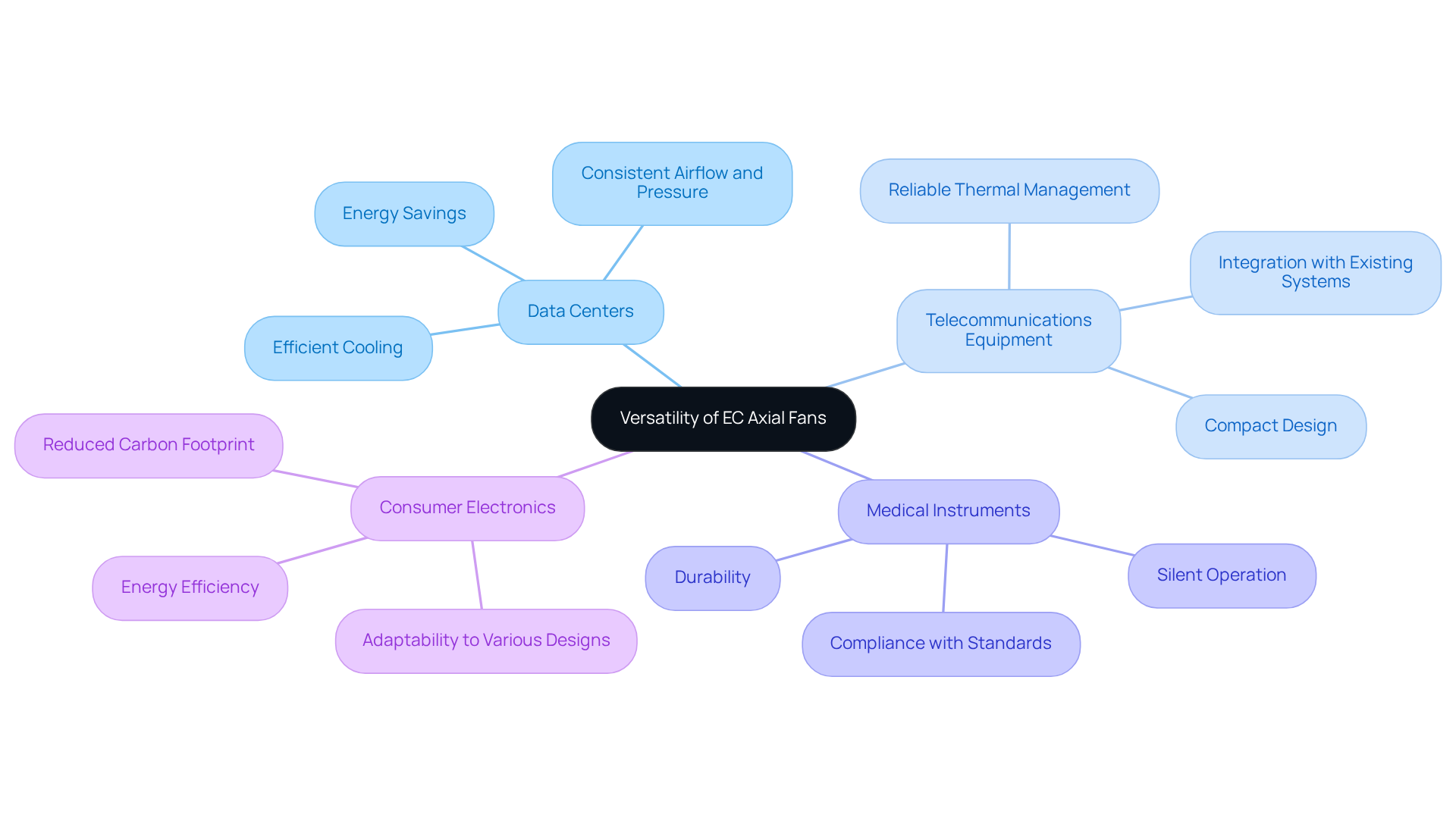

Versatility: Applications of EC Axial Fans in Modern Electronics

EC electronic blowers showcase remarkable adaptability, finding applications in:

- Data centers

- Telecommunications equipment

- Medical instruments

- Consumer electronics

Their compact design facilitates efficient cooling in confined spaces, making them indispensable for contemporary electronic systems that require reliable thermal management. For instance, in data centers, EC cooling devices deliver consistent airflow and pressure, which are crucial for sustaining optimal server performance.

The North America Fans for Electronics Cooling sector is projected to reach 1,142.58 million USD by 2033, highlighting the significant rise in EC fan utilization in these environments, driven by the demand for energy-efficient solutions that reduce operational costs. Additionally, their seamless integration into existing systems enables upgrades and retrofits across diverse settings.

Industry experts emphasize that the versatility of EC axial fans positions them as a transformative solution in the electronics sector, enhancing performance while bolstering sustainability initiatives. As noted by a site editor, “In today’s world, where energy efficiency and sustainability are paramount, electronically commutated (EC) devices have emerged as a game-changing solution for ventilation systems.”

In medical applications, their silent operation and durability ensure reliable temperature management, adhering to the stringent standards required for sensitive equipment. A case study on medical devices illustrates how EC units meet these demands with quiet performance and resilience.

Ultimately, the adaptability of EC units is revolutionizing temperature regulation solutions across various technological landscapes, contributing to reduced carbon emissions and compared to traditional AC units.

Noise Reduction: The Silent Operation of EC Axial Fans

EC axial fans stand out due to their remarkably quiet operation, a feature that is achieved through advanced motor control technology and aerodynamically optimized blade designs. Operating at reduced speeds while maintaining essential airflow with EC axial fans allows these devices to significantly lower noise levels, making them ideal for sound-sensitive environments such as offices, medical facilities, and residential air circulation systems.

The quiet operation of these EC axial fans enhances comfort and positively impacts workplace efficiency, as excessive noise can lead to distractions and diminished concentration. In settings like clean rooms and laboratories, where maintaining a low noise level is critical, EC centrifugal units excel in providing effective temperature regulation without disrupting the operational environment.

Engineers have recognized that the ability to achieve efficient temperature control while minimizing sound disruption is transformative in their designs, fostering a more pleasant and productive workspace. The versatility of EC axial fans across various applications demonstrates their efficiency in addressing the dual challenges of temperature regulation and .

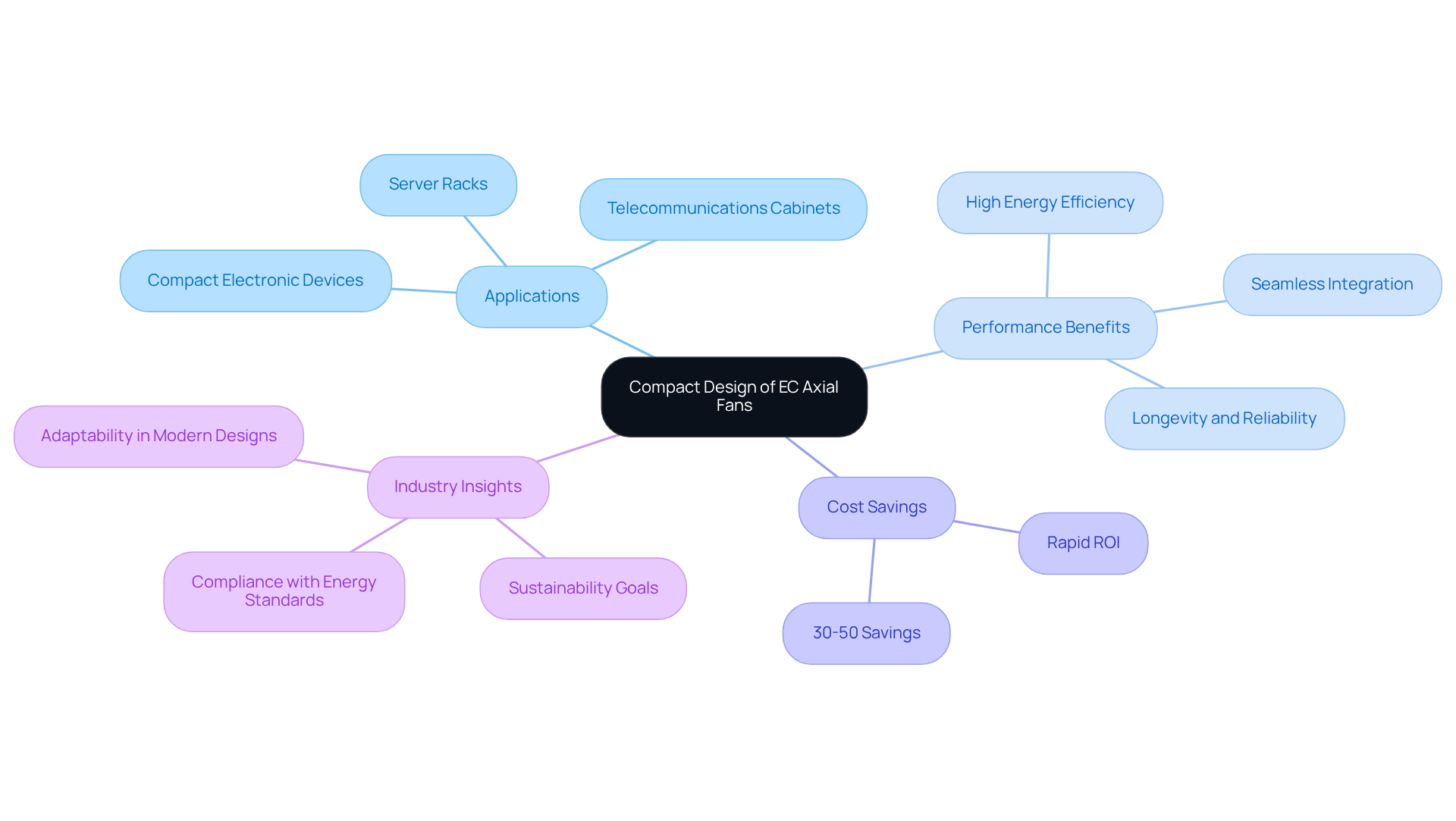

Compact Design: Space-Saving Features of EC Axial Fans

EC axial fans from Gagner-Toomey Associates are expertly engineered with a compact footprint, making them ideally suited for installations in space-constrained environments. Their streamlined design allows for seamless integration into various electronic systems, ensuring high performance without sacrificing functionality. This space-saving advantage is particularly critical in applications such as:

- Server racks

- Telecommunications cabinets

- Compact electronic devices

Where optimizing available space is essential for operational efficiency. For instance, data centers have successfully adapted Gagner-Toomey’s EC units, which range in size from 120-910mm, into current temperature regulation systems, achieving savings of 30-50% compared to conventional AC units. The compact characteristics of these devices not only enhance system design but also contribute to reducing operational expenses, as evidenced by rapid return on investment (ROI) in retrofit projects. As industry leaders like Sam Pelonis emphasize, ‘The high energy efficiency of the EC fan motor results from the decrease in energy usage,’ highlighting the importance of integrating space-saving technologies in temperature control solutions to meet the growing demands of high-density environments.

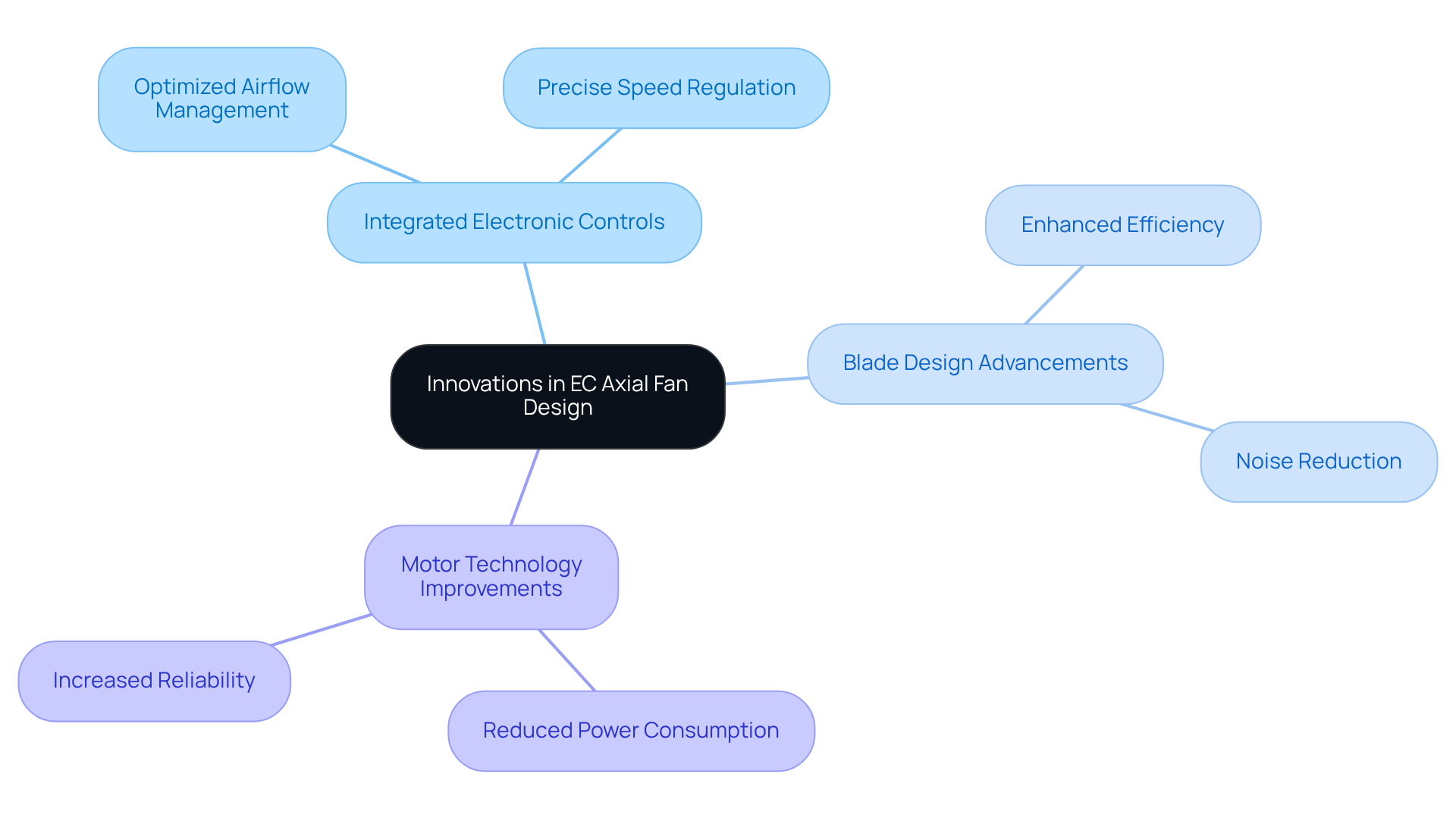

Advanced Technology: Innovations in EC Axial Fan Design

EC axial fans are at the forefront of thermal management technology, presenting innovative designs that significantly enhance performance and efficiency. By incorporating integrated electronic controls, these devices enable precise speed regulation, thereby optimizing airflow management to accommodate fluctuating temperature requirements. Furthermore, and motor technology elevate the devices’ efficiency while reducing power consumption. As a result, EC axial fans represent a groundbreaking solution for engineers seeking to implement advanced cooling systems in their projects, aligning with the industry’s shift towards sustainability and energy efficiency.

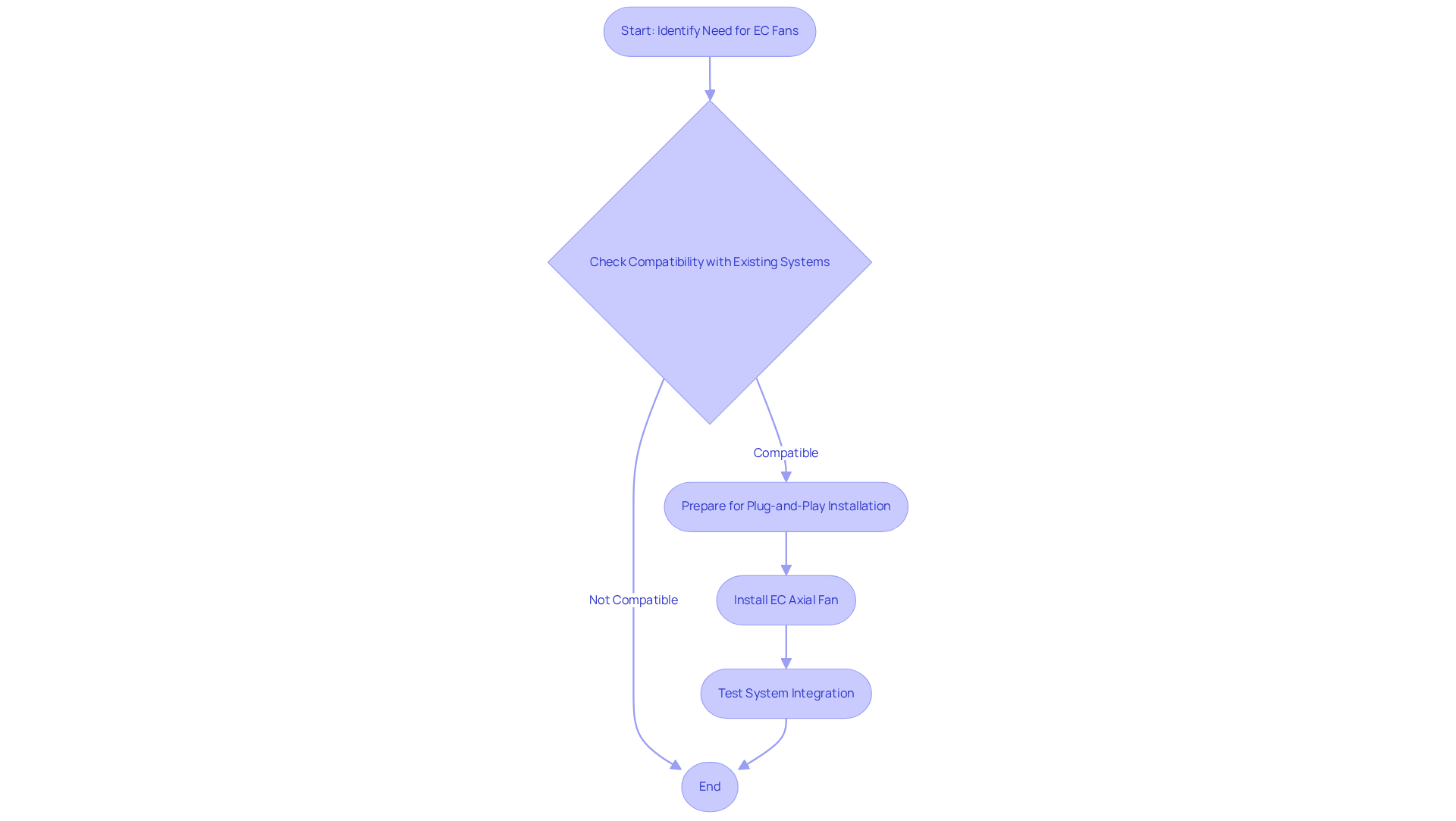

Ease of Integration: Implementing EC Axial Fans in Electronic Systems

EC electronic ventilators are designed for seamless integration into existing electronic systems. Their compatibility with standard interfaces and plug-and-play installation features significantly streamline the upgrade process for engineers. This facilitates rapid implementation without necessitating extensive modifications to current designs. As a result, EC devices emerge as a practical choice for both new projects and retrofits, providing an efficient solution that meets the demands of modern engineering.

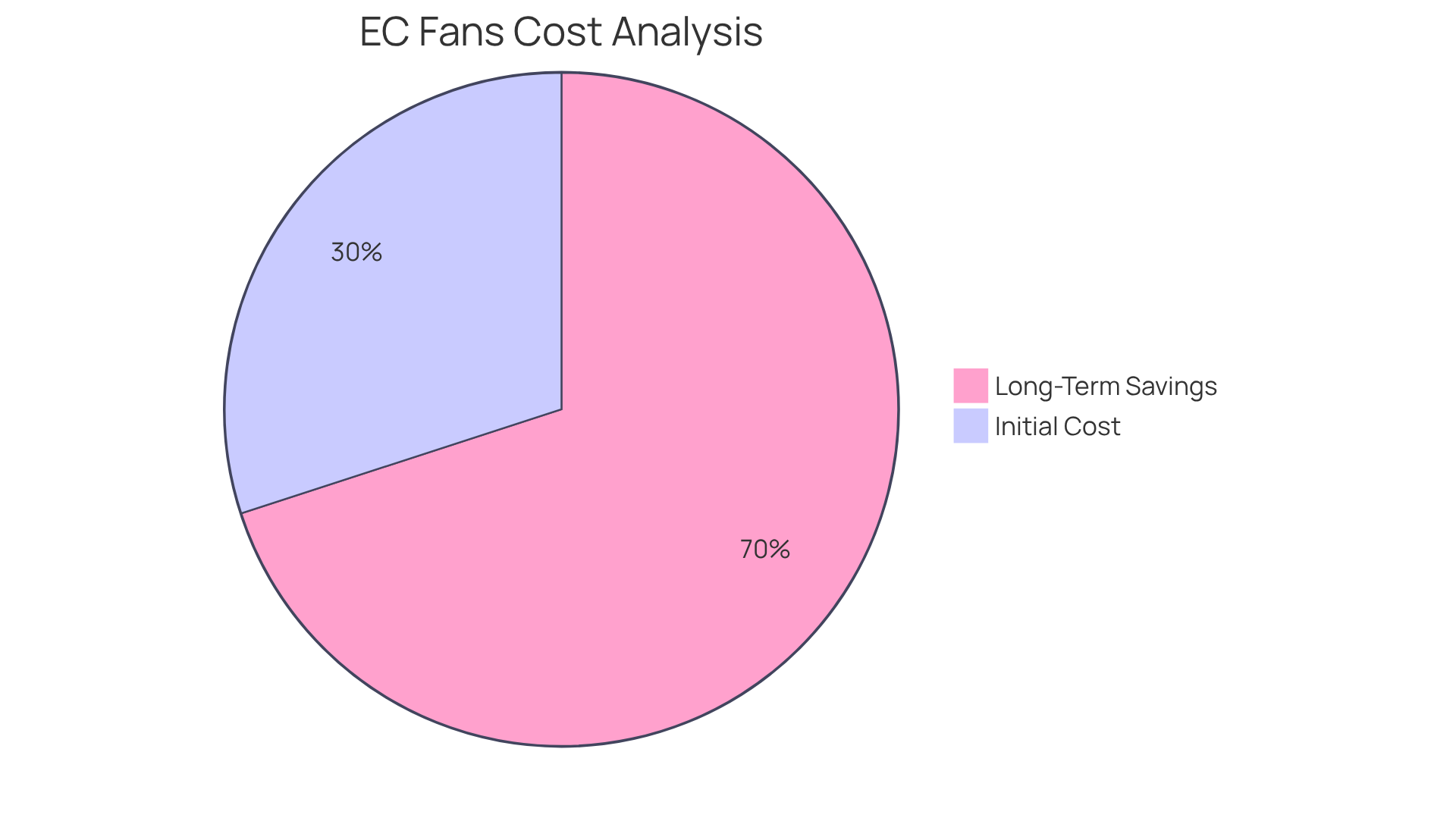

Cost-Effectiveness: The Economic Benefits of EC Axial Fans

While EC devices may present a higher initial acquisition cost compared to conventional AC units, their is compelling. These devices offer substantial savings in power consumption, utilizing up to 70% less electricity than traditional air conditioning systems, which translates to significantly lower operational expenses. Furthermore, their minimal maintenance requirements—often necessitating little to no upkeep—and extended lifespan—averaging 10 to 15 years versus 5 to 8 years for AC fans—further bolster their economic attractiveness.

Financial analysts note that the overall cost of ownership decreases markedly over time, as the initial investment in EC ventilation devices is offset by ongoing savings in both energy and maintenance. For electronics engineers, this positions EC radial ventilators as not only a sustainable choice but also a financially prudent one, ensuring improved system efficiency and reduced long-term costs.

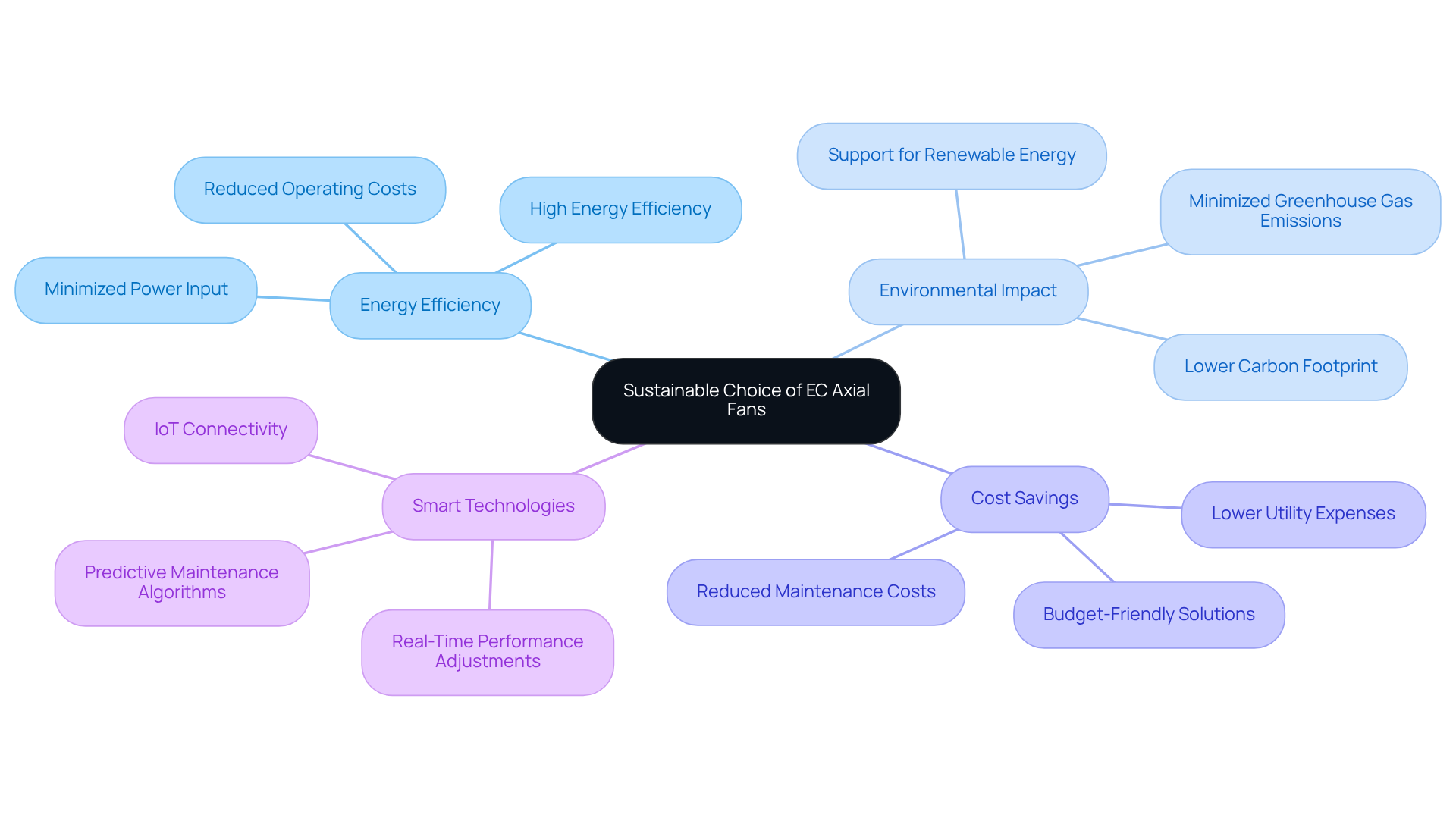

Environmental Impact: The Sustainable Choice of EC Axial Fans

EC radial blowers represent a pivotal sustainable solution for temperature regulation within the electronics sector, delivering exceptional energy efficiency that significantly curtails electricity consumption and minimizes greenhouse gas emissions. By opting for EC blowers, engineers enhance cooling efficiency while simultaneously advancing their organizations’ sustainability objectives. This decision exemplifies a growing dedication to , aligning with industry trends that emphasize greener technologies and practices.

The incorporation of smart technologies further elevates their efficiency, enabling real-time adjustments that optimize performance in response to environmental conditions. Consequently, businesses can realize substantial cost savings while contributing to global initiatives aimed at reducing carbon footprints.

The operational benefits of EC axial fans, along with their environmentally friendly design, make them an optimal choice for organizations aiming to achieve sustainability goals in a highly competitive landscape.

Conclusion

The advantages of EC axial fans are evident, establishing them as a crucial element for electronics engineers dedicated to improving cooling efficiency and sustainability. These fans not only provide significant energy savings but also guarantee dependable performance, showcasing their importance in contemporary electronic applications.

This article has underscored key benefits such as:

- Reduced power consumption

- An extended lifespan

- Versatile applications across diverse industries

The capacity of EC axial fans to function quietly while maintaining efficiency further underscores their appropriateness for settings where noise reduction is paramount. Moreover, their compact design allows for seamless integration into existing systems, rendering them a practical choice for both new initiatives and retrofits.

As the demand for energy-efficient and environmentally conscious cooling solutions escalates, the adoption of EC axial fans becomes increasingly essential. Engineers are urged to contemplate these innovative devices not solely for their economic advantages but also for their contribution to advancing sustainability objectives within the electronics sector. Embracing this technology can yield considerable operational enhancements and positively impact the broader environmental landscape.

Frequently Asked Questions

What products does Gagner-Toomey Associates offer for electronics cooling?

Gagner-Toomey Associates offers EC axial fans, including DC input Tube Axial devices ranging from 15 to 280mm and DC input Centrifugal Blowers from 15 to 225mm, designed specifically for the electronics industry.

How do EC axial fans improve energy efficiency?

EC axial fans achieve effectiveness levels of up to 90% compared to traditional AC units, significantly reducing power consumption by as much as 70%. They utilize electronically commutated motors that minimize power losses and enhance airflow, leading to lower operational expenses and a reduced carbon footprint.

What is the expected growth rate of the EC fan market?

The EC fan market is projected to grow at a compound annual growth rate (CAGR) of approximately 6.5% from 2025 to 2033.

What is the lifespan of Gagner-Toomey’s EC axial fans?

Gagner-Toomey’s advanced radial blower models can achieve a service life expectancy of up to 350,000 hours, while EC electric blowers typically operate for 80,000 to 100,000 hours, which is significantly longer than traditional models.

How do EC axial fans compare to traditional blowers in terms of reliability?

EC axial fans are designed with robust structures and fewer moving components, resulting in less mechanical wear and extended lifespans. They typically last 80,000 to 100,000 hours, compared to 40,000 to 50,000 hours for traditional blowers, leading to substantial long-term cost savings.

In what applications are EC axial fans particularly beneficial?

EC axial fans are especially beneficial in essential applications such as data centers and telecommunications, where maintaining constant temperature control is critical.

What advantages do EC axial fans offer in terms of maintenance?

The enhanced durability of EC axial fans leads to lower maintenance needs, as they are designed to minimize the likelihood of malfunction and operate reliably even in demanding environments.

How do EC ducted units perform across different speeds?

EC ducted units maintain relatively constant efficiency across various speeds, unlike AC motors that peak at a single speed, making them more adaptable for integration into existing setups.