Overview

Centrifugal fan blowers are sophisticated mechanical devices engineered to propel air or gases outward from their center of rotation. By employing a rotating impeller, these blowers create a pressure differential that effectively draws air in and expels it. Their unique characteristics, including high pressure and airflow capabilities, make them indispensable in various applications, particularly within cooling and ventilation systems. In the realm of electronics, where heat management is critical in densely packed environments such as data centers, centrifugal fan blowers play a vital role in maintaining optimal operating conditions.

Introduction

In the realm of industrial and electronic cooling, centrifugal fan blowers are indispensable for ensuring optimal performance and longevity of equipment. These mechanical devices, engineered to move air radially outward, harness the principles of centrifugal force to generate efficient airflow across a multitude of applications.

With technological advancements yielding improved blade designs and energy-efficient models, the significance of these fans has escalated, particularly within data centers and densely packed electronic systems. As the demand for effective cooling solutions intensifies, comprehending the functionality and advantages of centrifugal fan blowers becomes essential for engineers and industry professionals alike.

This article explores the characteristics, operational principles, and applications of centrifugal fans, underscoring their critical role in maintaining performance and energy efficiency across diverse environments.

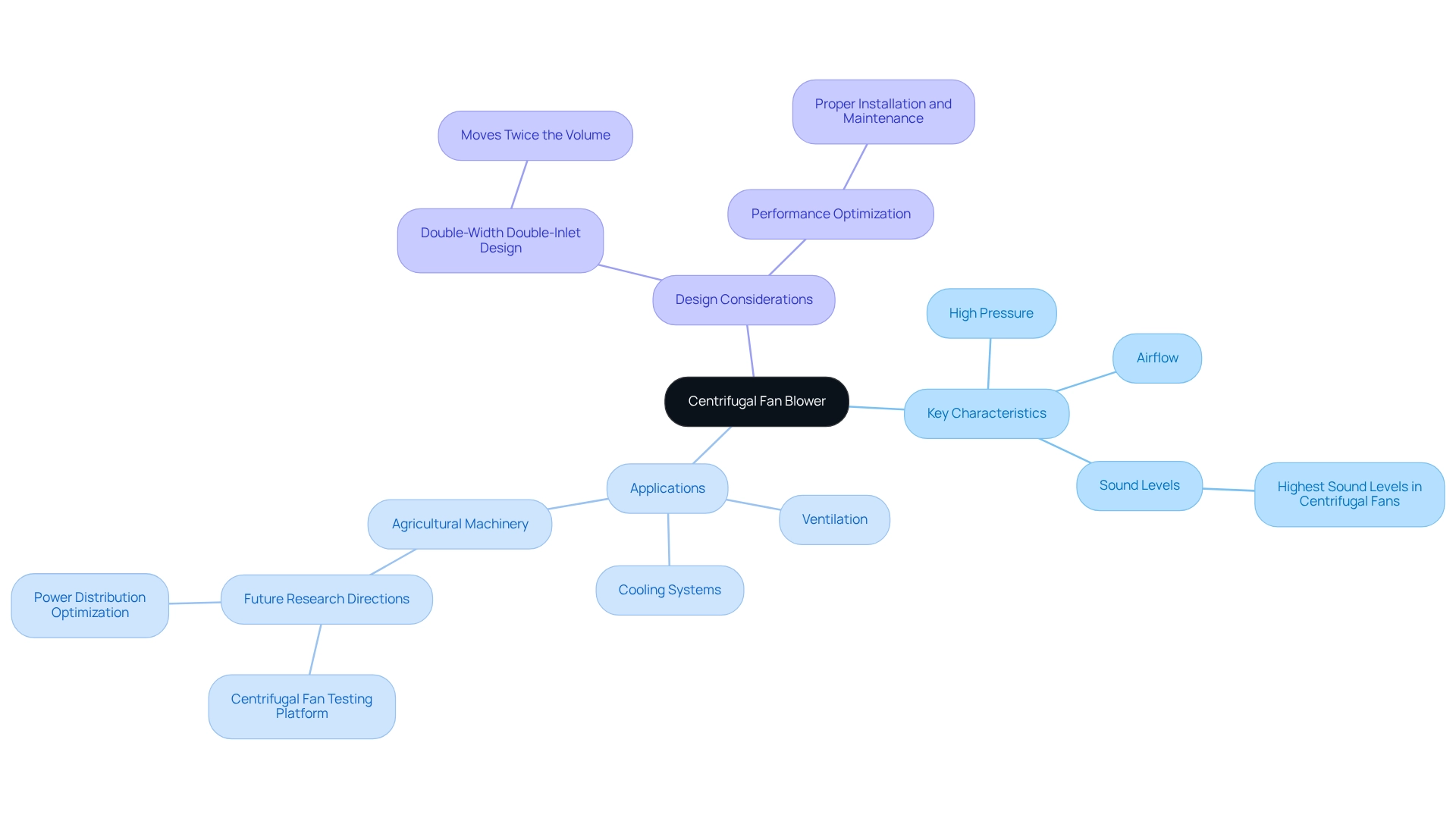

Define Centrifugal Fan Blower: Key Characteristics and Functionality

, commonly known as a radial ventilator, serves as a mechanical apparatus engineered to propel air or gases outward from its center of rotation. This device operates by employing a rotating impeller that draws air into the fan through an inlet and expels it at a 90-degree angle via an outlet. Notable characteristics of the include its capacity to generate , rendering it particularly effective in cooling and ventilation systems. Unlike axial air movers that direct air parallel to the rotational axis, radial blowers excel in managing higher static pressures, making them indispensable in environments that demand robust airflow control.

stands out as the largest global producer of both standard and custom air-movers, offering an extensive array of DC input radial blowers ranging from 15 to 225mm in size. These fans are meticulously optimized for performance, efficiency, and low noise, with IP protection available in most models upon request. Recent advancements in fan technology have focused on enhancing performance and efficiency. Innovations in blade design and materials have yielded improved airflow dynamics and reduced energy consumption. Research indicates that , ensuring longevity and reliability in industrial applications. Additionally, the is paving the way for future research aimed at enhancing efficiency and functionality across various applications, including agricultural machinery, which holds particular relevance for engineers in these sectors.

As highlighted by industry experts such as Bevan IEng, MIPIantE Michael Farrell CEng, FCIBSE, FIMechE, the ranks among the most frequently utilized configurations, capable of moving twice the volume for a given wheel diameter. This design consideration is crucial for engineers to assess when selecting ventilation devices for specific applications. Current statistics reveal that radial-blade fans, while effective, often exhibit the highest sound levels among centrifugal fan blowers. This factor is essential for engineers to contemplate during the selection process, as it can significantly impact operational noise levels in sensitive environments.

In summary, understanding these characteristics and advancements is vital for electronics engineers to make informed decisions regarding fan systems in their projects, particularly when evaluating the offered by Gagner-Toomey Associates.

Explain How Centrifugal Fan Blowers Work: Principles of Operation

operate based on the principles of centrifugal force, a fundamental concept in fluid dynamics. When the impeller, characterized by blades arranged in a circular configuration, rotates, it generates a low-pressure zone at the center of the fan. This effectively draws air into the fan through the inlet. As the air traverses the impeller, it acquires kinetic energy from the rotation, which propels it outward with increased velocity.

The configuration of the —be it forward-curved, backward-curved, or radial—plays a critical role in determining the efficiency and performance of the fan. The expelled air exits the fan perpendicular to the intake, facilitating effective across various systems, including .

Discuss the Role of Centrifugal Fan Blowers in Electronics Cooling: Applications and Benefits

play a crucial role in effective , ensuring that the heat generated by components is dissipated efficiently. In environments such as computers, servers, and telecommunications equipment, maintaining is essential for both performance and longevity. These devices excel at moving substantial volumes of air at high pressures, making them particularly suited for . For instance, in data centers, fans circulate air through server racks, preventing overheating and guaranteeing dependable operation. Their also makes them ideal for consumer electronics, where noise reduction is a significant concern.

Moreover, the incorporation of fan mechanisms into electronic cooling systems not only enhances performance but also promotes , leading to lower operational expenses. With the radial fan market projected to expand at a CAGR of 4.9%, the demand for these solutions in data centers is increasingly recognized, especially as liquid cooling technologies help facilities comply with stringent environmental regulations. This underscores the in contemporary cooling systems.

As noted by Maurizio Di Paolo Emilio, “The role of is strategic in the integration of renewable energy,” highlighting the broader relevance of energy efficiency within . Case studies, such as the initiative by ebm‑papst to establish a , further illustrate the critical nature of efficient cooling in managing heat and supporting the growing complexity of data centers. This commitment to efficiency and environmental responsibility highlights the strategic role of centrifugal fan blowers in contemporary electronics cooling solutions.

Conclusion

Centrifugal fan blowers are essential in industrial and electronic cooling applications, renowned for their capacity to efficiently move air and generate high pressure. Recent advancements in design and technology have further optimized these fans, enhancing airflow dynamics while minimizing energy consumption. This evolution renders them indispensable for maintaining optimal operating conditions for sensitive electronic equipment. Their operational principles, driven by centrifugal force, enable effective airflow management across diverse environments, from data centers to consumer electronics.

The importance of centrifugal fan blowers transcends basic functionality; they are crucial for ensuring the longevity and reliability of electronic systems. By effectively dissipating heat, these fans not only enhance performance but also contribute significantly to energy efficiency—a vital consideration in today’s environmentally conscious landscape. As the demand for effective cooling solutions escalates, a comprehensive understanding of the characteristics and applications of centrifugal fans becomes imperative for engineers and industry professionals.

In conclusion, the strategic significance of centrifugal fan blowers in contemporary cooling solutions is paramount. Their capability to support advanced technologies while adhering to environmental regulations positions them as a critical component in the evolution of electronic cooling systems. As industries navigate the complexities of modern technology, the role of these fans will remain central to achieving efficient, reliable, and sustainable operations across a myriad of applications.

Frequently Asked Questions

What is a radial fan and how does it operate?

A radial fan, also known as a radial ventilator, is a mechanical device designed to propel air or gases outward from its center of rotation. It operates using a rotating impeller that draws air into the fan through an inlet and expels it at a 90-degree angle via an outlet.

What are the key characteristics of a centrifugal fan blower?

Centrifugal fan blowers are known for their ability to generate high pressure and airflow, making them effective in cooling and ventilation systems. They excel in managing higher static pressures compared to axial air movers, which direct air parallel to the rotational axis.

Who is the largest producer of radial blowers and what do they offer?

Gagner-Toomey Associates is the largest global producer of both standard and custom air-movers, offering a wide range of DC input radial blowers from 15 to 225mm in size, optimized for performance, efficiency, and low noise.

What advancements have been made in fan technology?

Recent advancements in fan technology include improvements in blade design and materials, leading to better airflow dynamics and reduced energy consumption. Additionally, proper installation and maintenance have been shown to enhance fan performance and longevity.

What is the significance of the double-width double-inlet centrifugal fan blower design?

The double-width double-inlet centrifugal fan blower design is one of the most commonly used configurations, capable of moving twice the volume for a given wheel diameter. This design is crucial for engineers to consider when selecting ventilation devices for specific applications.

What should engineers consider regarding sound levels when selecting radial-blade fans?

Engineers should be aware that radial-blade fans often produce the highest sound levels among centrifugal fan blowers. This factor is important to consider, especially in sensitive environments where operational noise levels can be a concern.

Why is it important for electronics engineers to understand the characteristics of centrifugal fan blowers?

Understanding the characteristics and advancements of centrifugal fan blowers is vital for electronics engineers to make informed decisions regarding fan systems in their projects, particularly when evaluating advanced cooling solutions.