Overview

This article provides a comprehensive comparison of ball bearings and sleeve bearings, essential for electronics engineers navigating the complexities of bearing selection.

Understanding the Distinction

Ball bearings are particularly suited for high-speed applications. Their design minimizes friction and noise, making them the go-to choice for scenarios where speed is paramount. Conversely, sleeve bearings shine in heavy-load situations. They offer remarkable durability and ease of maintenance, which are critical factors for engineers dealing with demanding operational environments.

Guiding Informed Choices

By understanding these distinct functionalities, engineers can make informed choices tailored to specific operational requirements. Whether prioritizing speed or load capacity, recognizing the strengths of each bearing type is crucial for optimizing performance in electronic applications.

In conclusion, this article serves as a valuable resource, guiding engineers in selecting the appropriate bearing type based on their unique needs. With the right information at hand, making the best choice becomes a straightforward process.

Introduction

Choosing between ball and sleeve bearings can profoundly influence the performance and reliability of electronic systems. As engineers tackle the intricacies of machinery design, grasping the distinct characteristics of these two bearing types is crucial. This article examines the advantages and limitations of ball and sleeve bearings, highlighting their unique applications, performance metrics, and construction features.

How do engineers identify the optimal option for their specific requirements, particularly when navigating the trade-offs between speed, load capacity, and maintenance needs?

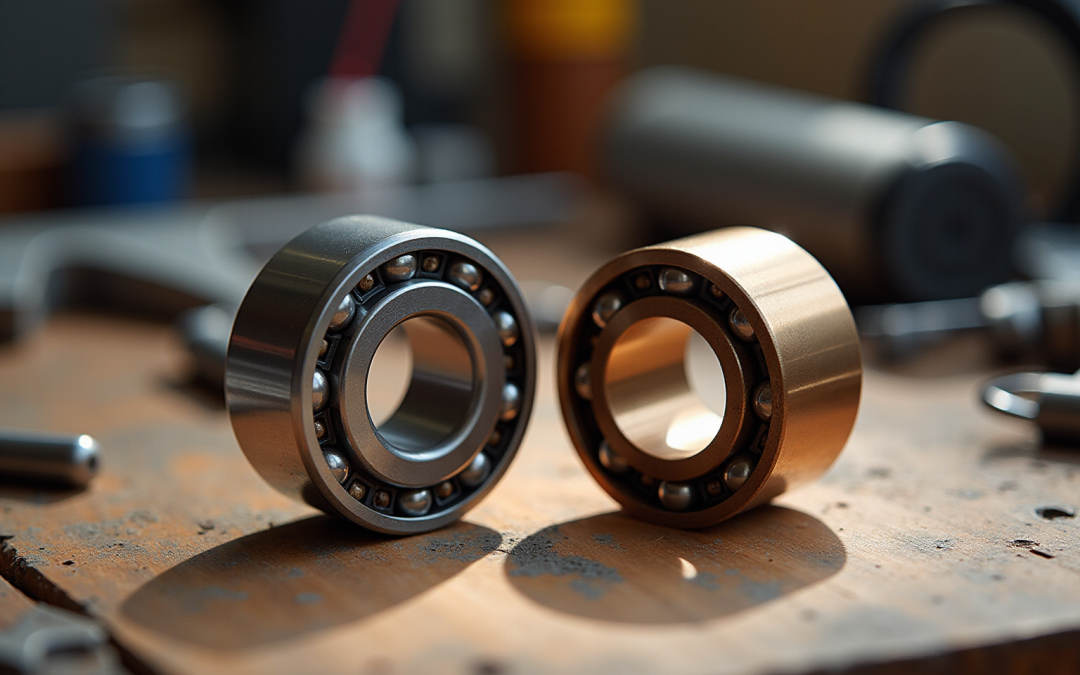

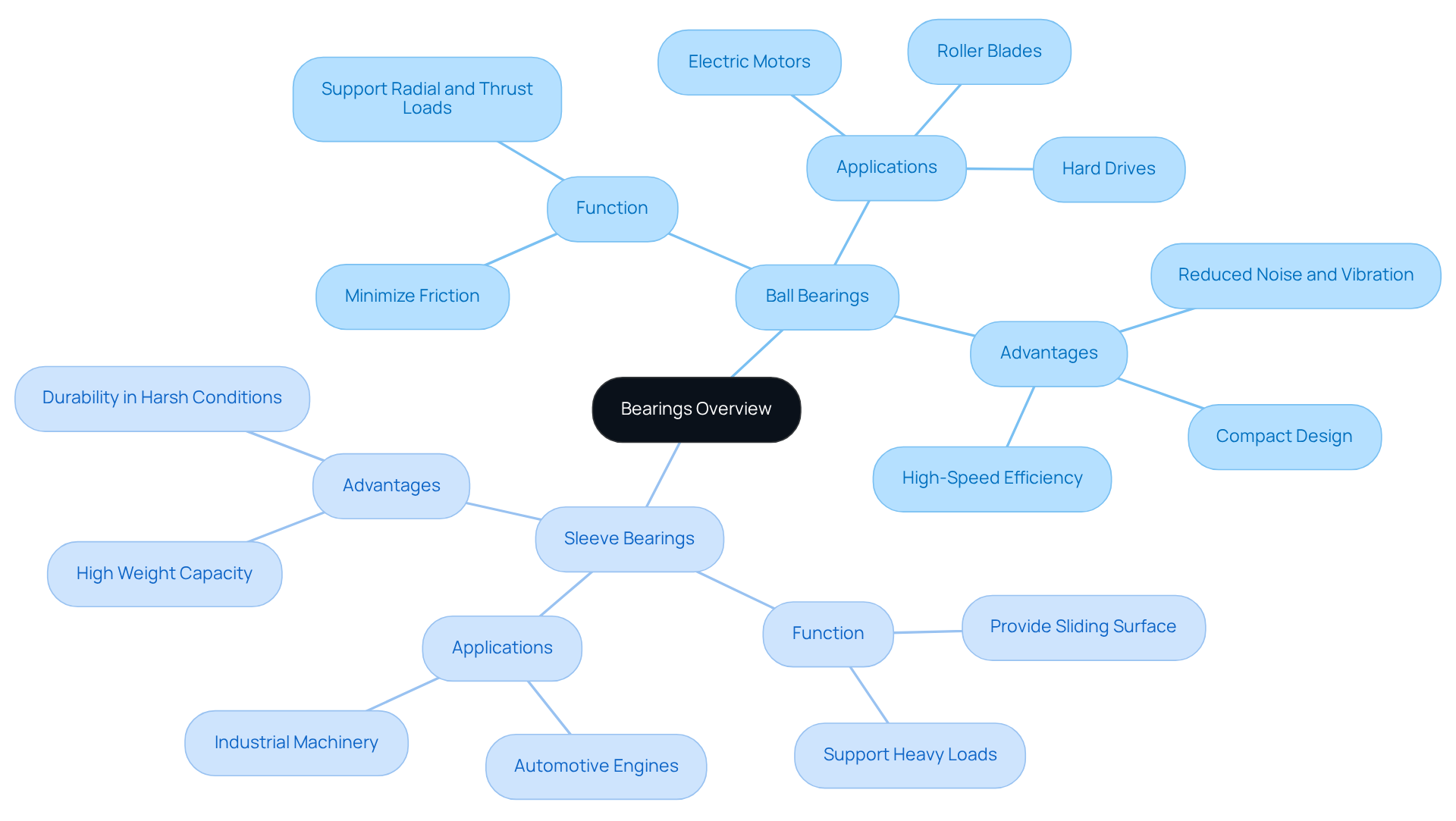

Define Ball Bearings and Sleeve Bearings

Ball components leverage spherical designs to minimize friction between moving parts, facilitating smooth rotation. They are particularly effective in high-speed applications where low friction is essential, making them ideal for machinery such as electric motors and hard drives. As Robert aptly states, “the main function of supports is to carry weights with minimal friction and wear, ensuring efficient movement, reducing energy use, and offering stability, accuracy, and dependability to mechanical systems while lessening noise and vibration.”

In contrast, cylindrical supports provide a sliding surface for shafts, prioritizing weight capacity and durability over speed. These components are commonly found in applications like automotive engines and industrial machinery, where they bear heavier loads and withstand harsh conditions. For example, sleeve supports play a crucial role in automotive engines, delivering reliable support in demanding environments.

Understanding the distinctions between ball vs sleeve bearing is vital for engineers, as it enables them to make informed decisions when selecting the appropriate type of support for their specific engineering challenges. Recent trends in support technology highlight a growing focus on efficiency and performance, which are critical for modern engineering applications. By recognizing the unique advantages of each support type, engineers can enhance the reliability and effectiveness of their designs.

Compare Construction and Design Features

Ball components feature an advanced design that includes an inner and outer race with small spheres positioned in between. This configuration minimizes the contact area, significantly reducing friction and enabling high-speed operation. In contrast, cylindrical supports can be analyzed in the context of ball vs sleeve bearing, consisting of a simple tubular casing that the shaft rotates inside, typically made from materials like bronze or plastic. These materials directly influence wear resistance and lubrication requirements, which in turn impacts overall performance.

For instance, high-quality cylindrical supports can achieve near-silent operation below 20 dB, while precision ball components rarely fall below 30 dB. This highlights a notable difference in noise performance. Moreover, journal supports usually cost 30-50% less than comparable ball supports, making them an attractive option for budget-conscious projects.

However, sleeve supports have a lifespan of 8,000 to 10,000 hours, which is shorter than that of ball vs sleeve bearing supports, and they generally reach a maximum of around 3,000 RPM. This limitation restricts their use in high-speed applications. Understanding these design variations, material compositions, and economic factors is crucial for engineers when selecting the appropriate type of support for specific electronic applications.

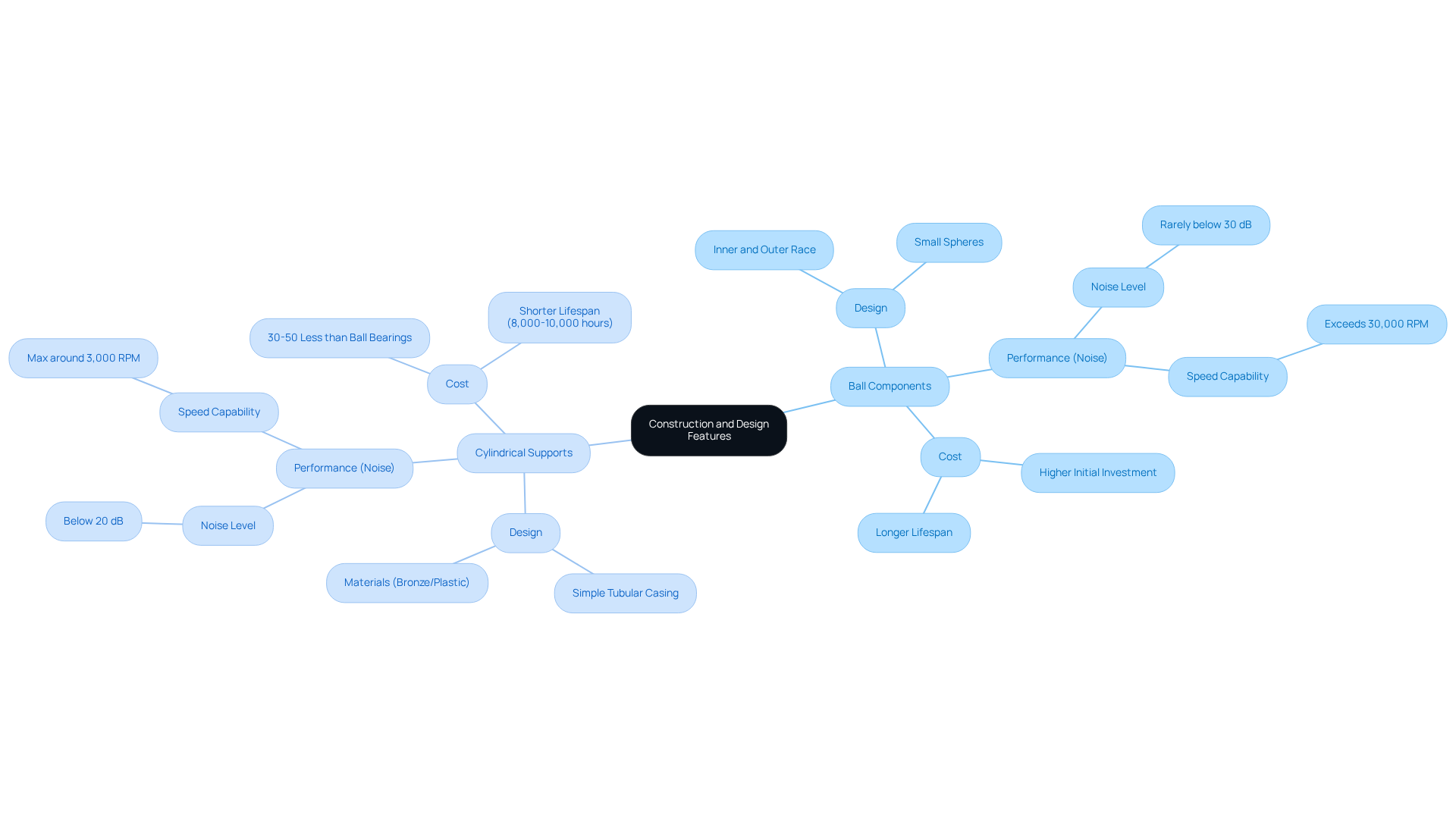

Evaluate Performance Metrics: Temperature, Noise, and Efficiency

When selecting between ball vs sleeve bearing components and journal supports, it’s essential to understand their distinct functionalities and applications. Ball components typically operate at lower temperatures due to reduced friction, making them ideal for high-velocity applications. Their design facilitates efficient heat dissipation, resulting in quieter operation—an important factor in sound-sensitive environments.

In contrast, journal supports can handle greater loads but often generate more heat and noise, especially under heavy loads or inadequate lubrication. This issue becomes particularly evident in scenarios where sleeve supports frequently start and stop, leading to increased wear and potential noise problems. Moreover, sleeve supports generally have a shorter lifespan compared to roller supports and require more frequent maintenance and replacement, which is a critical consideration for long-term applications.

While ball vs sleeve bearing components usually offer superior efficiency and longevity, their precision can come at a higher cost. On the other hand, sleeve supports can excel in low-speed applications where load capacity and vibration damping are crucial. For example, in low-speed exhaust fans and ventilation systems, sleeve supports provide quieter operation and lower costs, making them a preferred choice despite their higher maintenance needs.

Ultimately, the decision between these support types should be guided by specific operational requirements, including temperature management, noise reduction, and cost-effectiveness. By carefully evaluating these factors, you can make an informed choice that aligns with your operational goals.

Analyze Pros and Cons of Ball and Sleeve Bearings

Ball components are celebrated for their high-speed performance, low friction, and minimal noise, making them particularly suitable for applications such as motors and fans. Their design facilitates efficient operation at elevated speeds, which is crucial in many electronic devices. However, these components can be sensitive to misalignment, necessitating precise installation to avoid premature failure.

In contrast, sleeve supports, also known as plain supports, represent some of the oldest and simplest types of supports utilized in mechanical systems. They are generally more durable and excel in managing greater weights, making them ideal for heavy machinery applications. Crafted from diverse materials like bronze, brass, and composites, sleeve supports accommodate various weight types and environmental conditions, especially in settings where durability is paramount, such as in industrial motors and construction machinery.

Despite their advantages, journal supports can experience heightened friction and deterioration over time, particularly if lubrication is insufficient. Their simpler construction often leads to easier installation and maintenance, which can be beneficial in various engineering contexts. Industry specialists note that journal supports typically exhibit reduced failure rates in heavy-duty applications due to their ability to distribute loads uniformly over a broader surface area, enhancing their load-bearing capacity. Furthermore, journal supports generally require less upkeep than ball bearings, making them an attractive option for budget-conscious initiatives.

Real-world examples illustrate the resilience of cylindrical supports in heavy machinery, where they often outperform ball supports in challenging environments. For instance, cylindrical supports are frequently employed in farming machinery and maritime devices, demonstrating durability against high temperatures and corrosive conditions. Moreover, case studies reveal that cylindrical supports operate notably quieter than ball supports, making them favorable for applications requiring low noise, although wear may lead to varying noise characteristics over time.

In conclusion, while ball rollers are favored for high-velocity applications due to their minimal resistance and compact structure, a ball vs sleeve bearing analysis shows that sleeve supports provide significant advantages in terms of weight capacity, longevity, and ease of maintenance, particularly in heavy-duty and demanding conditions.

Identify Suitable Applications for Each Bearing Type

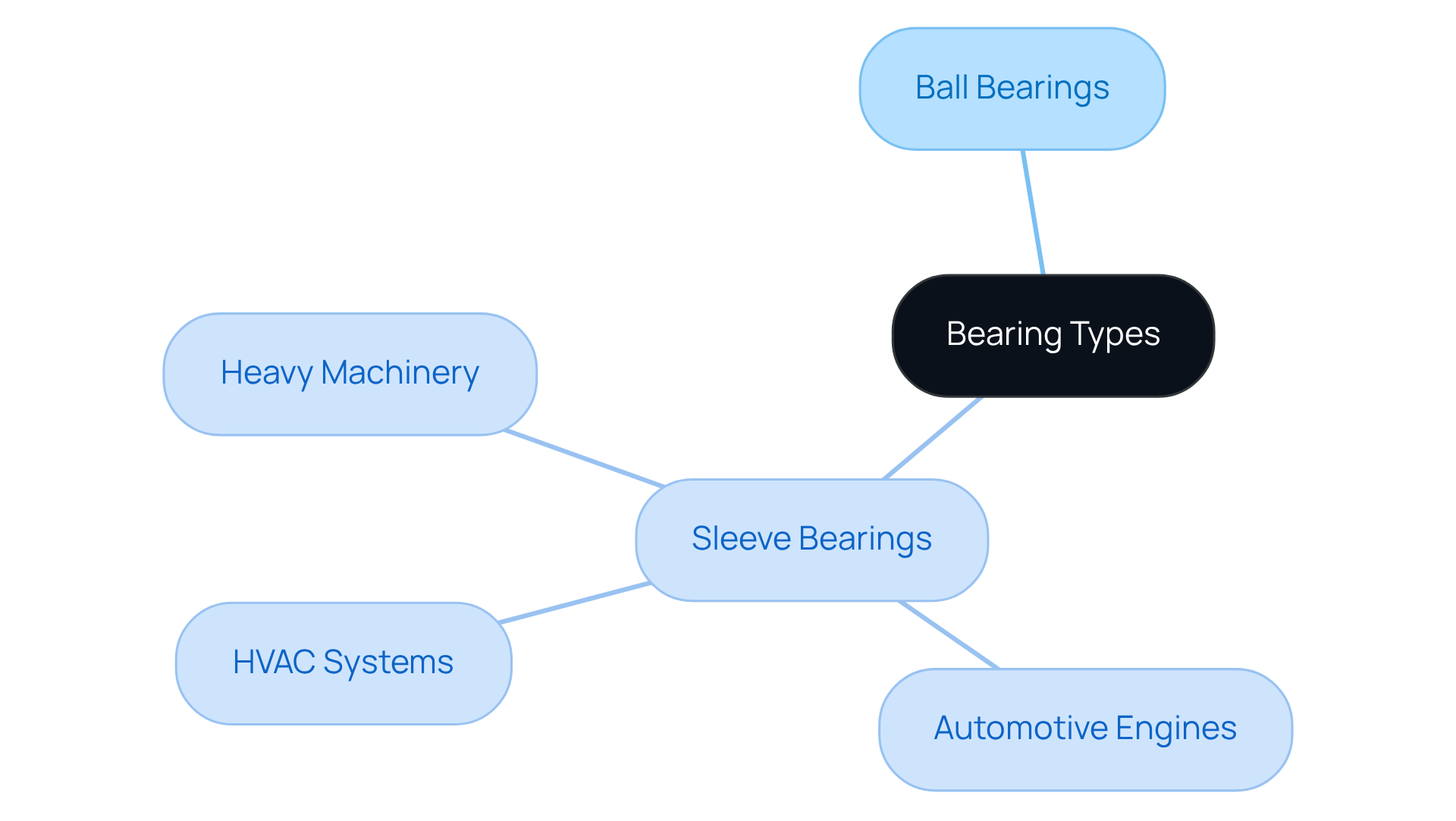

In high-velocity applications such as electric motors, hard drives, and robotics, the comparison of ball vs sleeve bearing elements plays a crucial role where efficiency and speed are paramount. In the discussion of ball vs sleeve bearing, sleeve supports are essential in scenarios demanding high load capacity, including:

- Heavy machinery

- Automotive engines

- HVAC systems

By understanding the specific requirements of each application, engineers can select the most suitable bearing type, ensuring optimal performance and longevity. This careful selection process not only enhances functionality but also contributes to the overall reliability of the systems in which these components are utilized.

Conclusion

Understanding the differences between ball and sleeve bearings is essential for engineers who need to select the right components for their designs. Ball bearings, characterized by their spherical design, excel in high-speed applications, providing low friction and reduced noise. In contrast, sleeve bearings offer robust support for heavy loads, prioritizing durability over speed. Recognizing these distinctions empowers engineers to make informed decisions that enhance the performance and reliability of their systems.

This article highlights several key points, including:

- The construction and design features of each bearing type

- Their performance metrics regarding temperature and noise

- The pros and cons associated with their use

Ball bearings are preferred for applications demanding high efficiency and speed, while sleeve bearings are ideal for heavy machinery and environments where durability is crucial. Analyzing these factors underscores the importance of aligning bearing selection with specific operational requirements.

Ultimately, the choice between ball and sleeve bearings should be guided by the unique demands of each application. Engineers must consider not only the technical specifications but also the long-term implications of their choices on system performance and maintenance needs. By doing so, they can ensure optimal functionality and longevity in their engineering projects, contributing to the success of their designs across various industries.

Frequently Asked Questions

What are ball bearings and sleeve bearings?

Ball bearings utilize spherical designs to minimize friction between moving parts, facilitating smooth rotation and are ideal for high-speed applications. Sleeve bearings, on the other hand, provide a sliding surface for shafts, focusing on weight capacity and durability, commonly used in applications like automotive engines.

What are the main functions of ball bearings?

The main functions of ball bearings are to carry weights with minimal friction and wear, ensuring efficient movement, reducing energy use, and providing stability, accuracy, and dependability to mechanical systems while minimizing noise and vibration.

In what applications are sleeve bearings typically used?

Sleeve bearings are commonly found in automotive engines and industrial machinery, where they bear heavier loads and withstand harsh conditions.

How do the designs of ball bearings and sleeve bearings differ?

Ball bearings consist of an inner and outer race with small spheres in between, reducing contact area and friction for high-speed operation. Sleeve bearings consist of a simple tubular casing that the shaft rotates inside, usually made from materials like bronze or plastic.

What are the noise performance differences between ball bearings and sleeve bearings?

High-quality sleeve bearings can achieve near-silent operation below 20 dB, while precision ball bearings rarely fall below 30 dB, indicating that sleeve bearings often perform better in terms of noise.

How do the costs of ball bearings compare to sleeve bearings?

Journal (sleeve) supports usually cost 30-50% less than comparable ball supports, making them a more budget-friendly option for certain projects.

What is the lifespan and speed limitation of sleeve bearings compared to ball bearings?

Sleeve bearings have a lifespan of 8,000 to 10,000 hours and typically reach a maximum speed of around 3,000 RPM, which is shorter and lower than that of ball bearings, limiting their use in high-speed applications.

Why is it important for engineers to understand the differences between ball and sleeve bearings?

Understanding the distinctions between ball and sleeve bearings helps engineers make informed decisions when selecting the appropriate type of support for specific engineering challenges, enhancing the reliability and effectiveness of their designs.