Overview

Dust proof fans play a crucial role in safeguarding sensitive electronic components from dust and debris, which can significantly impact their performance and lifespan. In environments such as electronics and HVAC systems, these specialized devices are engineered to prevent contaminants from infiltrating their internal mechanisms, thereby enhancing operational efficiency and longevity.

The importance of dust proof fans is underscored by their advanced features. For instance, sealed bearings and innovative coatings are designed to optimize airflow and cooling efficiency. These enhancements not only improve the overall functionality of the fans but also protect delicate electronic components from overheating and potential failure.

By investing in dust proof fans, organizations can ensure that their systems operate smoothly and reliably. This proactive approach not only mitigates the risk of equipment malfunction but also extends the lifespan of critical components, ultimately leading to cost savings and improved performance.

In conclusion, the implementation of dust proof fans is a strategic decision for any operation that relies on electronic systems. Their ability to maintain cleanliness and efficiency makes them an indispensable asset in today’s technology-driven environments.

Introduction

Dust proof fans have become indispensable in electronics and industrial applications, effectively addressing the persistent challenge of dust and debris that can hinder performance. These specialized devices not only boost operational efficiency but also significantly prolong the lifespan of critical equipment. As we delve into their unique features and functionalities, it becomes clear how essential they are in maintaining optimal performance.

However, with a variety of types available, determining the ideal dust proof fan for specific needs can be daunting. What innovations are currently shaping the future of this vital technology? By exploring these questions, readers can gain valuable insights into making informed decisions that enhance their operational capabilities.

Define Dust Proof Fan: Key Features and Functionality

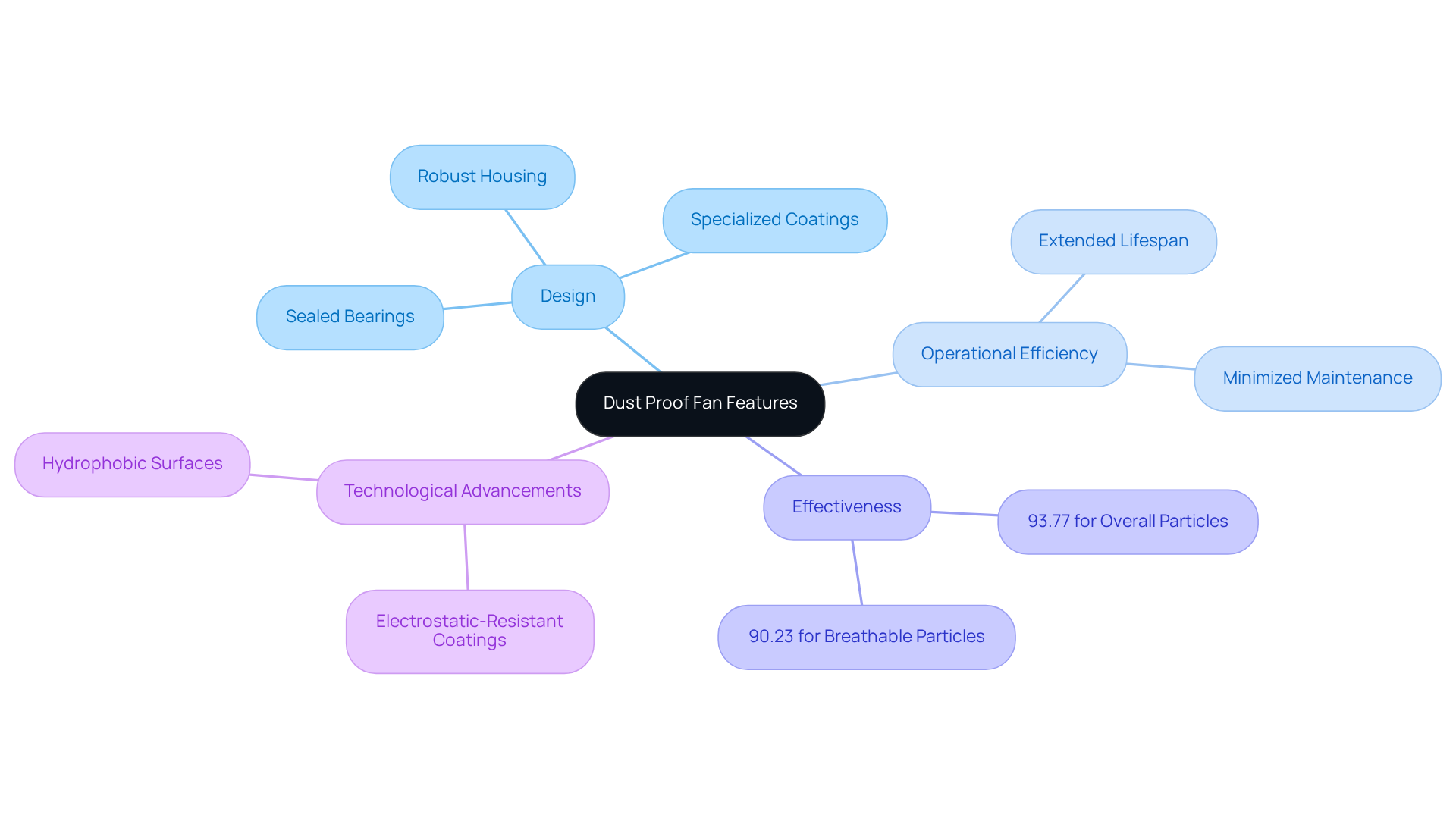

The dust proof fan from Gagner-Toomey Associates is meticulously engineered to prevent particles and debris from infiltrating its internal components. This design significantly boosts operational efficiency and extends the lifespan of the devices. Equipped with sealed bearings, specialized coatings, and robust housing designs, these blowers effectively minimize particle accumulation. Their functionality is vital in environments where contaminants can hinder performance, such as in electronic devices, HVAC systems, and various industrial applications.

By ensuring a clean operational environment, Gagner-Toomey’s dust-resistant devices facilitate optimal airflow and cooling efficiency, which is crucial for the reliability of sensitive electronic components. Research indicates that dust-resistant ventilators can achieve an impressive average particulate removal effectiveness of 90.23% for breathable particles and 93.77% for overall particles in rubber transport chutes. This underscores their importance in maintaining air quality and functionality in electronic systems.

Recent advancements in dust proof fan technology, such as the incorporation of electrostatic-resistant coatings and hydrophobic surfaces, further enhance their ability to remain clean for a longer duration. This innovation reduces maintenance requirements and minimizes operational disruptions. Engineers consistently highlight the significance of these components in electronics, noting that their effectiveness is directly linked to improved device reliability and longevity.

Gagner-Toomey Associates stands out as a premier supplier of cutting-edge cooling solutions, offering a comprehensive range of standard and custom air movers and blowers tailored for diverse applications. With a commitment to quality and innovation, Gagner-Toomey is poised to meet the evolving needs of the industry.

Importance of Dust Proof Fans in Electronics Engineering

In electronics engineering, particle-proof fans play a crucial role in maintaining the reliability and performance of electronic systems. Dust accumulation can severely impede airflow, resulting in overheating and potential component failure. For example, in data centers, particles can obstruct cooling pathways, leading to thermal throttling and equipment malfunctions.

Consider the case of IT manager Bates, who faced significant operational disruptions due to debris buildup. This issue disabled access for 10,000 users when critical networking components overheated. Bates emphasized the importance of routine debris management and equipment maintenance, highlighting the dangers associated with neglecting these practices.

By implementing protective ventilators, engineers can effectively mitigate these risks, ensuring systems operate within safe temperature ranges and maintain optimal performance. These devices not only prevent overheating but also extend the lifespan of components, thereby reducing maintenance costs and downtime related to cleaning and repairs.

Research indicates that pollution accounts for 35-78% of server-related outages, highlighting the necessity of a dust proof fan in enhancing operational efficiency and reliability in electronic systems. Furthermore, findings from ASHRAE reveal that even minor particle accumulation can increase cooling energy consumption by 2-5%, reinforcing the critical role of filtration fans.

The 9WPA-Type fan, which achieves IP68 water and particle protection, exemplifies a solution that meets high standards for environmental safeguarding. By prioritizing the use of such advanced technologies, organizations can significantly improve their operational resilience and efficiency.

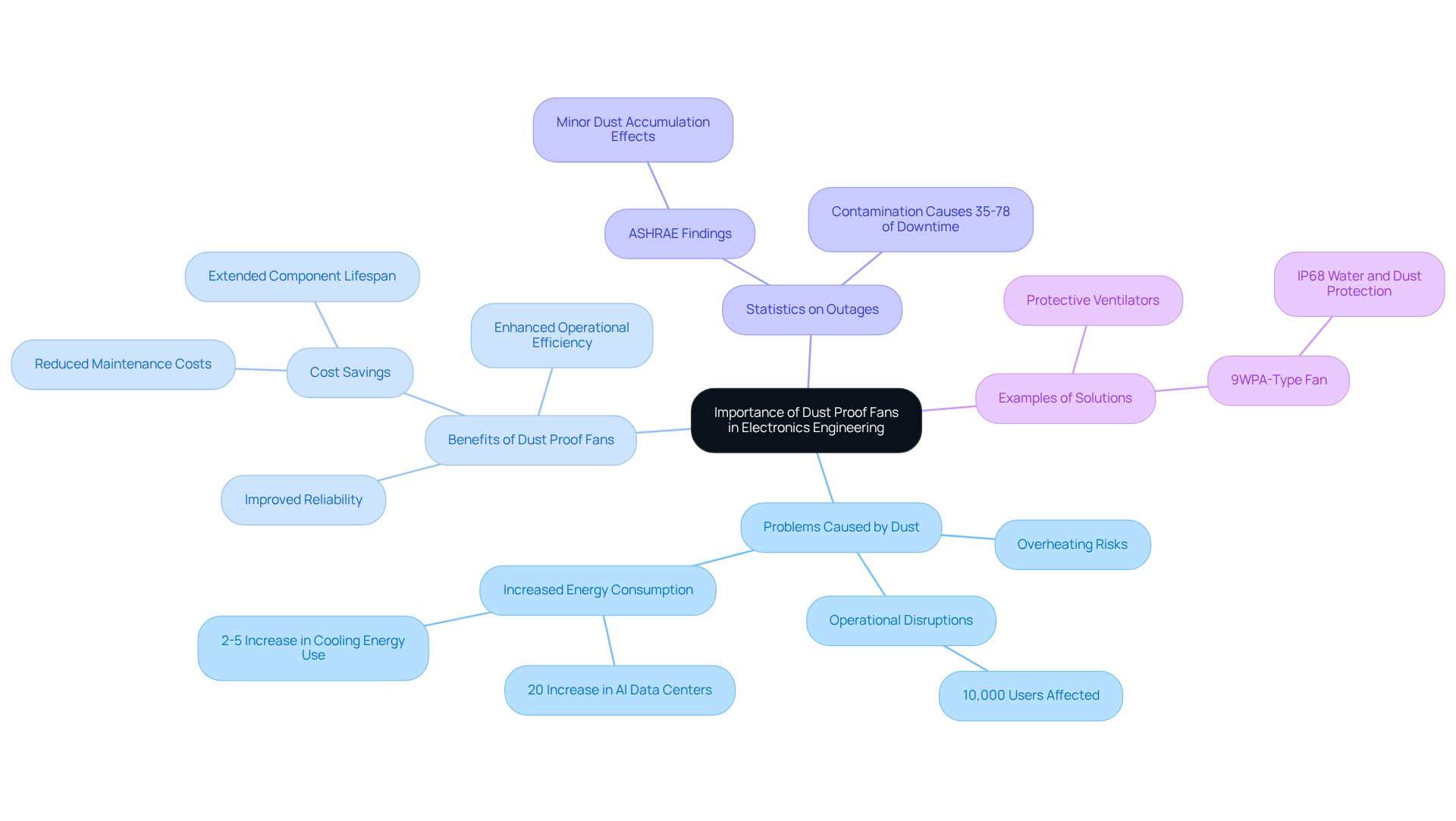

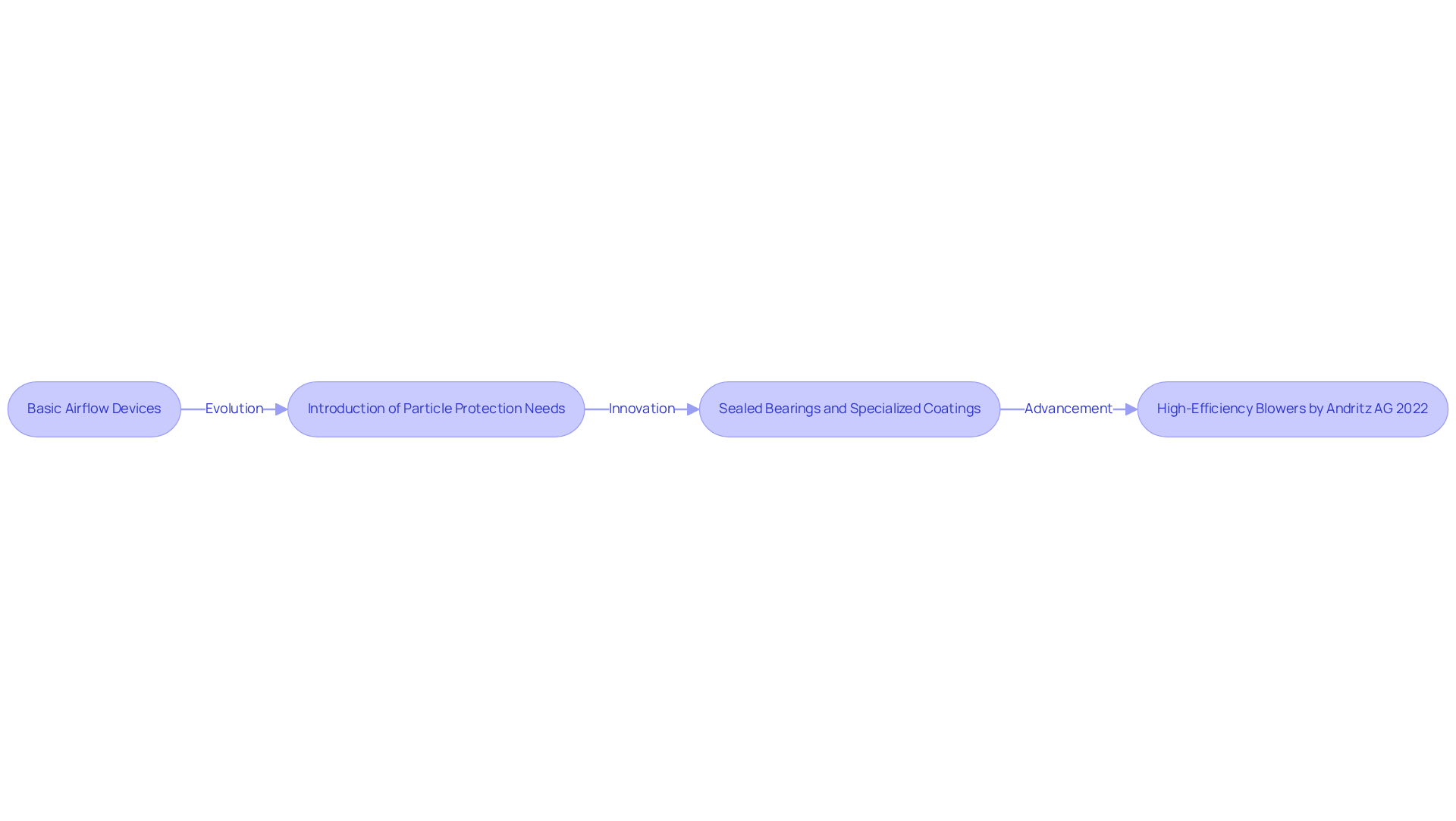

Historical Development of Dust Proof Fan Technology

The advancement of dust proof fan technology directly addresses the growing demand for reliable cooling solutions across industrial and technological sectors. Initially, devices were designed solely for basic airflow, neglecting the critical issue of debris entry. However, as electronic components became more compact and sensitive, the necessity for enhanced particle protection became increasingly clear. By the late 20th century, significant innovations emerged, such as sealed bearings and specialized coatings, marking a pivotal shift in fan design. These advancements were primarily driven by the need for improved performance in challenging environments, particularly within telecommunications, computing, and manufacturing industries.

For instance, the introduction of high-efficiency blowers by Andritz AG in 2022 exemplifies how advancements in ventilation technology have led to more effective particulate removal solutions. Furthermore, industry pioneer Gerhard Sturm highlighted that the transformative phases of fan technology underscore the importance of ongoing innovation. Case studies illustrate how these developments have resulted in the creation of modern dust proof fans, which are now essential for maintaining optimal operating conditions across various applications.

The continuous evolution of cooling solutions in electronics reflects the industry’s commitment to tackling environmental challenges and enhancing device longevity. As we move forward, it is crucial to recognize the role of these innovations in shaping the future of cooling technologies.

Types and Characteristics of Dust Proof Fans

Dust proof fans play a crucial role in various applications, each one designed to effectively tackle specific environmental challenges. Understanding the primary types can help you make informed decisions:

-

Axial Devices: These units move air parallel to their axis, making them ideal for high airflow with low pressure. Capable of moving up to 5,000 cubic feet of air per minute (CFM) at a static pressure of 0.5 inwg, they are essential for maintaining optimal temperatures in cooling systems for electronic devices. In HVAC systems, for instance, axial blowers circulate air efficiently, enhancing temperature regulation and comfort in both residential and commercial settings. Their origins trace back to Persian windmills in 500 A.D., showcasing their long-standing effectiveness in air circulation.

-

Centrifugal Devices: Unlike axial devices, centrifugal blowers draw air into the center and expel it at a right angle, generating higher pressure. These blowers can achieve pressures of up to 10 inwg with a volumetric airflow of 1,000 CFM, making them particularly effective in high-pressure applications. This design is advantageous in environments where particles and debris are prevalent, as it improves airflow management and counters resistance in ductwork. Commonly found in industrial settings, centrifugal blowers are vital for particle collection and fume removal, where air quality preservation is critical.

-

DC Brushless Devices: Known for their energy efficiency and low noise levels, these units are often used in sensitive electronic applications, such as computer cooling systems. Their design minimizes electromagnetic interference, making them suitable for environments where noise reduction is paramount.

-

High-Performance Blowers: Built for harsh environments, these devices are made from durable materials to withstand particles and moisture intrusion. They are typically employed in industrial settings where reliability and durability are essential.

Each dust proof fan type features specific characteristics, such as IP ratings (Ingress Protection), indicating their resistance to dust and water, along with specialized coatings that enhance their dust-repelling capabilities. For example, axial blowers are generally quieter and more cost-effective due to their simpler structure, making them suitable for general ventilation and cooling systems. In contrast, while centrifugal fans may be more complex and noisier, they excel in high-pressure applications, providing consistent airflow even under challenging conditions. Understanding these characteristics is vital for engineers when selecting the right fan for their specific needs. As industry specialist Ryan Smoot emphasizes, “Choosing the optimal choice will genuinely rely on the intended use, available space, and overall thermal demands of the final system.

Conclusion

Dust proof fans stand as a crucial advancement in ensuring the reliability and efficiency of electronic systems and industrial applications. By effectively preventing dust and debris from infiltrating their mechanisms, these fans not only enhance airflow and cooling efficiency but also significantly contribute to the longevity of critical components. Essential design features, such as sealed bearings and specialized coatings, play a vital role in maintaining optimal performance, particularly in environments prone to contamination.

Key insights throughout this discussion highlight the importance of dust proof fans in electronics engineering, where they prevent overheating and operational disruptions. For instance, case studies like that of IT manager Bates illustrate the real-world consequences of neglecting dust management, underscoring the necessity for these advanced cooling solutions. Moreover, the historical evolution of dust proof fan technology reflects a commitment to innovation aimed at addressing the growing challenges faced across various industries.

In summary, the significance of dust proof fans cannot be overstated. As technology continues to advance, the demand for reliable cooling solutions in increasingly compact and sensitive electronic devices will only escalate. Organizations must prioritize the integration of dust proof fans in their systems—not just to enhance operational efficiency but also to safeguard the longevity and reliability of their equipment. Embracing these innovations is crucial for navigating the future landscape of electronics and industrial applications.

Frequently Asked Questions

What is a dust proof fan?

A dust proof fan is a specialized fan designed to prevent particles and debris from entering its internal components, enhancing operational efficiency and extending the lifespan of devices.

What are the key features of Gagner-Toomey’s dust proof fan?

Key features include sealed bearings, specialized coatings, and robust housing designs that minimize particle accumulation and ensure optimal airflow and cooling efficiency.

In what environments are dust proof fans particularly important?

Dust proof fans are vital in environments where contaminants can hinder performance, such as in electronic devices, HVAC systems, and various industrial applications.

How effective are dust-resistant ventilators in removing particles?

Research indicates that dust-resistant ventilators can achieve an average particulate removal effectiveness of 90.23% for breathable particles and 93.77% for overall particles in rubber transport chutes.

What recent advancements have been made in dust proof fan technology?

Recent advancements include the incorporation of electrostatic-resistant coatings and hydrophobic surfaces, which enhance the fans’ ability to remain clean for longer durations and reduce maintenance requirements.

Why is the functionality of dust proof fans important for electronic components?

Their functionality is crucial for maintaining a clean operational environment, which facilitates optimal airflow and cooling efficiency, thereby ensuring the reliability of sensitive electronic components.

What does Gagner-Toomey Associates offer in terms of cooling solutions?

Gagner-Toomey Associates offers a comprehensive range of standard and custom air movers and blowers tailored for diverse applications, focusing on quality and innovation to meet industry needs.