Overview

The article highlights the critical importance of fan pressure in electronics engineering, underscoring its vital role in enhancing cooling efficiency and ensuring component reliability. Fan pressure significantly influences airflow, static pressure, and impedance relationships, which are essential for maintaining optimal system performance.

To illustrate this, consider how inadequate fan pressure can lead to overheating, ultimately compromising the reliability of electronic components. Therefore, selecting the right fans based on specific system requirements is not just advisable; it is imperative. This selection process directly impacts the overall effectiveness of cooling solutions, preventing potential failures and extending the lifespan of electronic devices.

In conclusion, understanding and leveraging fan pressure is crucial for engineers aiming to optimize performance in their designs. By prioritizing appropriate fan selection and considering the intricate relationships between airflow and pressure, professionals can ensure their systems operate efficiently and reliably.

Introduction

Understanding the dynamics of fan pressure is crucial for electronics engineers aiming to maintain optimal cooling in increasingly complex systems. As electronic components grow more powerful, effective thermal management becomes essential. Fan pressure emerges as a critical factor in preventing overheating and ensuring longevity.

However, engineers often grapple with the intricate relationships between airflow, static pressure, and impedance. How can they select the most suitable fans for their specific applications? This article delves into the nuances of fan pressure, offering valuable insights and practical guidance for optimizing cooling solutions in electronics engineering.

By exploring these dynamics, engineers can enhance their designs, ensuring reliability and performance in their systems.

Define Fan Pressure and Its Importance in Electronics Engineering

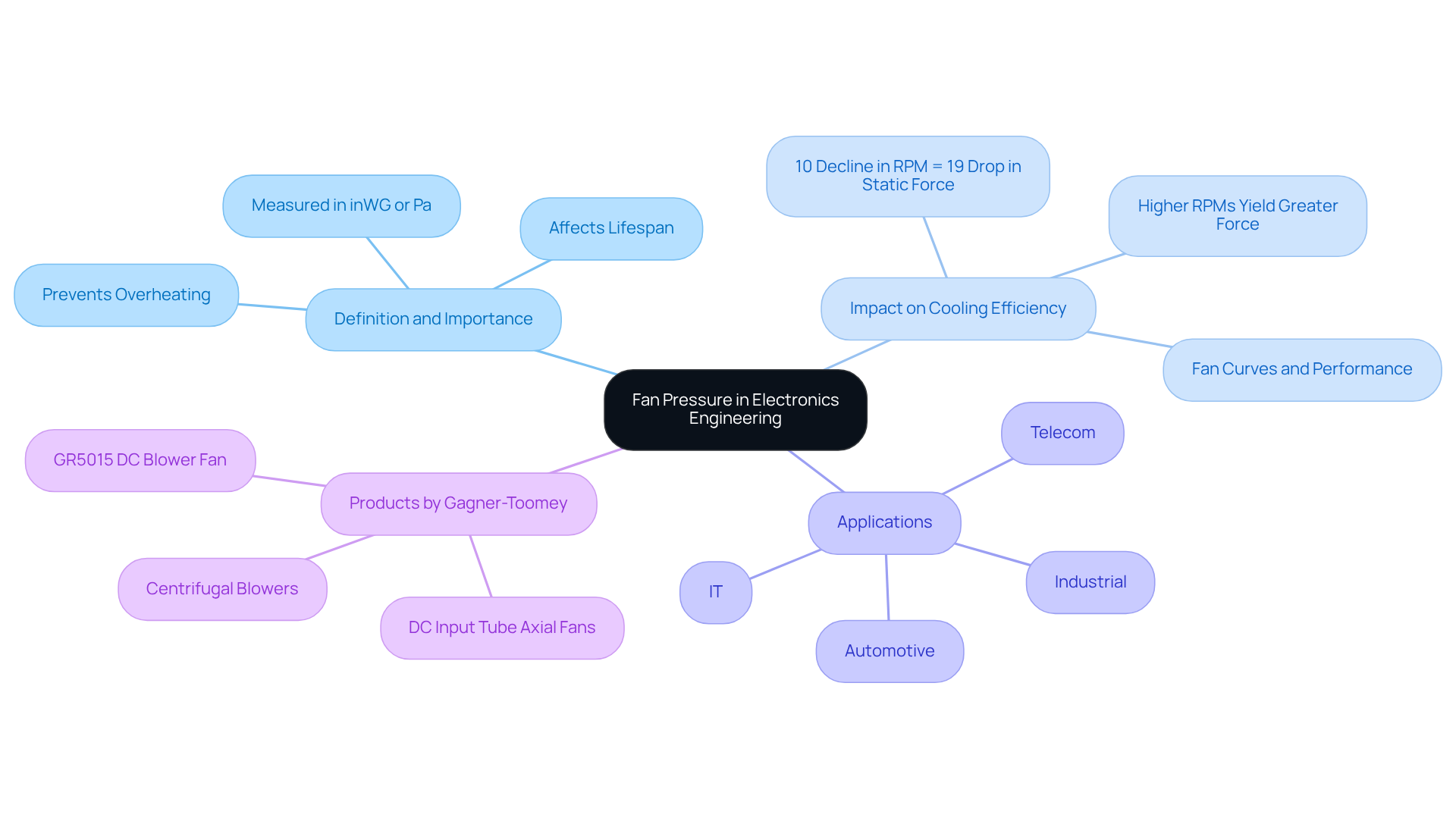

Fan force is the energy exerted by a fan to move air through a system, measured in units such as inches of water gauge (inWG) or Pascals (Pa). This concept is crucial in electronics engineering, as it directly impacts the cooling efficiency of components, ensuring they operate within safe temperature ranges. Adequate fan pressure is vital in preventing overheating, which can lead to component failure and a reduced lifespan. For instance, a mere 10% decline in fan RPM can result in a 19% drop in static force and a 10% decrease in airflow. This illustrates the critical role fan performance plays in maintaining effective cooling.

Gagner-Toomey Associates, recognized as the world’s largest manufacturer of standard and custom air-movers, provides an extensive product line of DC input Tube Axial fans and Centrifugal Blowers. These products are optimized for performance, efficiency, and low noise, making them essential for various electronics applications, including:

- Automotive

- Telecom

- IT

- Industrial sectors

In these fields, maintaining optimal fan pressure is not just beneficial; it is crucial.

Recent advancements in fan force technology, exemplified by the GR5015 DC Blower fan, demonstrate that higher RPMs yield greater force and air movement, making these fans ideal for high-velocity cooling applications. Understanding the effects of fixed resistance and air movement in relation to fan pressure and performance curves is essential for enhancing cooling efficiency and ensuring the durability and reliability of electronic components.

Gagner-Toomey’s comprehensive portfolio, which includes integrated cooling solutions and custom designs ranging from 15mm to 910mm, empowers engineers to achieve effective thermal management in high-performance applications. By leveraging these innovative solutions, professionals can ensure that their systems operate efficiently and reliably.

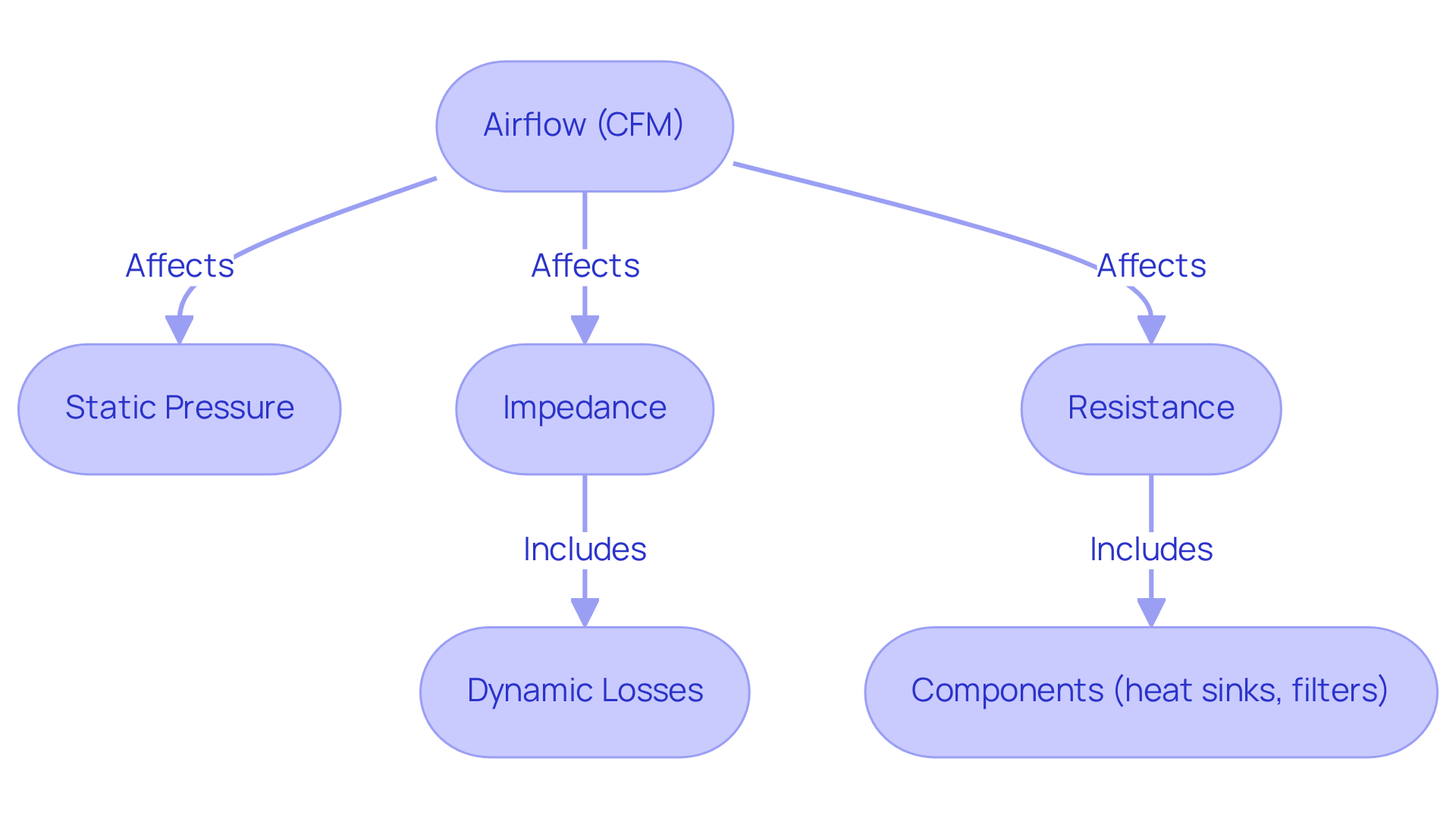

Analyze Airflow, Static Pressure, and Impedance Relationships

Airflow, ambient force, and impedance are crucial interconnected elements that dictate a fan’s effectiveness in transporting air through a system. Airflow, quantified in cubic feet per minute (CFM), indicates the volume of air a fan can move. For instance, a fan can deliver a flow of approximately 15 CFM of air at 4.5 mmH2O of resistance, showcasing how resistance impacts air movement in real-world scenarios. Conversely, static force represents the resistance encountered by this air movement as it navigates through components like heat sinks, filters, and ducts. Impedance encompasses the total resistance to air movement, integrating both fixed force and dynamic losses. Engineers must meticulously assess these connections to ensure that the fan pressure can effectively counter the system’s resistance while providing sufficient air movement.

In high-resistance environments, such as densely packed server racks, high airflow fans excel at pushing air through systems while managing fan pressure levels ranging from 10 to over 100 mmH2O, thereby ensuring optimal cooling performance. As Johann Tang notes, “The connection between air movement and resistance of a fan is illustrated in the graph above,” underscoring the importance of understanding these dynamics. A mismatch between fan capabilities and system requirements can result in inadequate cooling, increased noise levels, and ultimately, compromised system reliability.

Moreover, accessories like filters can significantly influence air movement and resistance characteristics, adding complexity to fan performance dynamics. Recognizing these factors is essential for effective fan selection and application in electronics, where maintaining optimal temperatures is vital for component longevity and performance.

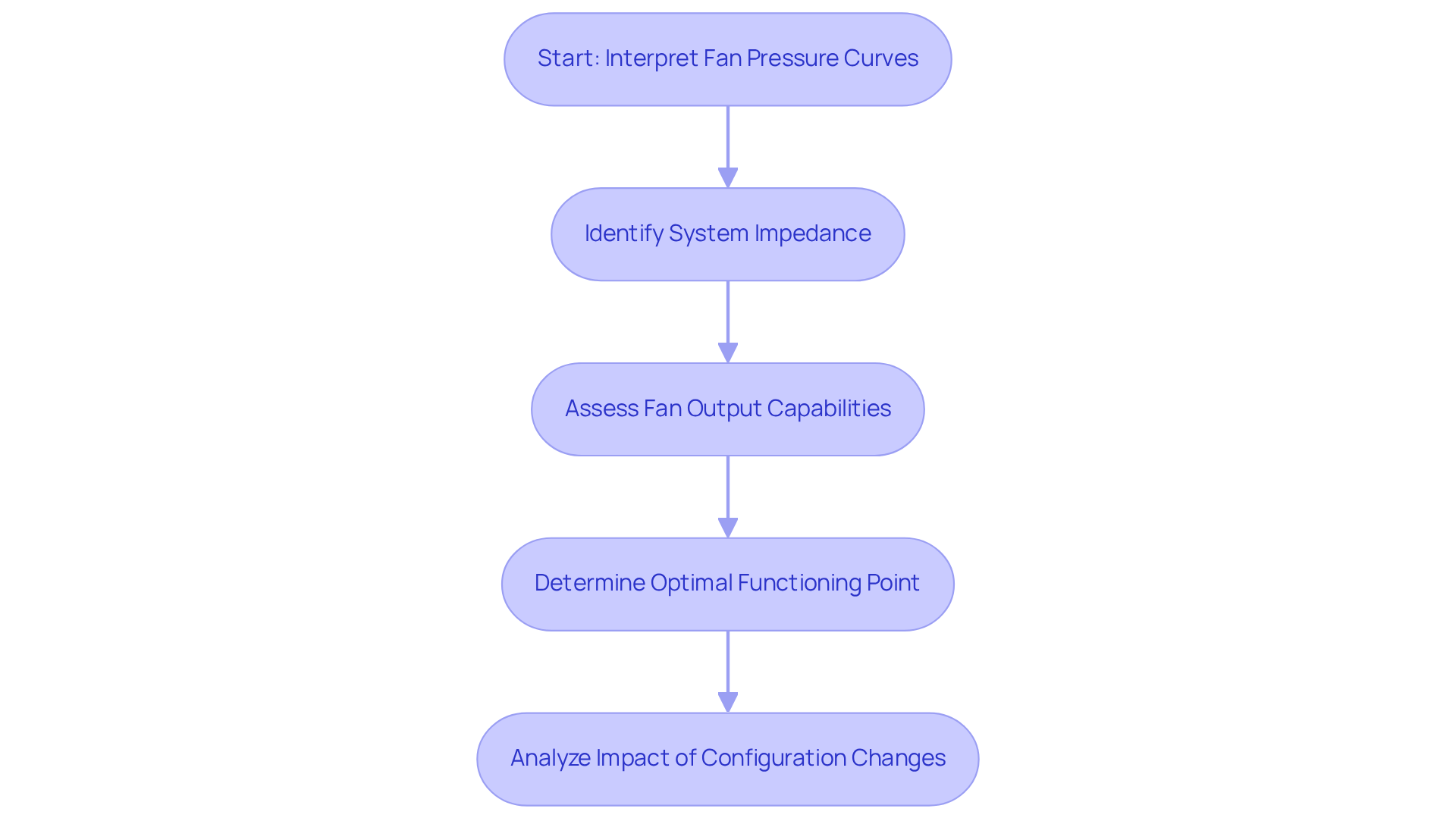

Interpret Fan Pressure Curves for Effective System Design

Fan performance curves serve as vital tools for engineers, visually illustrating the relationship between air movement (CFM) and static force (inWG or Pa) for specific fan models. These curves are essential for assessing a fan’s operational efficiency under various conditions. To interpret these curves effectively, engineers must identify the intersection where the system’s impedance aligns with the fan’s output capabilities. This point signifies the optimal functioning condition, allowing the fan to achieve the necessary air movement while maintaining adequate force. Mastering these curves is crucial for effective system design, as it enables engineers to predict how changes in system configuration will impact fan performance and fan pressure.

Industry experts emphasize that understanding fan pressure performance curves is key to improving cooling solutions in electronics. For instance, high-performance CPU cooling systems necessitate devices with sharp resistance versus movement curves to ensure efficient thermal regulation. Recent trends reveal an increasing emphasis on advanced modeling techniques, including polynomial and machine learning approaches, to enhance the accuracy of fan performance predictions across diverse operational states.

Data suggests that for maximum efficiency, devices should operate at their specified ideal settings, ensuring that circulation and resistance are balanced to optimize fan pressure. This equilibrium is essential, as deviations can result in inefficiencies and heightened energy consumption. By leveraging insights from successful fan response curve analyses, engineers can make informed decisions that enhance system reliability and efficiency, ultimately contributing to the development of innovative electronic solutions.

Select Appropriate Fans Based on System Requirements

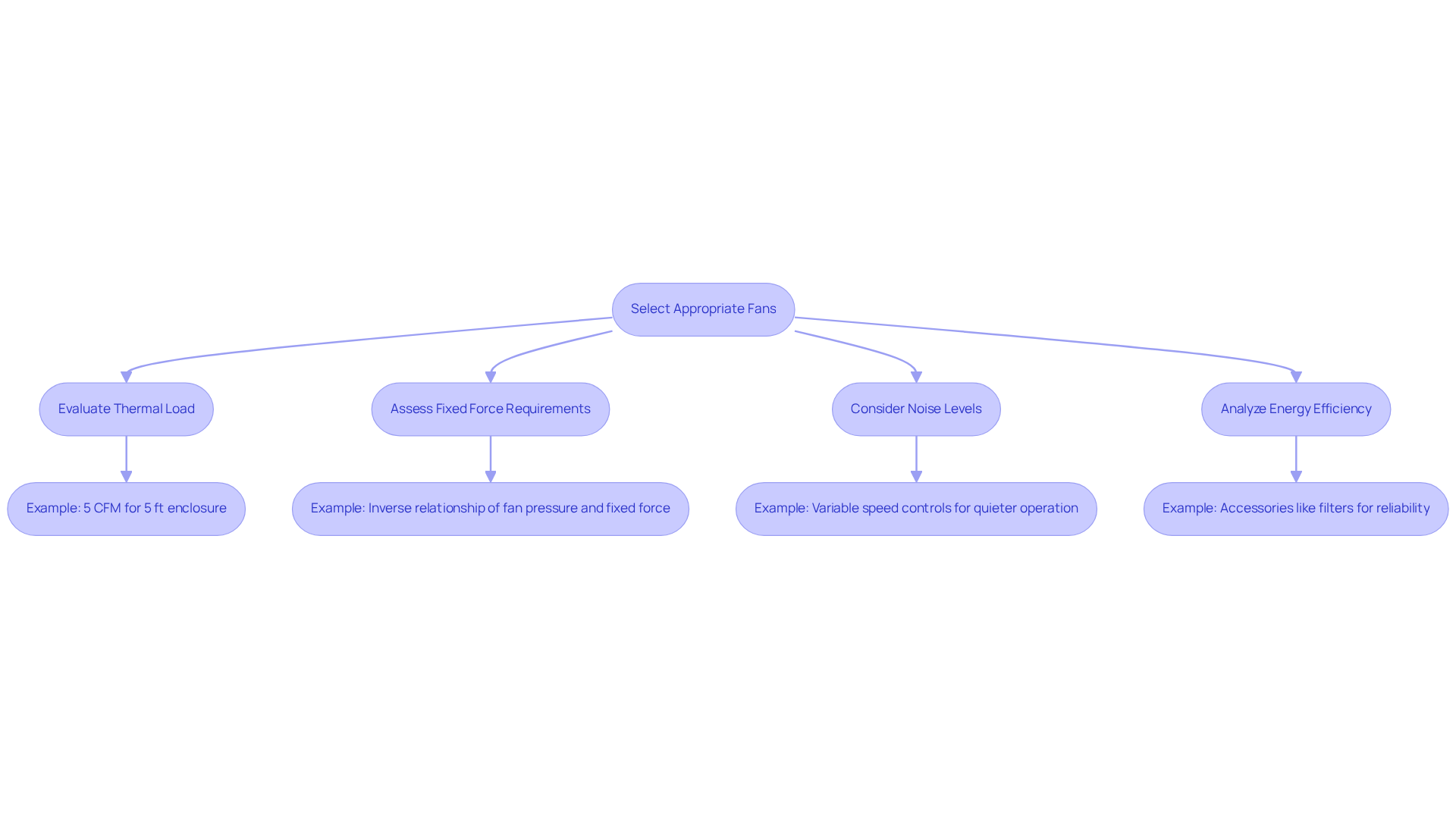

Choosing the right fans for electronic systems is a critical task that requires a strategic approach to manage fan pressure. It’s essential to consider ventilation needs, static pressure ratings, noise levels, and fan pressure for energy efficiency. Start by evaluating the thermal load produced by the components, as this is vital for determining the necessary ventilation. For instance, a fan generating 5 CFM can ventilate a 5 ft x 5 ft x 5 ft enclosure in approximately 25 minutes. This example underscores the importance of aligning ventilation with the specific cooling requirements of the system to manage fan pressure effectively.

Next, assess the fixed force requirements based on the system’s resistance and the fan pressure. It’s important to note that fan pressure and fixed force have an inverse relationship; increasing fan pressure typically reduces the other. Engineers must also be mindful of noise levels, especially in environments where sound is a significant concern. Recent advancements in fan technology have introduced variable speed controls, which not only improve energy efficiency but also facilitate quieter operation.

Energy efficiency plays a crucial role, as more effective devices can significantly reduce overall power consumption and heat generation. For example, incorporating accessories like filters can enhance reliability in dusty environments, though they may also affect airflow and static pressure characteristics. By carefully evaluating these factors, engineers can select fans that meet performance requirements while also enhancing the longevity and reliability of electronic systems.

Conclusion

Mastering fan pressure is crucial for electronics engineers, as it plays a pivotal role in ensuring effective cooling of electronic components. Understanding fan pressure not only helps maintain optimal temperatures but also extends device lifespan by preventing overheating. The intricate relationship between airflow, static pressure, and impedance must be navigated carefully to achieve desired performance across various applications, from automotive to industrial sectors.

Key insights highlighted throughout this article emphasize the importance of fan performance curves in system design. Engineers can predict and optimize fan performance based on specific system requirements. Additionally, selecting the right fans according to ventilation needs, static pressure ratings, and noise considerations is essential, underscoring a strategic approach to fan selection. Advancements in fan technology, including variable speed controls and innovative designs, further enhance the ability to manage fan pressure effectively.

Ultimately, mastering fan pressure is significant beyond mere functionality; it encompasses the reliability and efficiency of electronic systems as a whole. Engineers are encouraged to leverage the insights provided in this article to refine their approaches to cooling solutions, ensuring systems operate at peak performance. By prioritizing fan pressure management, professionals can drive innovation in electronic design, leading to more sustainable and efficient technologies in the future.

Frequently Asked Questions

What is fan pressure and why is it important in electronics engineering?

Fan pressure, or fan force, is the energy exerted by a fan to move air through a system, measured in units such as inches of water gauge (inWG) or Pascals (Pa). It is crucial in electronics engineering because it directly impacts the cooling efficiency of components, helping to maintain safe temperature ranges and prevent overheating, which can lead to component failure and reduced lifespan.

How does a decline in fan RPM affect fan performance?

A mere 10% decline in fan RPM can result in a 19% drop in static force and a 10% decrease in airflow. This highlights the critical role that fan performance plays in maintaining effective cooling.

What types of applications benefit from optimal fan pressure?

Optimal fan pressure is essential in various applications, including automotive, telecom, IT, and industrial sectors. Maintaining adequate fan pressure in these fields is crucial for effective thermal management.

What advancements have been made in fan force technology?

Recent advancements in fan force technology, such as the GR5015 DC Blower fan, show that higher RPMs yield greater force and air movement, making these fans ideal for high-velocity cooling applications.

How does Gagner-Toomey Associates contribute to fan pressure management?

Gagner-Toomey Associates, the world’s largest manufacturer of standard and custom air-movers, offers a comprehensive product line of DC input Tube Axial fans and Centrifugal Blowers optimized for performance, efficiency, and low noise. Their portfolio includes integrated cooling solutions and custom designs, empowering engineers to achieve effective thermal management in high-performance applications.

Why is understanding fan pressure and performance curves essential?

Understanding the effects of fixed resistance and air movement in relation to fan pressure and performance curves is essential for enhancing cooling efficiency and ensuring the durability and reliability of electronic components.