Overview

This article outlines the crucial steps electronics engineers must take to effectively mount fans, underscoring the significance of understanding fan types, airflow direction, thermal management, and proper installation techniques.

Understanding the problem at hand is essential: improper fan mounting can lead to inadequate cooling, which jeopardizes the performance and lifespan of electronic systems. Therefore, this article provides comprehensive guidance on the necessary tools and offers step-by-step instructions for installation. Additionally, it addresses common troubleshooting issues that may arise during the process.

By following these guidelines, engineers can ensure optimal cooling performance, which is vital for the longevity of their electronic systems. Proper fan mounting not only enhances efficiency but also contributes to the overall reliability of the equipment.

In conclusion, mastering these installation techniques is imperative for any electronics engineer aiming to achieve excellence in their projects. Take action now by implementing these strategies to elevate your cooling solutions.

Introduction

Mastering the art of fan mounting is essential for electronics engineers aiming to optimize cooling solutions in their designs. As electronic systems grow increasingly complex, a solid grasp of airflow, thermal management, and proper installation techniques becomes vital for enhancing performance and reliability. Yet, even seasoned engineers can face challenges during the mounting process. This raises an important question: what best practices can ensure a successful installation that maximizes efficiency and minimizes potential issues?

Understanding these fundamentals not only addresses common pitfalls but also empowers engineers to implement effective cooling strategies. By delving into the intricacies of airflow dynamics and thermal dissipation, engineers can significantly improve the longevity and functionality of their designs. In the following sections, we will explore actionable insights and proven techniques that can elevate your fan mounting practices to new heights.

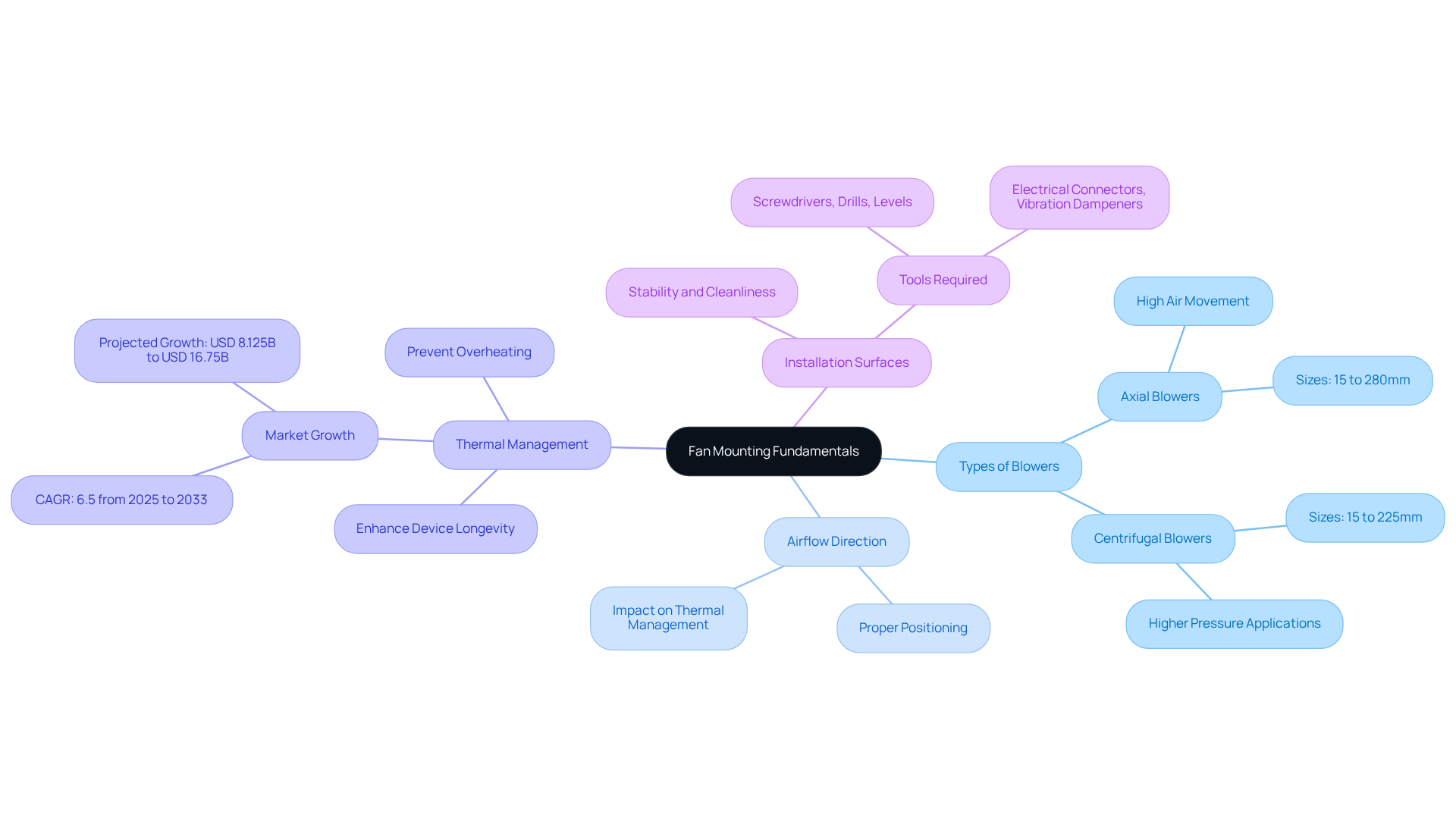

Understand Fan Mounting Fundamentals

Before diving into the fan mounting process, it’s essential to grasp the fundamental principles of fan operation and installation. Fans are designed to facilitate airflow, and their efficiency relies on several key factors:

-

Types of Blowers: Understanding the various types of blowers is crucial. Axial and centrifugal varieties serve different purposes. Gagner-Toomey Associates offers a broad selection of DC input Tube Axial devices, ranging from 15 to 280mm, which excel in cooling applications due to their capacity to move significant volumes of air—ideal for densely packed electronic components. Conversely, their centrifugal blowers, available in sizes from 15 to 225mm, are engineered for scenarios requiring higher pressure, effectively overcoming resistance in duct systems. Additionally, Gagner-Toomey provides EC units and blowers from 120 to 910mm, catering to diverse cooling needs. Most models can also be equipped with IP protection upon request, enhancing their versatility for various applications.

-

Airflow Direction: The direction of airflow is pivotal for cooling efficiency. Properly positioning air circulators can significantly enhance the thermal management of electronic components. Research shows that inadequate temperature control can reduce equipment longevity by up to 30%. Thus, ensuring fans are positioned correctly is vital for optimal performance. As Gagner-Toomey emphasizes, airflow is essential for maintaining ideal operating conditions and boosting the overall performance of electronic systems.

-

Thermal Management: Effective thermal management is critical in electronic systems to prevent overheating, which can jeopardize the reliability and lifespan of devices. Gagner-Toomey stands as the world’s largest provider of thermal management solutions for electronics cooling, offering a comprehensive portfolio that includes extruded aluminum heatsinks, copper-based heat sinks, and integrated cooling solutions. Proper fan mounting not only aids in heat dissipation but also helps maintain optimal operating conditions, thereby enhancing overall system performance. The electric cooling devices market is projected to grow from approximately USD 8.125 billion in 2024 to around USD 16.75 billion by 2033, reflecting a compound annual growth rate of 6.5% from 2025 to 2033, underscoring the rising demand for efficient cooling solutions.

-

Installation Surfaces: The stability of the installation surface is critical. It should be free from vibrations to minimize noise and inefficiency. Ensure that the area is clean and properly arranged for setup; a well-secured fan mounting will operate more effectively and contribute to improved thermal management. Essential tools for fan installation include screwdrivers, drills, levels, wire strippers, and multimeters, along with materials like screws, anchors, electrical connectors, and vibration dampeners. Consider utilizing Gagner-Toomey’s recommended products for optimal results.

By mastering these fundamentals, engineers can ensure their fan setups are successful, leading to enhanced cooling solutions and improved performance of electronic systems.

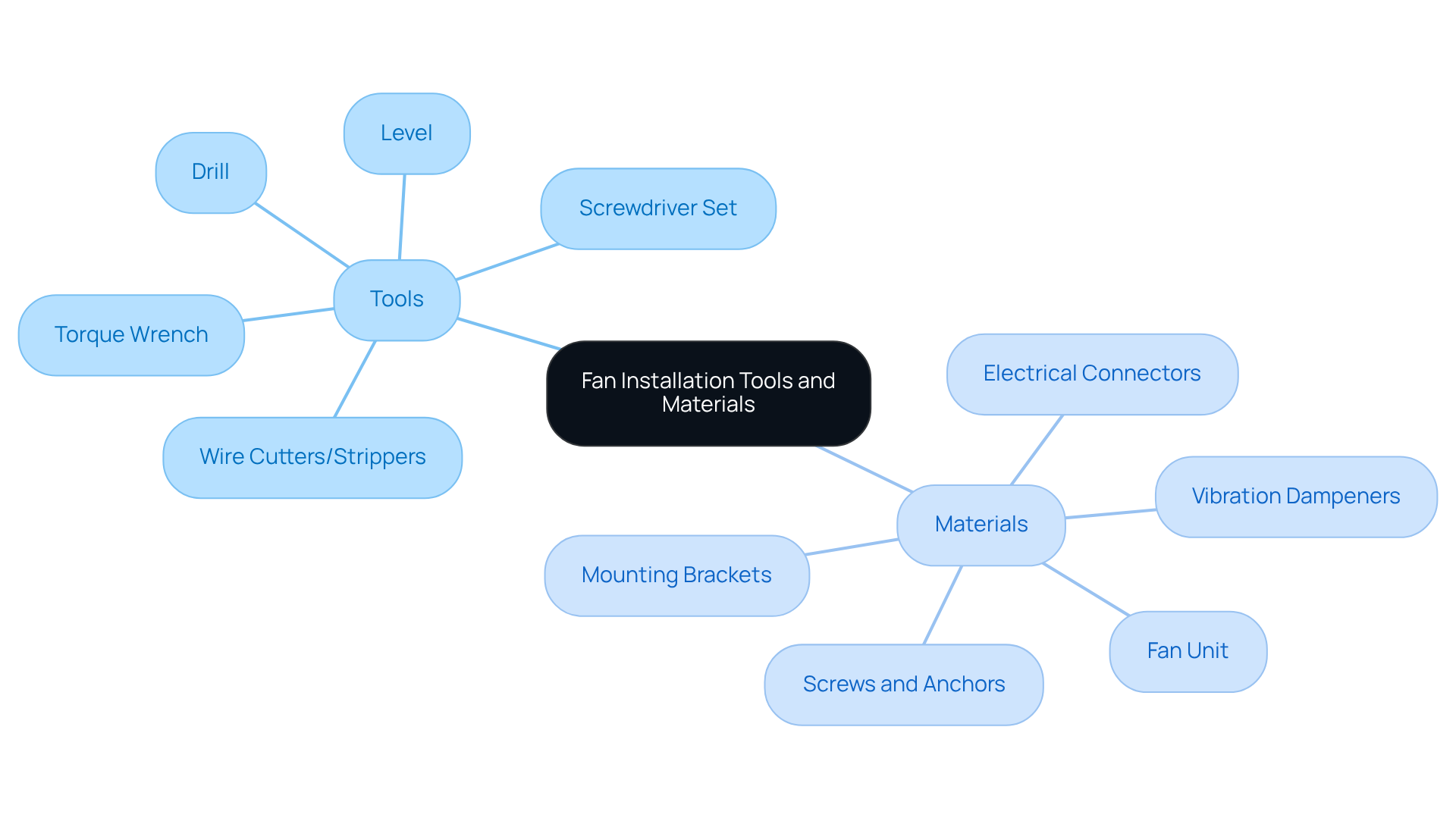

Gather Essential Tools and Materials

To successfully mount a fan, gathering the right tools and materials is essential:

Tools:

- Screwdriver set (both flathead and Phillips)

- Drill with appropriate bits for mounting

- Level to ensure proper alignment

- Wire cutters/strippers for electrical connections

- Torque wrench to secure screws to the correct specifications

Materials:

- Fan unit that meets the specific requirements of your application

- Mounting brackets tailored to the fan type

- Screws and anchors suitable for the mounting surface

- Vibration dampeners, which can significantly reduce operational noise and enhance performance

- Electrical connectors, if applicable for wiring

Before starting the installation, ensure safety by turning off power at the breaker box and using a voltage tester to confirm no live current in the wires. Removing obstacles from the setup area is also crucial to prevent accidents and guarantee a seamless process.

Having these tools and materials easily accessible simplifies the setup process and reduces the likelihood of mistakes. For instance, using vibration dampeners can improve fan efficiency by up to 30%, making them a valuable addition in environments where noise reduction is critical. Furthermore, ensuring compatibility of the fan unit and support brackets during fan mounting is vital for optimal performance and safety. Proper preparation and adherence to specifications for fan mounting will ensure a successful installation, enhancing both functionality and longevity of the fan system.

As Azael Electrical emphasizes, “Using the correct materials for fan installation is crucial for safety and efficiency.” If you need expert help, contact us today to schedule an appointment. Your safety and satisfaction are our top priorities.

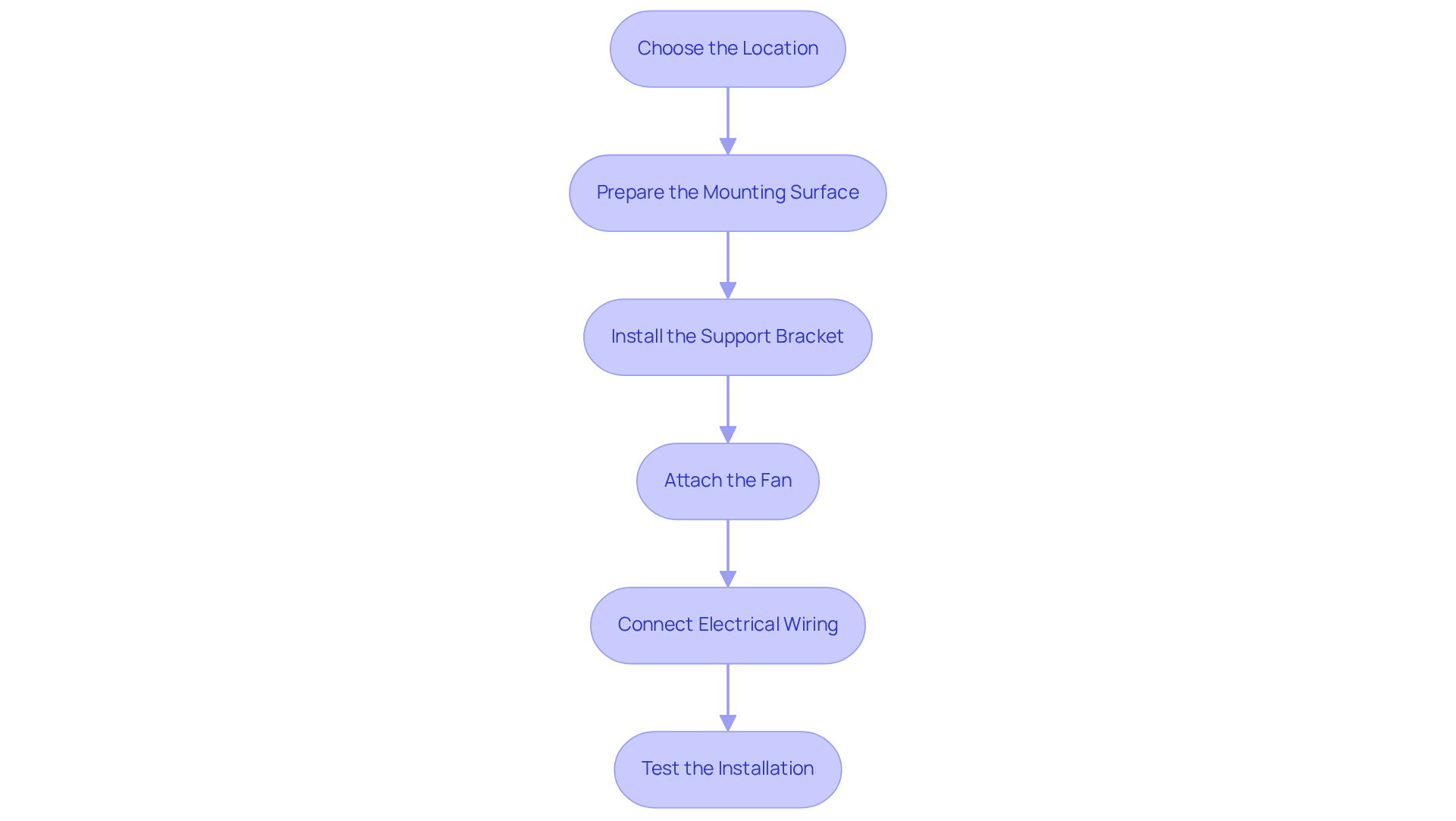

Follow Step-by-Step Mounting Instructions

To successfully mount your fan, follow these step-by-step instructions:

-

Choose the Location: Start by identifying the optimal location for your fan. Consider the airflow direction and its proximity to heat sources. To maximize efficiency, ensure the area is free from obstructions for fan mounting.

-

Prepare the Mounting Surface: Clean the surface where the fan will be mounted. If necessary, reinforce the area to guarantee stability for fan mounting, ensuring a secure installation.

-

Install the Support Bracket: Secure the support bracket to the surface using screws and anchors. Utilize a level to confirm that it is straight, as this is crucial for proper fan mounting and operation.

-

Attach the Fan: Align the fan with the mounting bracket and secure it using the provided screws. Ensure that the fan mounting is firmly attached and does not wobble, as stability is key to performance.

-

Connect Electrical Wiring: If your fan requires electrical connections, carefully strip the wires and connect them according to the manufacturer’s instructions. Use electrical connectors to secure these connections, ensuring safety and reliability.

-

Test the Installation: Once everything is secured, power on the fan to ensure it operates correctly. Check for any unusual noises or vibrations that may indicate improper installation. This final step is essential to confirm that your fan mounting is functioning as intended.

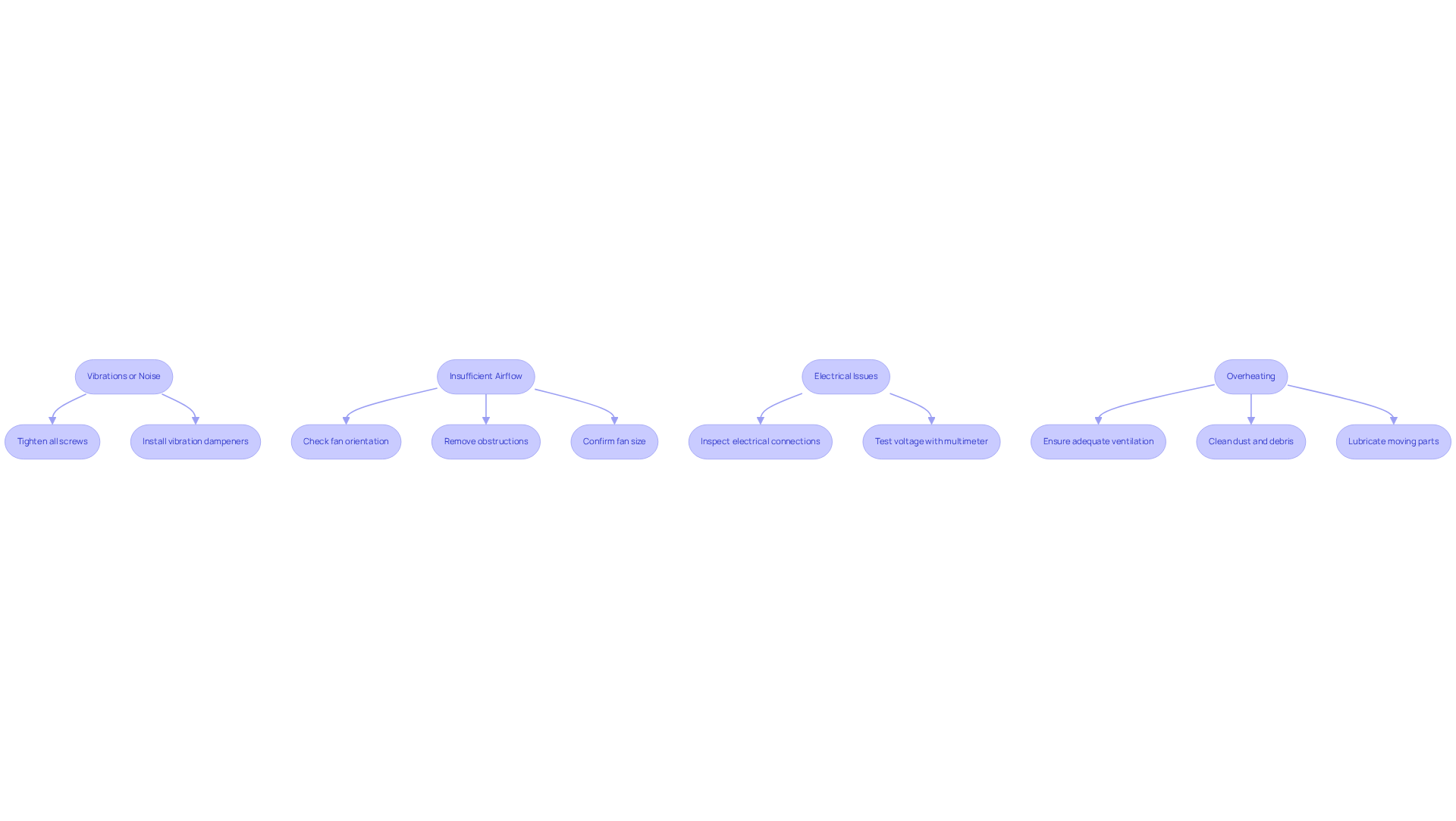

Troubleshoot Common Mounting Issues

When encountering challenges during or after the fan mounting process, it’s crucial to implement effective troubleshooting strategies:

-

Vibrations or Noise: Excessive noise or vibrations often stem from loose screws or an unstable mounting surface. Ensure all screws are securely tightened. Additionally, consider installing vibration dampeners, which can significantly reduce noise levels in fan installations. Industry sources indicate that using vibration dampeners can decrease noise by up to 30%, thereby enhancing overall comfort in the environment.

-

Insufficient Airflow: If the fan appears to be underperforming, first check its orientation and ensure there are no obstructions in the airflow path. Confirm that the fan size is appropriate for the intended application, as improper sizing can severely hinder performance. For example, a case study revealed that using a fan that is too small for a room can reduce airflow efficiency by 40%.

-

Electrical Issues: For fans that fail to power on, inspect the electrical connections for loose wires or incorrect configurations. Utilizing a multimeter to test voltage at the fan terminals can help identify any electrical faults. Regular checks of electrical connections are essential to prevent potential failures and ensure longevity.

-

Overheating: If the fan is overheating, it may be obstructed by dust or debris. Ensure that the installation site allows for adequate ventilation and that the fan is free from blockages. Overheating can also occur due to friction from a lack of lubrication; therefore, regular maintenance is vital to keep the fan operating smoothly.

By adhering to these troubleshooting steps, you can effectively address common issues with fan mounting, ensuring optimal fan performance and longevity.

Conclusion

Mastering fan mounting techniques is essential for electronics engineers who want to boost the performance and longevity of electronic systems. Proper fan installation not only ensures efficient airflow but also plays a critical role in thermal management, keeping devices within optimal temperature ranges. By grasping the fundamentals of fan operation and following best practices, engineers can develop effective cooling solutions that significantly enhance system reliability.

This article discussed several key insights, such as:

- The importance of selecting the right type of blower for specific applications

- Ensuring proper airflow direction

- Maintaining stable installation surfaces

The necessity of using appropriate tools and materials was highlighted, along with a detailed step-by-step guide for successfully mounting a fan. Additionally, common troubleshooting strategies were provided to tackle potential issues like vibrations, insufficient airflow, and electrical concerns, equipping engineers to handle challenges that may arise during installation.

The significance of effective fan mounting cannot be overstated. As the demand for advanced cooling solutions continues to grow, engineers must prioritize proper installation techniques to protect the performance and durability of electronic devices. By implementing the strategies outlined in this guide, engineers can contribute to the development of more reliable and efficient electronic systems, ultimately fostering enhanced technological advancements in the field.

Frequently Asked Questions

What are the key types of blowers mentioned in the article?

The article mentions two key types of blowers: axial and centrifugal. Axial blowers are designed for cooling applications and can move significant volumes of air, while centrifugal blowers are engineered for scenarios requiring higher pressure to overcome resistance in duct systems.

How does airflow direction impact cooling efficiency?

Properly positioning air circulators is crucial for enhancing thermal management of electronic components. Inadequate temperature control can reduce equipment longevity by up to 30%, making correct airflow direction vital for optimal performance.

Why is thermal management important in electronic systems?

Effective thermal management prevents overheating, which can jeopardize the reliability and lifespan of electronic devices. Proper fan mounting aids in heat dissipation and helps maintain optimal operating conditions, enhancing overall system performance.

What is the projected growth of the electric cooling devices market?

The electric cooling devices market is projected to grow from approximately USD 8.125 billion in 2024 to around USD 16.75 billion by 2033, reflecting a compound annual growth rate of 6.5% from 2025 to 2033.

What should be considered regarding the installation surface for fan mounting?

The installation surface should be stable and free from vibrations to minimize noise and inefficiency. A clean and properly arranged area contributes to effective fan operation and improved thermal management.

What tools and materials are essential for fan installation?

Essential tools for fan installation include screwdrivers, drills, levels, wire strippers, and multimeters. Necessary materials include screws, anchors, electrical connectors, and vibration dampeners.

How can understanding fan mounting fundamentals benefit engineers?

By mastering fan mounting fundamentals, engineers can ensure successful fan setups, leading to enhanced cooling solutions and improved performance of electronic systems.