Introduction

High pressure fan blowers are increasingly essential in industries that require efficient cooling and ventilation solutions. Engineers face the challenge of optimizing performance while managing the complexities of airflow and pressure requirements. Understanding the latest advancements and key features of these devices is crucial for making informed decisions. What obstacles do engineers encounter when selecting the right high pressure fan blower? Innovative technologies and expert insights can provide the clarity needed to navigate these challenges.

This article explores ten critical insights that illuminate the capabilities, benefits, and best practices surrounding high pressure fan blowers. By delving into these insights, engineers will be equipped with the knowledge necessary to excel in their projects.

Gagner-Toomey Associates: Innovative Solutions for High Pressure Fan Blowers

Gagner-Toomey Associates stands at the forefront of the electronics sector, delivering innovative solutions tailored for high pressure fan blowers. Since 1981, the company has built a rich history serving Northern California’s technology markets, leveraging extensive experience and a synergistic line card to represent a diverse portfolio of manufacturers. This approach guarantees that engineers have access to cutting-edge technologies designed to optimize performance and efficiency.

As the demand for advanced cooling technologies intensifies, Gagner-Toomey focuses on understanding customer needs and nurturing strong relationships. This commitment facilitates the development of products that not only meet but exceed industry standards. The worldwide industrial fans and exhaust systems market is projected to grow from $23.49 billion in 2024 to $36.98 billion by 2034, reflecting a compound annual growth rate (CAGR) of 4.64% from 2025 to 2034.

Recent advancements in high pressure fan blower technologies, including LONGWELL’s EC motor technology, which can achieve energy efficiency improvements of up to 90%, exemplify the innovative solutions Gagner-Toomey champions. Expert insights underscore the importance of these technologies in enhancing cooling systems, particularly in the electronics sector, where effective thermal management is vital for reliability and efficiency.

Gagner-Toomey Associates is strategically positioned to capitalize on this market growth through its consultative approach and unwavering commitment to delivering specialized solutions across thermal, power, RF, interconnect, and electromechanical technologies.

Performance Range: Understanding the Capabilities of High Pressure Fan Blowers

The high pressure fan blower devices from Gagner-Toomey Associates stand out for their exceptional efficiency across a broad spectrum of performance metrics. Capable of achieving static pressures exceeding 100 inches of water column (WC) and airflow rates ranging from 100 to 50,000 cubic feet per minute (CFM), high pressure fan blowers are crucial for engineers tasked with selecting fans that can effectively overcome specific system resistances and fulfill precise airflow requirements.

Gagner-Toomey offers a robust portfolio of DC input centrifugal ventilators and tube axial fans, all optimized for performance, efficiency, and low noise. This makes them ideal for a variety of applications in the electronics, automotive, and industrial sectors. Recent advancements in fan technology, particularly the integration of EC motors and optimized impeller designs, have led to significant efficiency improvements, enabling energy savings of up to 40% at partial loads.

In practical applications, high pressure fan blowers are utilized in environments such as industrial drying processes and HVAC systems, where they facilitate rapid moisture removal and ensure consistent airflow. Understanding the relationship between static pressure and airflow rates is vital; high pressure fan blowers typically generate static pressures around 15 inches of water gauge (in. wg), making them particularly suited for applications involving a high pressure fan blower.

By leveraging these capabilities, engineers can ensure optimal performance in cooling, ventilation, and pneumatic conveying systems, supported by Gagner-Toomey’s innovative cooling solutions.

Key Features: Essential Attributes of High Pressure Fan Blowers

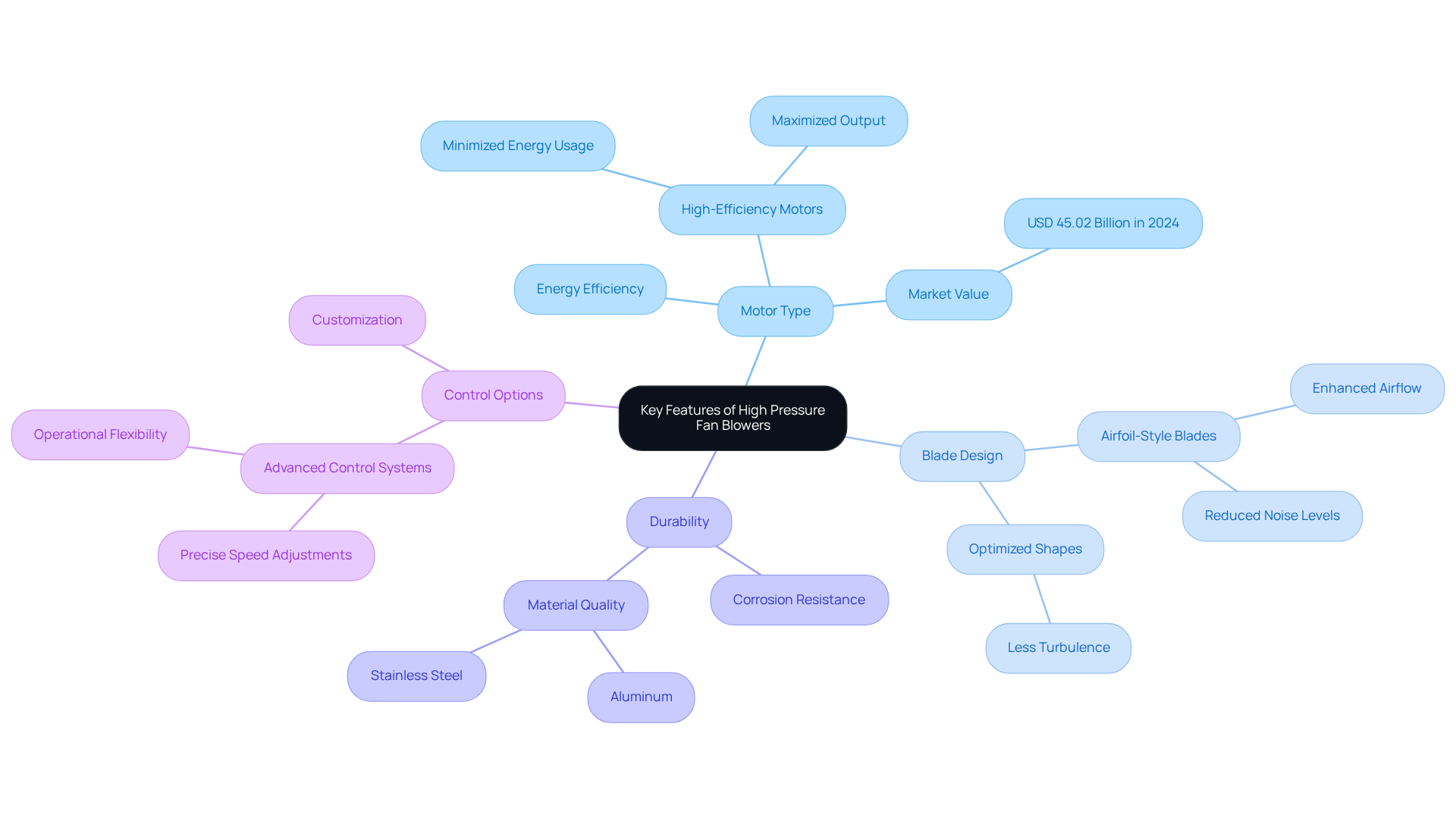

When selecting high pressure fan blowers, engineers must prioritize several essential features that significantly impact their performance and efficiency.

-

Motor Type: The choice of motor is crucial, as it directly influences energy efficiency and operational performance. High-efficiency motors are specifically designed to minimize energy usage while maximizing output. This makes them a vital consideration in fan selection. Notably, the global energy-efficient motor market was valued at USD 45.02 billion in 2024, highlighting the importance of selecting the right motor technology.

-

Blade Design: Innovations in blade design, particularly airfoil-style blades, enhance airflow and pressure capabilities. These optimized shapes not only improve efficiency but also reduce noise levels, contributing to a more comfortable operational environment. Airfoil blades are recognized as the most efficient design, facilitating smoother airflow with less turbulence, which is essential for maintaining high performance in demanding applications.

-

Durability: The longevity and reliability of high-pressure devices are heavily influenced by the materials used in their construction. High-quality metals, such as stainless steel and aluminum, are preferred for their corrosion resistance and ability to withstand harsh environments. This ensures that the devices operate efficiently over time, even in extreme conditions.

-

Control Options: Advanced control systems are indispensable for achieving precise speed adjustments, enhancing energy efficiency and operational flexibility. These systems empower engineers to customize fan operation according to specific application requirements, thereby improving overall system efficiency through dynamic speed modifications based on temperature.

By concentrating on these essential characteristics, engineers can make informed decisions that significantly enhance the efficiency and durability of the high pressure fan blower.

Benefits: Why Choose High Pressure Fan Blowers for Your Projects

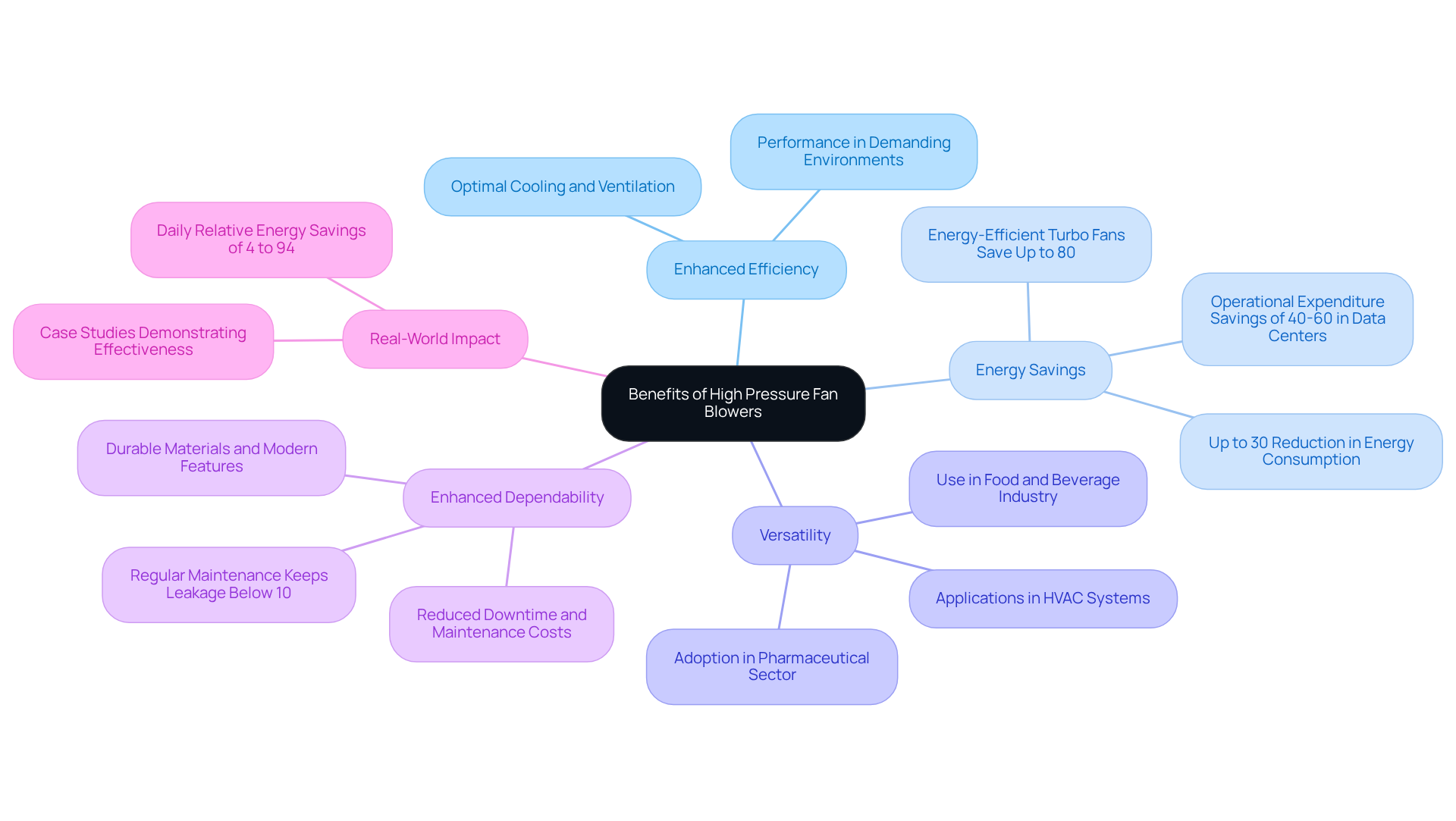

High-pressure fan blowers offer significant advantages for engineering projects:

- Enhanced Efficiency: Designed to effectively move air against high resistance, these blowers ensure optimal cooling and ventilation. This capability is crucial for maintaining system performance in demanding environments.

- Energy Savings: By integrating advanced motor technologies, energy consumption can be reduced by up to 30% compared to traditional models. Furthermore, energy-efficient turbo fans can cut energy use by as much as 80%, leading to substantial operational cost savings. For instance, facilities utilizing a high pressure fan blower have reported operational expenditure savings of 40-60% in data centers, as highlighted in various case studies.

- Versatility: The high pressure fan blower is adaptable across a range of applications, from HVAC systems to industrial processes, including the food and beverage and pharmaceutical sectors. This versatility makes them suitable for diverse operational needs.

- Enhanced Dependability: Constructed with durable materials and equipped with modern features, these devices provide steady operation, significantly reducing downtime and maintenance costs. Regular maintenance is essential to keep leakage below 10% for optimal operation, ensuring reliability in high-stakes environments.

- Real-World Impact: Case studies demonstrate that high pressure fan blowers not only enhance airflow but also contribute to energy savings. Some installations have achieved daily relative energy savings between 4% and 94%. This showcases their effectiveness in improving system performance while minimizing energy consumption.

Higher Capacities: Meeting Demands with High Pressure Fan Blowers

As industries evolve, the demand for higher capacity fans is on the rise. Gagner-Toomey Associates, the world’s largest producer of both standard and custom air-movers, offers devices such as the high pressure fan blower, engineered to deliver substantial airflow while maintaining high static pressure. These devices are ideal for applications such as:

- Dust collection

- Pneumatic conveying

- Industrial ventilation

With capacities reaching up to 50,000 CFM, Gagner-Toomey’s solutions effectively address the increased airflow requirements of modern systems, ensuring optimal performance even in the most challenging environments. Their extensive portfolio features DC input centrifugal fans alongside a variety of custom cooling solutions, positioning them as a leading provider of innovative cooling technologies for electronics and beyond.

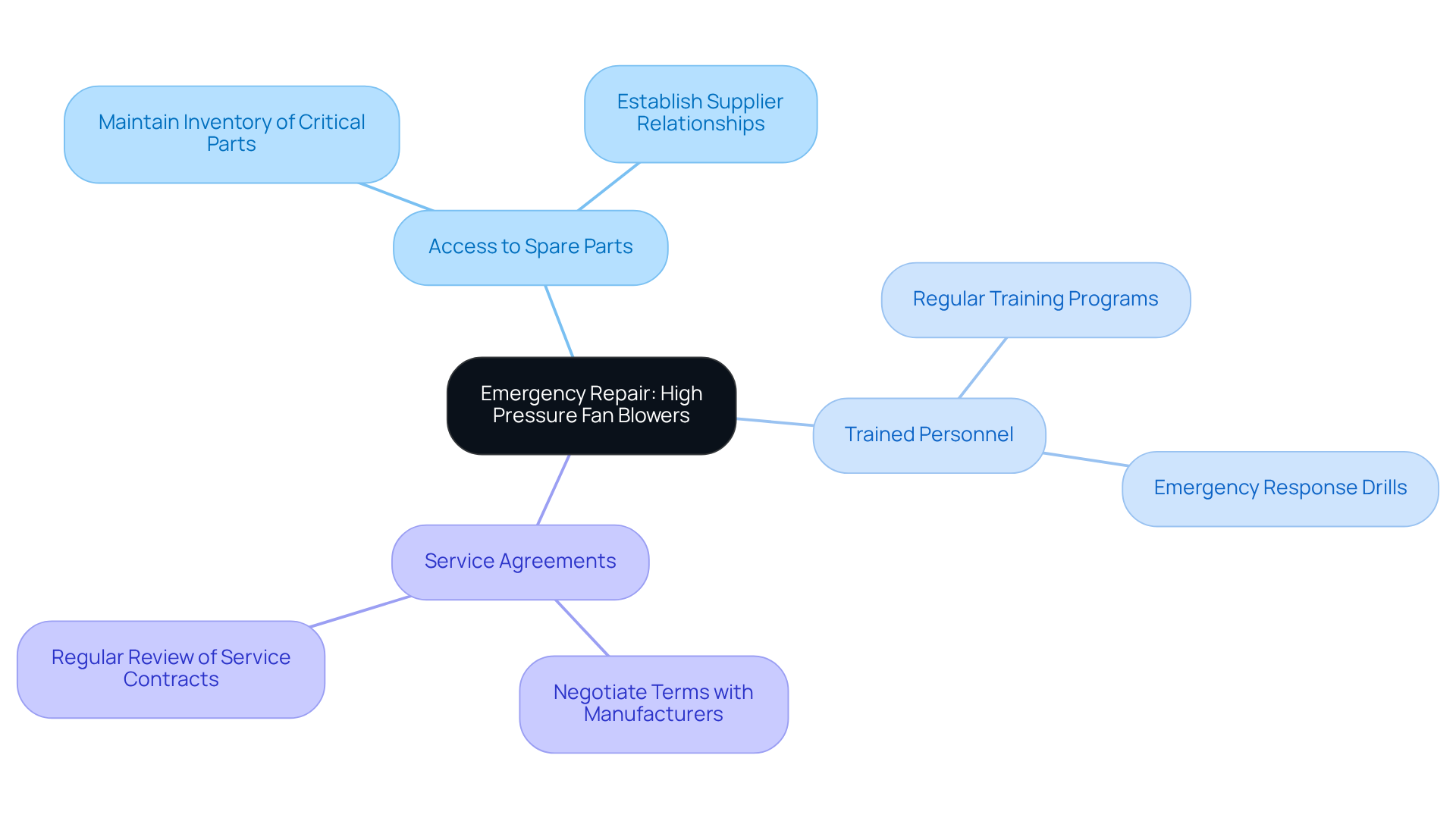

Emergency Repair: Ensuring Reliability of High Pressure Fan Blowers

In critical applications, the reliability of the high pressure fan blower is essential for maintaining operational integrity. Engineers must implement robust protocols for emergency repairs to minimize downtime. This includes:

- Ensuring access to spare parts

- Having trained personnel on standby

- Establishing service agreements with manufacturers

Regular maintenance checks are vital, as they help identify potential issues before they escalate into failures. This proactive approach not only ensures that blowers operate efficiently but also enhances their reliability under varying conditions. For instance, a well-structured maintenance schedule based on usage and environmental factors can significantly extend the lifespan of these systems. Routine inspections can uncover wear and tear that might otherwise go unnoticed.

According to recent statistics, the adoption of high-performance centrifugal devices in manufacturing units has risen by 40%, highlighting the increasing significance of reliability in these systems. Additionally, centrifugal fans can achieve energy savings of up to 30% compared to traditional methods, further emphasizing the efficiency benefits of reliable fan systems.

By emphasizing these strategies, engineers can protect against unforeseen interruptions and sustain peak effectiveness in demanding situations.

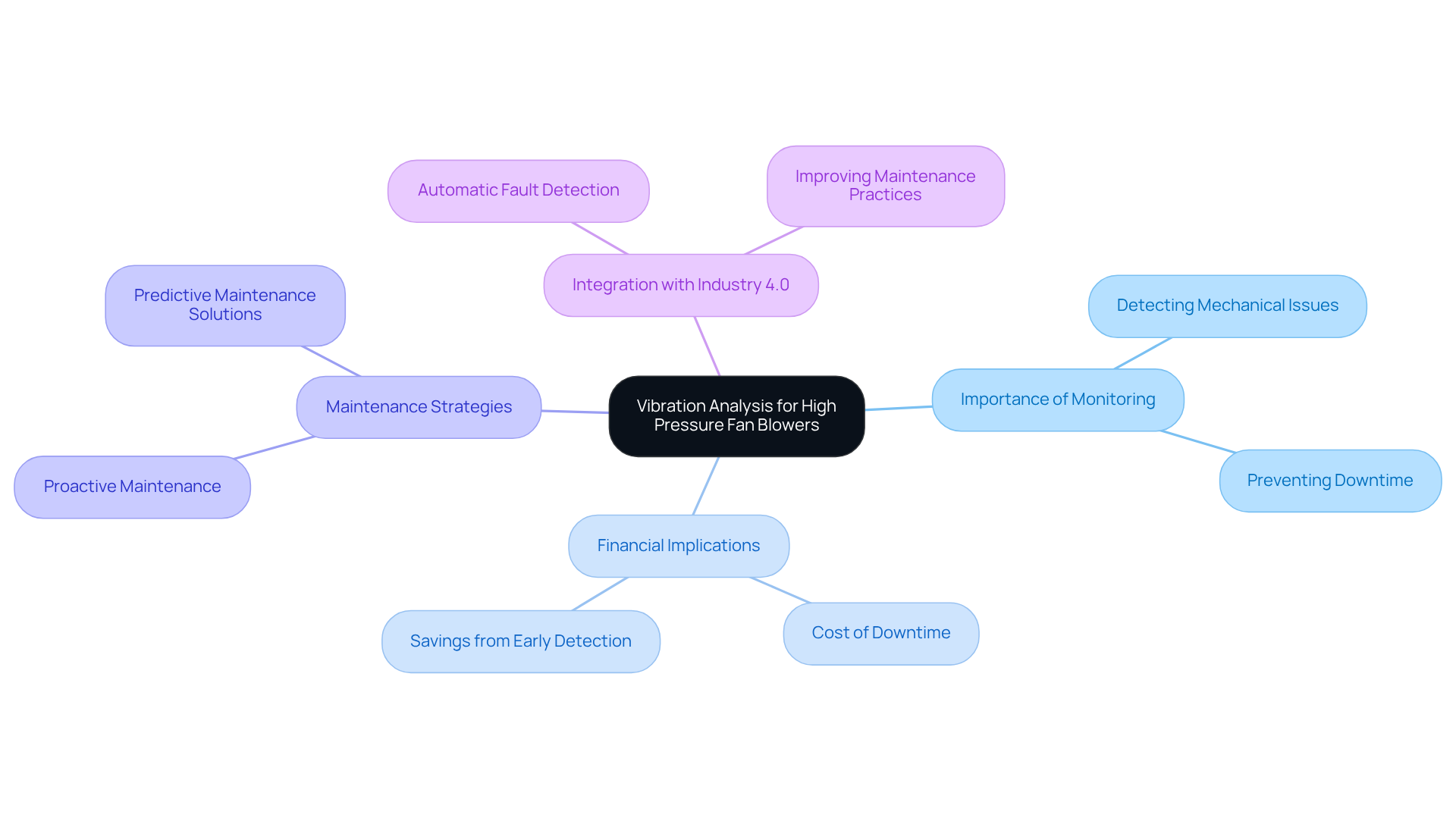

Vibration Analysis: Monitoring Performance of High Pressure Fan Blowers

Vibration analysis serves as a vital tool for monitoring the efficiency of high pressure fan blower units. By regularly assessing vibration levels, engineers can detect early signs of mechanical issues, such as imbalance or misalignment, which may lead to significant operational failures. For example, studies reveal that excessive vibrations can result in costly downtime, with each critical fault potentially costing up to $1,200 per hour. Furthermore, early fault detection has been shown to prevent $9,600 in lost production, highlighting the financial implications of effective monitoring.

Implementing a robust vibration monitoring program allows organizations to adopt proactive maintenance strategies, ensuring fans operate within optimal performance parameters and extending their service life. This approach not only enhances reliability but also contributes to energy efficiency. Predictive maintenance solutions can reduce energy waste by $537 daily, potentially translating to over $100,000 annually across monitored equipment.

Recent findings indicate that integrating vibration monitoring technologies aligns with Industry 4.0 principles, facilitating automatic fault detection and improving overall maintenance practices for high pressure fan blowers. Predictive maintenance emerges as a crucial tool in automating these processes, further boosting operational efficiency.

Custom Fans: Tailoring High Pressure Solutions for Specific Needs

Custom high pressure fan blower units are essential for applications where standard models fall short. Gagner-Toomey Associates empowers engineers to collaborate on designing blowers tailored to unique dimensions, airflow requirements, and pressure specifications. Their extensive product line includes a diverse range of DC input Tube Axial fans, with sizes from 15 to 280mm, and Centrifugal Blowers, ranging from 15 to 225mm. These products are optimized for efficiency and low noise, ensuring seamless compatibility with existing infrastructure.

Custom solutions not only enhance system performance but also improve energy efficiency, ultimately leading to superior project outcomes. The rising demand for oil-free and Class 0-certified devices in sectors like food & beverage and wastewater treatment underscores the importance of customized solutions. As one engineer aptly noted, “Creating customized high pressure fan blowers enables us to satisfy specific operational requirements that standard models cannot fulfill.”

With the market for air-moving devices valued at USD 3.7 billion in 2023 and projected to grow to USD 4.6 billion by 2028, investing in custom air-moving solutions from Gagner-Toomey is crucial for optimizing systems to meet unique operational needs.

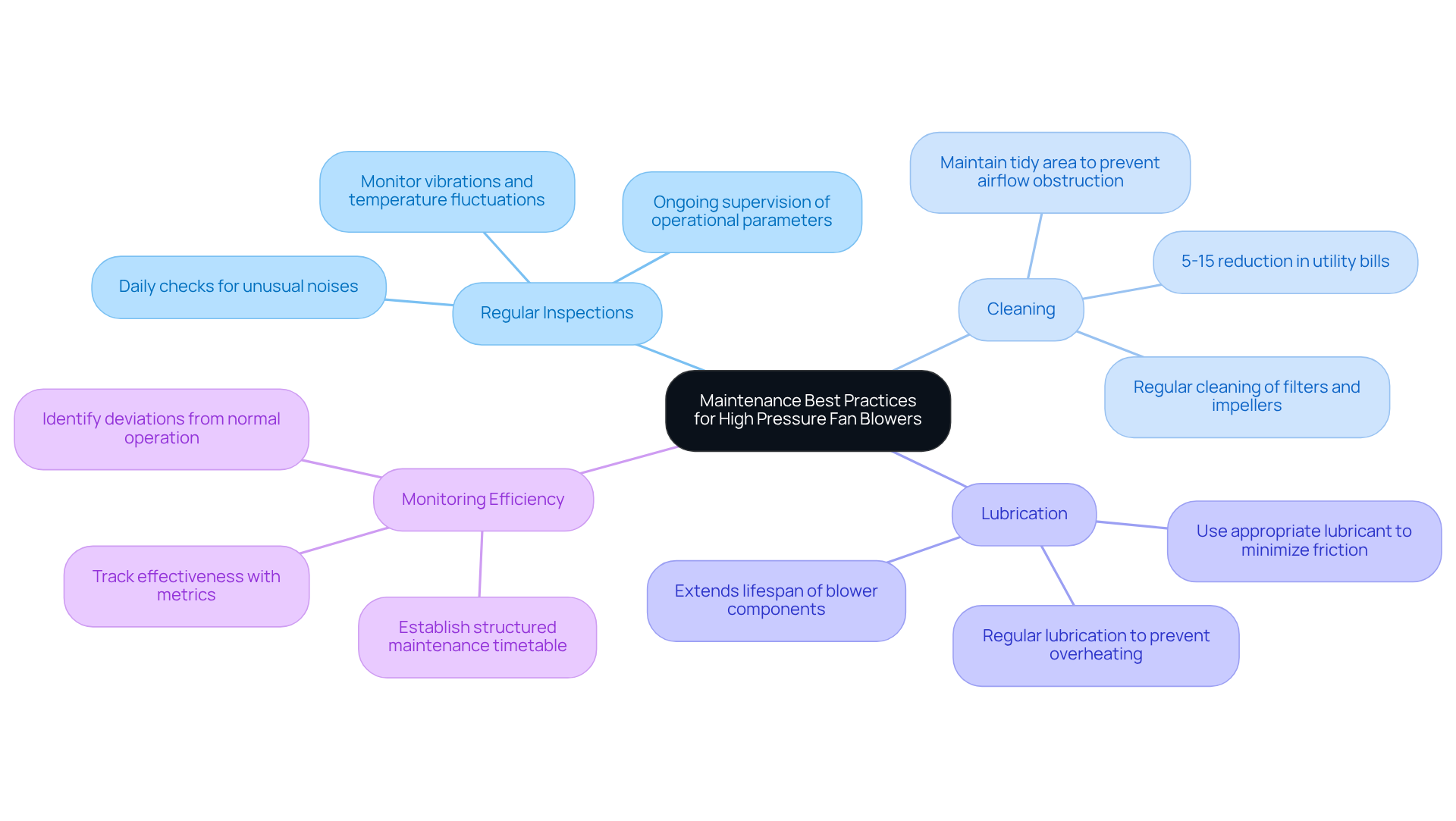

Maintenance: Best Practices for High Pressure Fan Blowers

To maintain high-pressure fan blowers effectively, engineers must adhere to essential practices that ensure optimal performance and longevity:

-

Regular Inspections: Routine checks are vital for identifying wear and tear, ensuring all components function correctly. Daily inspections should encompass monitoring for unusual noises, vibrations, and temperature fluctuations, which can signal potential issues. Ongoing supervision of operational parameters such as airflow and pressure is crucial for early identification of inefficiencies. As Mr. Vishwesh Pardeshi, CEO of Acme Air Equipments Company Pvt. Ltd., asserts, “Regular inspection and monitoring are essential for sustaining the efficiency and lifespan of turbo fans.”

-

Cleaning: Maintaining a tidy area around the fan is critical to prevent dust and debris from obstructing airflow and impacting efficiency. Regular cleaning of components, including filters and impellers, is necessary to avoid buildup that can hinder performance. Well-maintained systems can achieve a 5-15% reduction in monthly utility bills through consistent filter changes.

-

Lubrication: It is imperative to ensure that moving parts are adequately lubricated with the appropriate type of lubricant to minimize friction and wear. Regular lubrication not only extends the lifespan of the high pressure fan blower but also prevents overheating, which can lead to costly repairs. Mr. Pardeshi emphasizes, “Regular lubrication with the appropriate type of lubricant reduces friction and prevents overheating.”

-

Monitoring Efficiency: Employ metrics to track effectiveness and identify deviations from normal operation. Establishing a structured maintenance timetable that incorporates monitoring can significantly enhance operational availability and decrease energy usage, resulting in substantial cost savings. A case study on the importance of regular inspection and monitoring highlights that ongoing observation of operational metrics aids in detecting inefficiencies early, enabling prompt interventions before issues escalate.

By implementing these strategies, engineers can significantly enhance the efficiency and lifespan of high pressure fan blower units, ensuring reliable operation and minimizing unforeseen failures.

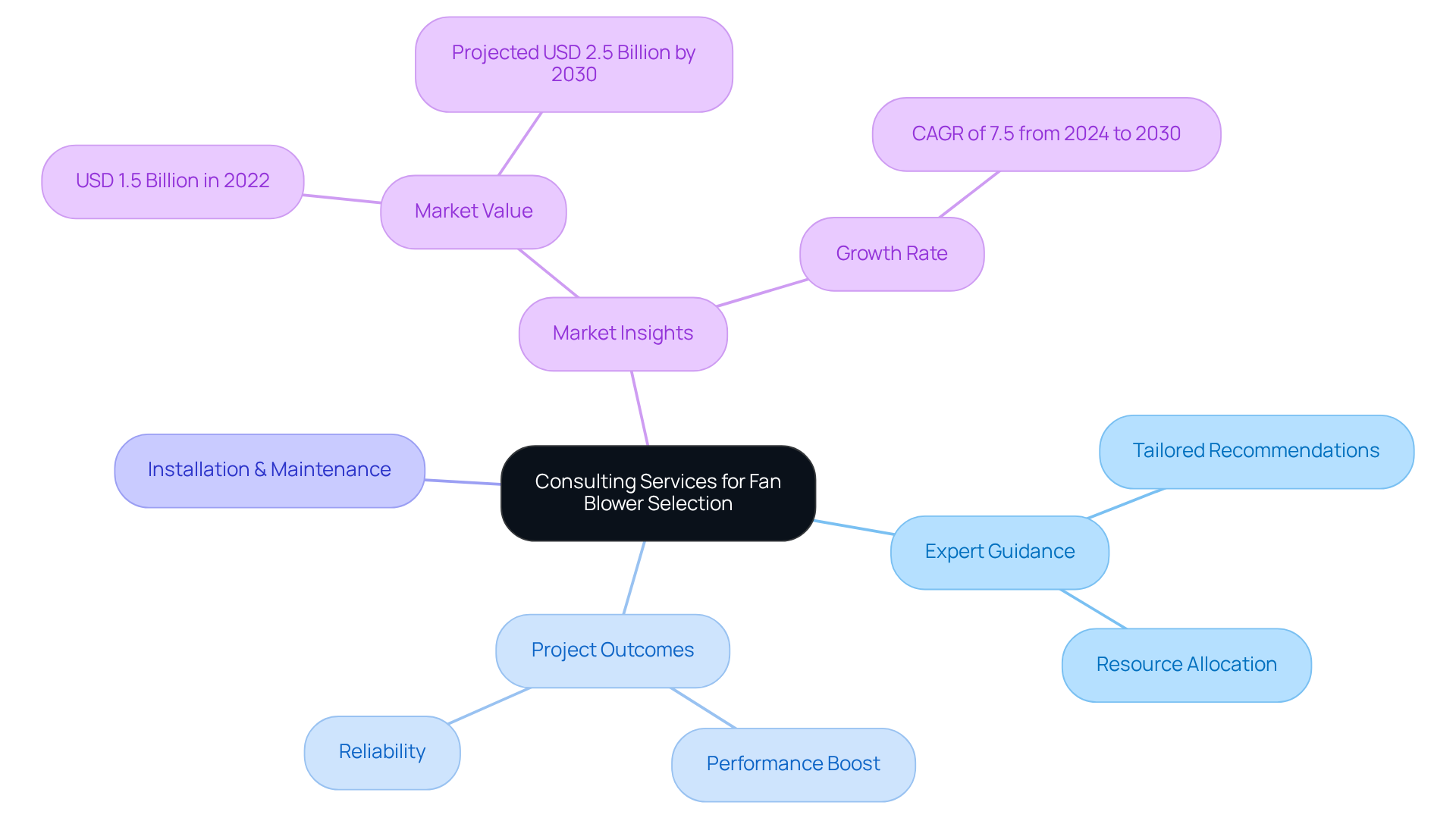

Consulting Services: Expert Guidance for High Pressure Fan Blower Selection

Consulting services play a crucial role in optimizing the selection process for high-pressure fan devices. Experts assess project needs and recommend fan models tailored to specific applications. Engineering consultants often highlight that precise fan selection can enhance project outcomes by as much as 30%, underscoring the value of professional guidance. Moreover, they offer insights into installation and maintenance practices, ensuring engineers choose the most effective solutions for their systems.

This professional support not only boosts system performance and reliability but also streamlines decision-making, facilitating a more efficient allocation of resources. As the high pressure fan blower market, valued at USD 1.5 billion in 2022, is projected to reach USD 2.5 billion by 2030, leveraging expert advice in 2025 will be vital for engineers striving to excel in their projects. With an expected growth rate of 7.5% CAGR from 2024 to 2030, the urgency for expert consulting becomes increasingly evident.

Conclusion

Gagner-Toomey Associates stands at the forefront of innovation in high pressure fan blowers, delivering advanced solutions that significantly enhance performance and efficiency for engineers. These technologies play a critical role in various applications, especially in sectors where effective thermal management is essential. As the market for high pressure blowers expands, understanding their capabilities and features becomes crucial for optimizing engineering projects.

Selecting the right motor type, blade design, and durability features is vital for maximizing energy efficiency and operational reliability. The benefits of high pressure fan blowers – such as improved cooling capabilities, energy savings, and versatility – underscore their value across diverse industrial applications. Moreover, emphasizing maintenance best practices and the role of consulting services highlights the necessity for proactive strategies to ensure optimal performance and longevity.

With the increasing demand for customized solutions and advancements in blower technology, engineers are urged to leverage these insights and expert guidance. This approach enables informed decision-making that not only meets specific operational requirements but also fosters significant energy savings and enhanced system performance. Embracing these innovations is essential for maintaining a competitive edge in an evolving market landscape.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in providing innovative solutions for high pressure fan blowers, primarily serving Northern California’s technology markets since 1981.

What is the market trend for industrial fans and exhaust systems?

The worldwide industrial fans and exhaust systems market is projected to grow from $23.49 billion in 2024 to $36.98 billion by 2034, with a compound annual growth rate (CAGR) of 4.64% from 2025 to 2034.

What recent advancements have been made in high pressure fan blower technologies?

Recent advancements include LONGWELL’s EC motor technology, which can achieve energy efficiency improvements of up to 90%, enhancing cooling systems, especially in the electronics sector.

What are the performance capabilities of high pressure fan blowers offered by Gagner-Toomey?

Gagner-Toomey’s high pressure fan blowers can achieve static pressures exceeding 100 inches of water column (WC) and airflow rates ranging from 100 to 50,000 cubic feet per minute (CFM).

What types of fans does Gagner-Toomey offer?

Gagner-Toomey offers a robust portfolio of DC input centrifugal ventilators and tube axial fans that are optimized for performance, efficiency, and low noise.

In what applications are high pressure fan blowers typically used?

High pressure fan blowers are used in industrial drying processes and HVAC systems, facilitating rapid moisture removal and ensuring consistent airflow.

What essential features should engineers consider when selecting high pressure fan blowers?

Engineers should prioritize motor type, blade design, durability, and control options when selecting high pressure fan blowers, as these factors significantly impact performance and efficiency.

Why is motor type important in high pressure fan blowers?

The choice of motor directly influences energy efficiency and operational performance, with high-efficiency motors designed to minimize energy usage while maximizing output.

How does blade design affect the performance of high pressure fan blowers?

Innovations in blade design, particularly airfoil-style blades, enhance airflow and pressure capabilities, improving efficiency and reducing noise levels.

What materials are preferred for the construction of high pressure fan blowers?

High-quality metals such as stainless steel and aluminum are preferred for their corrosion resistance and ability to withstand harsh environments, ensuring long-term efficiency.

How do advanced control options benefit high pressure fan blowers?

Advanced control systems allow for precise speed adjustments, enhancing energy efficiency and operational flexibility by customizing fan operation according to specific application requirements.