Introduction

High pressure axial fans stand as pivotal components across numerous industries, especially as the need for efficient cooling solutions intensifies. Engineers are on a relentless quest for insights into these robust devices, which not only promise enhanced airflow capacity but also substantial energy savings. Yet, with the rapid pace of technological advancements, what key factors must engineers consider to optimize both performance and reliability? This article explores ten critical insights into high pressure axial fans, examining their innovative designs, diverse applications, and the challenges inherent in their implementation.

Gagner-Toomey Associates: Innovative Cooling Solutions for High Pressure Axial Fans

Gagner-Toomey Associates stands out in delivering innovative cooling solutions designed specifically for high pressure axial fans. In an industry where performance is paramount, the company collaborates with leading manufacturers to ensure engineers have access to cutting-edge technologies that significantly enhance electronic systems’ performance.

This commitment to innovation is evident in their extensive product range, which caters to various applications within the electronics sector, including power management and RF technologies. Recent advancements in high pressure axial fans have achieved static pressures of up to 15 inches of water gauge and performance levels reaching 85%. These developments are crucial for effective thermal management in high-demand environments.

As the electronics industry continues to evolve, Gagner-Toomey remains at the forefront, equipping engineers with the necessary tools to optimize system performance. This proactive approach addresses the growing demands for energy efficiency and reliability, ensuring that Gagner-Toomey Associates not only meets but exceeds industry expectations.

High Airflow Capacity: Essential Feature of High Pressure Axial Fans

High pressure axial fans, like those provided by Gagner-Toomey Associates, are designed to deliver substantial volumes of air efficiently, making them indispensable in applications that require significant air movement against resistance. In data centers, where the average facility generates around 20 MW of heat – enough to power approximately 16,500 homes – these devices are vital for maintaining optimal operating conditions. Their ability to sustain high airflow rates, reaching up to 28,800 m³/hr, is essential for effective cooling and preventing equipment failure.

The practical applications of high pressure axial fans in data centers highlight their effectiveness in enhancing cooling performance. Facilities utilizing Gagner-Toomey Associates’ devices have reported improved thermal management, which is crucial for protecting sensitive electronic systems. Engineers stress that maximizing airflow efficiency is key to operational reliability. As one expert noted, “The efficiency of a fan depends on several factors, including the fan’s design, size, and operating conditions.” This insight underscores the importance of design considerations in achieving optimal performance.

Moreover, the straightforward design of high pressure axial fans, characterized by fewer components, simplifies installation and maintenance, further enhancing their appeal in high-demand environments. Additionally, these devices are recognized for their cost-effectiveness and minimal energy consumption, making them a preferred choice for data centers. As the industry evolves, the integration of high-pressure radial ventilators from Gagner-Toomey Associates will remain a critical strategy for improving air management and ensuring the sustainability of cooling systems.

Energy Efficiency: A Key Advantage of High Pressure Axial Fans

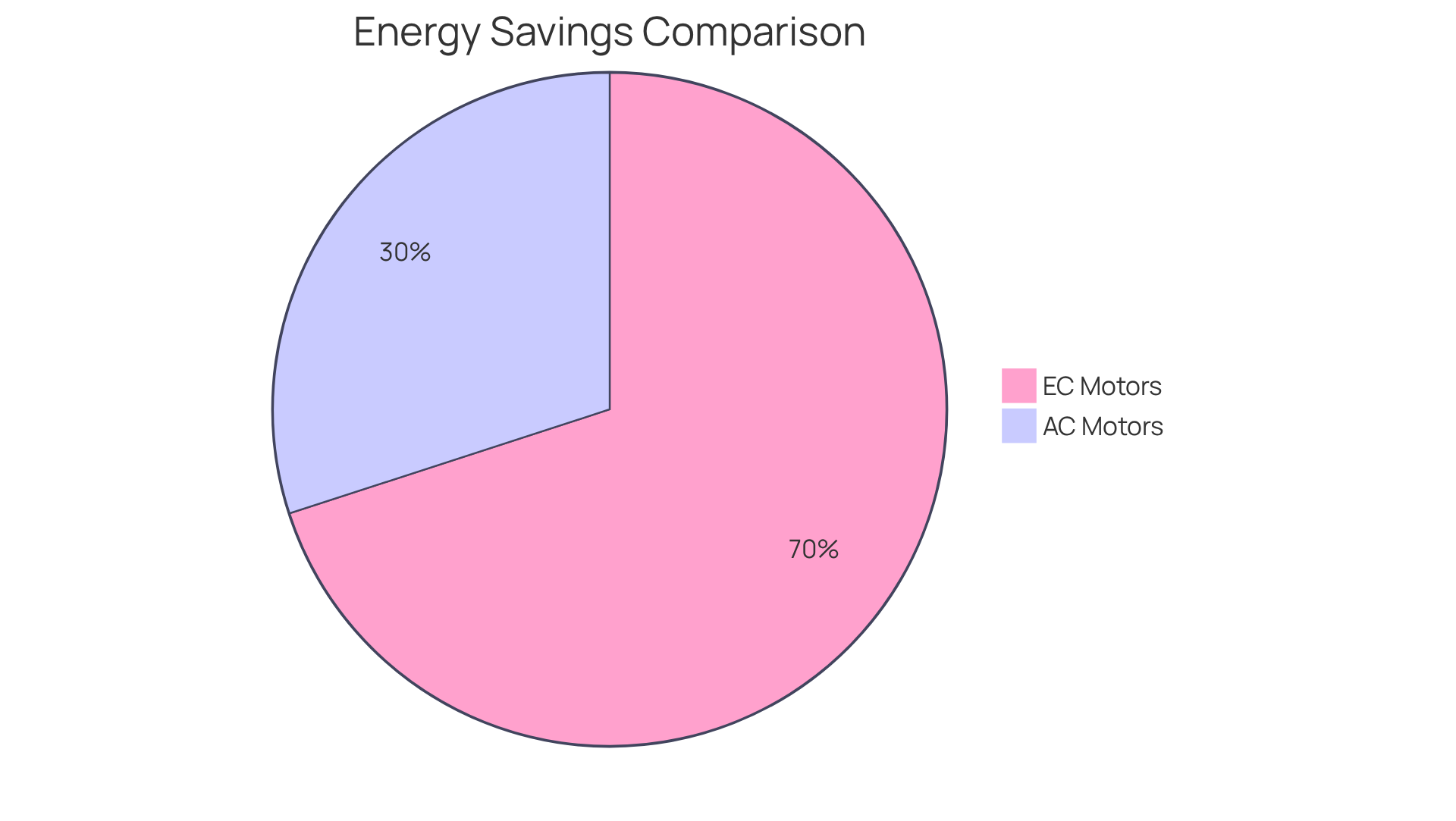

High pressure axial fans are pivotal in achieving substantial energy savings, a critical factor in minimizing operational expenses. These devices are meticulously engineered to optimize airflow while consuming minimal energy. A key component of their effectiveness lies in the integration of advanced motor technologies, particularly EC (electronically commutated) motors. These motors enable variable speed operation, allowing the devices to adjust to real-time cooling demands. This adaptability can result in energy savings of up to 70% when compared to traditional AC motors, positioning them as the optimal choice for contemporary cooling solutions.

For example, the total power consumption of the fan array can be reduced by as much as 13.94% at a wind speed of 12 m/s through the implementation of these strategies. Furthermore, Wenhui Huang highlighted that “the energy efficiency of ACCs can be improved by the uniform flow field,” underscoring the significance of effective airflow management. The deployment of EC motors has shown considerable reductions in energy consumption, leading to lower operational costs and enhanced sustainability.

As the demand for energy-efficient solutions continues to grow, the integration of EC motors in high pressure axial fans is becoming increasingly vital for engineers who aim to enhance performance while reducing costs.

Blade Design: Critical Factor in High Pressure Axial Fan Performance

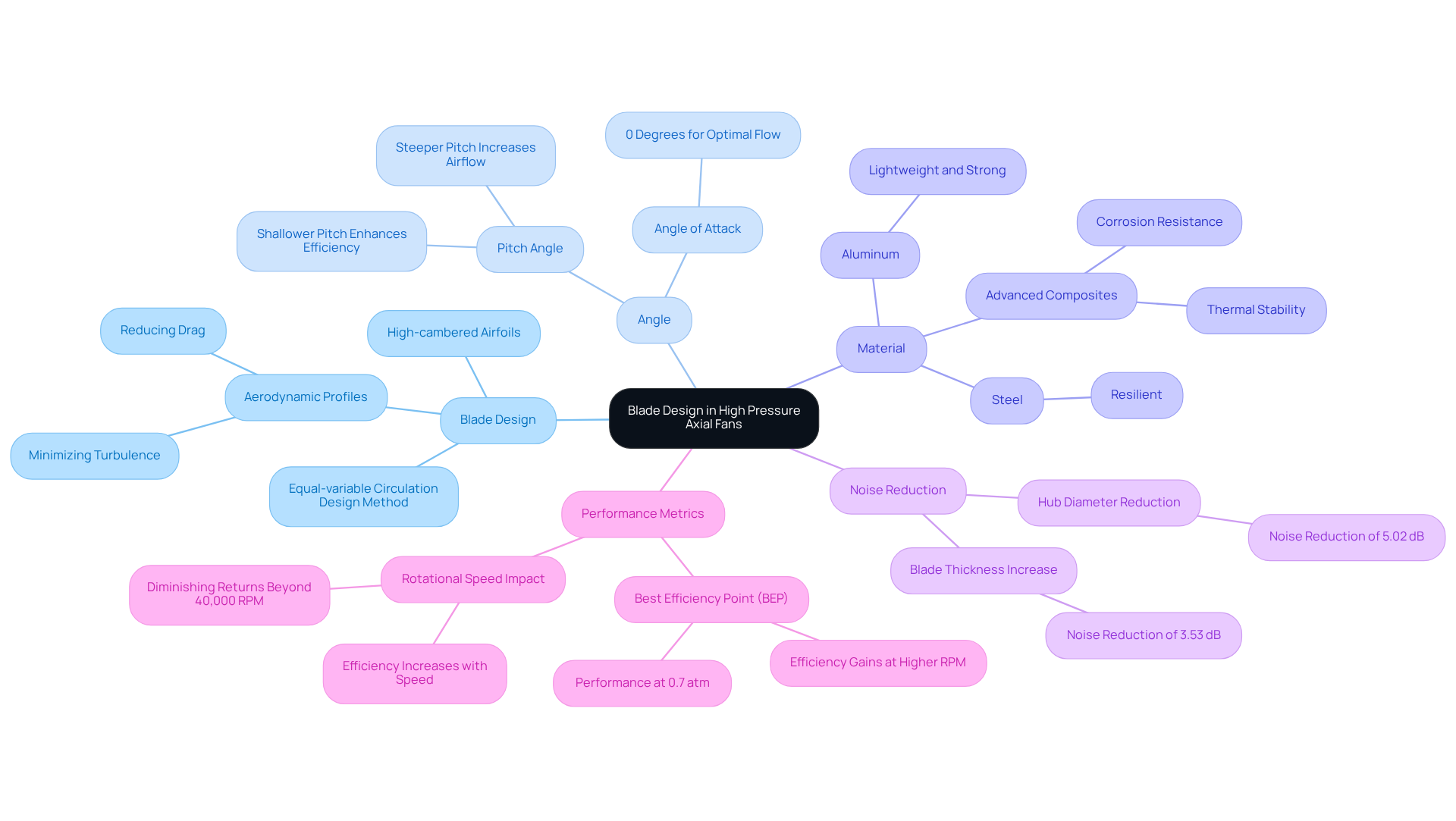

The design of blades in a high pressure axial fan is crucial for optimizing performance. Key elements such as blade design, angle, and material significantly influence air movement efficiency and sound production. For instance, aerodynamic blade profiles are specifically engineered to minimize turbulence, enhancing airflow while simultaneously reducing noise levels. As John P. Kizito notes, optimizing airfoil design can markedly improve the performance of an axial flow fan, leading to reduced input power requirements and increased fluid power.

Recent advancements in blade design, particularly the equal-variable circulation design method, have introduced high-cambered airfoils that excel at higher rotational speeds, demonstrating a notable enhancement in effectiveness. The S1210 high-cambered airfoil, for example, did not achieve a higher Best Efficiency Point (BEP) at lower speeds but showed superior performance at elevated speeds, such as 40,000 rpm.

Moreover, research indicates that noise generation is influenced by blade geometry. Reducing hub diameter and increasing blade thickness can result in significant noise reductions, reaching up to 5.02 dB at specific rotational speeds of 2,400 rpm and 4,500 rpm. Engineers must meticulously evaluate these design elements, alongside the critical role of routine maintenance, to achieve optimal performance tailored to their specific applications. Prioritizing both airflow efficiency and noise control is essential for maximizing the effectiveness of high pressure axial fans.

Types of High Pressure Axial Fans: Understanding Your Options

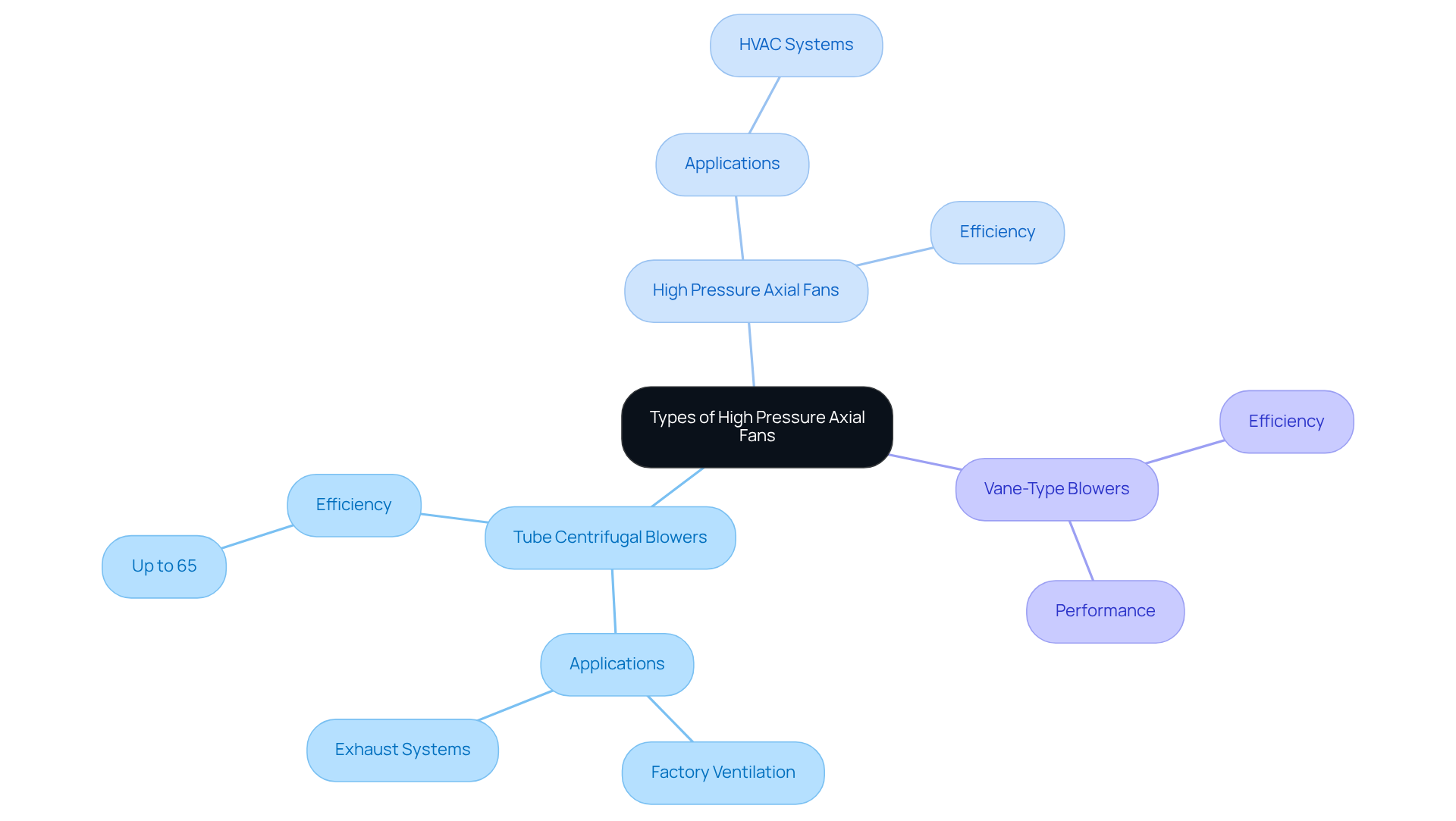

High-pressure tube and vane models, along with propeller types, are each designed for specific applications. Tube centrifugal blowers excel in confined spaces, effectively transporting substantial amounts of air at low pressures. This makes them ideal for factory ventilation and exhaust systems. In contrast, high pressure axial fans are engineered for enhanced efficiency in larger systems, capable of managing higher air pressures. This capability is crucial for applications requiring regulated air movement over extended distances, such as HVAC systems in commercial buildings.

Vane-type blowers generally demonstrate greater efficiency than tube-type blowers due to the inclusion of vanes in the casing, which significantly improves their performance as a high pressure axial fan. Understanding these distinctions is essential for engineers when selecting the appropriate fan type based on ventilation needs and installation constraints.

Statistics indicate that tube ventilators can achieve airflow efficiency of up to 65%, underscoring their effectiveness in specific applications. This knowledge empowers engineers to make informed decisions, as grasping the various types of directional blowers is vital for choosing the right equipment tailored to their unique requirements.

Common Applications: Where High Pressure Axial Fans Excel

High pressure cylindrical blowers play a crucial role in various applications, particularly in industrial cooling, HVAC systems, and electronic equipment cooling. Their design facilitates substantial airflow, making them exceptionally effective in environments that demand efficient heat dissipation, such as data centers, manufacturing facilities, and power generation plants.

As we look ahead to 2025, the demand for high pressure airflow devices in data centers is projected to surge significantly. This increase is driven by the urgent need for reliable cooling solutions to manage the escalating heat loads generated by advanced computing technologies. The fan market is anticipated to grow from USD 7.6 billion in 2023 to USD 12.1 billion by 2032, underscoring the rising necessity for efficient cooling solutions.

These devices maintain peak efficiency even under high pressure, ensuring consistent ventilation and temperature control – critical factors in preventing equipment overheating. Engineers emphasize the importance of selecting appropriate cooling solutions, noting that using high pressure axial fans can enhance operational performance and reliability in essential applications.

Moreover, their ability to operate quietly while delivering high airflow rates makes them particularly suitable for sensitive environments, further solidifying their status as indispensable components in modern cooling systems. Directional ventilators, for instance, can achieve energy-saving ratios of up to 13.94% under optimal conditions, showcasing their efficiency.

Regular maintenance of these systems can lead to significant operational cost reductions, making high pressure cylindrical blowers a prudent choice for engineers aiming to optimize their cooling systems.

Noise Levels: Managing Sound in High Pressure Axial Fan Operations

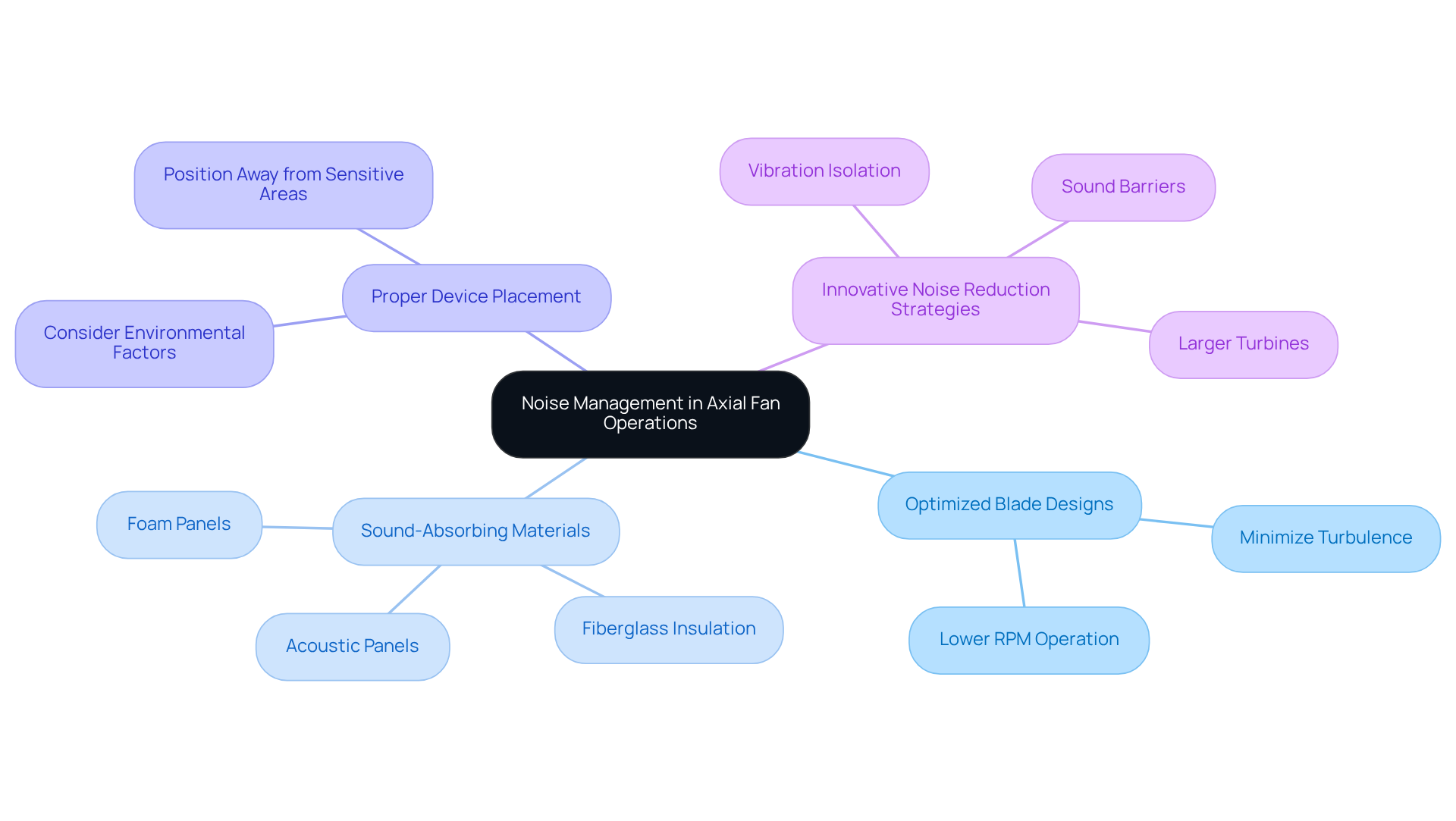

Effectively managing noise levels in high pressure axial fan operations is crucial, especially in sound-sensitive environments. Engineers face the challenge of mitigating noise, and several strategies can be employed to address this issue. One effective approach is selecting devices with optimized blade designs that minimize turbulence and noise generation. Additionally, incorporating sound-absorbing materials during installation is vital for dampening sound transmission. Options such as acoustic panels and insulation materials, including fiberglass insulation and foam panels, have proven particularly effective in significantly reducing noise levels. Proper placement of these devices is equally important; positioning them away from sensitive areas can greatly lessen the noise impact.

Looking ahead to 2025, engineers are encouraged to explore innovative noise reduction strategies. For instance, employing larger turbines that operate at lower RPMs can produce a much quieter sound profile. Furthermore, implementing advanced noise control techniques, such as vibration isolation and sound barriers, can enhance acoustic comfort in sensitive environments. As noted, “Another way to help reduce exceeded sound ratings is the reduction of fan speeds, particularly when the production is not expected to operate at full capacity,” which aligns with NIOSH recommendations for limiting exposure to noise levels below 85 dBA. It is also essential to recognize that noise levels above 84 dB necessitate the use of hearing protectors, highlighting the importance of managing noise levels in sensitive environments. By integrating these approaches, engineers can ensure compliance with noise regulations while enhancing user comfort and operational efficiency.

Durability and Material Selection: Ensuring Longevity in High Pressure Axial Fans

The durability of high pressure axial fans hinges significantly on the materials chosen for their construction. Common materials such as aluminum, stainless steel, and high-performance plastics each present unique advantages that can greatly influence performance and longevity.

Stainless steel, renowned for its exceptional corrosion resistance, is particularly suited for harsh environments. This makes it an ideal choice for applications in food processing and chemical handling, where reliability is paramount. For example, stainless steel ventilators are frequently employed in settings that demand strict hygiene standards. In contrast, aluminum models are favored for their lightweight characteristics and ease of installation, which reduces strain on motors.

Statistics reveal that stainless steel wall-mounted devices operate at a noise level of approximately 58-60 dBA, making them suitable for quieter environments. Furthermore, industrial centrifugal blowers, which share similar material considerations, boast a lifespan of 15 to 20 years. This underscores the critical role that material selection plays in ensuring the long-term performance of a high pressure axial fan.

The choice between these materials not only affects the blower’s performance but also its maintenance requirements and overall operational costs. Regular upkeep is essential for extending the lifespan of ventilators, ensuring they function effectively over time. Therefore, selecting the appropriate material is crucial for enhancing the longevity and performance of high pressure axial fans across various industrial applications.

Motor Efficiency: Enhancing Performance in High Pressure Axial Fans

Maximizing performance in high pressure axial fans hinges on the effectiveness of the motors driving them. High-efficiency motors, such as EC motors, significantly reduce energy consumption while maintaining high flow rates. This dual benefit not only enhances operational efficiency but also contributes to long-term cost savings.

When selecting blowers, engineers must prioritize the performance of high pressure axial fans. By doing so, they ensure that their cooling solutions are not only effective but also economical over time. The choice of motor directly impacts the overall system efficiency, making it a critical factor in the design and implementation of cooling systems that incorporate a high pressure axial fan.

In conclusion, investing in high-efficiency motors is a strategic decision that pays dividends in both performance and energy savings. Engineers are encouraged to evaluate their options carefully, considering the long-term benefits of superior motor technology.

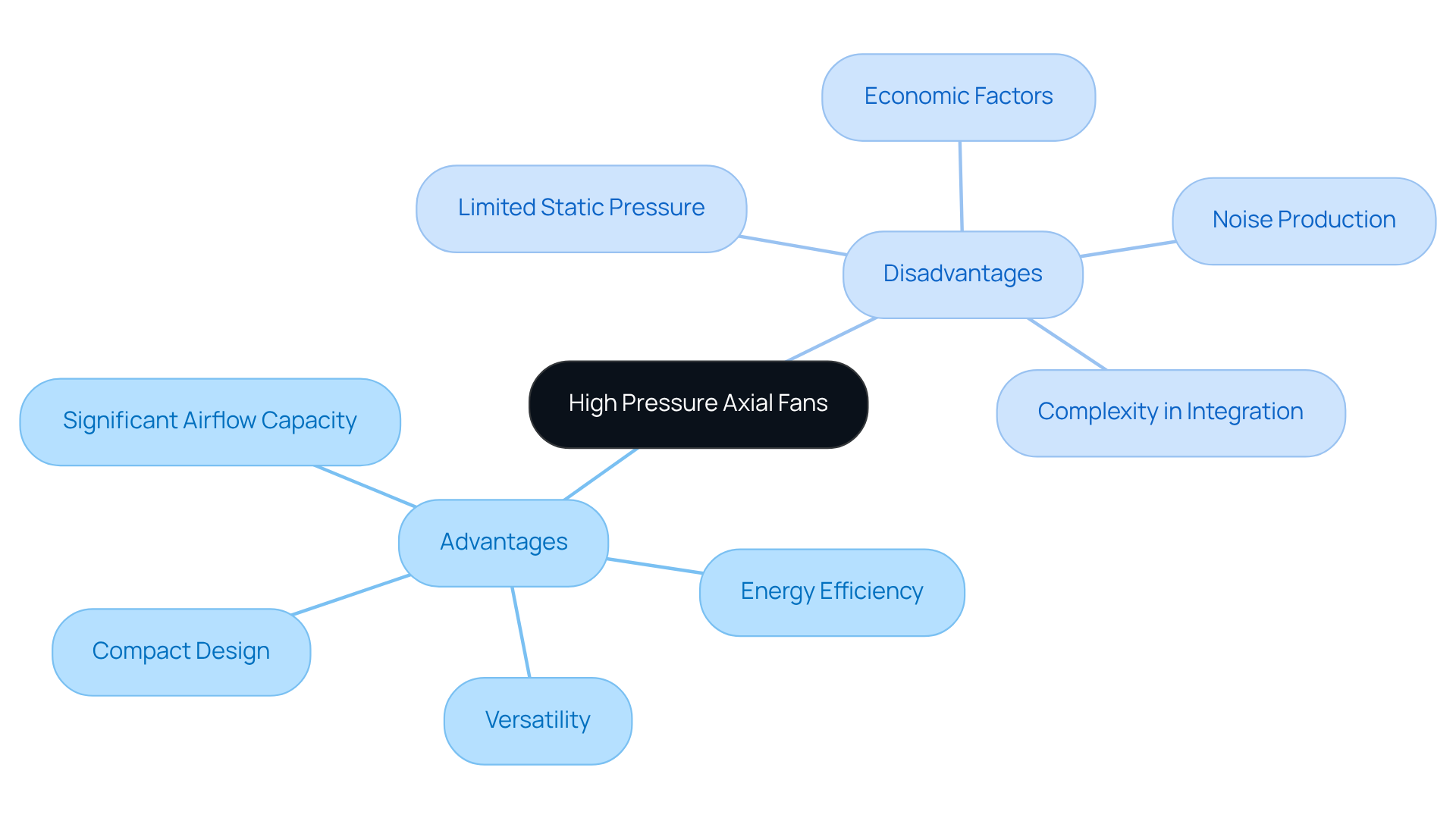

Advantages and Disadvantages: Weighing the Pros and Cons of High Pressure Axial Fans

High pressure axial fans offer a compelling solution for various applications, boasting significant airflow capacity, energy efficiency, and remarkable versatility. Available in an array of sizes, speeds, and configurations, these ventilators offer exceptional flexibility in both design and implementation. Their innovative design facilitates the movement of large volumes of air while consuming relatively low power, making them an attractive choice for numerous cooling scenarios. Notably, axial blowers excel at lower pressures, reinforcing their advantages in specific contexts.

However, it is essential to recognize that these devices face limitations in their ability to generate static pressure when compared to high pressure axial fans, which thrive in high-pressure environments. This constraint can impact their performance in ducted systems or applications with restrictive airflow paths. While straight-flow devices are generally quieter than their centrifugal counterparts, they can still produce considerable noise, especially at elevated speeds. This may necessitate the implementation of noise-reduction measures, introducing additional complexity and cost to the overall system.

Engineers must also weigh the economic factors, as certain types of blowers are often more cost-effective to produce and operate than other ventilator varieties. This consideration is crucial for budget-conscious projects. Furthermore, the compact and space-saving design of these ventilators allows for seamless integration into systems with limited space, maximizing utilization efficiency.

Ultimately, a thorough evaluation of these pros and cons is vital in relation to specific application requirements. For instance, in environments where substantial air movement at low pressure is critical, axial blowers frequently emerge as the preferred choice. Conversely, for applications that demand higher pressure and airflow rates, a high pressure axial fan may be more suitable. The decision should be guided by the unique needs of the project, striking a balance between performance, efficiency, and operational considerations.

Conclusion

High pressure axial fans are pivotal in modern cooling solutions, especially in high-demand environments like data centers and industrial applications. Their capacity to deliver substantial airflow while ensuring energy efficiency makes them indispensable for engineers aiming to optimize system performance. Innovative designs, effective motor technologies, and strategic material selection are crucial elements that enhance the operational reliability and effectiveness of these fans.

Significant advancements in airflow capacity and energy efficiency have emerged, largely due to the integration of EC motors and optimized blade designs. These innovations not only improve cooling performance but also result in considerable energy savings, establishing high pressure axial fans as a cost-effective choice. Moreover, a thorough understanding of the various types of fans and their specific applications empowers engineers to make informed decisions tailored to their unique requirements.

As the demand for efficient cooling solutions escalates, particularly with evolving technology and increasing heat loads, the significance of high pressure axial fans becomes even more pronounced. Engineers are urged to embrace these advancements and recognize the long-term benefits of incorporating high pressure axial fans into their designs. By prioritizing innovation and efficiency, the industry can secure reliable and sustainable cooling solutions that effectively address the challenges of tomorrow.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is known for delivering innovative cooling solutions specifically designed for high pressure axial fans, collaborating with leading manufacturers to enhance electronic systems’ performance.

What advancements have been made in high pressure axial fans?

Recent advancements in high pressure axial fans have achieved static pressures of up to 15 inches of water gauge and performance levels reaching 85%, which are crucial for effective thermal management in high-demand environments.

Why are high pressure axial fans important in data centers?

High pressure axial fans are vital in data centers for maintaining optimal operating conditions by delivering substantial volumes of air efficiently, which helps manage the significant heat generated by electronic equipment.

What is the maximum airflow capacity of high pressure axial fans provided by Gagner-Toomey Associates?

The high pressure axial fans can sustain airflow rates reaching up to 28,800 m³/hr, essential for effective cooling and preventing equipment failure.

How do high pressure axial fans contribute to energy efficiency?

High pressure axial fans are engineered to optimize airflow while consuming minimal energy, particularly through the use of advanced EC (electronically commutated) motors, which enable variable speed operation and can lead to energy savings of up to 70% compared to traditional AC motors.

What are the benefits of using EC motors in high pressure axial fans?

EC motors allow for variable speed operation that adjusts to real-time cooling demands, resulting in significant reductions in energy consumption and lower operational costs, enhancing overall sustainability.

What makes high pressure axial fans cost-effective?

Their straightforward design, characterized by fewer components, simplifies installation and maintenance, while their energy efficiency and minimal energy consumption make them a preferred choice, especially in data centers.