Overview

This article provides essential insights into axial fan blades, specifically tailored for engineers aiming to optimize performance and efficiency in their designs. It addresses critical factors such as:

- Material composition

- Blade design

- Operational principles

- Maintenance requirements

By guiding engineers in selecting the right components and strategies, the article enhances airflow efficiency while simultaneously addressing durability and energy efficiency.

Introduction

The intricate world of axial fan blades plays a pivotal role in engineering, influencing everything from cooling systems to energy efficiency. As engineers strive to optimize performance and sustainability, understanding the essential insights surrounding these components becomes crucial. Key factors that determine the effectiveness of axial fan blades include:

- Material selection

- Design intricacies

- Maintenance strategies

Engineers must navigate these complexities to achieve superior results, ensuring that their designs not only meet performance standards but also contribute to overall energy efficiency.

Gagner-Toomey Associates: Innovative Solutions for Axial Fan Blade Applications

Gagner-Toomey Associates excels in delivering innovative solutions for fan designs, with a keen focus on cooling, power management, and interconnect technologies. Their extensive expertise in representing a diverse portfolio of manufacturers empowers engineers to access that significantly enhance performance and efficiency in electronic systems. By thoroughly understanding the specific needs of the electronics industry, Gagner-Toomey offers tailored solutions that effectively address the complex challenges engineers encounter today.

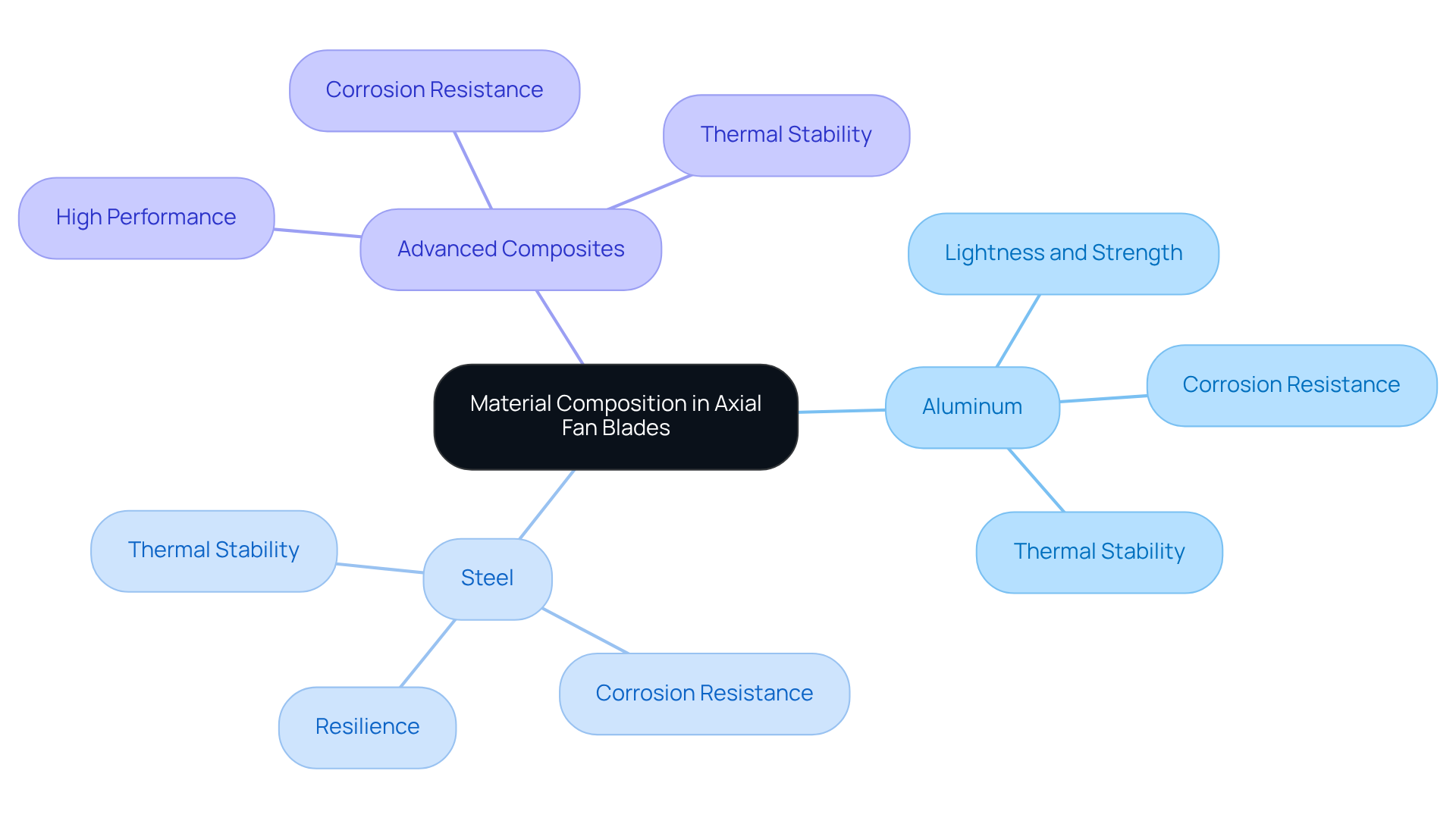

Material Composition: Key Factors in Axial Fan Blade Performance

The efficiency of fan components hinges significantly on their . Materials commonly used include:

- Aluminum, known for its lightness and strength

- Steel, valued for its resilience

- Advanced composites, which are ideal for high-performance applications

Each material presents distinct advantages, such as corrosion resistance and thermal stability, vital for sustaining efficiency across diverse operating conditions. Engineers must carefully evaluate the specific requirements of their projects to select the most suitable materials for fan components.

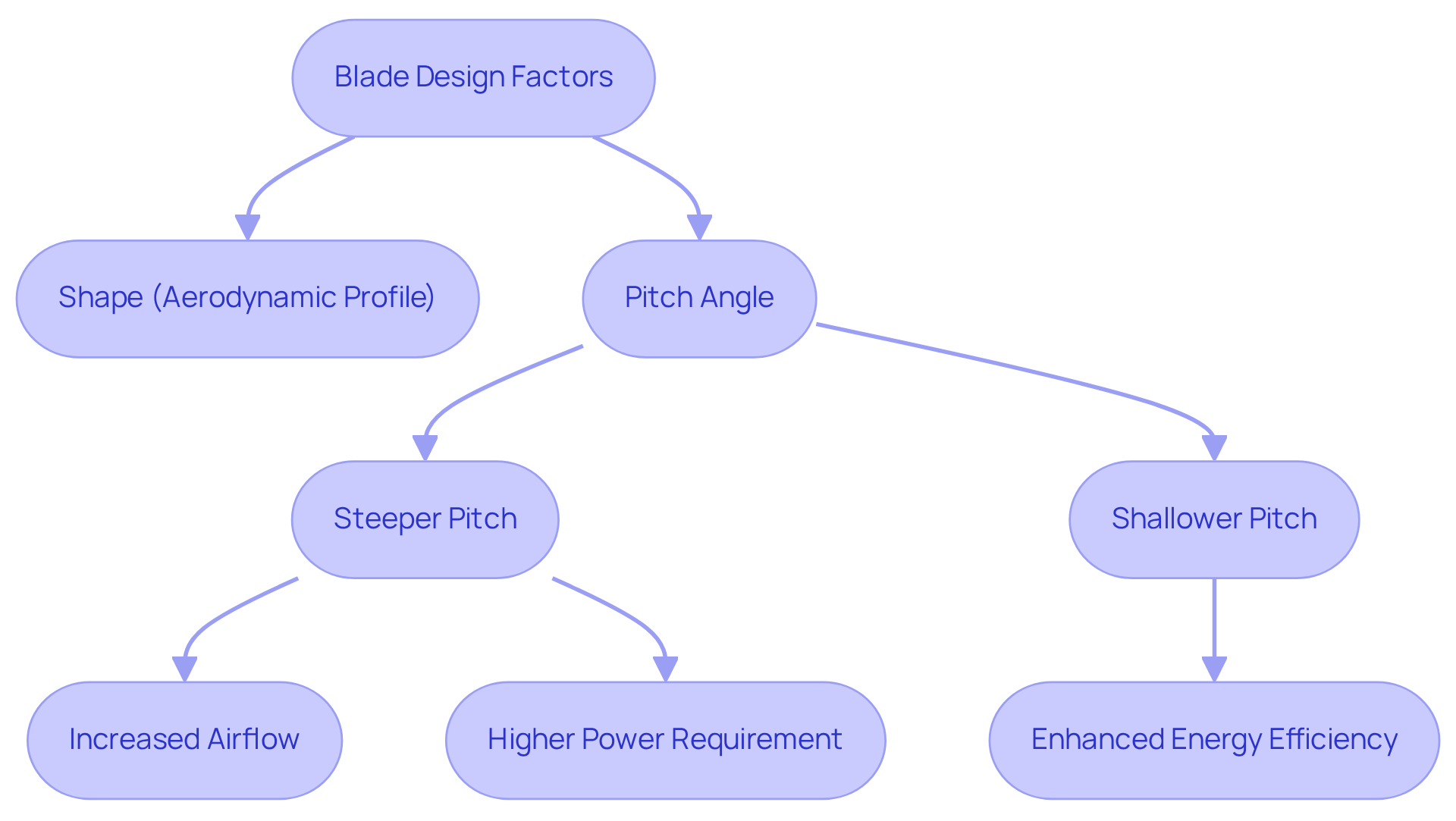

Blade Design: Impact of Shape and Pitch Angle on Airflow Efficiency

The form and pitch angle of axial fan blades are pivotal in determining airflow efficiency. Specifically, blades designed with an aerodynamic profile can significantly reduce drag, enhancing overall performance. The pitch angle, in particular, directly influences the volume of air moved; a typically increases airflow but may require more power. Conversely, a shallower pitch angle can enhance energy efficiency, presenting a critical trade-off. Engineers must meticulously balance these factors to achieve optimal performance tailored to specific applications. This nuanced understanding is essential for maximizing both efficiency and effectiveness in the design of axial fan blades.

Types of Axial Fan Blades: Understanding Options for Diverse Applications

Various types of axial fan blades are available, each designed for . Among the most common types are:

- Straight edges, which provide a simple and effective solution for general use.

- Curved edges that significantly enhance airflow efficiency.

- Adjustable pitch propellers that offer the flexibility to tailor performance according to operational requirements.

Understanding the features and applications of each type of axial fan blades empowers engineers to make informed decisions that optimize performance within their systems.

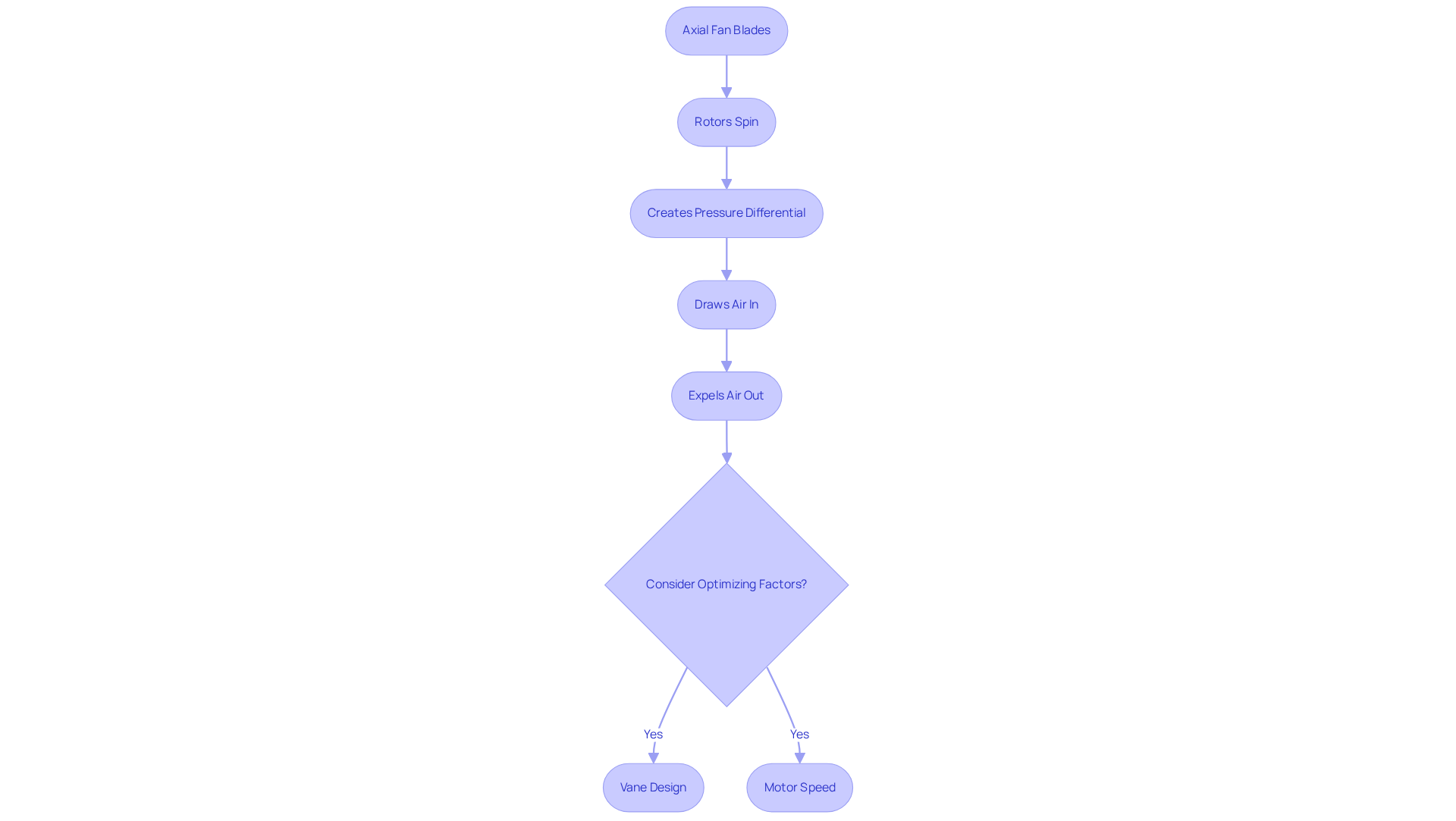

Operating Principles: How Axial Fan Blades Move Air Effectively

The components of axial fan blades function based on the principle of moving air parallel to the axis of rotation. As the rotors spin, they create a pressure differential that draws air in from one side and expels it from the other. This mechanism facilitates efficient airflow using axial fan blades in applications that demand high volumes of air at low pressure. Engineers must consider factors such as:

to optimize the efficiency of fans within their systems.

Maintenance Requirements: Ensuring Longevity of Axial Fan Blades

To ensure the durability of fan components, is imperative. This encompasses:

- Routine inspections for wear and tear

- Thorough cleaning to eliminate dust and debris

- Lubrication of moving parts

Engineers must develop a maintenance schedule tailored to the operating environment and usage patterns to avert performance degradation. By implementing these practices, one can significantly extend the lifespan of axial fan blades in systems.

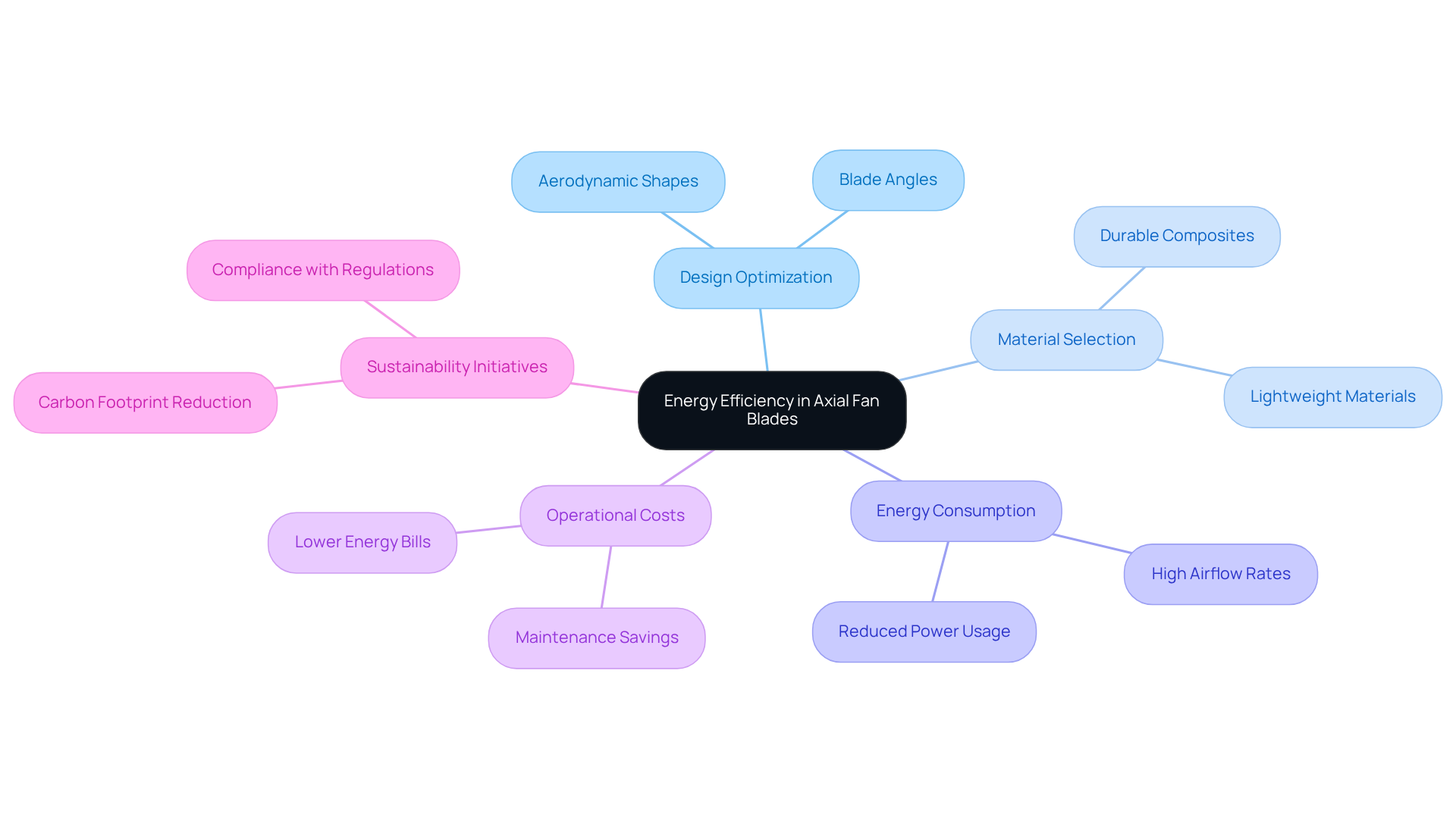

Energy Efficiency: The Role of Axial Fan Blades in Sustainable Engineering

The components of axial fan blades play a crucial role in enhancing energy efficiency within engineering applications. By optimizing design and selecting appropriate materials, engineers can significantly reduce energy consumption while maintaining high airflow rates. The implementation of energy-efficient fans not only lowers operational costs but also aligns with sustainability initiatives aimed at reducing carbon footprints. Therefore, it is imperative for engineers to prioritize in their designs, ensuring that they meet both performance and environmental objectives.

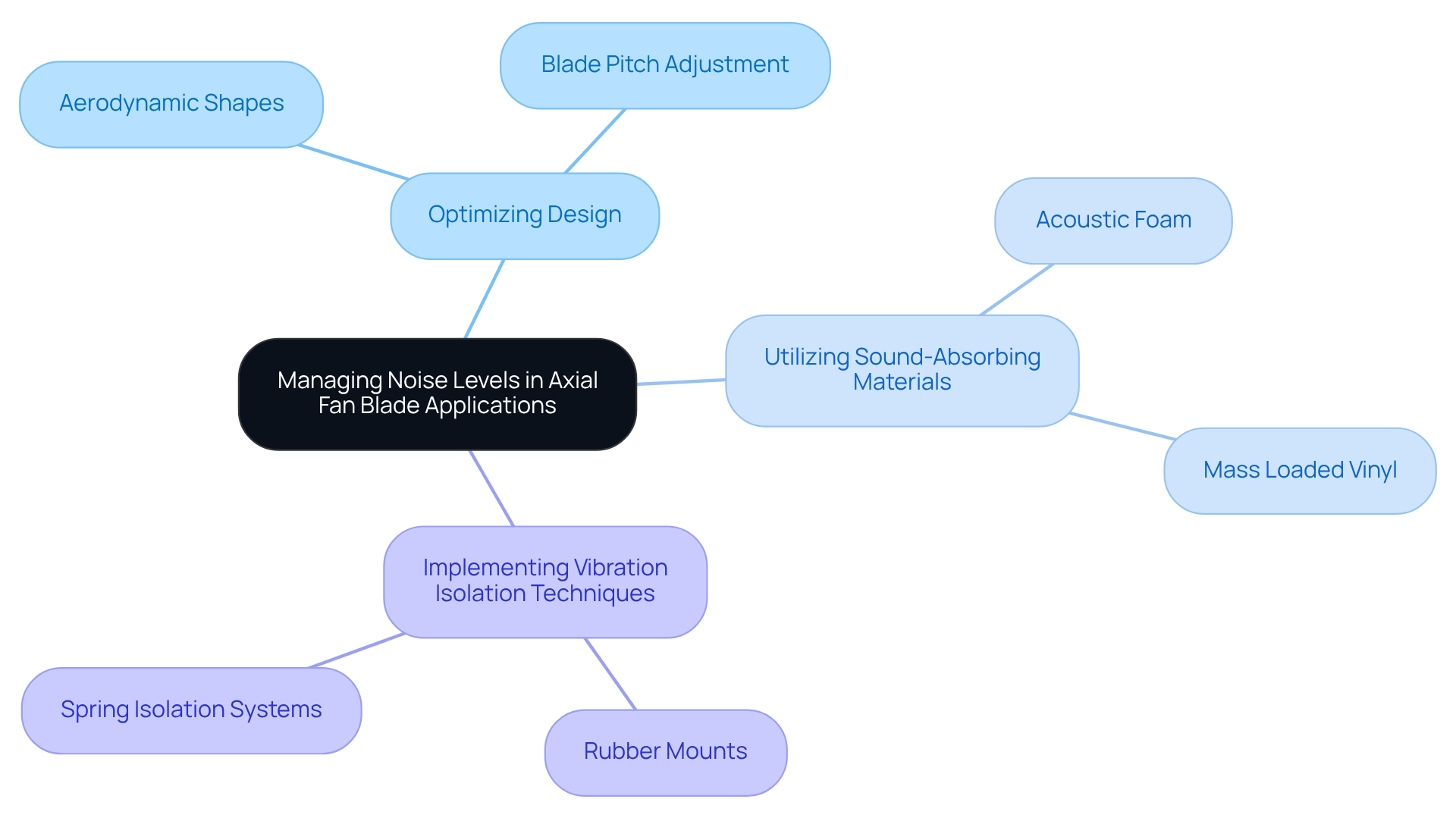

Noise Levels: Managing Sound in Axial Fan Blade Applications

Controlling noise levels in fan applications is crucial for ensuring user comfort and compliance with regulations. Engineers face the challenge of reducing noise, and they can employ a variety of strategies to achieve this goal. These strategies include:

- Optimizing design

- Utilizing sound-absorbing materials

- Implementing vibration isolation techniques

By proactively addressing noise concerns, engineers not only enhance the overall performance of their systems but also significantly improve the user experience, all while adhering to industry standards.

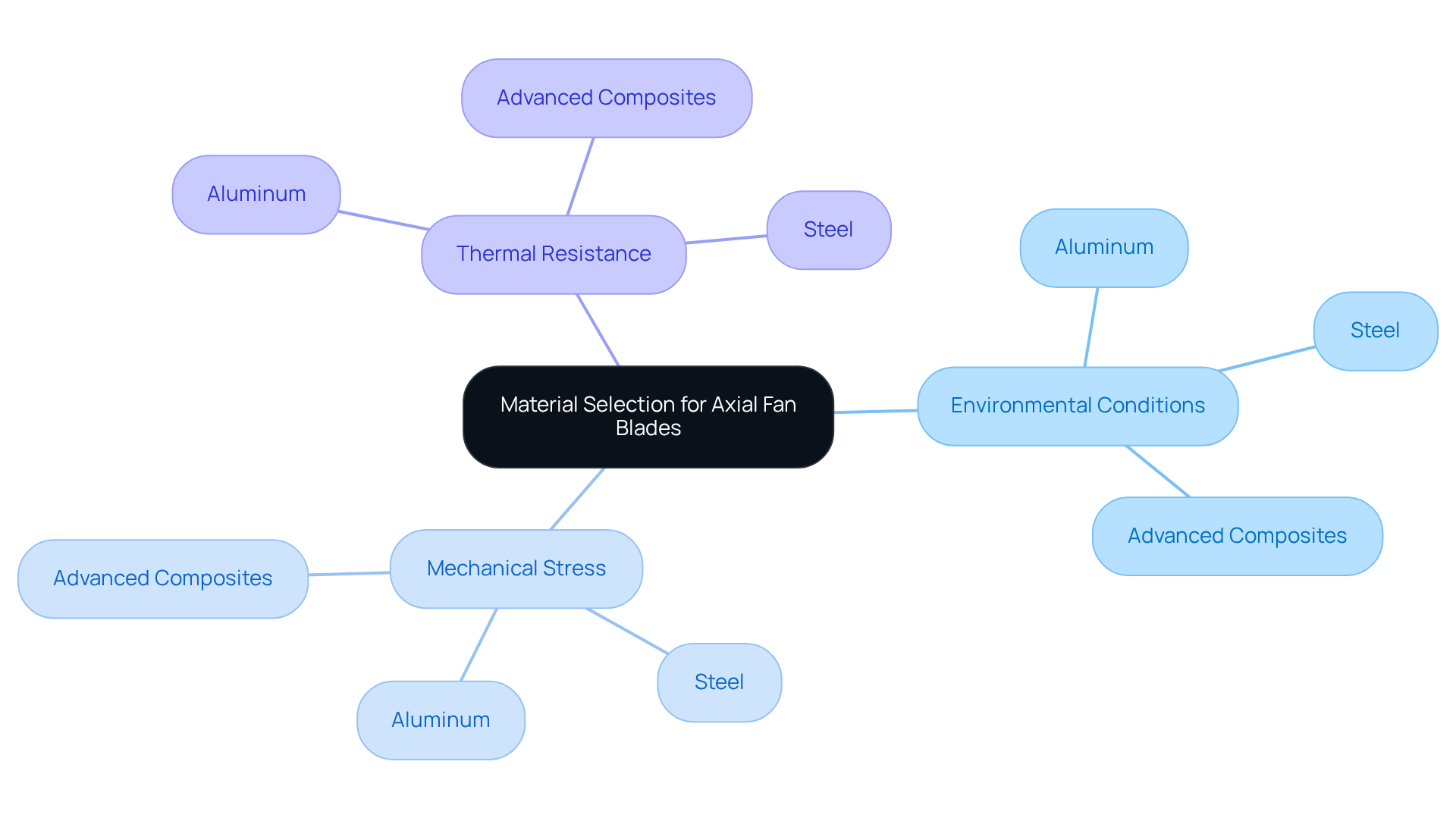

Durability and Material Selection: Choosing the Right Axial Fan Blades

Selecting the for fan blades is not merely a choice; it is a critical factor that directly impacts durability and performance. Engineers must meticulously consider various factors, including:

- Environmental conditions

- Mechanical stress

- Thermal resistance

when determining the most suitable materials. Commonly selected options encompass:

- Aluminum, lauded for its lightweight strength

- Steel, recognized for its exceptional durability

- Advanced composites, which excel in high-performance applications

By prioritizing material selection, engineers can significantly enhance the longevity and reliability of fan systems, ensuring optimal operation in diverse conditions.

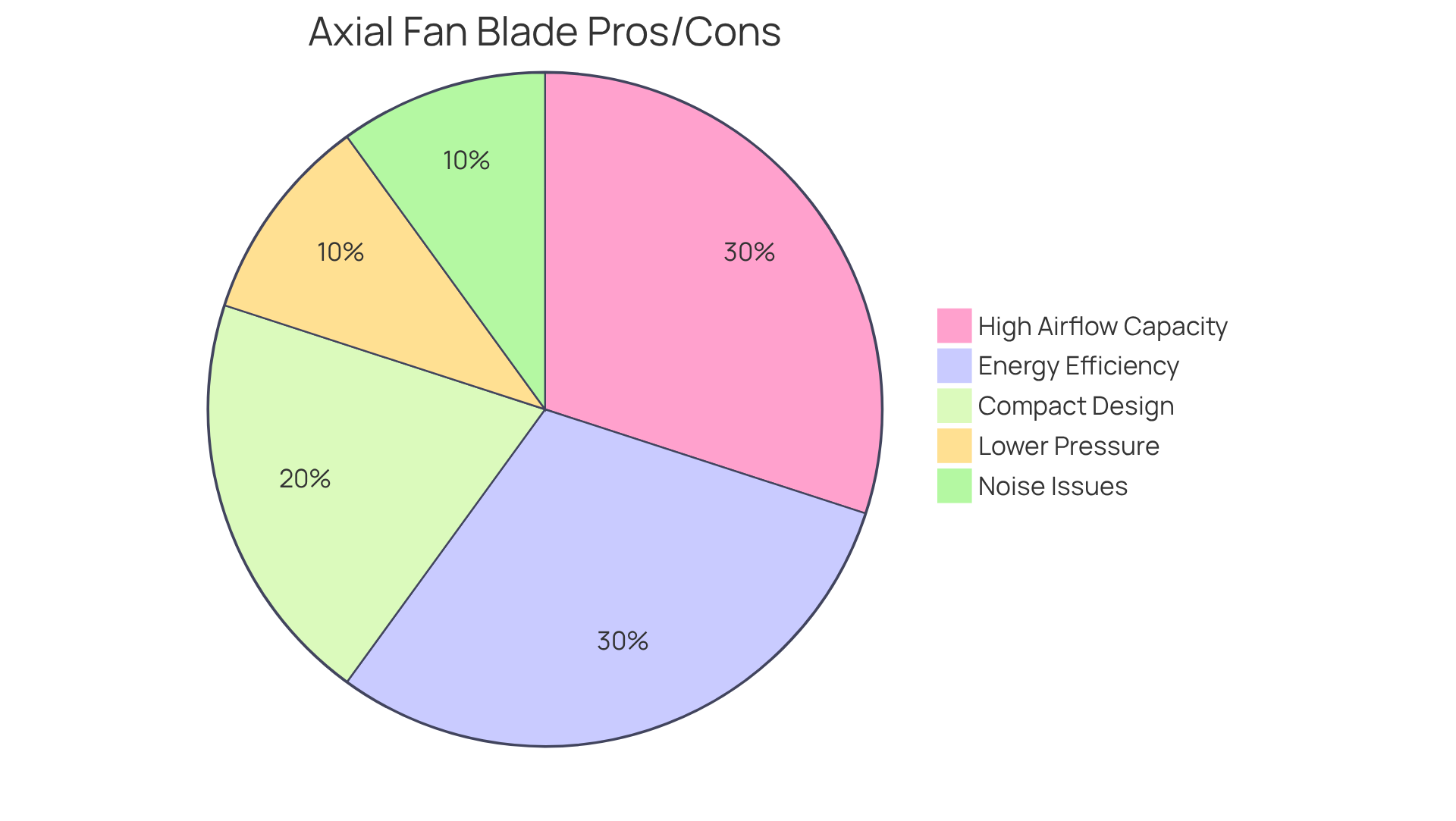

Advantages and Disadvantages: Evaluating Axial Fan Blades for Engineering Solutions

Evaluating the is essential for engineers striving to implement optimal solutions. The advantages of axial fan blades include:

- High airflow capacity

- Energy efficiency

- Compact design, making them suitable for a range of applications

Conversely, the disadvantages may encompass:

- Lower pressure capabilities when compared to centrifugal fans

- Potential noise issues that could arise

By comprehensively understanding these trade-offs, engineers are empowered to select the most appropriate fan blade designs tailored to their specific needs.

Conclusion

Understanding axial fan blades is crucial for engineers aiming to optimize performance across various applications. This article underscores the multifaceted aspects of fan blade design, encompassing material composition and maintenance practices, while emphasizing how these factors collectively influence efficiency, durability, and user comfort.

Key insights reveal the necessity of selecting appropriate materials—such as aluminum, steel, and advanced composites—to enhance both performance and longevity. Furthermore, design elements, including blade shape and pitch angle, significantly impact airflow efficiency and energy consumption. Engineers are reminded of the importance of regular maintenance to ensure optimal operation and mitigate noise levels, which can affect user experience and compliance with regulations.

Ultimately, the significance of axial fan blades transcends mere functionality; they are integral to driving energy efficiency and sustainability in engineering solutions. As the industry evolves, engineers are encouraged to remain informed about the latest trends and innovations. This knowledge ensures that their designs not only meet performance standards but also contribute positively to environmental objectives. By prioritizing these insights, engineers can enhance the effectiveness of their systems while addressing the challenges posed by modern engineering demands.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates specializes in providing innovative solutions for fan designs, focusing on cooling, power management, and interconnect technologies.

How does Gagner-Toomey Associates support engineers?

They represent a diverse portfolio of manufacturers, enabling engineers to access advanced products that enhance performance and efficiency in electronic systems.

What factors influence the efficiency of axial fan components?

The efficiency of fan components is significantly affected by their material composition, which includes materials like aluminum, steel, and advanced composites.

What are the advantages of using different materials for axial fan blades?

Aluminum is lightweight and strong, steel offers resilience, and advanced composites are ideal for high-performance applications. Each material also provides benefits like corrosion resistance and thermal stability.

How does blade design affect airflow efficiency in axial fans?

The shape and pitch angle of axial fan blades are crucial for airflow efficiency; aerodynamic profiles reduce drag, while the pitch angle influences the volume of air moved.

What is the relationship between pitch angle and airflow in fan blades?

A steeper pitch angle generally increases airflow but may require more power, while a shallower pitch angle can enhance energy efficiency, creating a trade-off that engineers must balance for optimal performance.