Introduction

Blowers are essential components in the electronics industry, playing a pivotal role in effective thermal management. They help prevent overheating and extend the lifespan of devices, making it crucial for engineers to understand the intricacies of blower sizes and their selection. However, navigating the complex metrics of airflow, static pressure, and air density can pose significant challenges.

How can engineers ensure they choose the right blower to optimize performance and efficiency in their applications? This question is vital, as the right blower not only enhances device longevity but also improves overall operational effectiveness. By delving into the specifics of blower selection, engineers can make informed decisions that lead to superior outcomes in their projects.

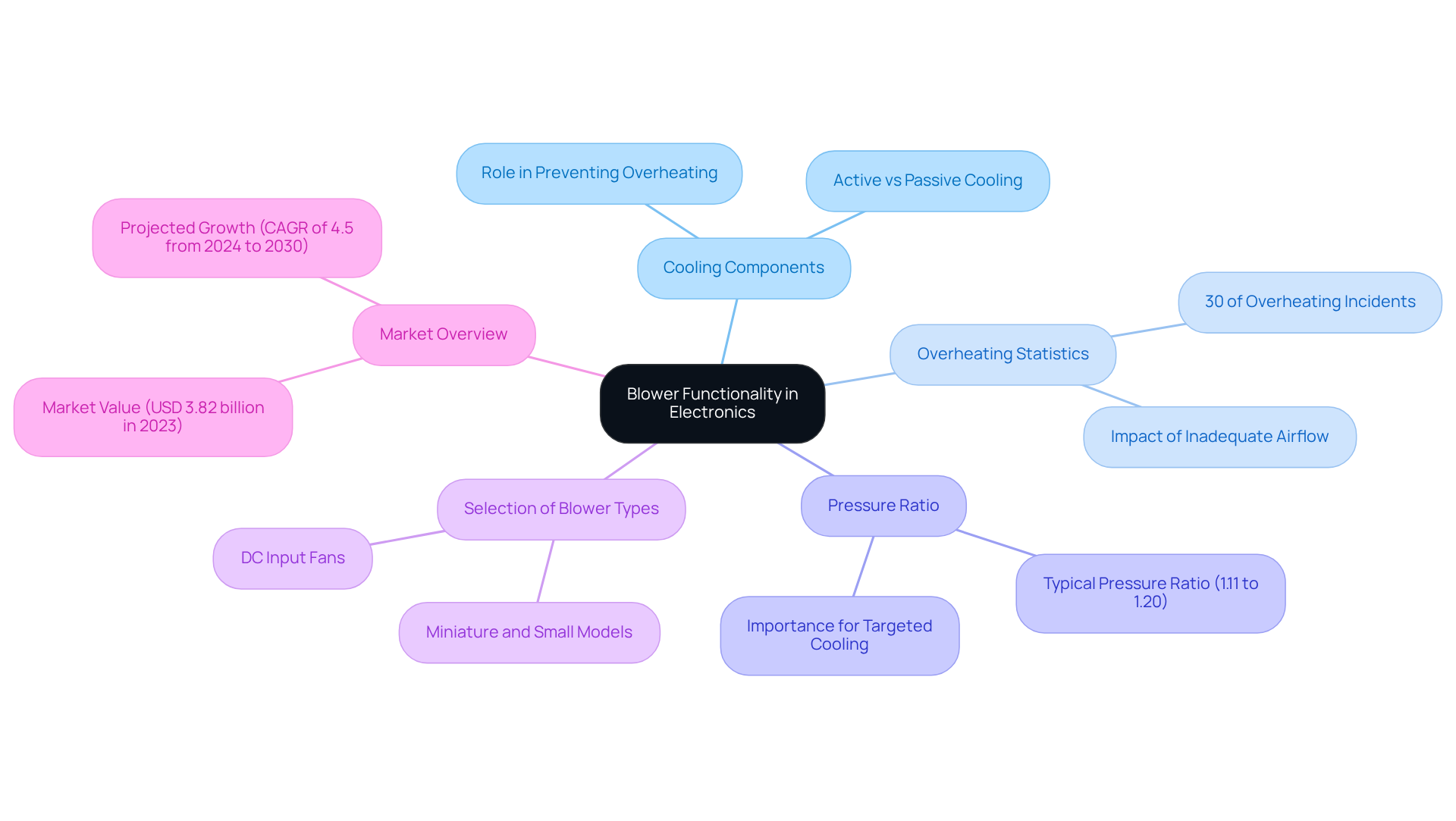

Clarify Blower Functionality and Importance in Electronics

Blowers are specialized mechanical devices engineered to move air or gas by enhancing its force and velocity, making them indispensable in the electronics sector. Their primary role is to cool components, effectively preventing overheating and ensuring optimal operational efficiency. By generating significant airflow, fans facilitate the removal of heat from electronic parts, which is crucial for maintaining functionality and reliability.

Studies reveal that inadequate airflow contributes to approximately 30% of overheating incidents in devices, highlighting the urgent need for effective cooling solutions. Furthermore, fans typically achieve a pressure ratio ranging from 1.11 to 1.20, enabling them to produce higher pressure compared to standard models. This capability is vital for targeted cooling in confined spaces. Understanding fan functionality allows engineers to select the appropriate blower sizes and types for their specific applications, ultimately enhancing product efficiency and extending the lifespan of electronic systems.

Gagner-Toomey Associates offers a comprehensive range of DC input fans, including miniature and small models optimized for performance, efficiency, and low noise, catering to various applications in the electronics sector. The fan market, valued at USD 3.82 billion in 2023, is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2024 to 2030, reflecting the increasing demand for efficient thermal management solutions in the electronics industry.

Evaluate Key Metrics: CFM, Static Pressure, and Air Density

When selecting a fan, it’s crucial to evaluate three key metrics:

- Cubic Feet per Minute (CFM)

- Static force

- Air density

CFM quantifies the volume of air a fan can move in one minute, which is vital for determining if the fan can satisfy the airflow requirements of your setup. For example, a 10% increase in airflow typically demands a 33% increase in horsepower, underscoring the necessity of accurately assessing CFM needs.

Static force, measured in inches of water gauge (inWG), reflects the resistance the fan must overcome to circulate air through the system. Understanding the relationship between CFM and static pressure is essential; a fan’s efficiency curve illustrates how these two metrics interact, revealing that a 10% rise in CFM can lead to a 21% increase in static pressure.

Lastly, air density, which varies with temperature and altitude, plays a significant role in the fan’s efficiency and effectiveness. As Tim De Stasio notes, “Grasping these operational traits becomes even more essential when dealing with contemporary BMS network structures where fan efficiency information integrates into building automation frameworks for optimal regulation.”

Engineers must carefully consider these factors to ensure optimal fan selection and system performance.

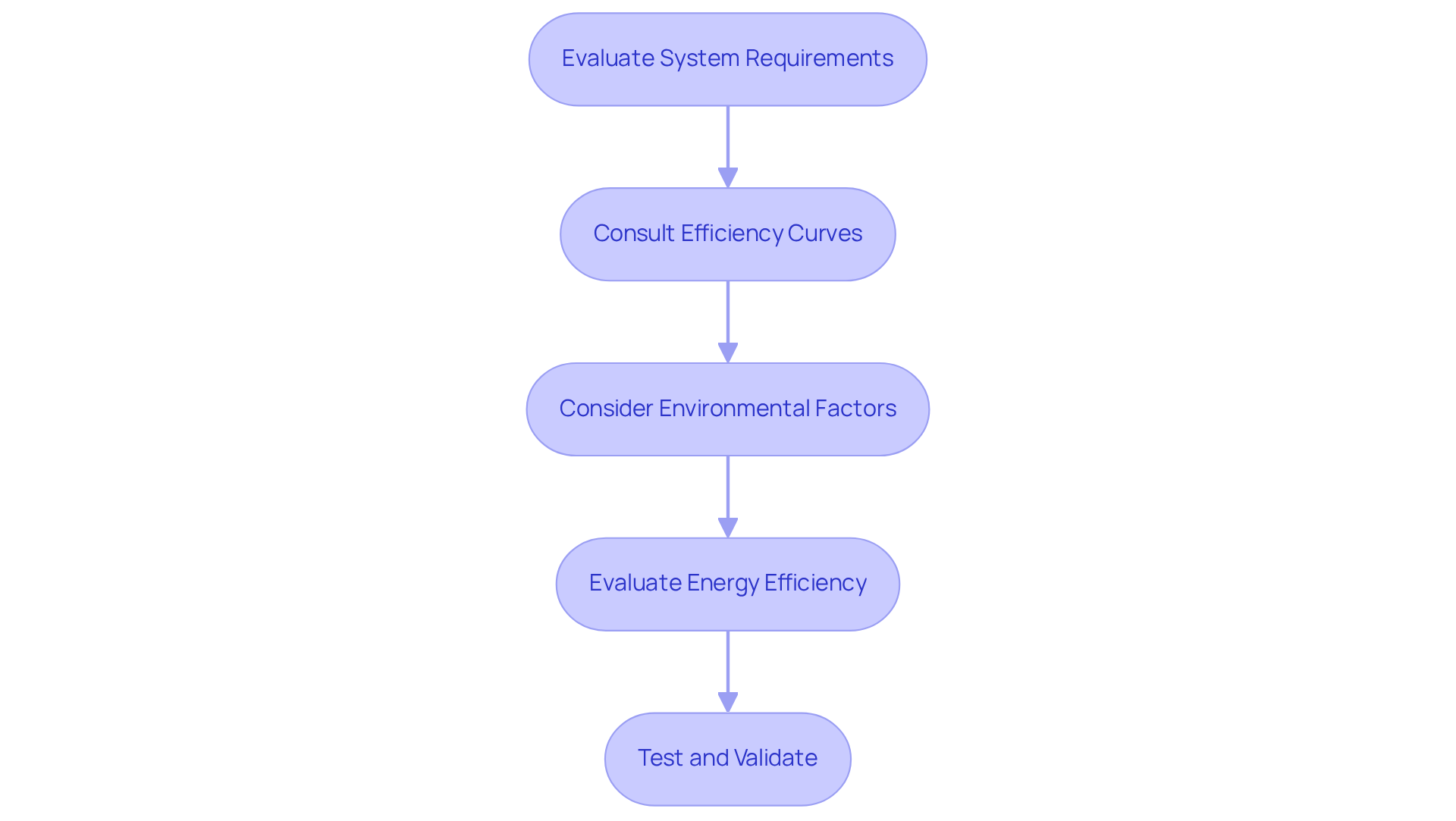

Implement Selection Strategies for Optimal Blower Performance

To implement effective selection strategies for blowers, engineers must follow a systematic approach:

-

Evaluate System Requirements: Start by identifying the airflow needs (CFM) and the static force necessary for the application. This involves a thorough analysis of the system’s layout and pinpointing any potential restrictions that could impede airflow.

-

Consult Efficiency Curves: Review the fan’s efficiency curves, which illustrate the relationship between CFM and static pressure. This analysis is crucial for identifying the appropriate blower sizes that operate efficiently within the desired range.

-

Consider Environmental Factors: Assess the operating environment, including temperature and altitude, as these elements can significantly influence air density and fan performance.

-

Evaluate Energy Efficiency: Opt for fans with high efficiency ratings, as these can substantially reduce energy consumption and operational costs. For example, a 10% decrease in RPM can lead to a 27% reduction in brake horsepower, while the same decrease results in a 19% drop in static pressure. This underscores the importance of selecting efficient models. Additionally, consider the Fan Energy Index (FEI) when assessing blower sizes, as it provides a clear metric for evaluating fan efficiency.

-

Test and Validate: After selecting a blower, conduct performance tests in the actual application to ensure it meets the required specifications. Modifications may be necessary to enhance airflow and cooling effectiveness, particularly in setups where static force management is critical. It’s essential to recognize that a static pressure setpoint of 1.5 in. WC is often misperceived as optimal and can lead to detrimental effects. This understanding can guide engineers in making informed decisions that enhance overall system performance.

Conclusion

Blowers are essential in the electronics industry, playing a crucial role in ensuring efficient cooling and preventing overheating. This is vital for the reliability and longevity of electronic devices. By understanding the intricacies of blower functionality – key metrics such as CFM, static pressure, and air density – engineers can make informed decisions that significantly enhance system performance.

Selecting the right blower sizes involves several essential strategies. Evaluating system requirements, consulting efficiency curves, and considering environmental factors are paramount. By focusing on energy efficiency and conducting thorough performance tests, engineers can optimize blower performance and substantially reduce operational costs.

In conclusion, the effective selection and implementation of blowers are vital for achieving optimal thermal management in electronic systems. As the demand for efficient cooling solutions continues to rise, engineers must apply these insights and strategies to ensure their designs not only meet but exceed performance expectations. This proactive approach enhances product efficiency and contributes to the sustainability of electronic systems in an increasingly competitive market.

Frequently Asked Questions

What is the primary function of blowers in electronics?

The primary function of blowers in electronics is to move air or gas to cool components, preventing overheating and ensuring optimal operational efficiency.

Why is adequate airflow important in electronic devices?

Adequate airflow is important because inadequate airflow contributes to approximately 30% of overheating incidents in devices, highlighting the need for effective cooling solutions.

What pressure ratio do fans typically achieve?

Fans typically achieve a pressure ratio ranging from 1.11 to 1.20, allowing them to produce higher pressure compared to standard models.

How does understanding fan functionality benefit engineers?

Understanding fan functionality allows engineers to select the appropriate blower sizes and types for their specific applications, enhancing product efficiency and extending the lifespan of electronic systems.

What types of fans does Gagner-Toomey Associates offer?

Gagner-Toomey Associates offers a comprehensive range of DC input fans, including miniature and small models optimized for performance, efficiency, and low noise for various applications in the electronics sector.

What is the current market value of the fan industry and its projected growth?

The fan market is valued at USD 3.82 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2024 to 2030.