Introduction

Understanding the complexities of cooling fan technology is crucial for engineers and designers aiming to boost the efficiency of electronic systems. As the demand for energy-efficient solutions continues to rise, mastering best practices for cooling fans not only enhances performance but also leads to substantial energy savings. But how can professionals ensure they select the right fan types and optimize their usage for maximum effectiveness? This article explores best practices for energy-efficient cooling fans, providing insights that tackle common challenges and elevate the performance of electronic systems.

Understand Cooling Fan Types and Their Applications

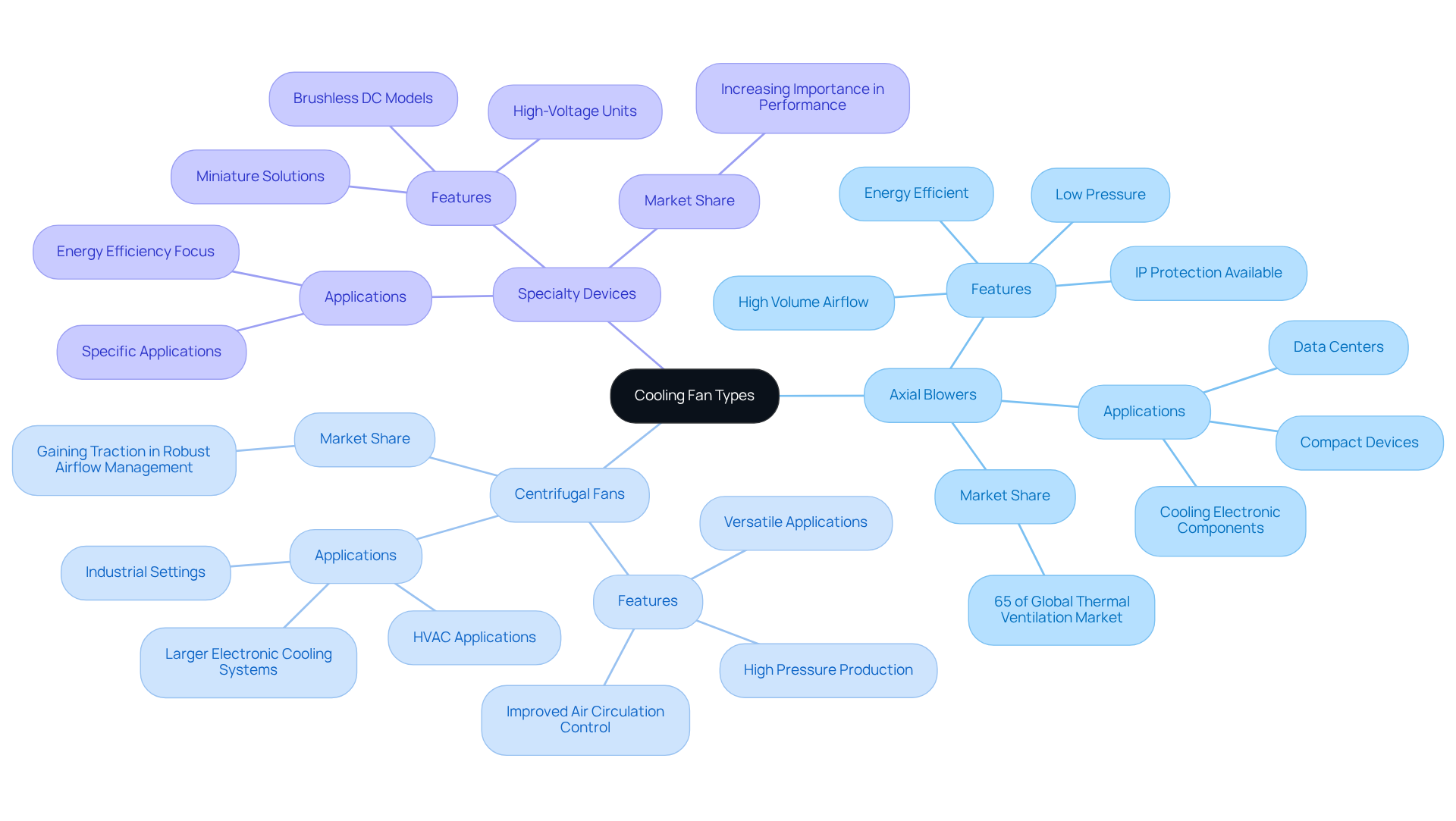

Circulating air devices play a vital role in electronic systems, designed to meet specific temperature regulation needs. Gagner-Toomey Associates, recognized as the world’s largest manufacturer of standard and custom air-movers, provides a comprehensive range of cooling solutions that prioritize performance, efficiency, and low noise. The two primary categories of fans are axial and centrifugal:

-

Axial Blowers: These devices move air parallel to their axis, making them ideal for applications requiring a high volume of air at low pressure. Gagner-Toomey’s DC input Tube Axial blowers, available in sizes from 15 to 280mm, excel in cooling electronic components within confined spaces, such as enclosures and compact devices. Engineers often prefer axial blowers as an energy efficient cooling fan for their efficiency and ability to deliver substantial air movement without significant energy consumption. Furthermore, many models offer IP protection upon request, enhancing their adaptability to various environments.

-

Centrifugal Fans: Also referred to as blowers, Gagner-Toomey’s centrifugal fans draw air in at the center and expel it at a right angle. This design allows for greater pressure production and improved air circulation control, making them suitable for larger electronic cooling systems and HVAC applications. Their capability to manage airflow in complex environments is a significant advantage, particularly in industrial settings where precise temperature regulation is essential. Gagner-Toomey offers a complete portfolio of DC input Centrifugal Blowers, ranging in size from 15 to 225mm, catering to diverse industrial requirements.

-

Specialty Devices: This category encompasses devices tailored for specific applications, including brushless DC models that emphasize energy efficiency and noise reduction, as well as high-voltage units designed for industrial use. Gagner-Toomey’s innovative designs, including miniature blower solutions starting from 15x3mm, are increasingly crucial as industries strive to enhance performance while utilizing energy efficient cooling fans to meet energy efficiency standards.

Understanding the distinctions between these fan types is essential for engineers seeking to optimize cooling solutions in electronic systems. For instance, the integration of Gagner-Toomey’s axial ventilators in data centers has demonstrated significant energy savings, with reports indicating reductions of 15-20% in energy usage from 2022 to 2024 when optimized air management is employed. Conversely, centrifugal blowers are often favored in larger setups where air movement control is critical, showcasing their versatility across various applications.

As of 2024, axial blowers hold approximately 65% of the global thermal ventilation market share, reflecting their widespread adoption in consumer electronics and industrial applications. Meanwhile, centrifugal blowers are gaining traction, particularly in environments that demand robust airflow management, indicating a dynamic shift in the landscape of temperature control solutions.

Optimize Fan Direction for Seasonal Efficiency

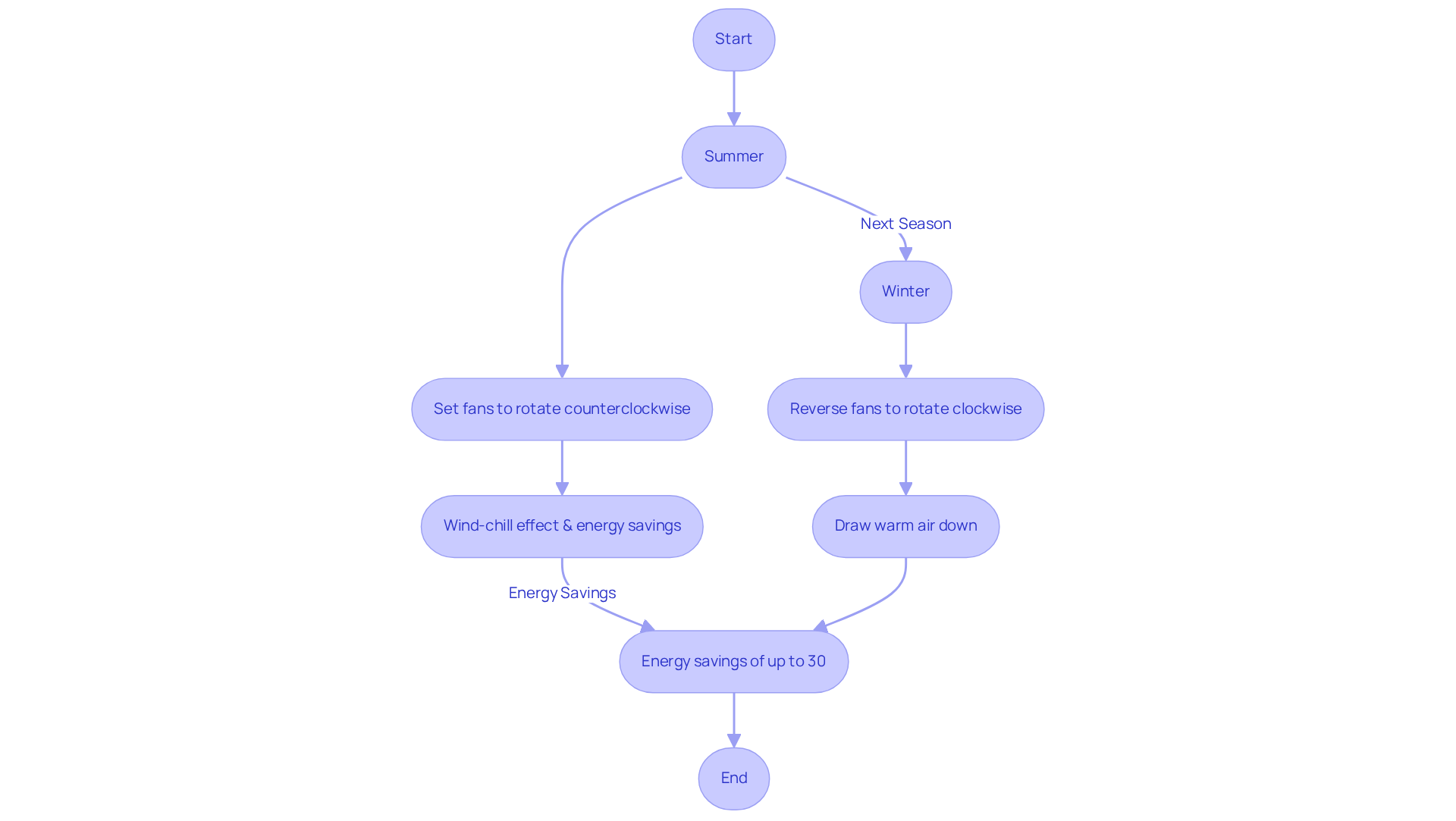

To maximize energy efficiency, adjusting the direction of cooling fans according to the seasons is essential:

- Summer: Set fans to rotate counterclockwise. This direction pushes cool air downward, creating a wind-chill effect that enhances comfort and reduces reliance on air conditioning.

- Winter: Reverse the fan direction to clockwise. This setting draws cool air upwards, enabling warm air to flow back down from the ceiling, which aids in maintaining a comfortable temperature without overburdening heating units.

Implementing these adjustments can lead to energy savings of up to 30%, as various studies on fan efficiency have noted. Regular reminders for seasonal changes can be integrated into maintenance schedules to ensure optimal performance year-round.

Integrate Cooling Fans with Electronic Systems for Compliance and Performance

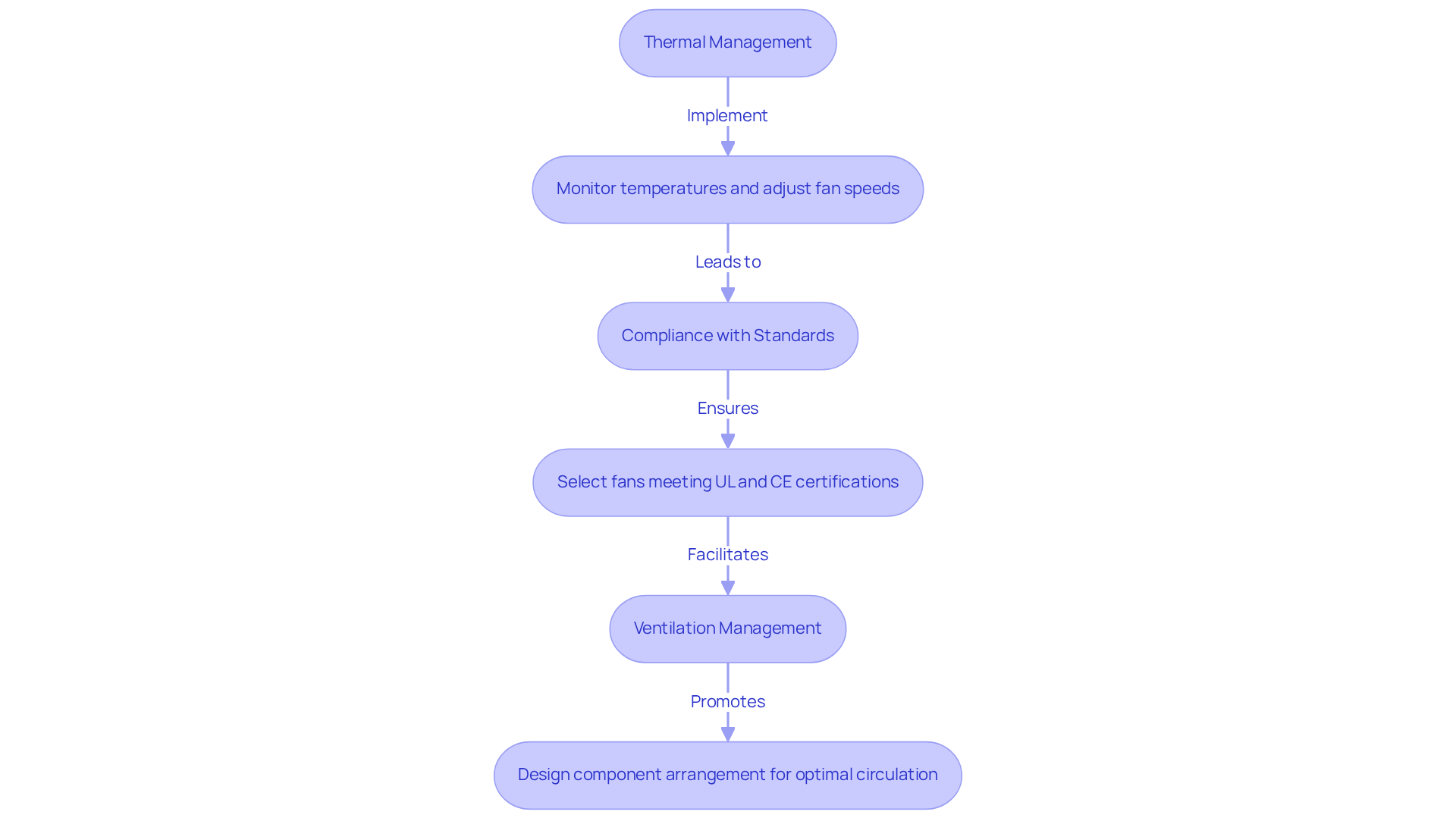

Integrating cooling fans into electronic systems is crucial for enhancing performance and ensuring compliance with industry standards. Here’s how to do it effectively:

-

Thermal Management: Implement thermal sensors to continuously monitor component temperatures and dynamically adjust fan speeds. This strategy not only ensures temperature regulation is applied only when necessary but also significantly enhances energy efficiency and prolongs the lifespan of electronic components by using an energy efficient cooling fan. As Gagner Toomey from the Content Team notes, ‘An energy efficient cooling fan can consume up to 70% less energy while delivering equivalent airflow.’

-

Compliance with Standards: It’s essential to select and install fans that meet industry standards, such as UL and CE certifications. Compliance not only guarantees safety but also boosts performance, ensuring that temperature control mechanisms operate within necessary safety parameters. The Thermal Management in Consumer Electronics System Market is projected to reach a valuation of 10,474.7 USD Million by 2035, highlighting the importance of adhering to these standards.

-

Ventilation Management: Design the arrangement of electronic components strategically to promote optimal circulation. Position heat-producing elements to allow clear passage for cooling fans, effectively minimizing hotspots and improving overall efficiency. Engineers must carefully consider these features to avoid common pitfalls in fan integration, such as obstructing airflow or miscalculating thermal loads.

By following these integration practices, engineers can significantly enhance the performance of their electronic systems while ensuring compliance with critical industry standards. This approach ultimately leads to more reliable and efficient products.

Implement Best Practices for Installation and Maintenance of Cooling Fans

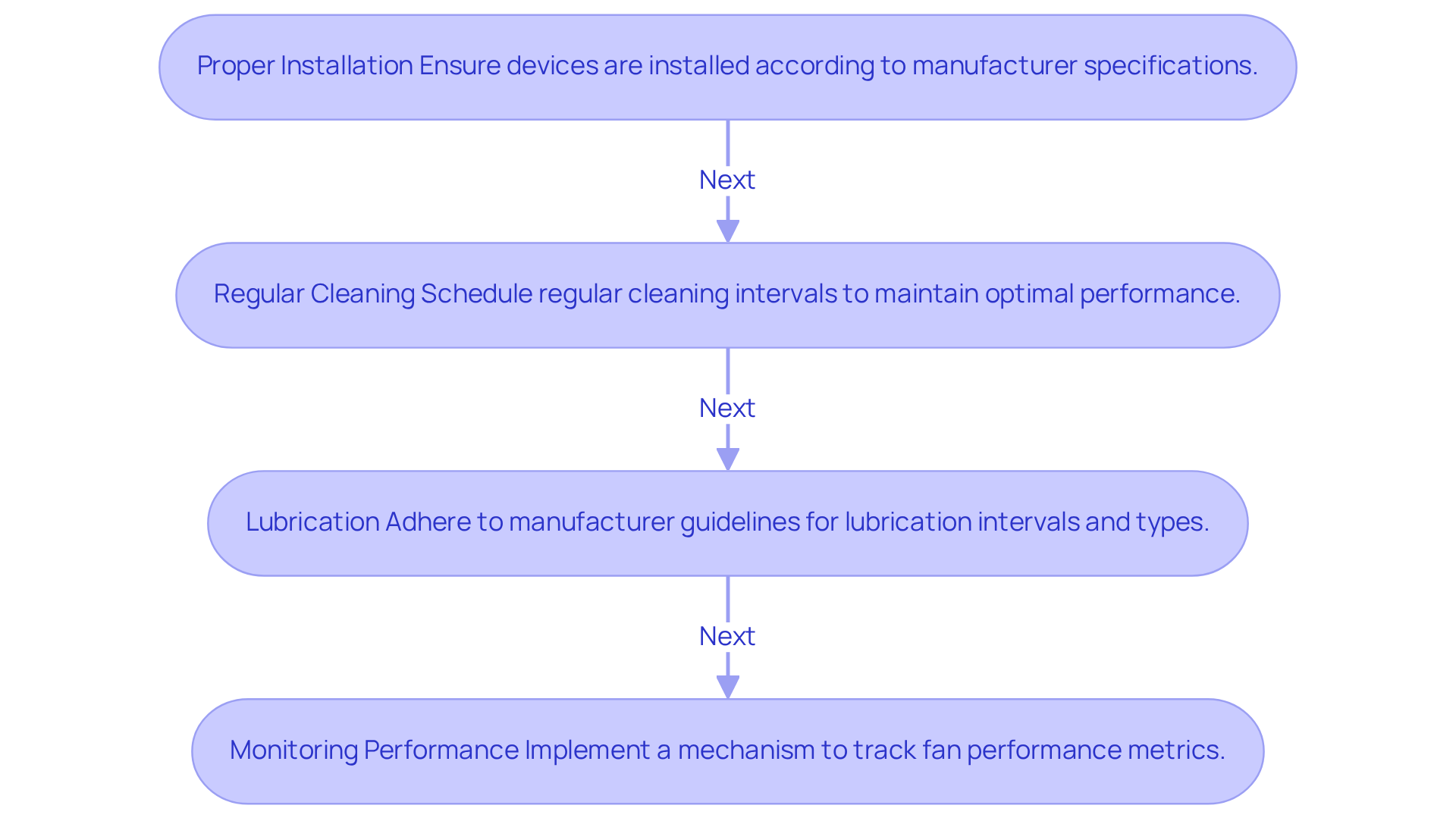

To ensure optimal performance and longevity of cooling fans, it’s crucial to follow these essential practices for installation and maintenance:

-

Proper Installation: Begin by ensuring that devices are installed according to manufacturer specifications. This includes correct orientation and secure mounting. Such precautions prevent vibrations and noise, which can lead to premature failure.

-

Regular Cleaning: Dust and debris can accumulate on fan blades and housing, significantly reducing airflow efficiency. Schedule regular cleaning intervals to maintain optimal performance. Utilize compressed air or gentle brushes to clean cooling devices without harming components.

-

Lubrication: For fans with moving parts, regular lubrication is essential to reduce friction and wear. Adhere to manufacturer guidelines regarding lubrication intervals and the types of lubricants to use.

-

Monitoring Performance: Implement a monitoring mechanism to track fan performance metrics, such as airflow and noise levels. This proactive approach can help identify potential problems before they escalate into network failures.

By adhering to these best practices for installation and maintenance, engineers can significantly enhance the reliability and efficiency of cooling fans in electronic systems.

Conclusion

Understanding the critical role of energy-efficient cooling fans in electronics is essential for optimizing performance and ensuring compliance with industry standards. Selecting the right type of fan – whether axial or centrifugal – and implementing effective installation and maintenance practices can significantly enhance the efficiency of electronic systems while reducing energy consumption.

Key insights highlight the importance of adjusting fan direction seasonally, which can lead to substantial energy savings. Furthermore, integrating cooling fans with thermal management systems and adhering to compliance standards elevates performance and reliability. Regular maintenance, including cleaning and lubrication, ensures that fans operate at peak efficiency, prolonging their lifespan and maintaining optimal airflow.

Ultimately, prioritizing energy-efficient cooling solutions not only contributes to cost savings but also supports sustainability efforts in the electronics industry. By embracing these best practices, engineers can create innovative designs that meet the growing demand for efficient thermal management, paving the way for advancements in electronic systems.

Frequently Asked Questions

What are the main types of cooling fans discussed in the article?

The main types of cooling fans are axial blowers and centrifugal fans.

How do axial blowers operate and what are their typical applications?

Axial blowers move air parallel to their axis, making them ideal for applications that require a high volume of air at low pressure, such as cooling electronic components in confined spaces like enclosures and compact devices.

What are the advantages of using axial blowers?

Axial blowers are energy efficient, capable of delivering substantial air movement with low energy consumption, and many models offer IP protection for adaptability to various environments.

How do centrifugal fans differ from axial blowers in terms of operation?

Centrifugal fans draw air in at the center and expel it at a right angle, allowing for greater pressure production and improved air circulation control.

What are the typical applications for centrifugal fans?

Centrifugal fans are suitable for larger electronic cooling systems and HVAC applications, particularly in industrial settings where precise temperature regulation is essential.

What specialty devices are mentioned in the article?

Specialty devices include brushless DC models that focus on energy efficiency and noise reduction, as well as high-voltage units designed for industrial use.

What is the significance of Gagner-Toomey’s innovative designs in the cooling fan market?

Gagner-Toomey’s innovative designs, including miniature blower solutions, are crucial for enhancing performance while meeting energy efficiency standards.

What are the market shares of axial and centrifugal blowers as of 2024?

As of 2024, axial blowers hold approximately 65% of the global thermal ventilation market share, while centrifugal blowers are gaining traction in environments that require robust airflow management.

How have axial ventilators impacted energy savings in data centers?

The integration of axial ventilators in data centers has led to significant energy savings, with reductions of 15-20% in energy usage reported from 2022 to 2024 when optimized air management is employed.